Patents

Literature

34 results about "Spinning dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In astronomy, spinning dust is a mechanism proposed to explain anomalous microwave emission from the Milky Way. The emission could arise from the electric dipole of very rapidly spinning (10–60 GHz) extremely small (nanometer) dust grains (Draine & Lazarian 1998), most likely polycyclic aromatic hydrocarbons. The anomalous emission was first discovered as a by-product of Cosmic Microwave Background observations which make very sensitive measurements of the microwave sky which have to identify and remove contamination from the galaxy.

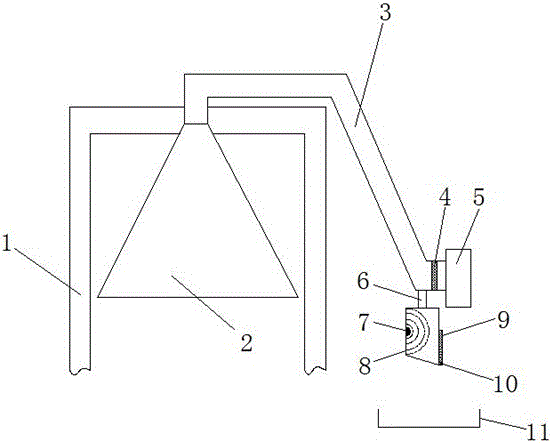

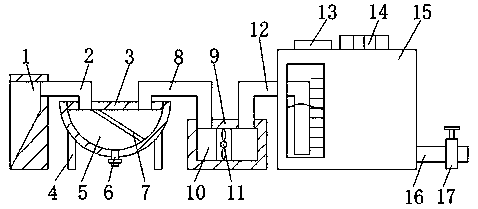

Spinning dust collecting device for spinning workshop

PendingCN109364656AEasy to recycleLow costUsing liquid separation agentStationary filtering element filtersFiberYarn

