Hydraulic dynamic synchronization control and position compensation system

A technology of synchronous control and compensation system, applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve the problems of machining accuracy error, leakage and skew of hydraulic components of the synchronous control unit, and achieve the solution of skew and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

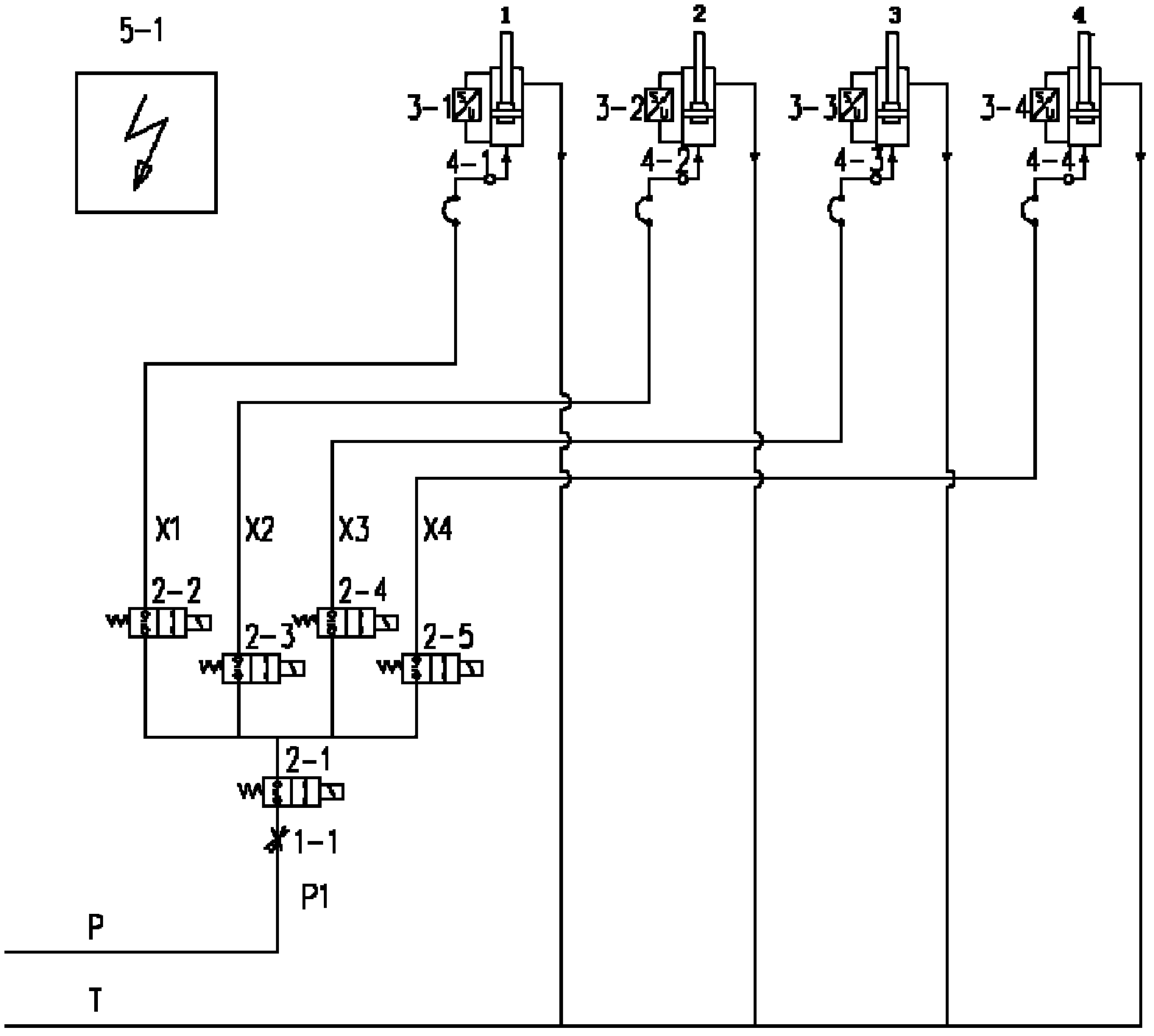

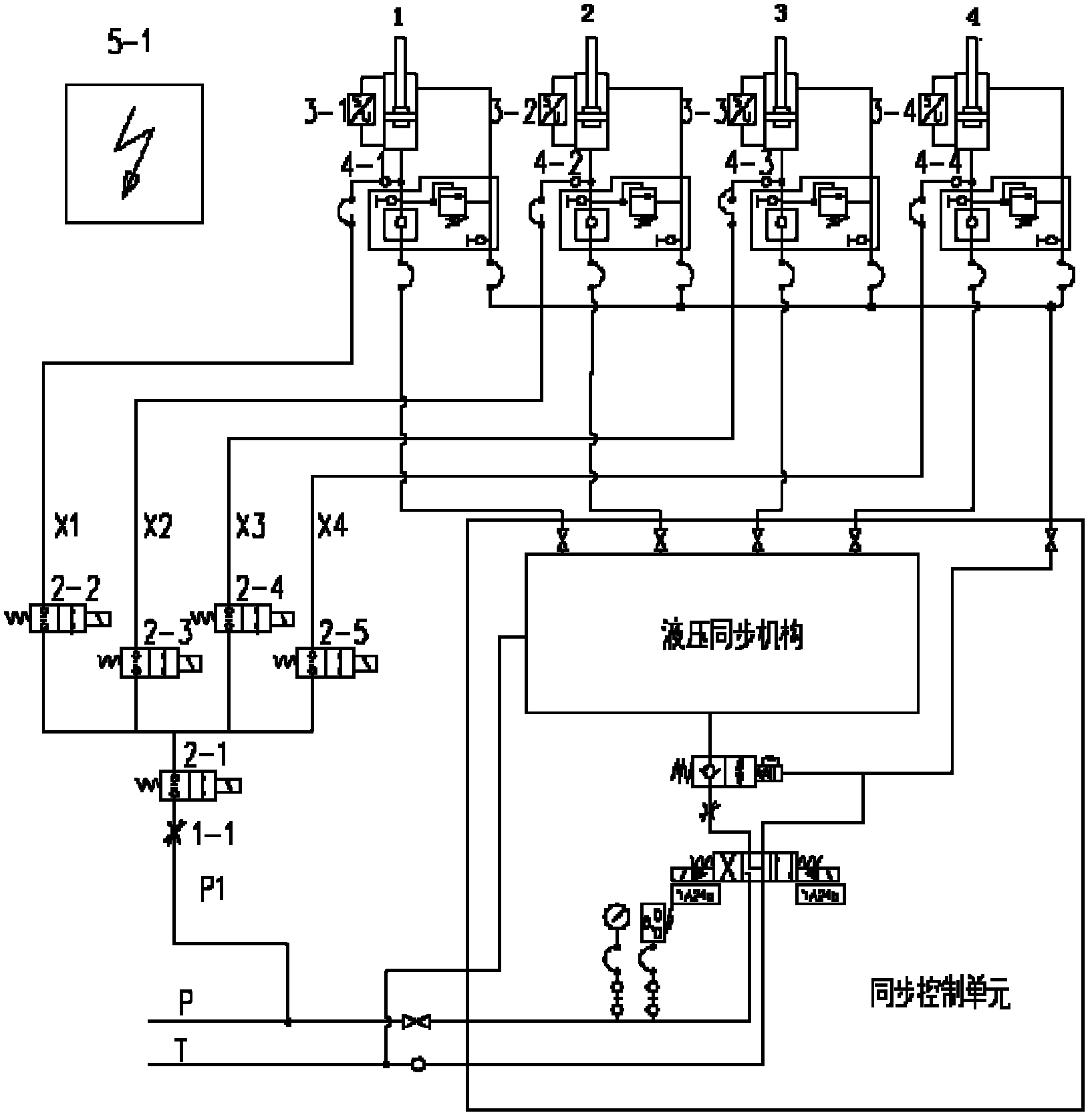

