Non-stand construction method for large bridge arch rib

A construction method and a support-free technology, which can be applied to bridges, bridge materials, bridge forms, etc., can solve the problems of cumbersome arch rib linear adjustment procedures, difficult control of inelastic deformation, difficult operation, etc., to reduce arch rib assembly site and installation Brackets, ensure the installation quality of arch ribs, and speed up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

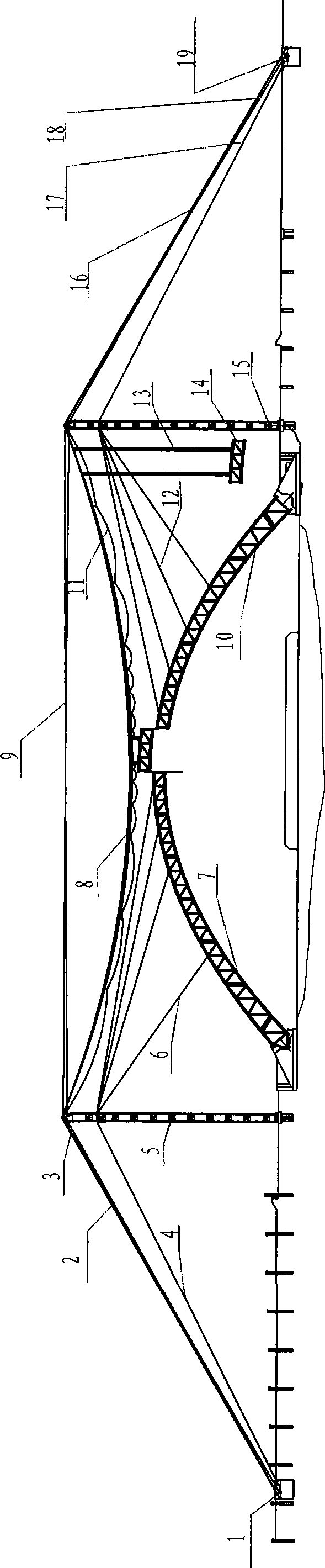

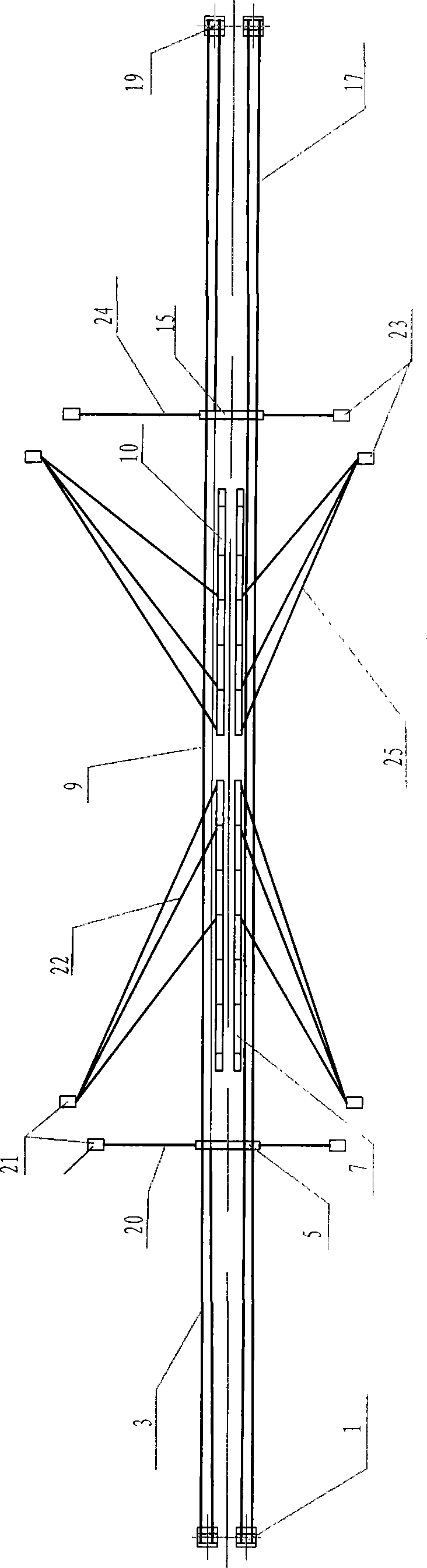

[0033] The implementation example of the present invention is the hoisting construction of the arch rib of the Yonghe Bridge in Nanning City.