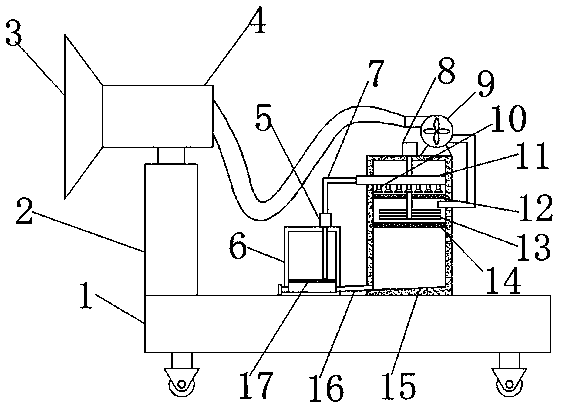

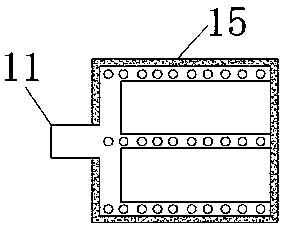

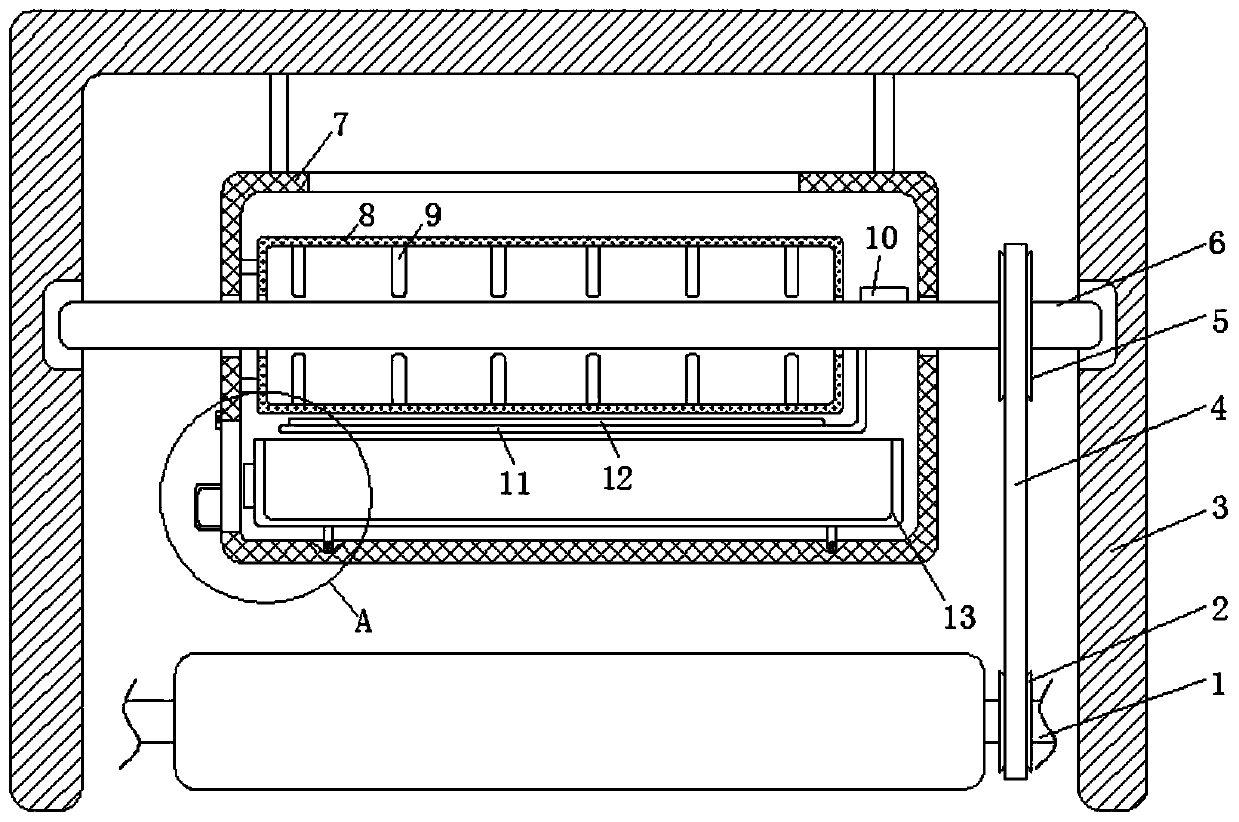

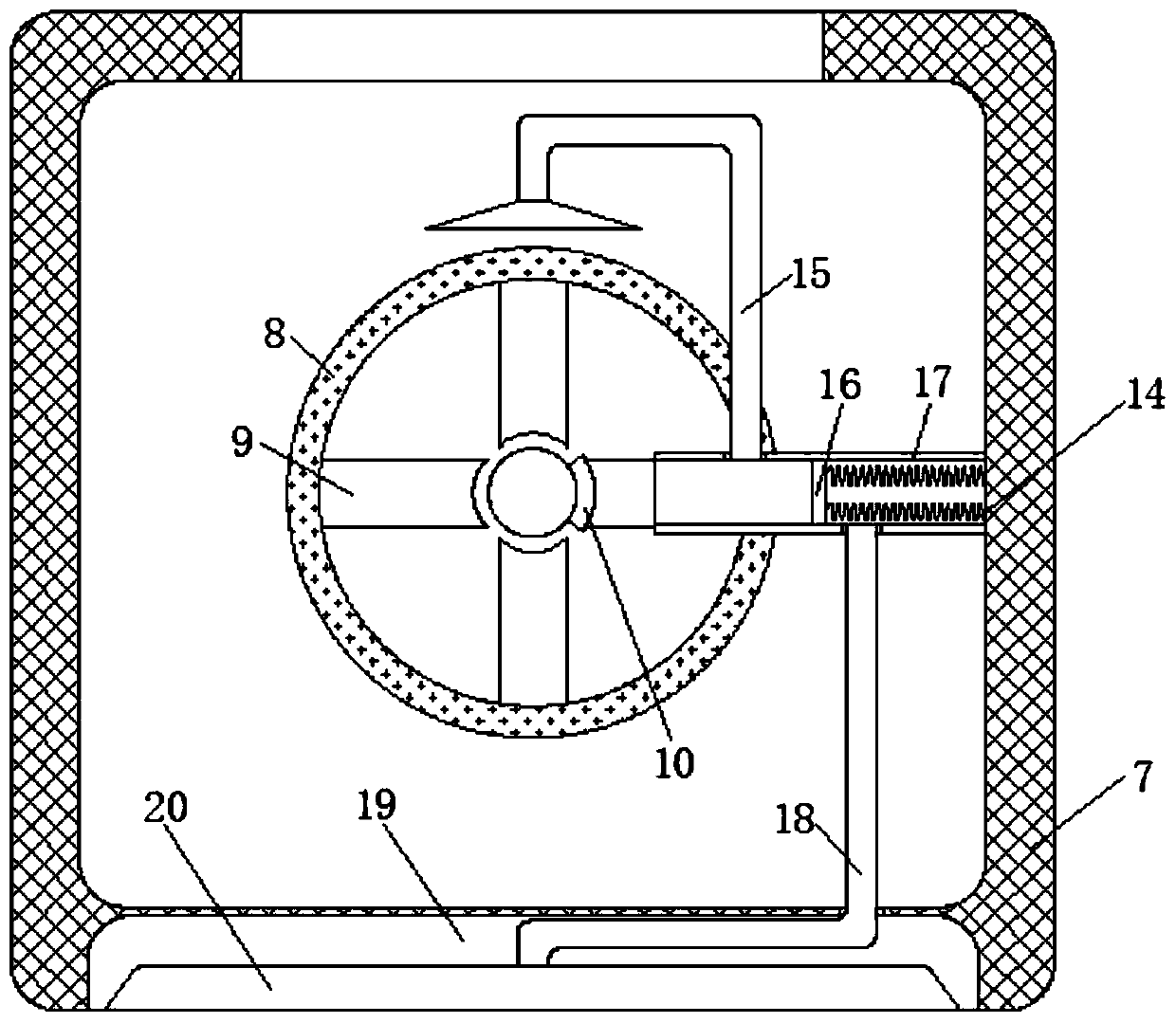

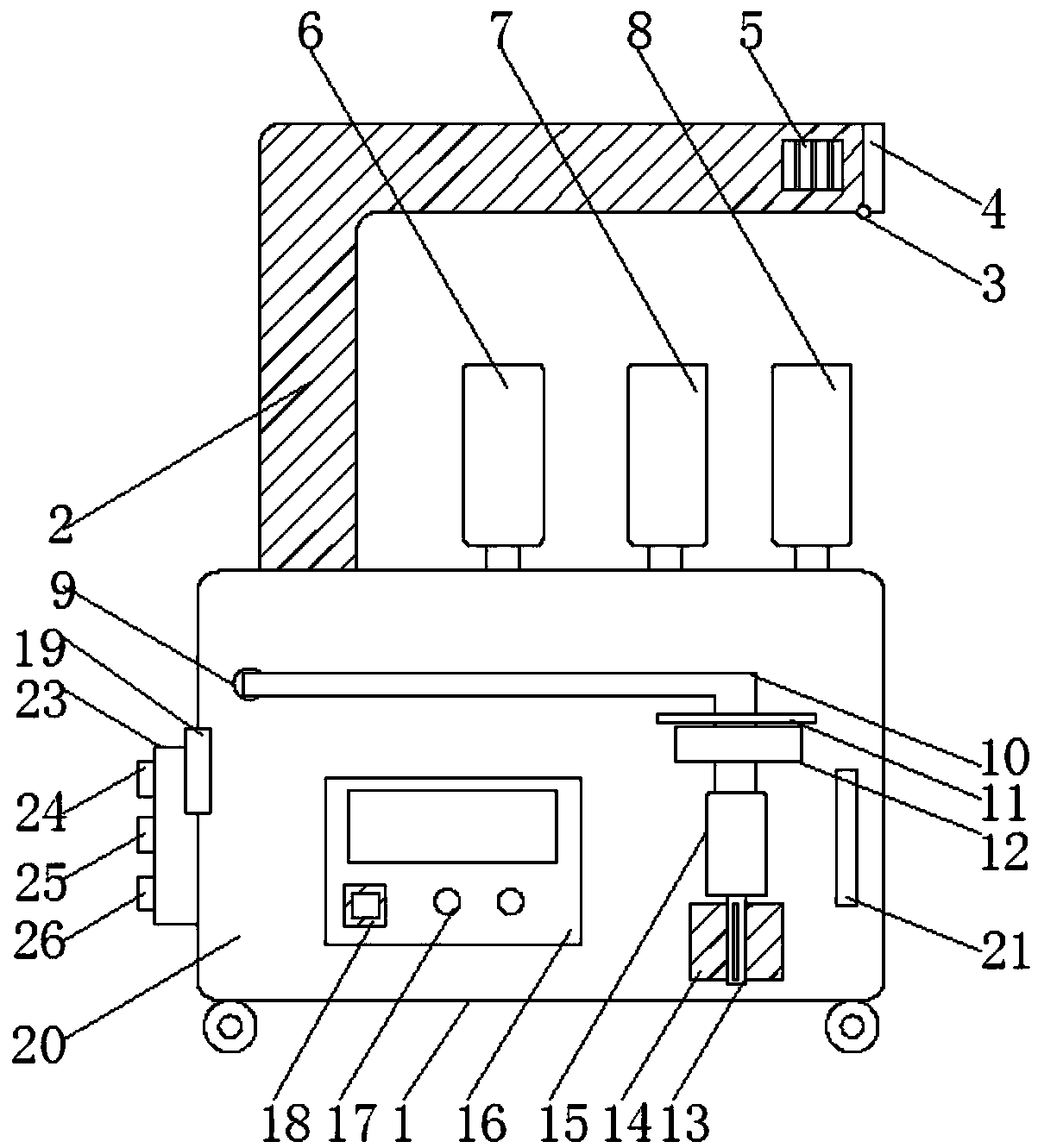

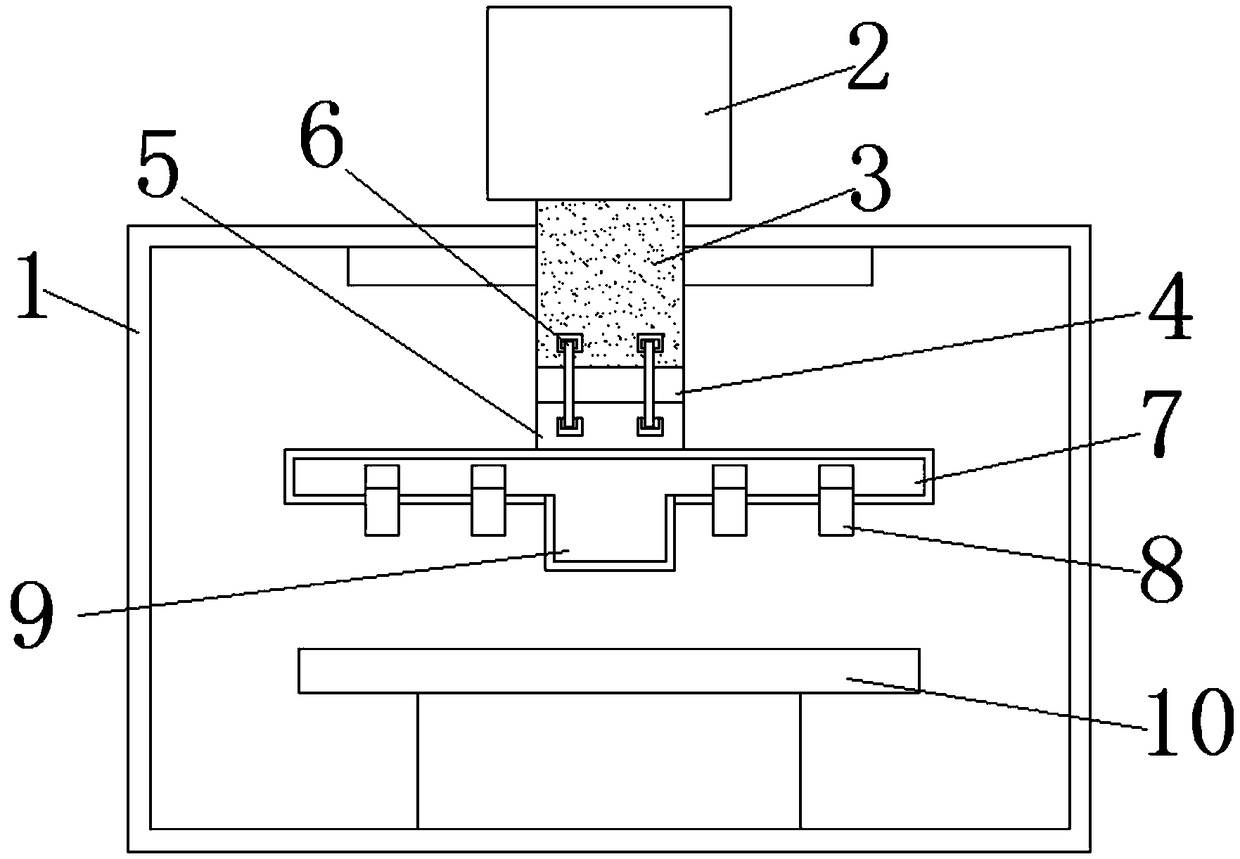

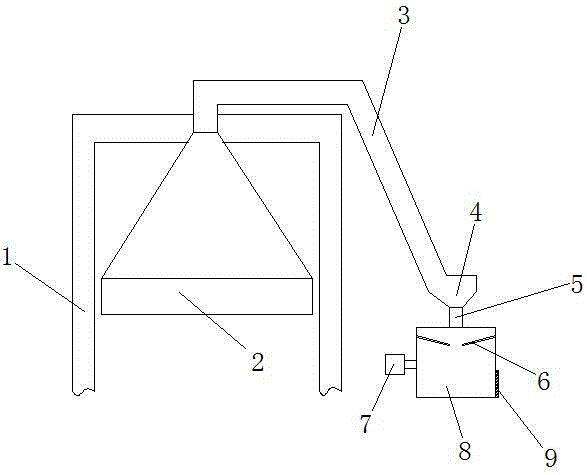

The invention discloses a spinning dust collecting device for a spinning workshop. The spinning dust collecting device for the spinning workshop comprises a bottom plate, wherein a supporting rod which is arranged vertically is fixed on one side of the top end of the bottom plate; the supporting rod is a telescopic rod; a dust guiding tube is fixed at the top end of the supporting rod; one end ofthe dust guiding tube is connected with a dust suction cover; the other end of the dust guiding tube is connected with a dust suction hose; a box is arranged at the top end of the bottom plate; a water delivering tube is fixed in the box; nozzles which are distributed in an arrayed manner are arranged at the bottom end of the water delivering tube; a first filter screen and a second filter screenwhich are arranged horizontally are successively arranged in the box; the first filter screen is positioned below the nozzles; a driving motor is fixed at the position of the center of the top end ofthe box; and the output shaft of the driving motor is connected with a rotating rod which is arranged vertically. The device is simple in structure, reasonable in design and skillful in conception, wastes such as yarns and cotton fibers of the workshop can be separated from dust, the wastes can be recycled, resources are saved, and the practicality is quite high.

Owner:阜宁县荣泰纺织品有限公司

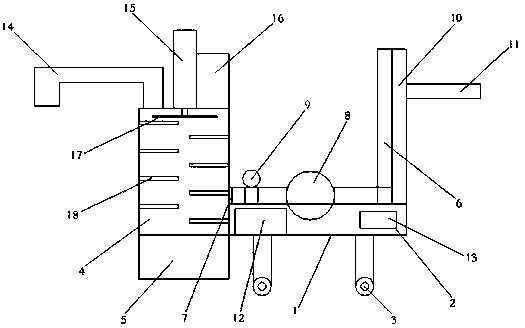

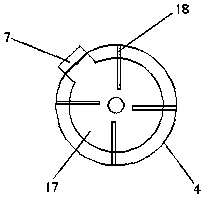

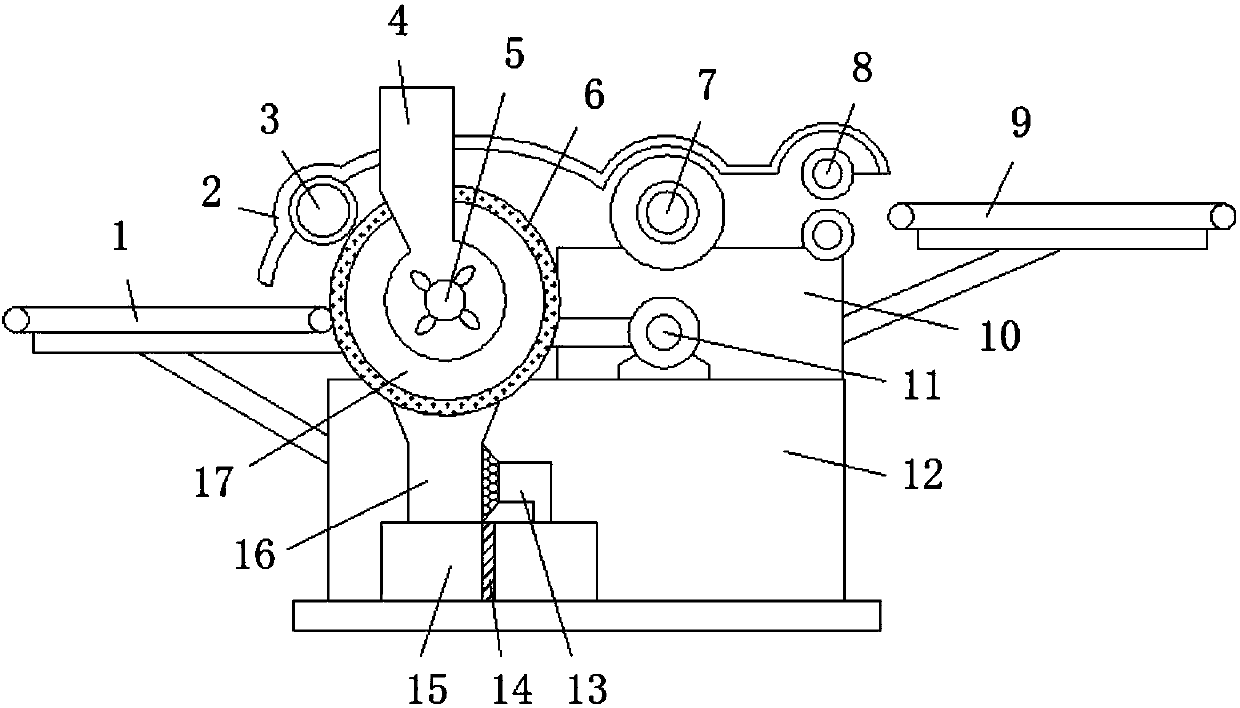

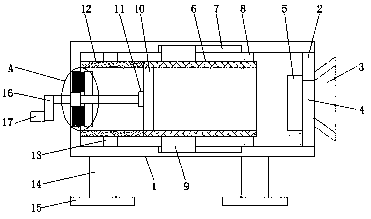

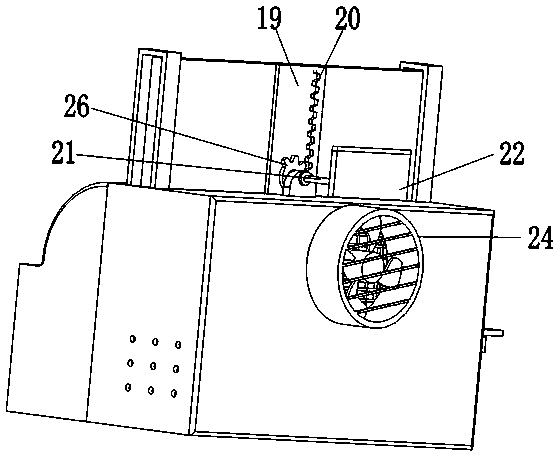

Spinning dust collecting mechanism for spinning machine

InactiveCN110404683APrevent fallingImprove adsorption capacityDirt cleaningElectrodes cleaningElectricityEngineering

