Ultra-deepwater offshore oil-gas engineering developing system and mounting method thereof

A technology of engineering development and installation method, applied in the direction of infrastructure engineering, fluid extraction, earthwork drilling, etc., can solve the problem that the safety, environmental protection, feasibility and economical applicability of engineering equipment and engineering models cannot meet the requirements, construction cost , high operating costs and maintenance costs, no effective technology to prevent typhoons and hurricanes, etc., to shorten the installation period, reduce investment costs, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

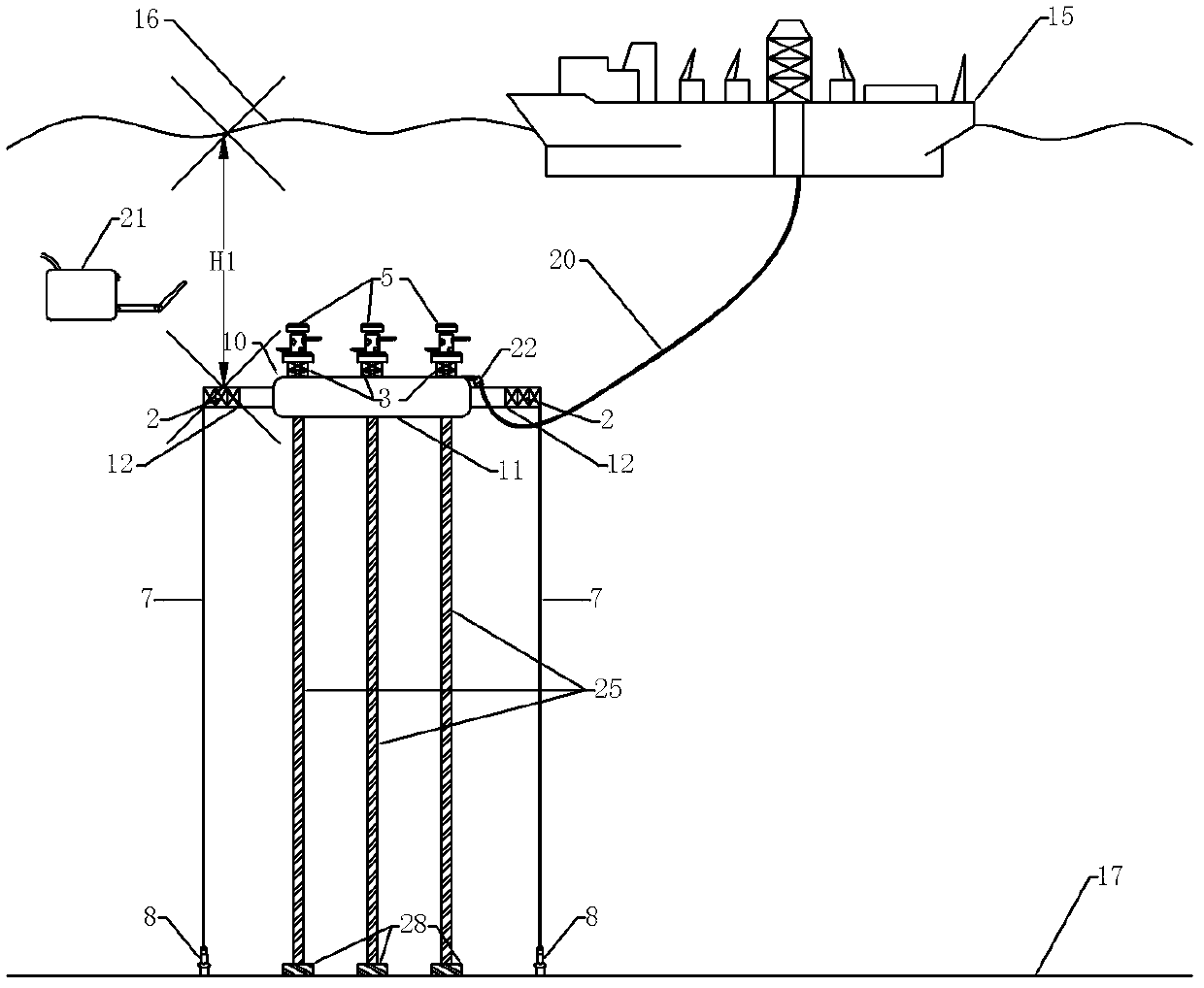

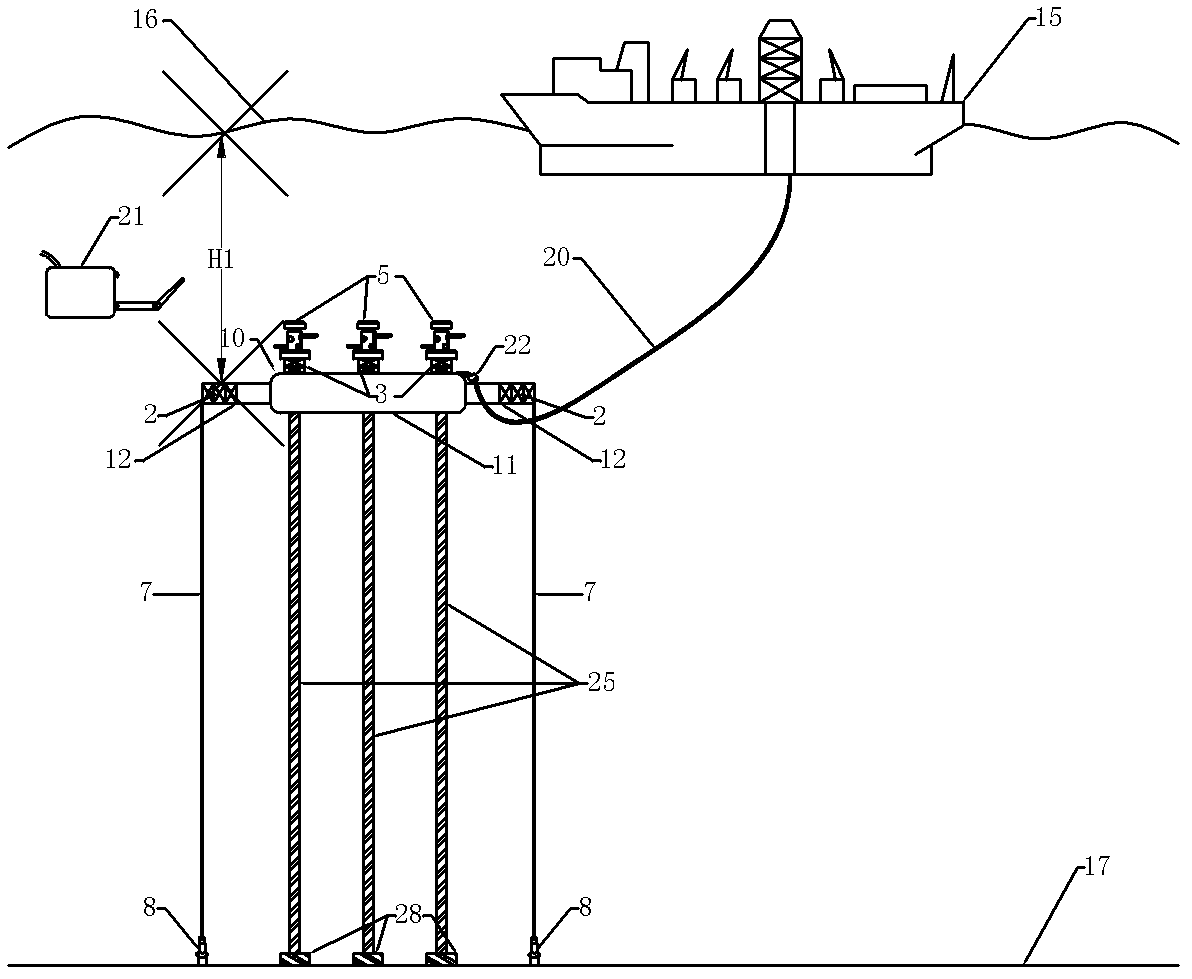