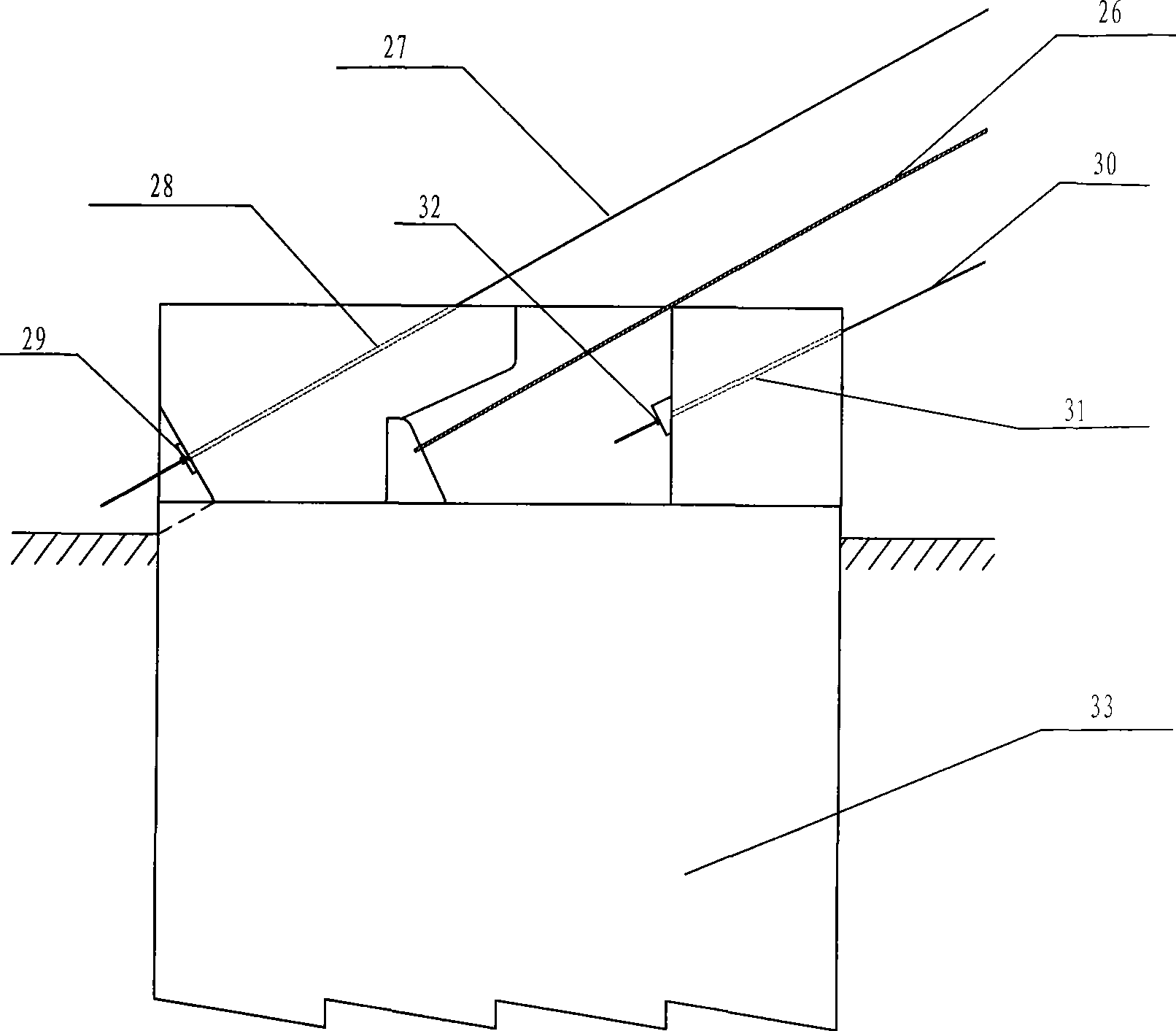

[0034] Yonghe Bridge in Nanning City is a bridge project across the Yongjiang River in the urban area. The main bridge is a thrust unhinged arch structure with variable truss height of 8-13.293m. It has a total length of 398.72m, a clear span of 335.4m, a net loss of height of 76.83m, and an equal width of 3m on one side of the arch rib. The cross-section of the upper and lower chords of the arch rib is dumbbell-shaped, and the outer diameter of the main pipe is 1220mm×16(20)mm, which are connected by pipes (plates). The web rod steel pipe is 610mm×10mm (510×10). 16 steel pipe braces are arranged horizontally between the two arch ribs. The steel pipe arch empty pipe weight of this bridge (including cross braces) reaches 3600t. In the design, each arch rib hollow pipe is divided into 14 sections for the convenience of manufacture and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com