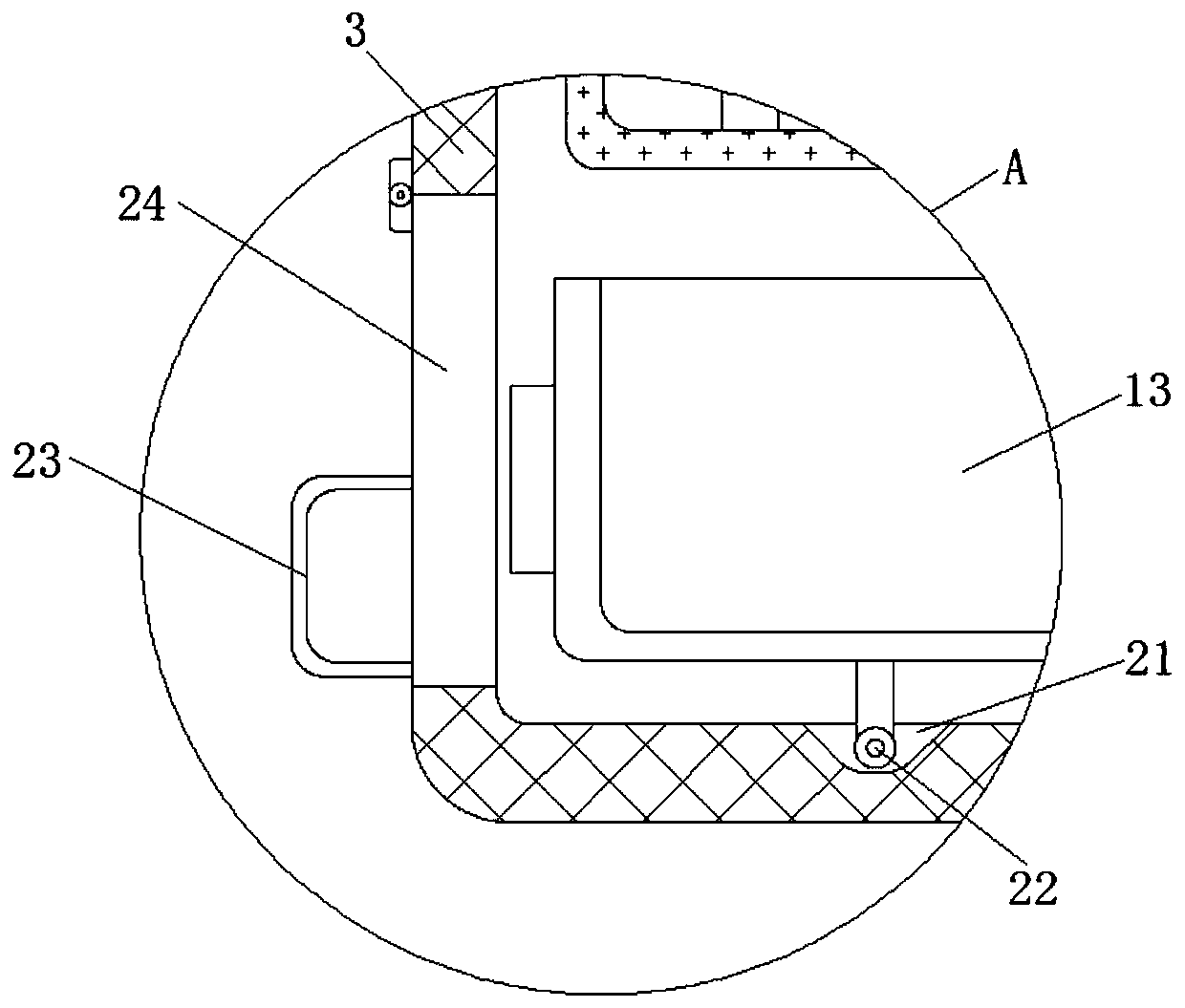

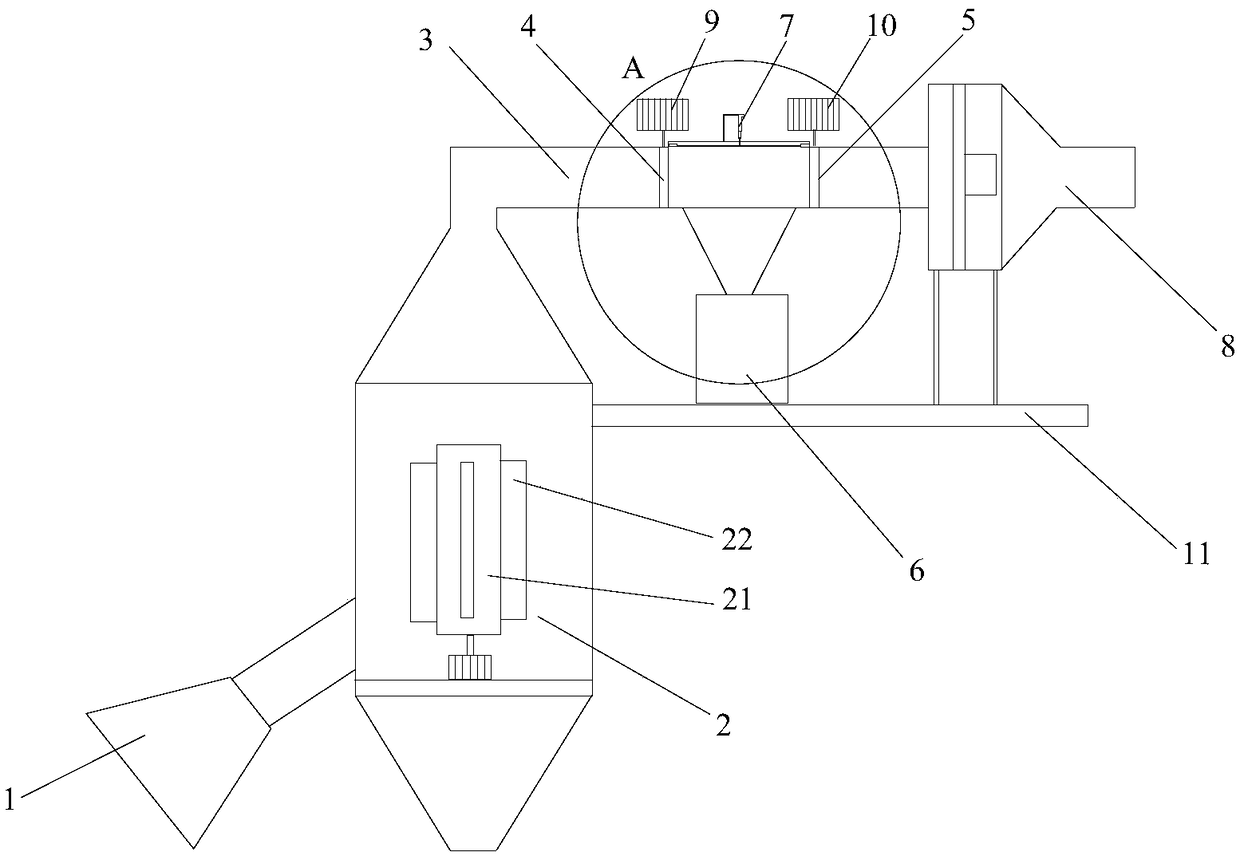

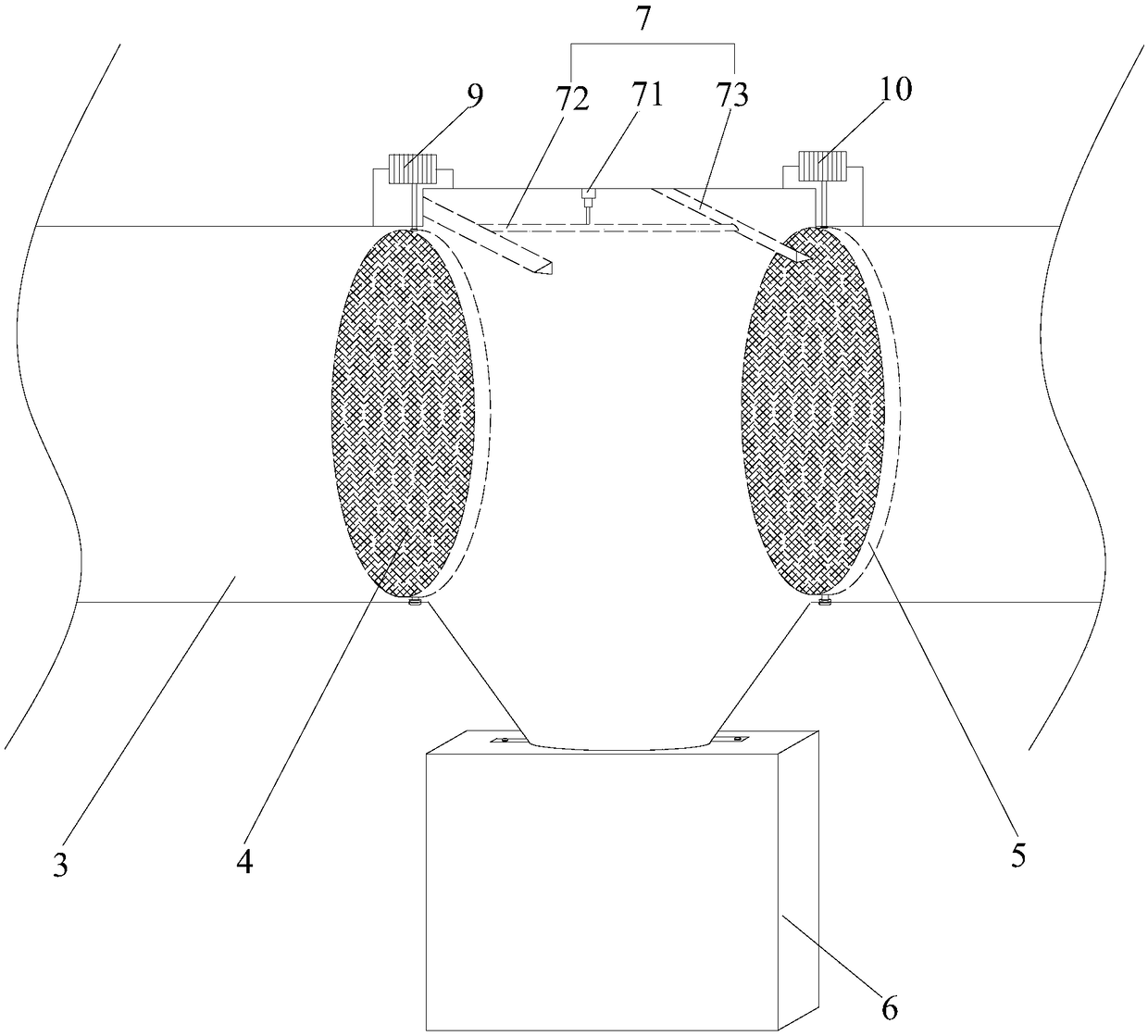

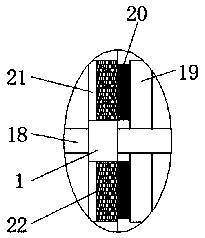

The invention discloses a spinning dust collecting mechanism for a spinning machine. The spinning dust collecting mechanism comprises a driving roll for driving the spinning machine to act and a housing mounted on the spinning machine, wherein the housing, relative to the inner wall, is rotatably connected with a rotating shaft; a dust collecting chamber is rotatably arranged on the rotating shaftin a sleeving mode; the inner wall of the dust collecting chamber is fixedly connected with a static cylinder arranged on the rotating shaft through a connecting column in the sleeving mode; and an adsorption device for adsorbing spinning dust is mounted inside the static cylinder. In the invention, the rotating shaft rotates to drive fur to rub with an arc-shaped block to generate electricity, the spinning dust is adsorbed through the static cylinder, a magnet connected with the side wall of the rotating shaft is attracted with a magnetic sliding plug inside a sleeve fixedly connected with the side wall of the dust collecting chamber oppositely, negative pressure is generated constantly inside the sleeve for constantly recycling spinning dust in the constant rotating process of the rotating process, the adsorption for spinning dust is strengthened, the surface of the static cylinder is cleaned by an elastic scraper plate in the rotating process of the rotating shaft, and the condition that much dust is adsorbed onto the static cylinder due to untimely cleaning to influence the adsorption effect is avoided.

Owner:温州浩僧服饰有限公司

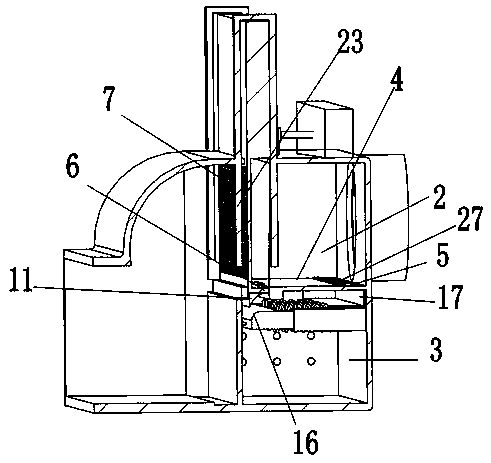

Spinning dust collection device for spinner

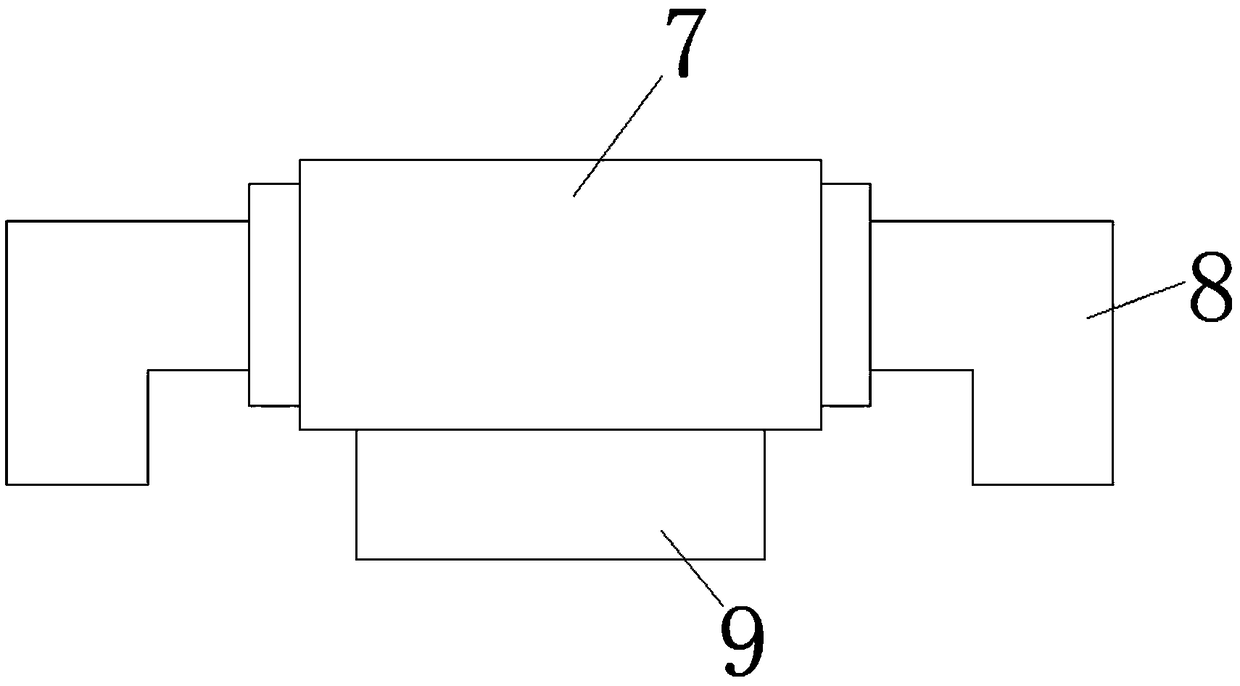

ActiveCN108939790AAvoid failureImprove cleanlinessCombination devicesDispersed particle filtrationSpinning dustWaste management

The invention discloses a spinning dust collection device for a spinner, and belongs to the technical field of spinning machinery. A first filter screen and a second filter screen are sequentially arranged in a filter pipeline, and a bottom opening is formed in the filter pipeline between the first filter screen and the second filter screen, and a dust collection tank is arranged at the bottom opening; a cavity for accommodating a cleaning device is formed in the top of the filter pipeline between the first filter screen and the second filter screen, and the cleaning device is arranged in thecavity; a first motor is fixedly connected with the first filter screen, and a second motor is fixedly connected with the second filter screen; bottoms of the first and second filter screens are movably connected with the inner wall of the filter pipeline. The collection device has a simple structure and can be used for conveniently cleaning spinning dust on the filter screens, so that the failurerate of the collection device can be reduced.

