Desulfuration technique with jet bubble process using red mud as absorbing agent

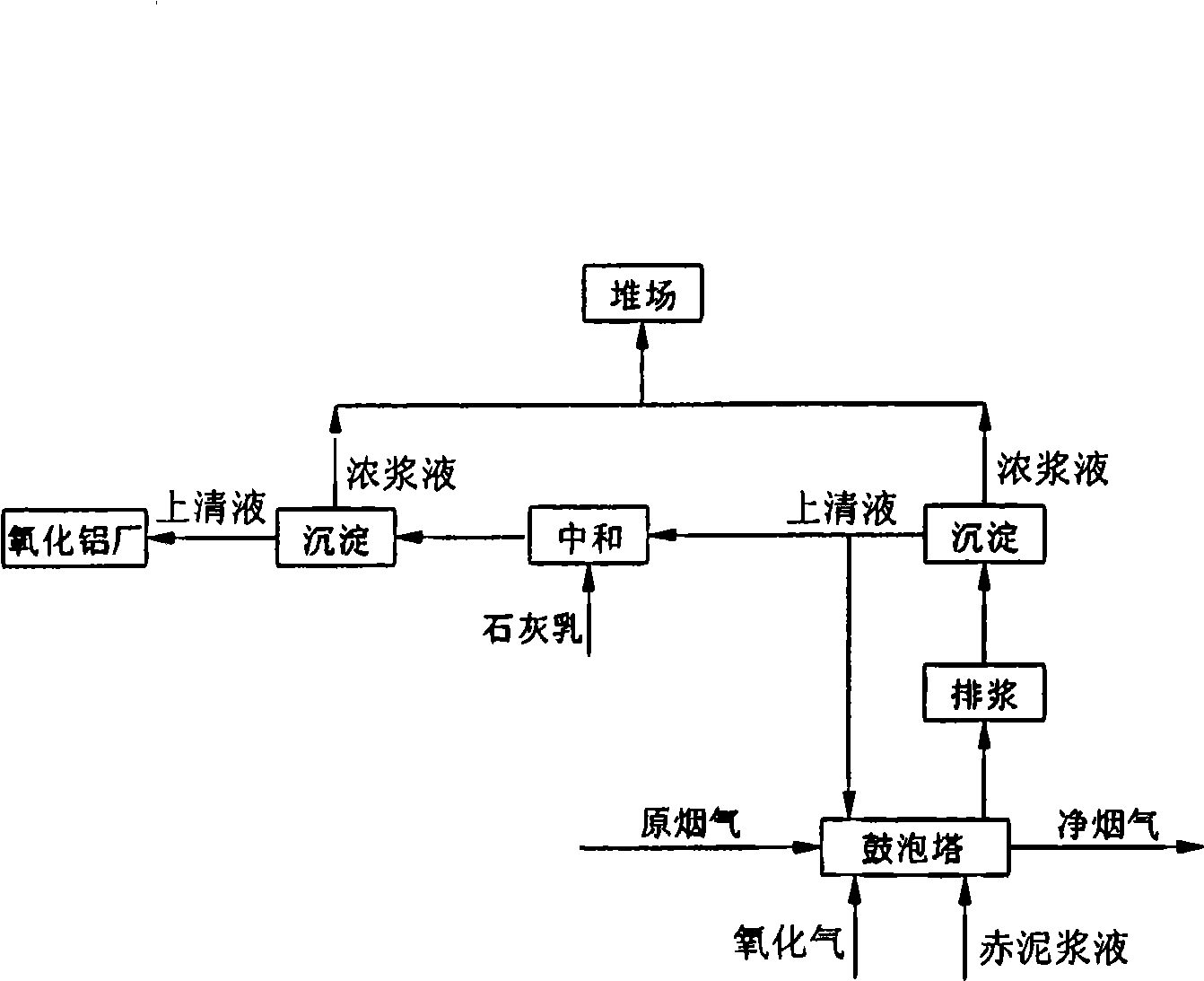

A technology of red mud slurry and bubble tower, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as scaling of alumina plant pipeline equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The flue gas volume at the inlet of the desulfurization unit is 10000Nm 3 / h, SO 2 The concentration is 4000mg / Nm 3 , The temperature is 120°C; the pH value of the red mud absorption slurry is 12.5, and the solid content of the slurry is 20%; the immersion depth of the bubble tube is 200mm, and the pH value of the slurry in the absorption tower is 5.0. Under the above conditions, SO at the outlet of the absorption tower 2 The content is 300mg / Nm 3 , The desulfurization efficiency can reach 92.5%.

Embodiment 2

[0032] The flue gas volume at the inlet of the desulfurization unit is 10000Nm 3 / h, SO 2 The concentration is 4000mg / Nm 3 , The temperature is 120°C; the pH value of the red mud absorption slurry is 12.5, and the solid content of the slurry is 20%; the immersion depth of the bubble tube is 200mm, and the pH value of the slurry in the absorption tower is 6.0. Under the above conditions, SO at the outlet of the absorption tower 2 The content is 250mg / Nm 3 , The desulfurization efficiency can reach 93.8%.

Embodiment 3

[0034] The flue gas volume at the inlet of the desulfurization unit is 10000Nm 3 / h, SO 2 The concentration is 4000mg / Nm 3 , The temperature is 120°C; the pH value of the red mud absorption slurry is 12.5, and the solid content of the slurry is 20%; the immersion depth of the bubble tube is 200mm, and the pH value of the slurry in the absorption tower is 7.0. Under the above conditions, SO at the outlet of the absorption tower 2 The content is 200mg / Nm 3 , Desulfurization efficiency can reach 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com