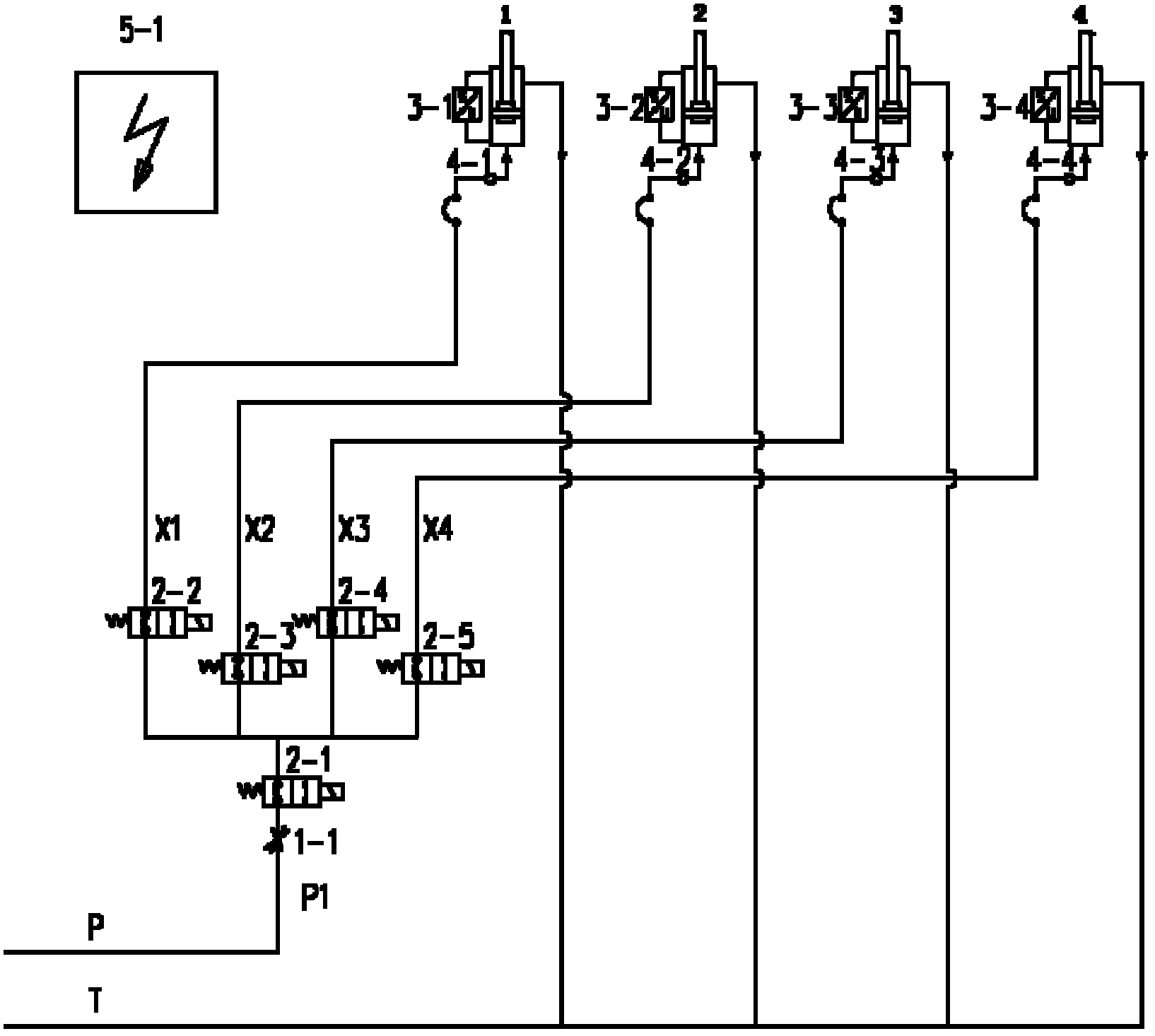

[0018] refer to figure 1 , a hydraulic dynamic synchronous control and position compensation system, including a detection unit, an electrical control unit and a hydraulic control unit,

[0019] The detection unit consists of the first displacement sensor 3-1 on the first lifting cylinder 1, the second displacement sensor 3-2 on the second lifting cylinder 2, the third displacement sensor 3-3 on the third lifting cylinder 3 and the first The fourth displacement sensor 3-4 on the four lifting oil cylinders 4 is formed,

[0020] The hydraulic control unit includes a speed regulating valve 1-1. The pressure oil circuit P communicates with the speed regulating valve 1-1 and the main circuit solenoid valve 2-1 through the pipeline, and the main circuit solenoid valve 2-1 passes through the oil circuit in the valve block. The channel communicates with the first branch so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com