Owner:HENAN INST OF ENG

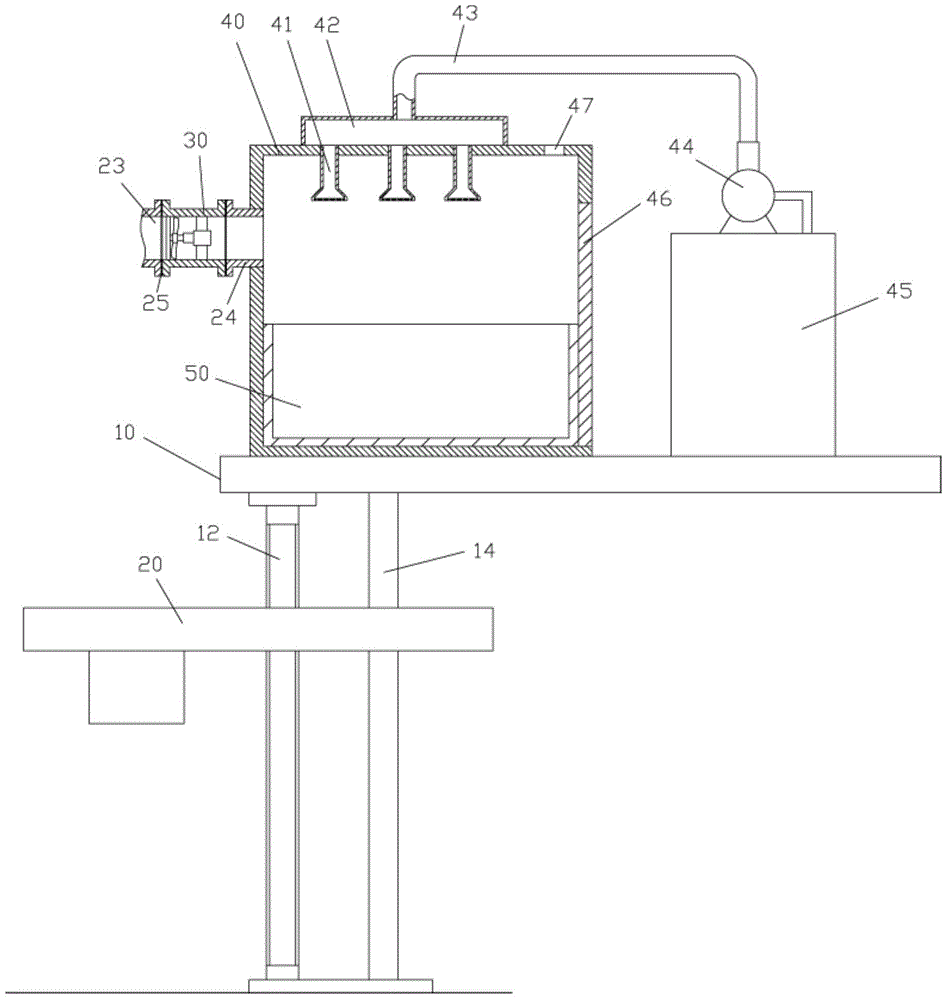

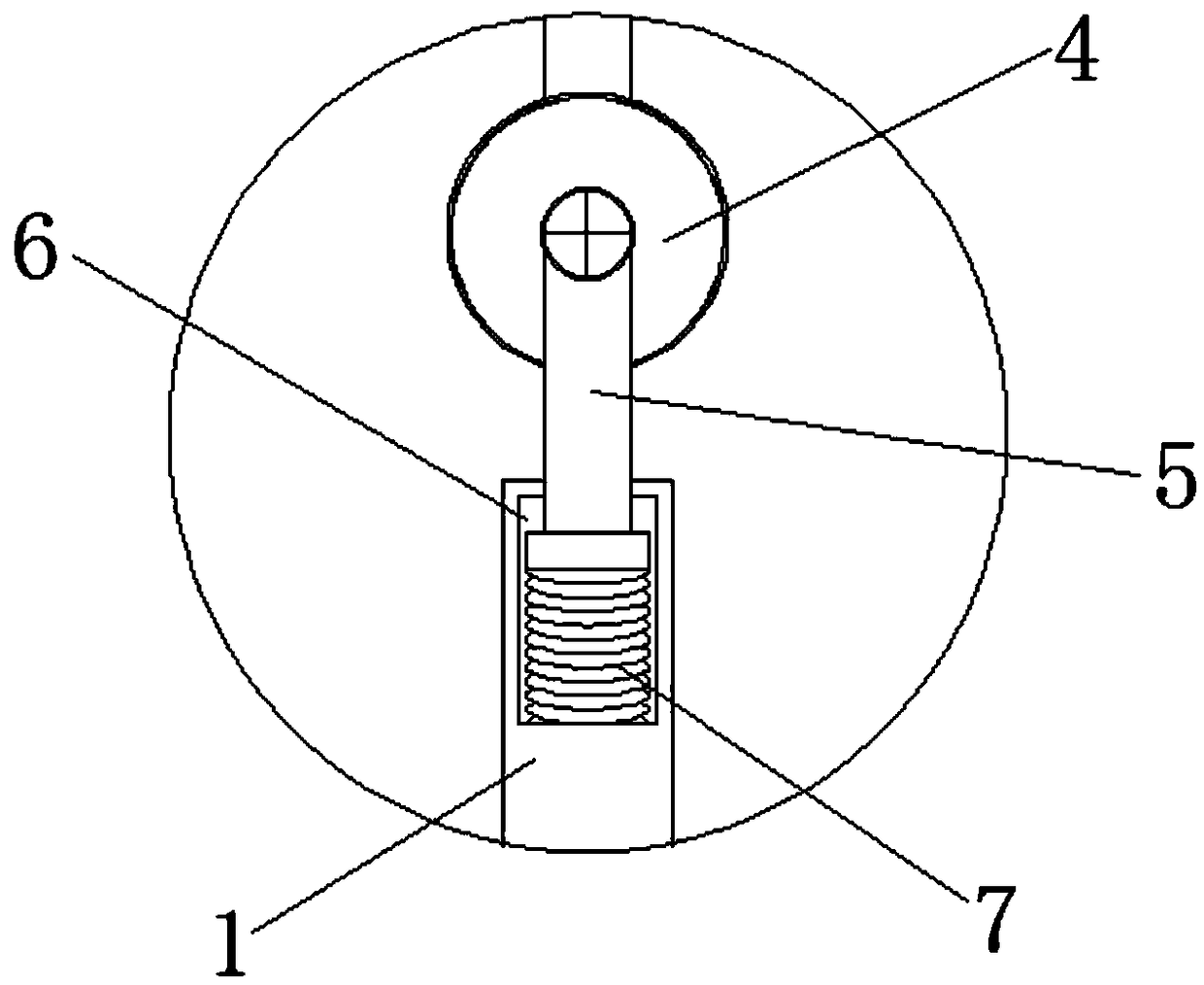

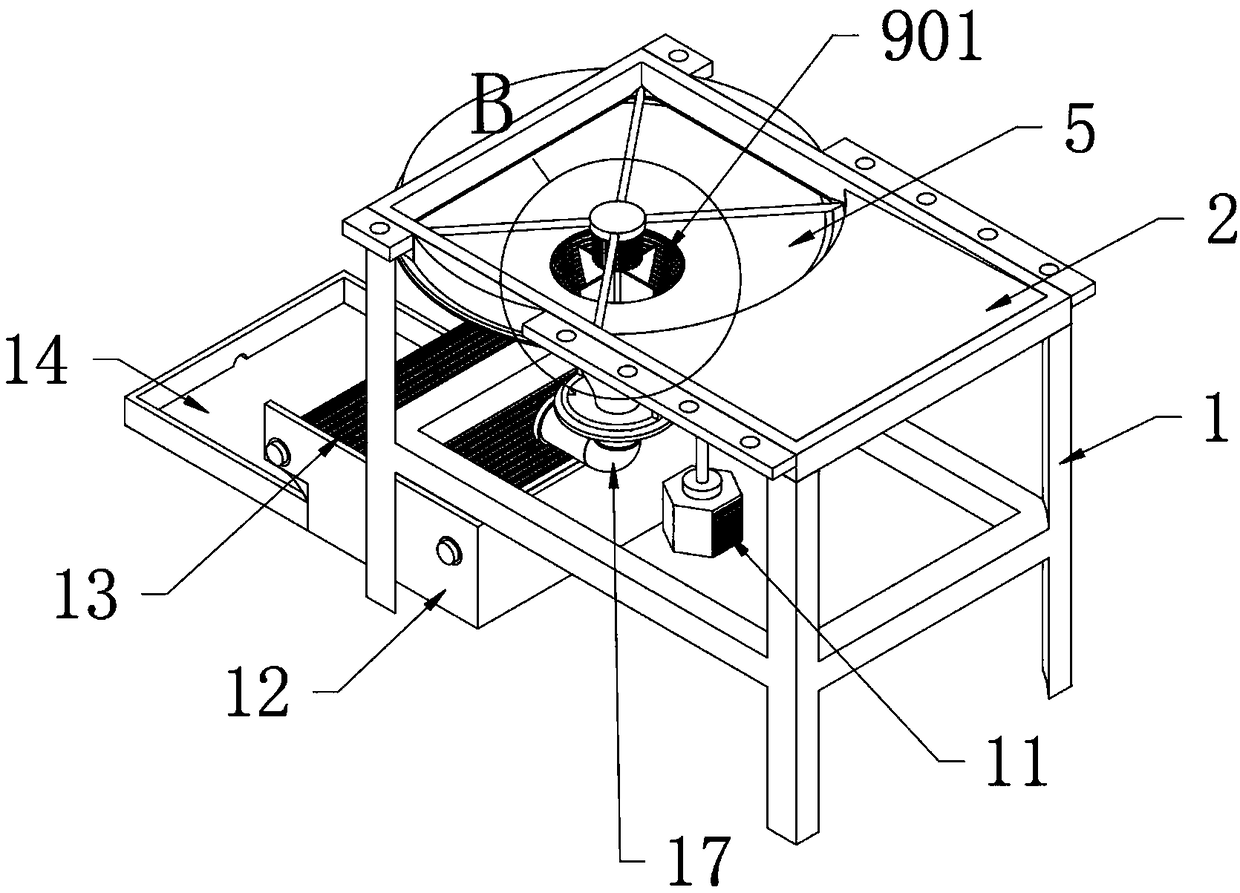

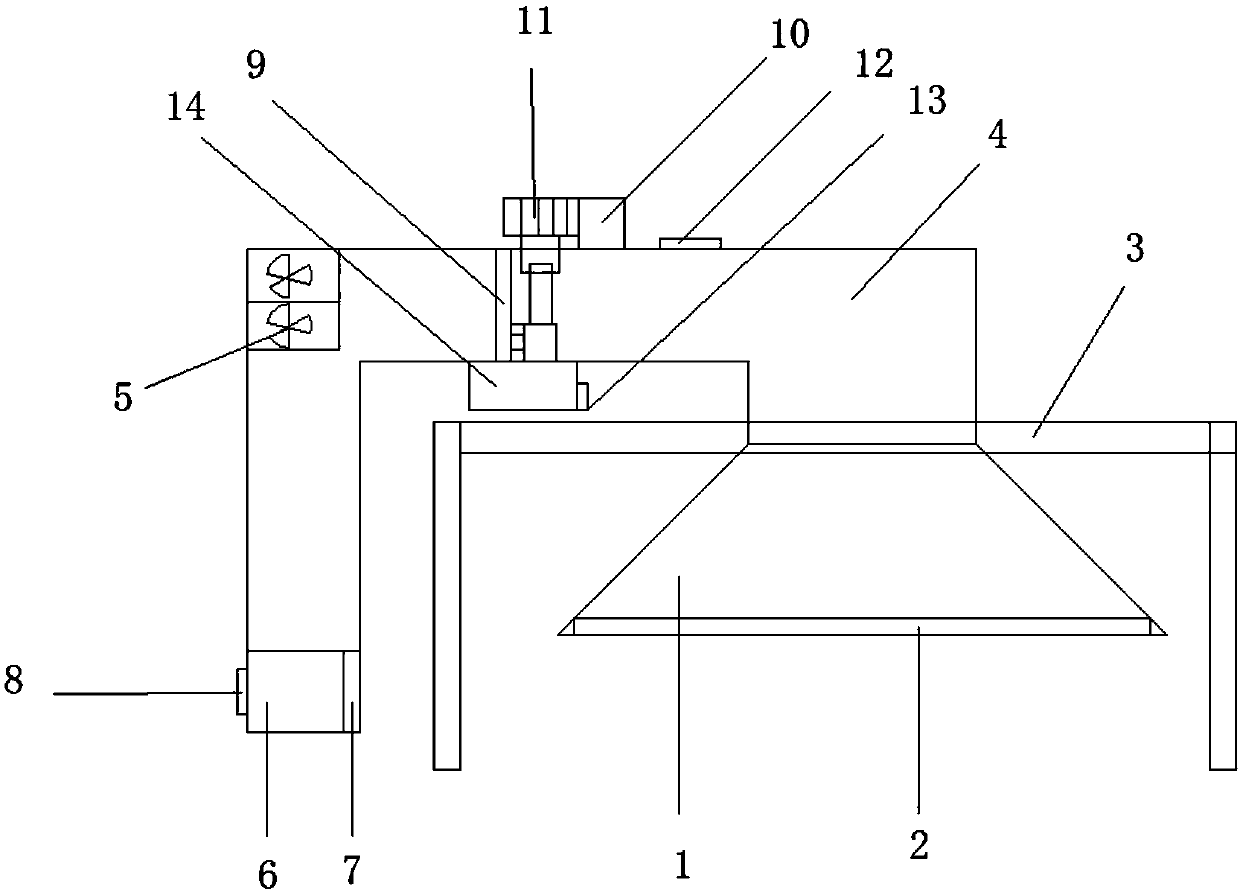

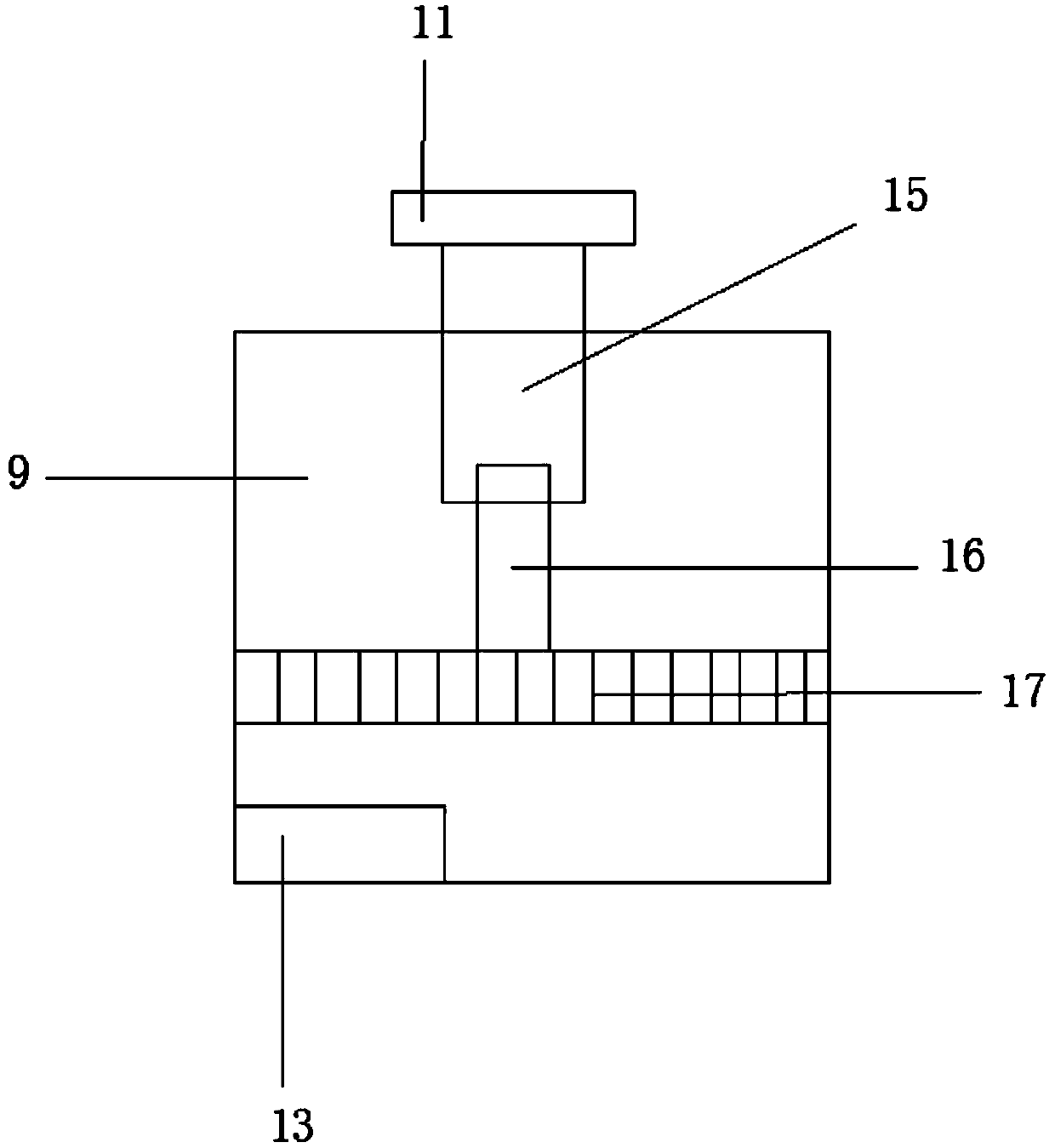

Height-adjustable spinning dust collector

InactiveCN104874577AReduce harmMeet different requirements for adsorbing airDirt cleaningFiberEngineering

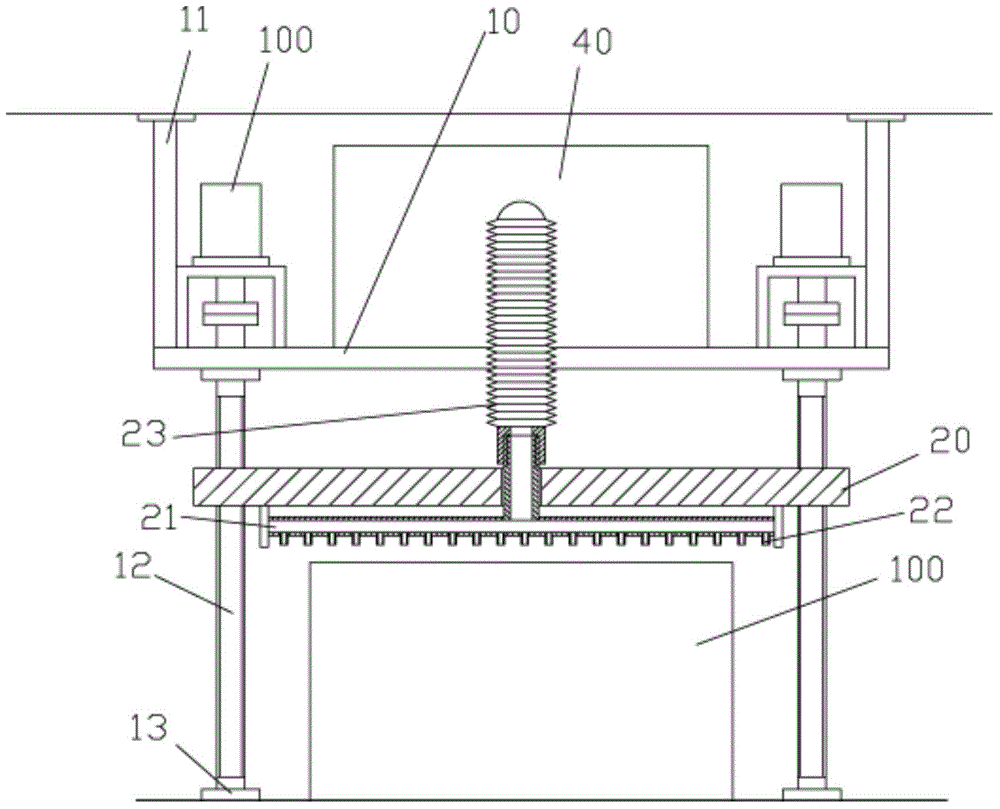

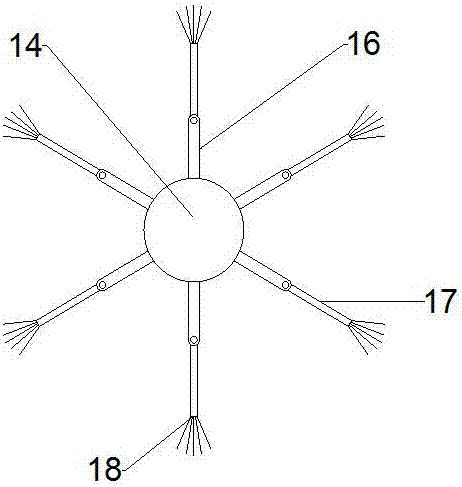

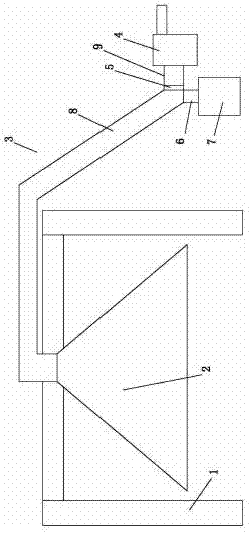

The invention discloses a height-adjustable spinning dust collector. The height-adjustable spinning dust collector comprises an upper support plate, a plurality of support rods are fixed on the upper surface of the upper support plate, the upper ends of the support rods are fixed on the top surface of a plant, the upper ends of at least two rotary screws are hinged to the two bottom sides of the upper support plate, the lower ends of the rotary screws are hinged to a bottom plate, the upper ends of the rotary screws penetrate upwards out of the upper support plate and are connected with an output shaft of a driving motor by a coupler, the driving motor is fixed on the upper support plate, a spinning device is arranged between the two rotary screws, an adjusting plate is screwed in the rotary screws and below the upper support plate, the bottom of the adjusting plate is provided with a transverse suction main pipe, and a plurality of suction pipes are connected with the side wall of the bottom of the transverse suction main pipe. The height-adjustable spinning dust collector is mounted at the spinning device and absorbs air in front of the device via suction nozzles, so as to filter the air with fibers and noils, in this way, harm for humans from fibers and noils can be reduced.

