Automatic lathe for processing spanner

An automatic lathe and spindle technology, applied in the field of lathes, can solve problems such as high cost, influence of positioning accuracy, inertia of the spindle, etc., and achieve the effect of low cost, simple design and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

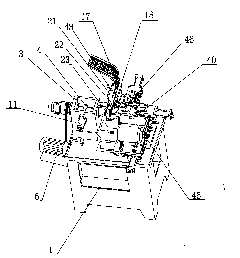

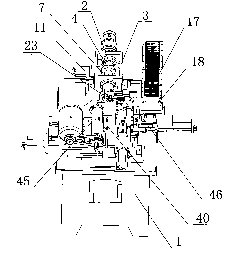

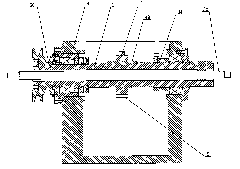

[0033] Such as Figure 1-6 As shown, the lathe includes a base 1. The base 1 is provided with a feeding system, a spindle system, a turning tool system 45 and a milling cutter system 46 for material processing. 2 Cross the box body 3 and fix it on the box body 3 through bearings. The front end of the main shaft 2 extends out of the box body 3 and is equipped with a clamping mechanism. And fixed on the middle part of the main shaft 2 by the flat key 49, the main shaft positioning ring 4 side is provided with a positioning groove 5, the rear end of the main shaft 2 is fixed with a pulley 50, the pulley 50 is connected to the motor 6 through the belt, and the motor 6 drives the main shaft 2 to rotate through the belt drive Main shaft 2 one side is provided with positioning system, and positioning system comprises positioning cylinder 11, and positioning cylinder 11 is fixed on the casing 3, and corresponds with main shaft positioning ring 4, and positioning block 7 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com