[0045] like figure 1 As shown, an ultra-deep water offshore oil and gas engineering development system mainly includes surface floating production device 15, riser support buoy 10, tension mooring device, upper flexible jumper 20, lower rigid riser 25, oil production equipment 5 and seabed Wellhead 28.

[0046] The oil recovery equipment 5 is installed on the riser support buoy 10 .

[0047] The riser support buoy 10 is located at H1 under the water surface 16 to avoid the turbulent flow area under the sea surface, so that the riser support buoy 10 is hardly affected by the wind, waves and currents near the sea surface, and maintains a good position. performance.

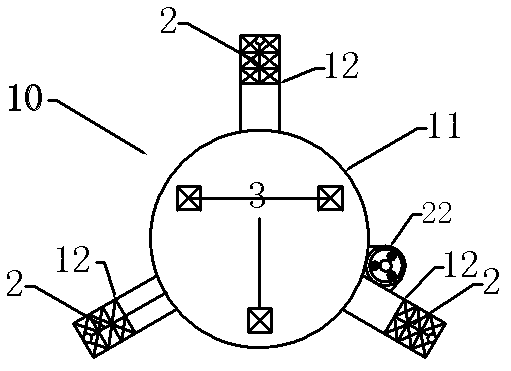

[0048] like Figure 1-2 As shown, the riser support buoy 10 adopts a combined structure of a central column structure 11 and three rectangular section cantilever buoys 12 connected to the edge of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com