Owner:NANTONG DOUBLE GREAT TEXTILE

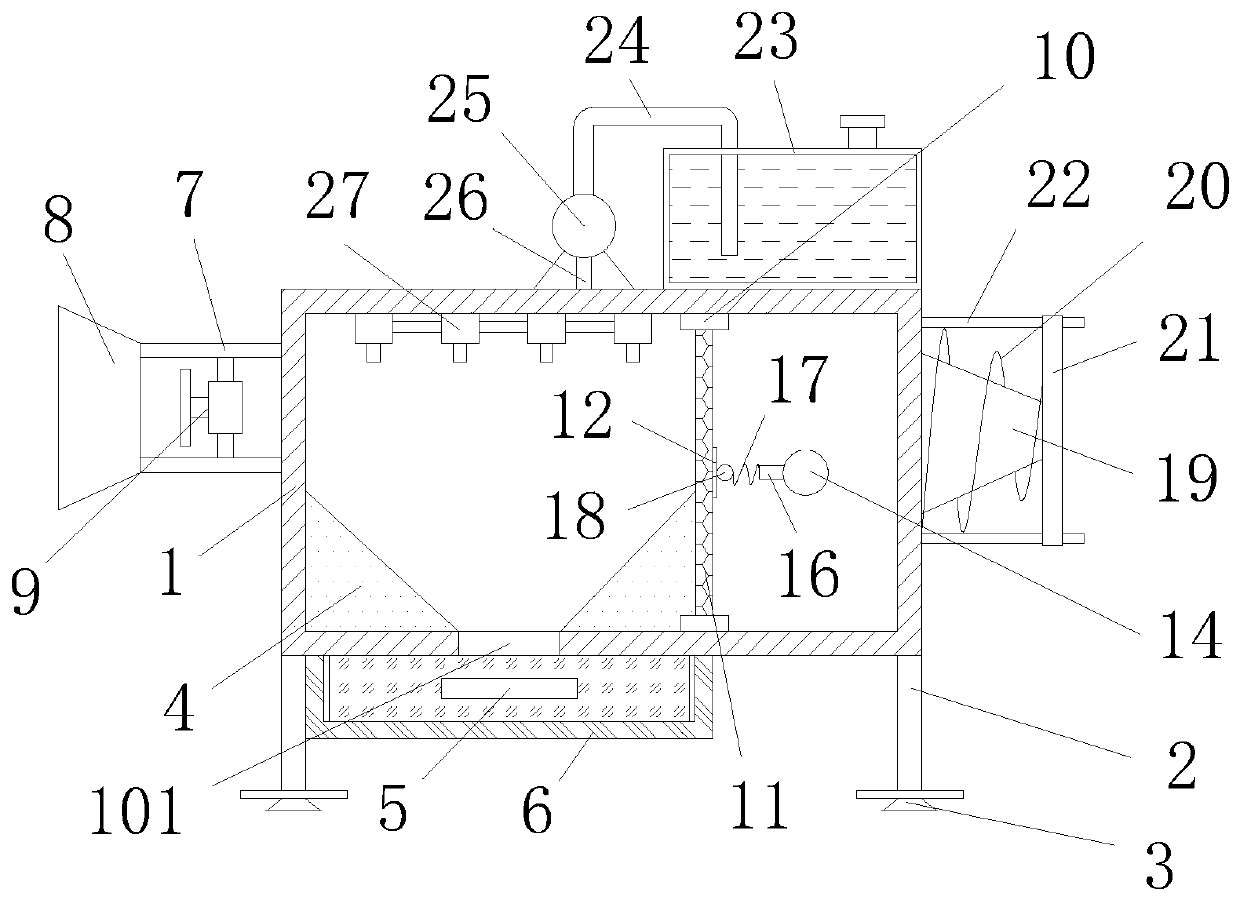

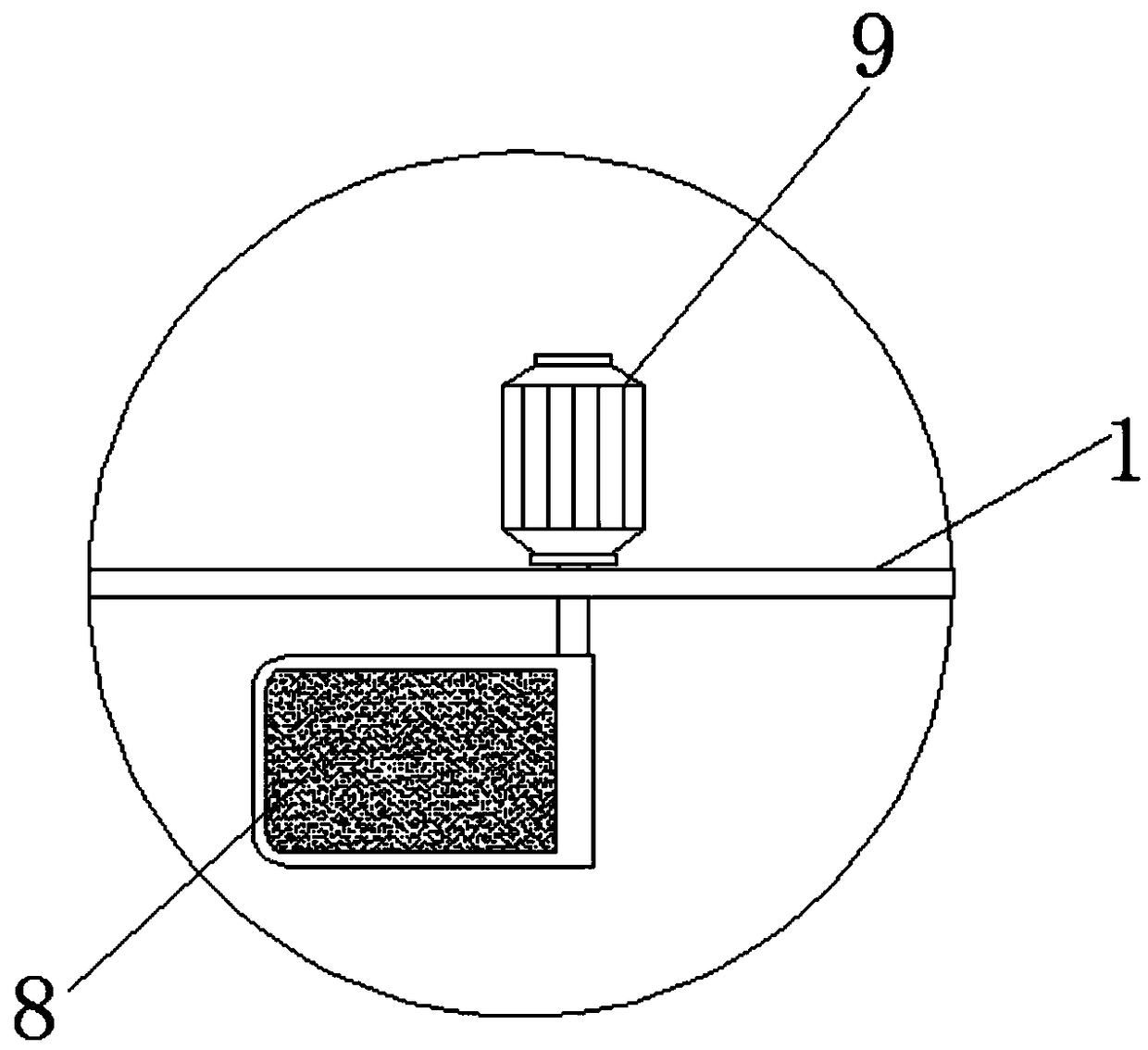

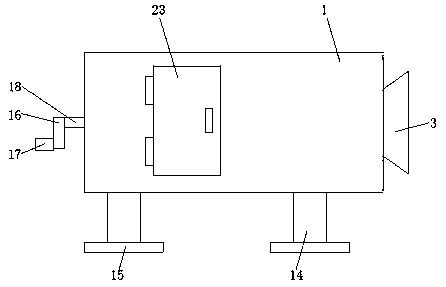

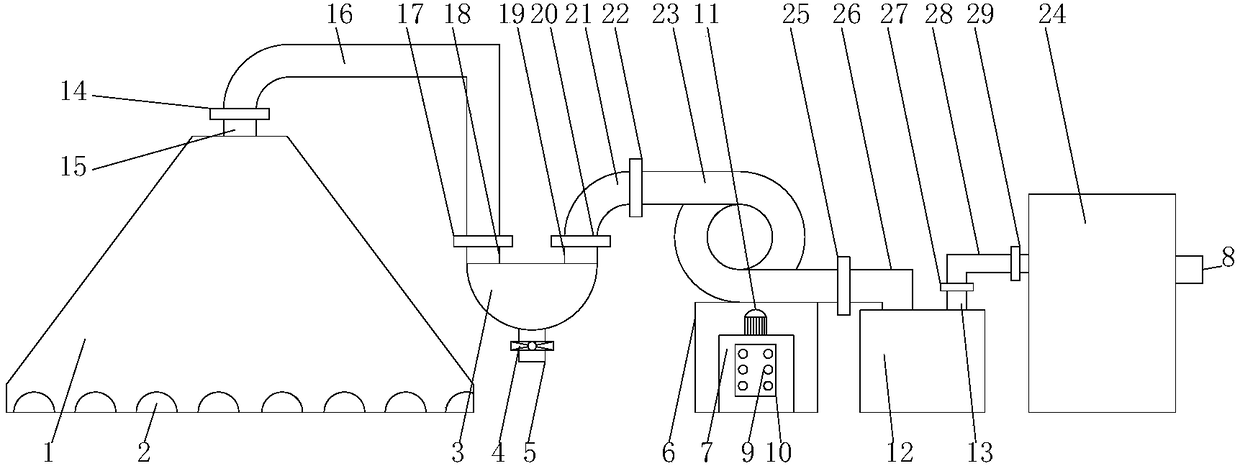

Intelligent spinning dust removal device

InactiveCN105944490AGo in and stopAvoid cloggingCombination devicesRadiationWater levelSpinning dust

The invention relates to an intelligent spinning dust removal device, which comprises a steam water tank, a support plate and electric rollers, wherein the steam water tank is arranged on the support plate; the electric rollers are arranged at the lower end of the support plate; an air inlet and an air outlet are formed in the steam water tank; a cyclone separation device and an exhaust fan are sequentially connected to the outer side of the air inlet through an admission pipe; a dust concentration sensor is arranged on the exhaust fan; a filter screen is horizontally arranged in the steam water tank; a pressure sensor is arranged on the filter screen; the filter screen and the air outlet are arranged above the water level in the steam water tank; a heating device is arranged at the bottom of the steam water tank; a controller is arranged on the outer side of the steam water tank; a sterilization device and a drying device are sequentially connected to the outer side of the air outlet through an outlet pipe; the exhaust fan, the electric rollers and the dust concentration sensor are connected with the controller respectively. According to the intelligent spinning dust removal device, the problems of serious environmental pollution and hazards of dust of a spinning workshop to health of a worker and low intelligence of an existing dust removal device are solved.

Owner:WUXI ELECTRICAL & HIGHER VOCATIONAL SCHOOLS

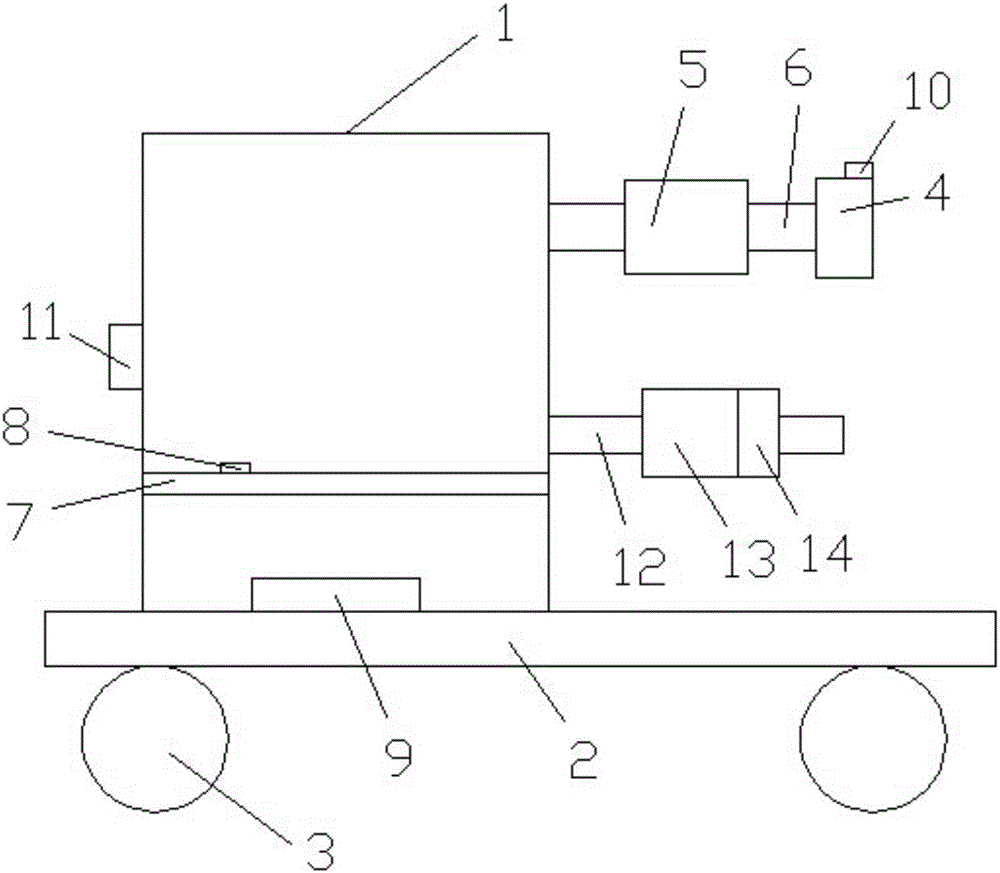

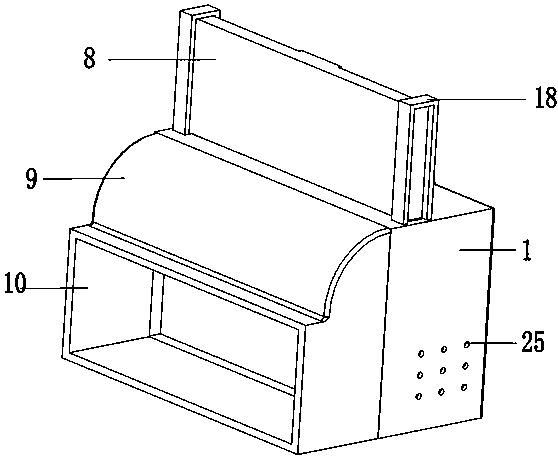

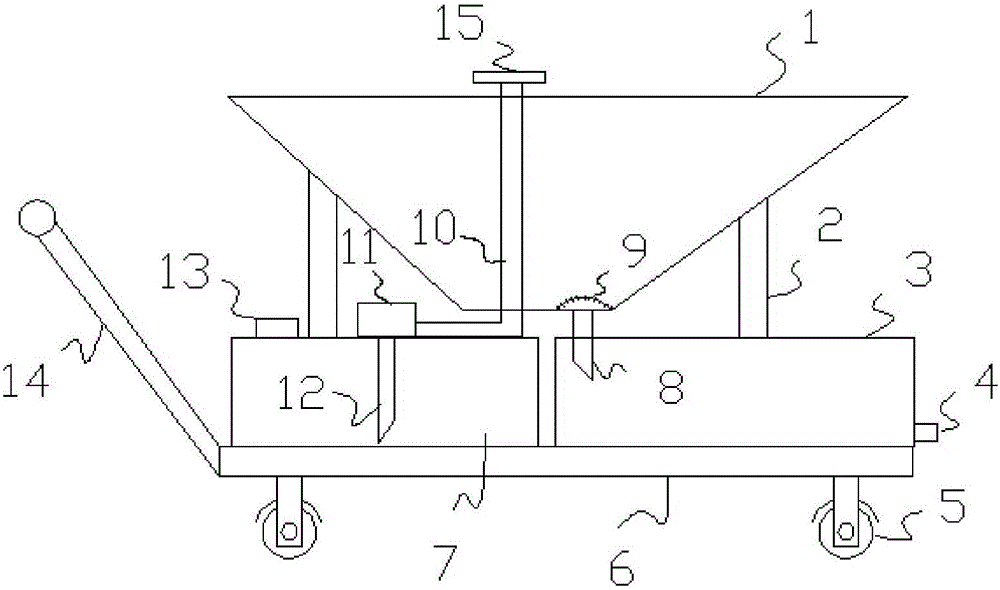

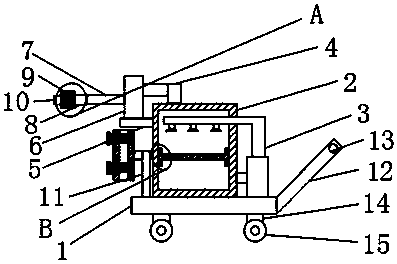

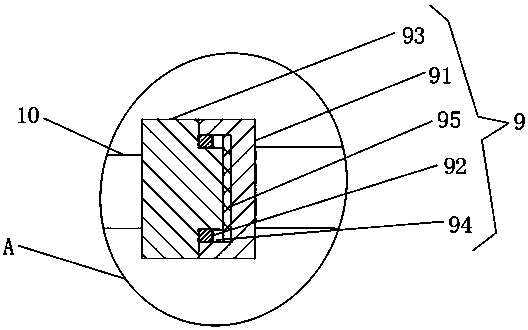

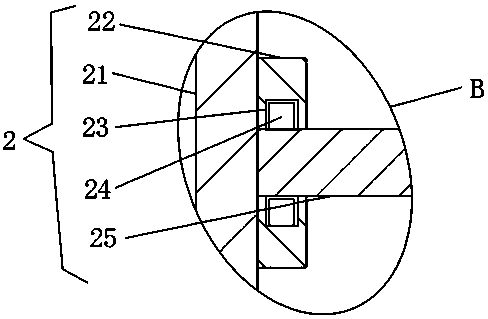

Spinning dust collecting device for spinning machine

InactiveCN108103643AEasy to cleanSimple structureAuxillary apparatusKnittingSpinning dustEngineering

The invention relates to a spinning dust collecting device for a spinning machine. The spinning dust collecting device for the spinning machine comprises a dust collecting base. The top of the dust collecting base is provided with a control box, and the bottom of the dust collecting base is provided with multiple travelling wheels. One end of the control box is provided with a filtering box. The bottom of the filtering box is connected with a dust collecting box. The top of the control box is provided with an air exhaust duct. The connection place of the air exhaust duct and the filtering boxis provided with a filtering screen. The air exhaust duct is connected with a draught fan. One side of the draught fan is provided with an air pressure detecting meter, and the air pressure detectingmeter is connected with the air exhaust duct through a pipe. One side of the air exhaust duct is provided with a baffle. One end of the baffle is connected with a push handle. The spinning dust collecting device is a moveable device, and is convenient for comprehensively cleaning the surrounding of the spinning machine. In a dust collection process, spinning dusts can be hanged on an elastic stoplever or the filtering screen. While the air pressure detecting meter detects that the wind power is decreased, an extruding plate is driven to be downwards moved to thrust the spinning dusts into thedust collecting box. The cleaning is convenient, and the structure is simple. A blocking phenomenon cannot be generated because the spinning machine cannot be used for a long time.

Owner:苏州闽国纺织科技有限公司

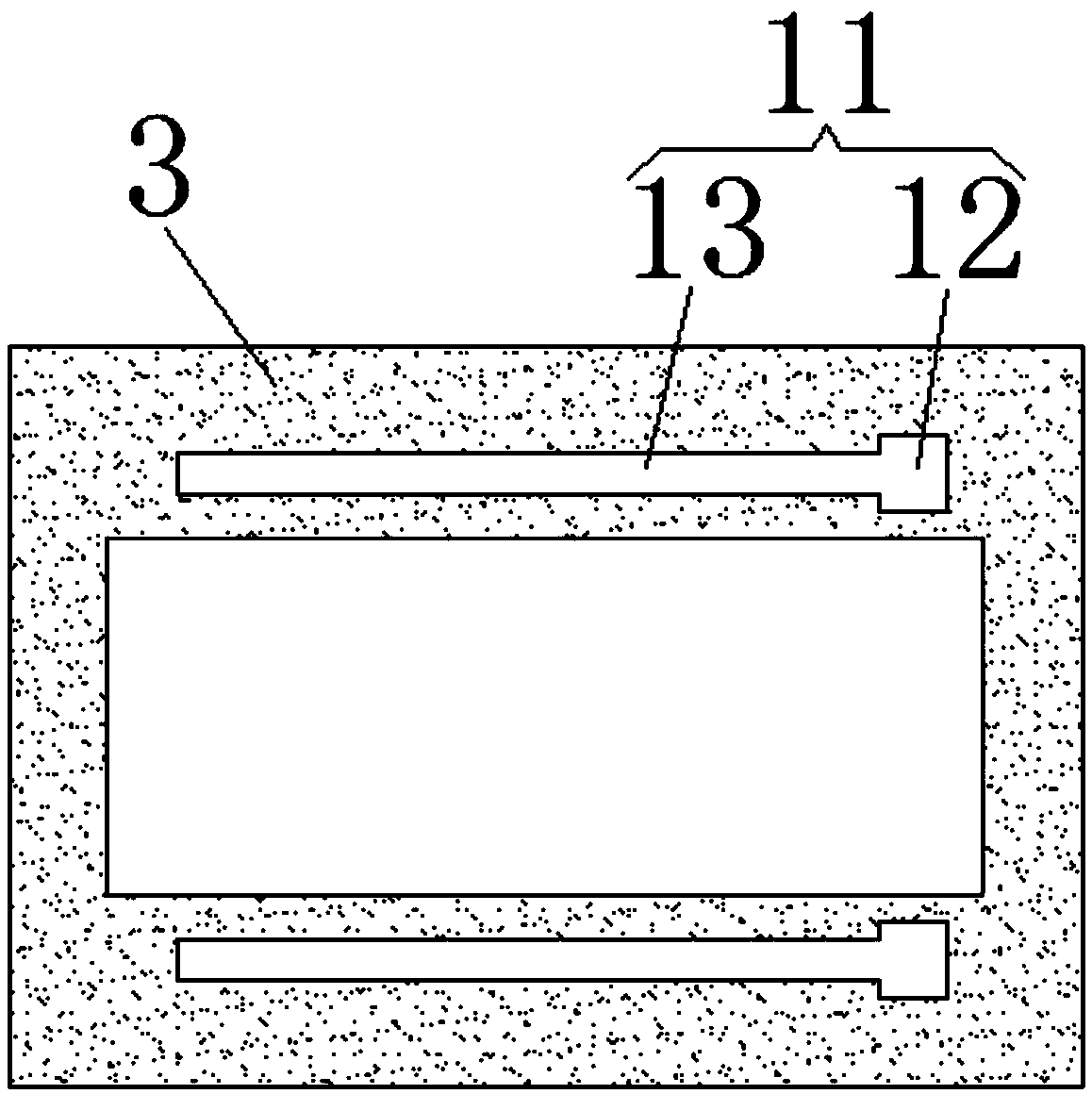

Spinning dust collector

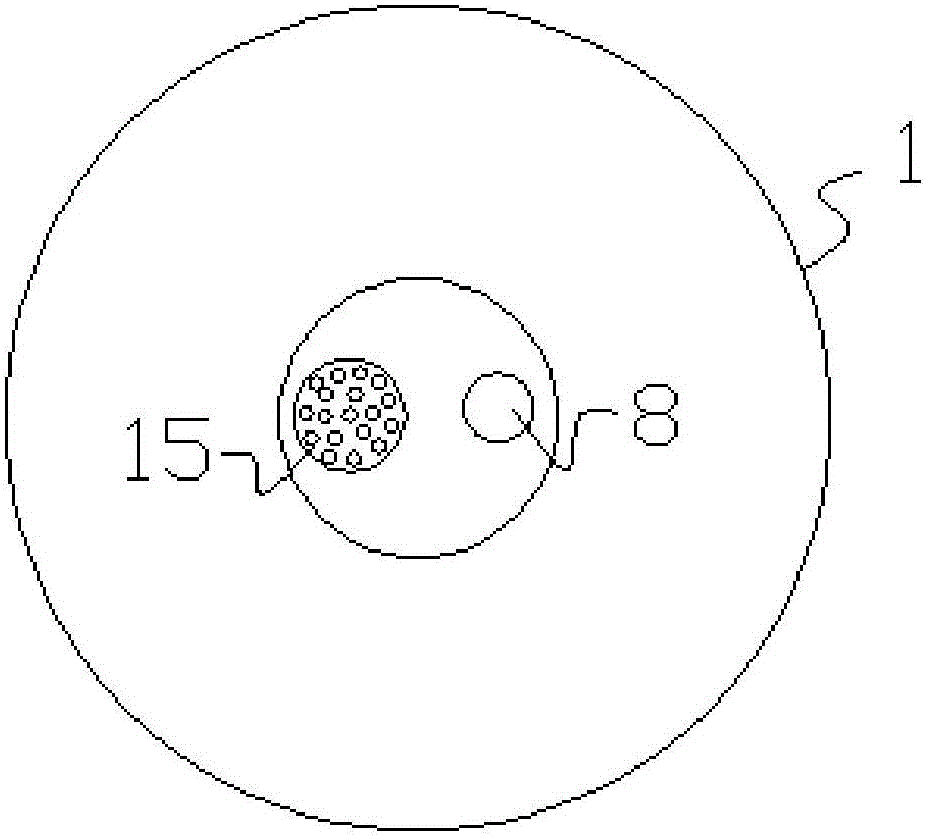

The invention relates to a spinning dust collector which comprises a suction device composed of an air collecting hood, an air intake pipe and an exhaust fan. The air collecting hood is provided with an air collecting hole communicated with the air intake pipe. A filter cartridge is disposed on the air collecting hole and comprises a barrel, a first filter net, a second filter net, a first cylinder and a second cylinder, wherein the first filter net and the second filter net are disposed in the barrel, the first cylinder and the second cylinder are connected with a controller through a first electromagnetic valve and a second electromagnetic valve, a piston rod of the first cylinder and a piston rod of the second cylinder are connected with a first blade and a second blade respectively, and the first blade and the second blade are perpendicularly contacted with the first filter net and the second filter net respectively. The spinning dust collector is simple in structure. The first blade and the second blade scrape off waste cloth and cloth strips respectively from the first filter net and the second filter net, and the waste cloth and cloth strips are discharged out of a spinning shop through a first waste discharge passage and a second waste discharge passage. Therefore, interior air quality of the spinning shop is guaranteed.

Owner:WUJIANG XIAOYU JET WEAVING

Spinning dust collecting device for spinning equipment

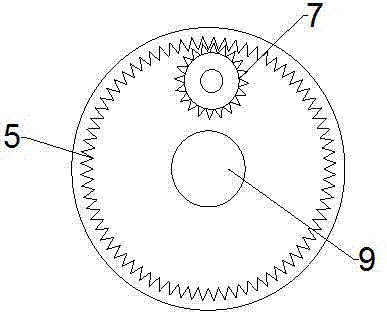

The invention discloses a spinning dust collecting device for spinning equipment. The spinning dust collecting device comprises a main shell, a falling opening, supporting legs, rubber suction cups, an inclined plate, a dust storage drawer, a sliding frame, an air inlet pipeline, a dust suction cover, an exhaust fan, a fixed frame, a filter screen, rubber pads, small gears, rotating rods, large gears, connecting rods, elastic springs, elastic balls, a conical exhaust pipe, conical spiral springs, a sliding plate, sliding rods, a water storage shell, a water sucking pipe, a water suction pump,a water outlet pipe, water mist sprayers and an electromotor. The spinning dust collecting device for the spinning equipment is simple in structure and novel in design, spinning dust falling in the main shell is stored through the dust storage drawer, a worker can conveniently take out and treat the collected spinning dust, operation difficulty is low, and the spinning dust collecting device is suitable for the worker to use; under the action of a dust removing mechanism, spinning dust in the main shell can be conveniently treated, the quality of exhausted air is improved, and spinning dust treatment efficiency is improved.

Owner:苏州华兆林纺织有限公司

Device for removing spinning dust on textile fabric

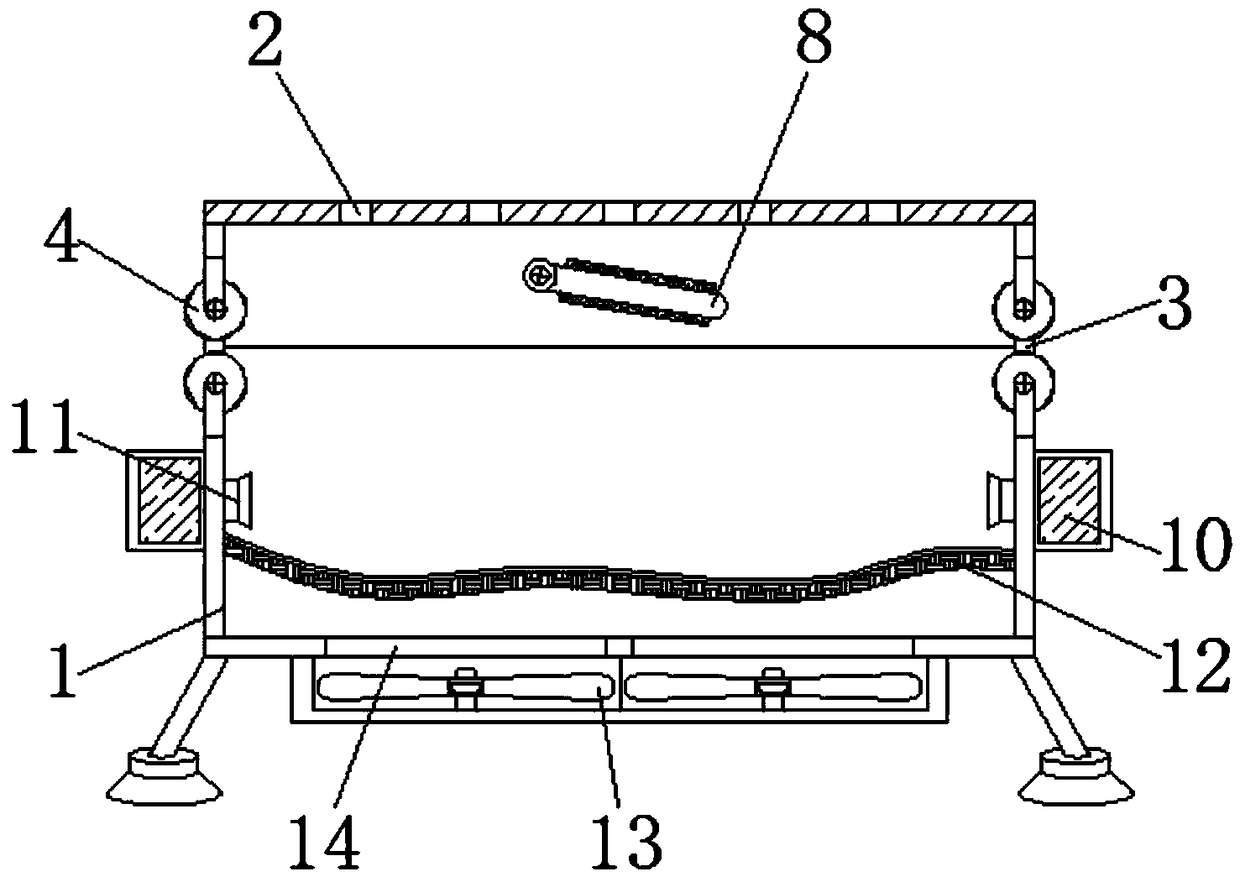

InactiveCN108691189AEasy to collect and processImpaired flexibilityMechanical cleaningPressure cleaningEngineeringSpinning dust

The invention discloses a device for removing spinning dust on textile fabric, and the device comprises a box body, a dust patting apparatus, a spraying apparatus and a dust collection bag. The upperend face of the box body is provided with a reserved vent hole, and a side edge of the box body is provided with a material conveying hole. A fixed pulley is connected with the left end of the material conveying hole through a connecting rod, and the joint of the material conveying hole and the connecting rod is provided with a groove. The dust patting apparatus is disposed on an inner wall of thebox body, and one side of the dust patting apparatus is provided with a servo motor. Moreover, the servo motor is fixedly installed at an outer side of the box body, and the spraying device is fixedbelow the fixed pulley on the outer wall of the box body. Moreover, one side, connected with the box body, of the spraying apparatus is provided with a fog pipe, and an end of the fog pipe is fixed onan inner wall of the box body. The dust collection apparatus is disposed below the fog pipe in the box body, and the bottom of the box body is fixedly connected with a dust collection fan. The deviceprovided by the invention prevents the excessive extruding of cloth from causing the reduction of production quality, can reduce the dust residual on the cloth, and achieves the maximized reduction of dust.

Owner:JIANGSU BEILIN TEXTILE CO LTD

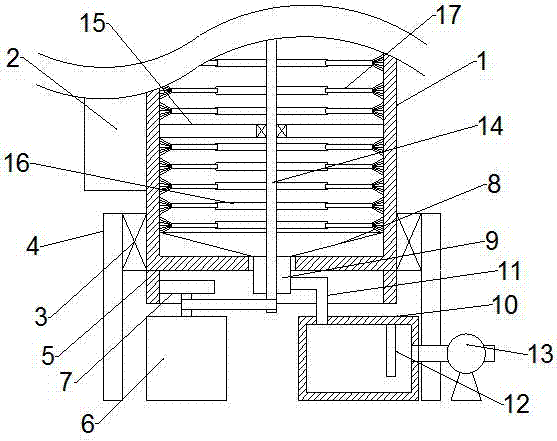

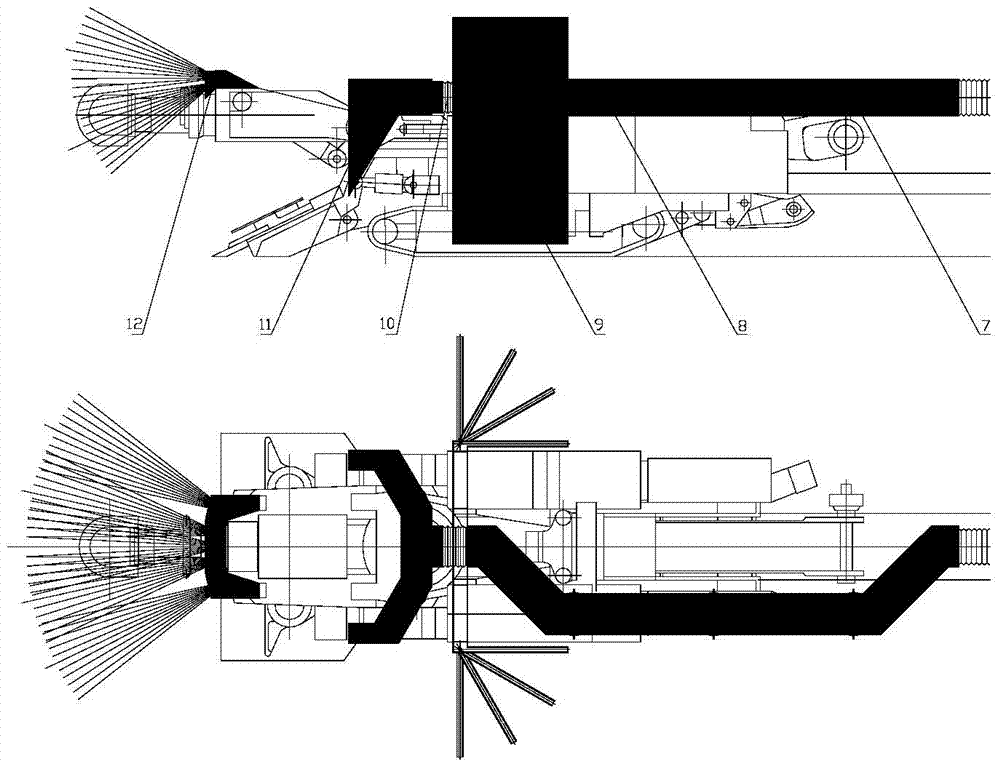

Anti-blocking efficient cotton spinning dust removal and impurity removal device

InactiveCN107313132AAvoid cloggingSpeed up entryFibre cleaning/opening by air draught arrangementsCarding machinesMotor driveEngineering

The invention discloses a high-efficiency anti-blocking dust removal and impurity removal device for cotton spinning, which comprises a dust cage, a cotton stripping roller and a dust collection box. The cotton stripping roller is arranged on the left side of the dust cage; a rotating bearing and a bracket are arranged on the periphery of the dust cage; The lower end of the dust cage is equipped with internal gears, motors, driving gears, dust collection boxes, connecting air pipes, baffles and air pumps; the inside of the dust cage is equipped with dust collection covers, dust suction pipes, rotating shafts, support frame plates, fixed rods, swing rods and brush. In the present invention, the driving gear on the motor cooperates with the internal gear at the lower end of the dust cage to drive the dust cage to rotate, and at the same time, the motor drives the rotating shaft to rotate, and the brush can continuously clean the inner wall of the dust cage through the speed difference with the dust cage to avoid blockage; through the action of the air pump , the air enters the dust collection box through the dust suction hood, dust suction pipe and connecting air pipe, so that the dust can be efficiently removed while the gas emission is clean.

Owner:洪飞飞

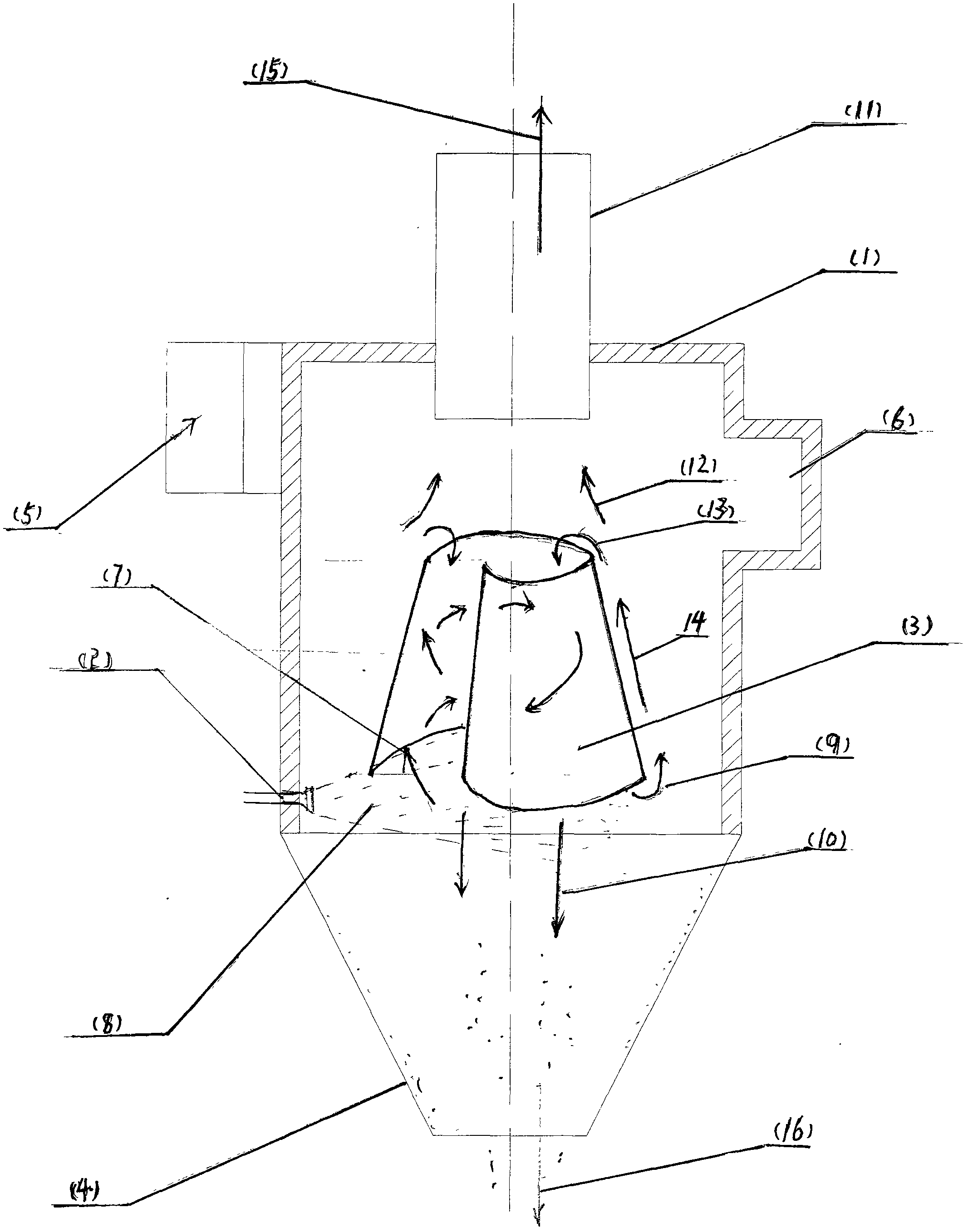

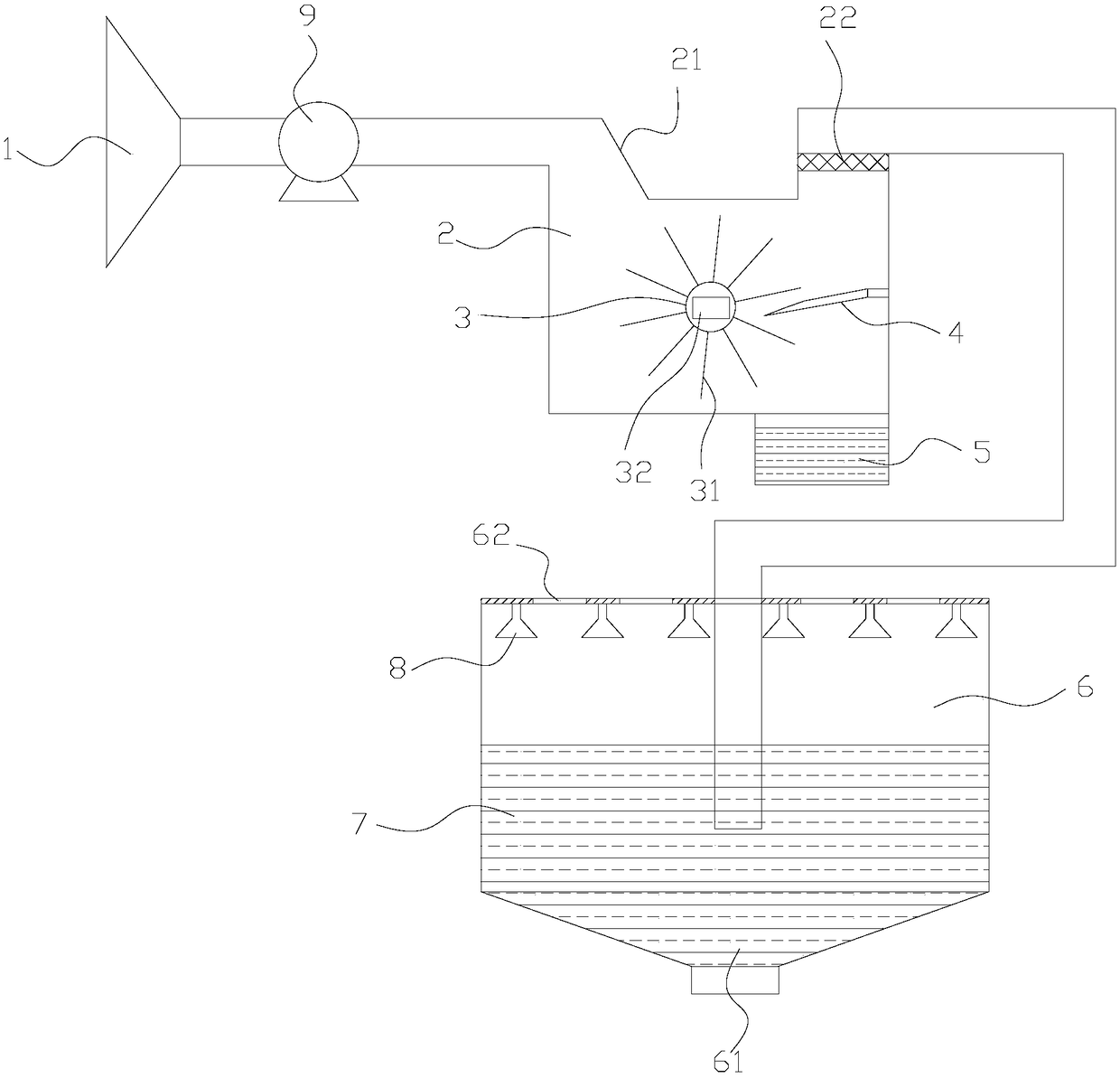

Atomizing spinning dust removing device

InactiveCN102861490AImprove dust removal effectIncrease dust removal granularityCombination devicesCycloneSpray nozzle

The invention discloses an atomizing spinning dust removing device applied to an industrial cyclone dust collector. The vertically-transparent opened taper-sleeve spinning dust removing device is installed in the industrial cyclone dust collector, the opening size of the taper-sleeve spinning dust removing device is 160mm-320mm, the taper of the taper-sleeve spinning dust removing device is 16-32 degrees, and an atomizing spray nozzle is arranged under the taper-sleeve spinning dust removing device and above a taper blanking groove and forms a sector atomization layer under the taper-sleeve spinning dust removing device. The atomizing spinning dust removing device has a vertical dust flow circulating function, enables dust to be stacked mutually, improves the dust removing efficiency in waste gas by about 30% through atomization and secondary centrifuging based on increasing of dust weight, improves the particle size of removed dust by 0.01mm, does not need a cloth bag to assist in dust removal, can resist 700-degree of high temperature, further widens an application range and is environment-friendly.

Owner:BEIJING SNTA ENERGY SAVING ELECTRICAL

Spinning dust-removing cotton fluffer

InactiveCN107699994AEfficient popping work efficiencyPlay the role of fixing and anti-looseningCarding machinesElectric machineryEngineering

The invention discloses a spinning dust-removing cotton fluffer which comprises a cotton fluffer body. A first roller is arranged on one side of the top of the cotton fluffer body, an induced draft fan is arranged inside the first roller, a vent pipe is arranged at the top of the induced draft fan, a hollow plate is arranged on the outer surface of the first roller, a conveying belt is arranged onone side of the first roller, a drying pad is arranged at the bottom of the conveying belt, a second roller and a pressing roller are horizontally and sequentially arranged at the top of an operatingboard, the first roller is in transmission connection with a motor in the operating board through a rotating shaft, a discharging belt is welded on the outer side of the operating board, a dust outlet pipe is welded at the bottom of the first roller, a dust separating pipe is welded on one side of the dust outlet pipe, a dust collecting bin is welded at the bottom of the dust outlet pipe, and a partition plate is welded on the inner surface wall of the dust collecting bin. The cotton fluffer is simple and reasonable in integral structural design, safe and stable in running, flexible and convenient to operate and high in practicability, and has strong self-protection capacity.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

Textile machine dust removing device with spraying structure

InactiveCN105944480ASimple structureWorking principle is clearCombination devicesDirt cleaningWorking environmentEngineering

The invention relates to a textile machine dust removing device with a spraying structure and belongs to the technical field of textile processing machinery. The textile machine dust removing device comprises a frame, a collecting cover arranged on the frame, a collecting tube arranged above the collecting cover and a water dripping box, wherein a fan is arranged at the tail end of the collecting tube, a first filter screen is arranged between the collecting tube and the fan, a dust alleviation box is arranged on the bottom left of the first filter screen, the dust alleviation box is fixedly connected with the collecting tube through a dust fall tube, a sprayer is arranged on the inner wall of the dust alleviation box, a dust discharge water outlet is formed in the bottom of the dust alleviation box, a second filter screen is arranged at the dust discharge water outlet, and the water dripping box is arranged below the dust alleviation box. The textile machine dust removing device has the advantages that the device is simple and reasonable in structure and clear in working principle, the collecting cover is combined with the fan and the sprayer sprays water to achieve alleviation of spinning dust, the spinning dust is precipitated after the spraying to avoid dust return, convenience in operation is achieved, the working environment of an operator is improved, and health of the operator can be protected favorably.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

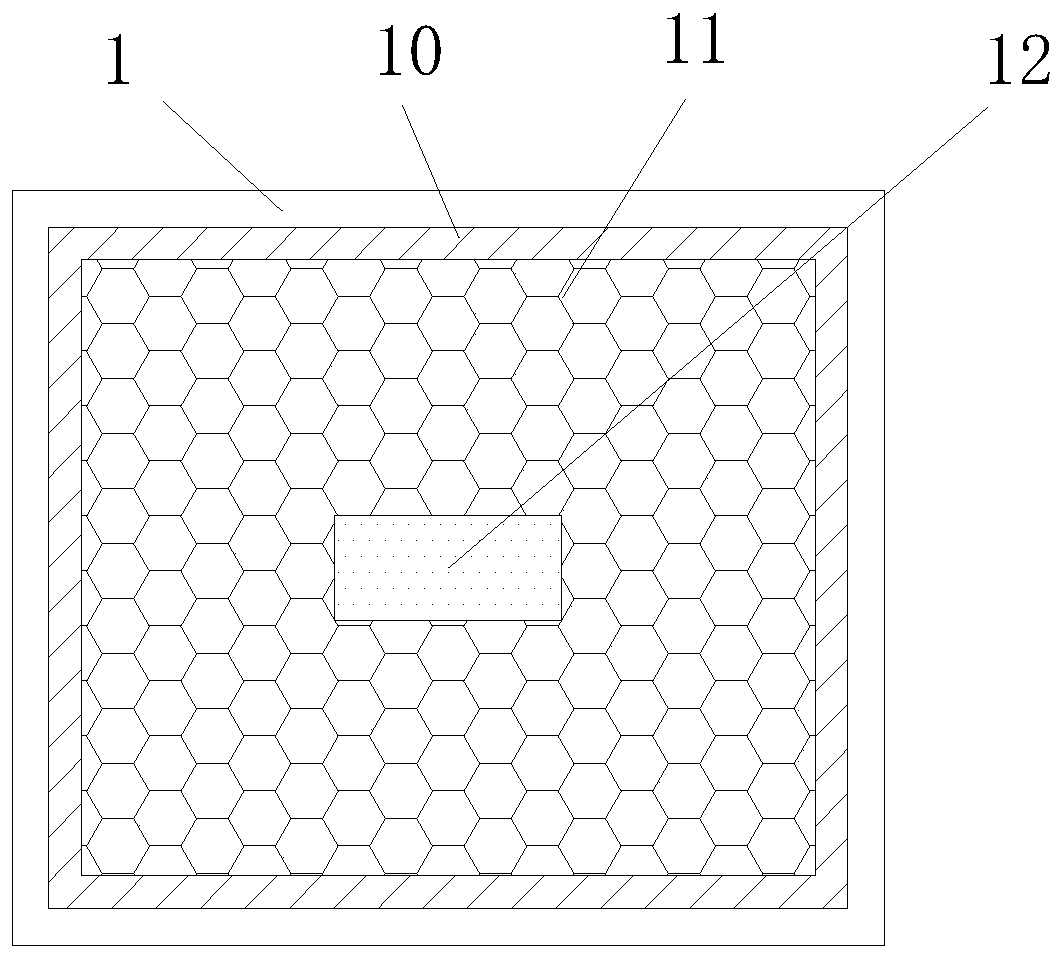

Air filtering device for spinning workshop

InactiveCN109482012ASingle solutionReduce filtration efficiencyDispersed particle filtrationTransportation and packagingAir filterFiltration

The invention discloses an air filtering device for a spinning workshop. The air filtering device comprises a filtering tank body, wherein a cavity is formed in the filtering tank body; support legs are fixedly connected to the positions, close to the left and right sides, of the bottom of the filtering tank body; mounting plates are fixedly connected to the bottoms of the support legs, and a sideplate is movably mounted on the right side in the filtering tank body; and a dust collection cover is fixedly mounted on the right side of the side plate. By virtue of the combined use of a first filtering cylinder, a coarse mesh filtering net, a bearing seat, a second filtering cylinder, a crank, a rotating rod, a hairbrush plate, a hairbrush, a through slot and a fine mesh filtering net, the problems that a traditional filtering device is single in structure, a large number of spinning dust is accumulated in the filtering device after the long-term filtration, an air outlet of the filteringdevice is blocked due to overmuch spinning dust sometimes, the filtering efficiency of the filtering device is reduced, and the filtering device cannot meet the use demands of people are solved; andby utilizing the air filtering device for the spinning workshop, the through slot can be conveniently dredged by a user.

Owner:嘉兴富宏纺织有限公司

Textile dust collection device of textile machine

InactiveCN107541848AImprove cleanlinessPhysical health threatAuxillary apparatusBlood Collection TubeEngineering

The invention relates to the technical field of textiles, in particular to a textile dust collection device for a textile machine, which includes a bracket installed on textile equipment, a collecting bucket with a conical cross-section is arranged on the bracket, and a collection bucket with a collecting bucket is arranged on the collecting bucket. The collection pipe connected with the cavity, the collection pipe is connected with the input end of a fan, and a filter screen is arranged in the collection pipe, and the collection pipe at the front end of the filter screen is connected with a dust outlet pipe, and the outlet end of the dust outlet pipe is in a collection bag. The collecting bucket can concentrate the dust generated in the weaving process, and then pump it into the collecting pipe through the fan. Due to the setting of the filter screen, the dust can be blocked, and then fall into the collecting bag through the dust pipe, so as to collect the dust Centralized collection ensures the cleanliness of the workshop and avoids the threat of dust to the health of the staff.

Owner:孙斌

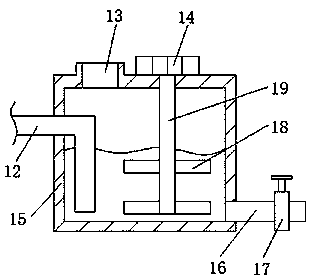

Spinning dust collection and prevention device for spinners

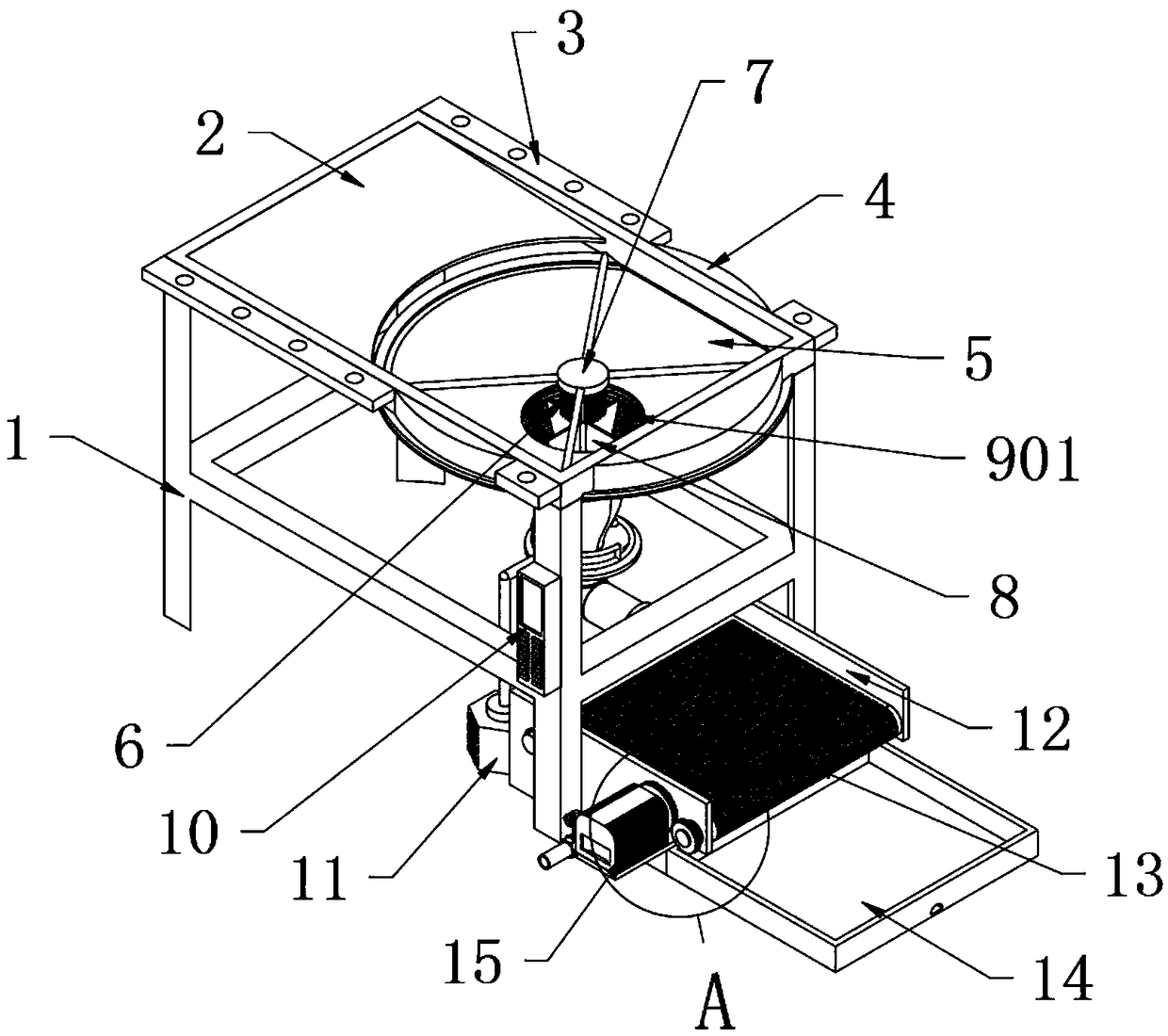

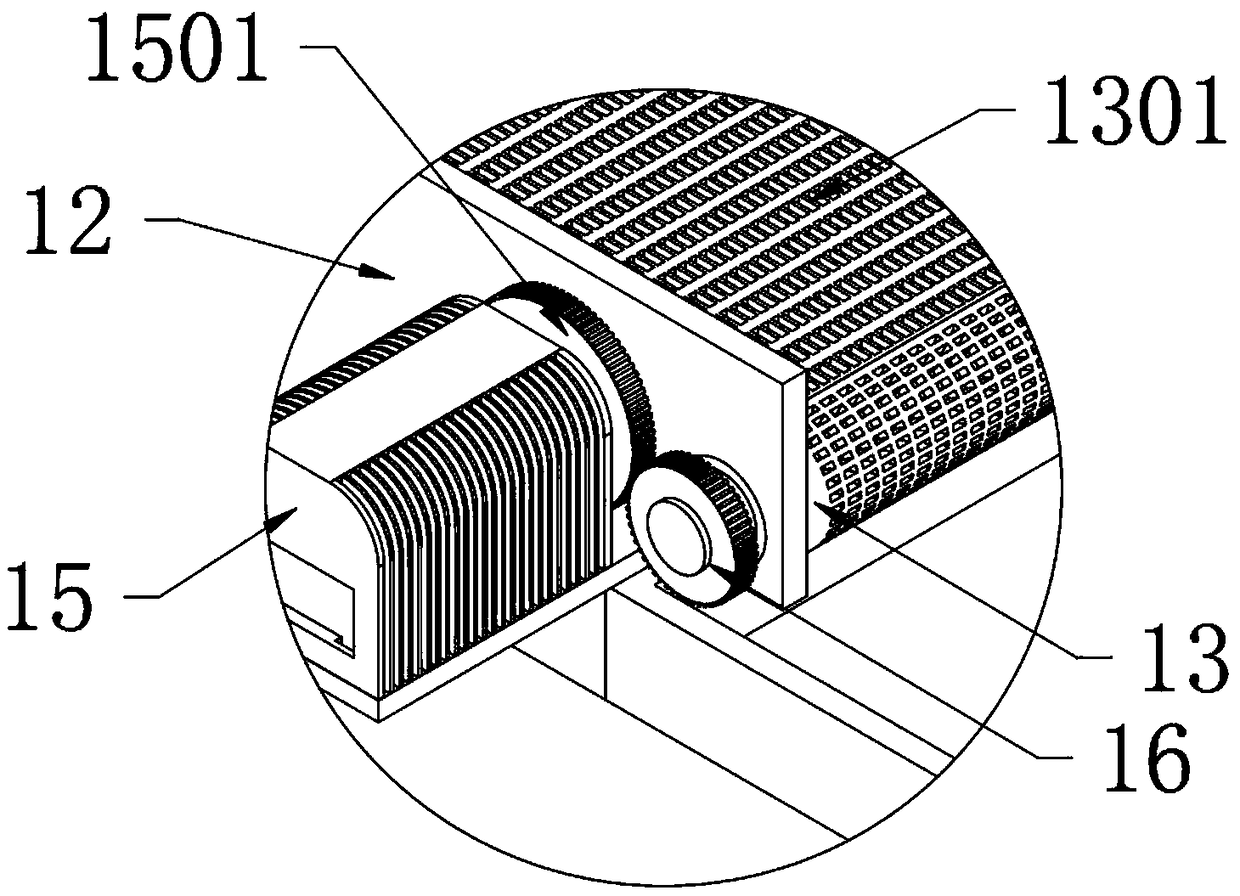

PendingCN109126337AGood for booting intoEnter fast and stableUsing liquid separation agentDirt cleaningEngineeringSpinning dust

The invention provides a spinning dust collection and prevention device for spinners. The device comprises a rack, a water inlet pipe and a shower pipe, wherein the rack is of a cuboid frame-shaped structure matched with traditional spinners; mounting plates are horizontally welded on the side wall of front ends and rear ends of a top frame of the rack; a dust collection disk is welded at the bottom of the right end of the rack through a circular fixed disk; an inverted cone-shaped dust guiding body is arranged at the lower end of the dust collection disk; and the lower end of the dust guidingbody is downwardly and fixedly connected with a discharging pipe through a flange plate by using bolts. According to the spinning dust collection and prevention device for spinners, a material guiding plate is arranged to exactly cover areas, which cannot be covered by the dust collection disk, in the rack, the material guiding plate is inclined toward the lower side of the dust collection disk for 15 degrees, and when the spinners at the upper side generate thread residues and chippings, the thread residues and chippings can be collected by the dust collection device at the lower side, so that the dust generated by spinning can be prevented from spreading in workshops.

Owner:新昌县利安轴承有限公司

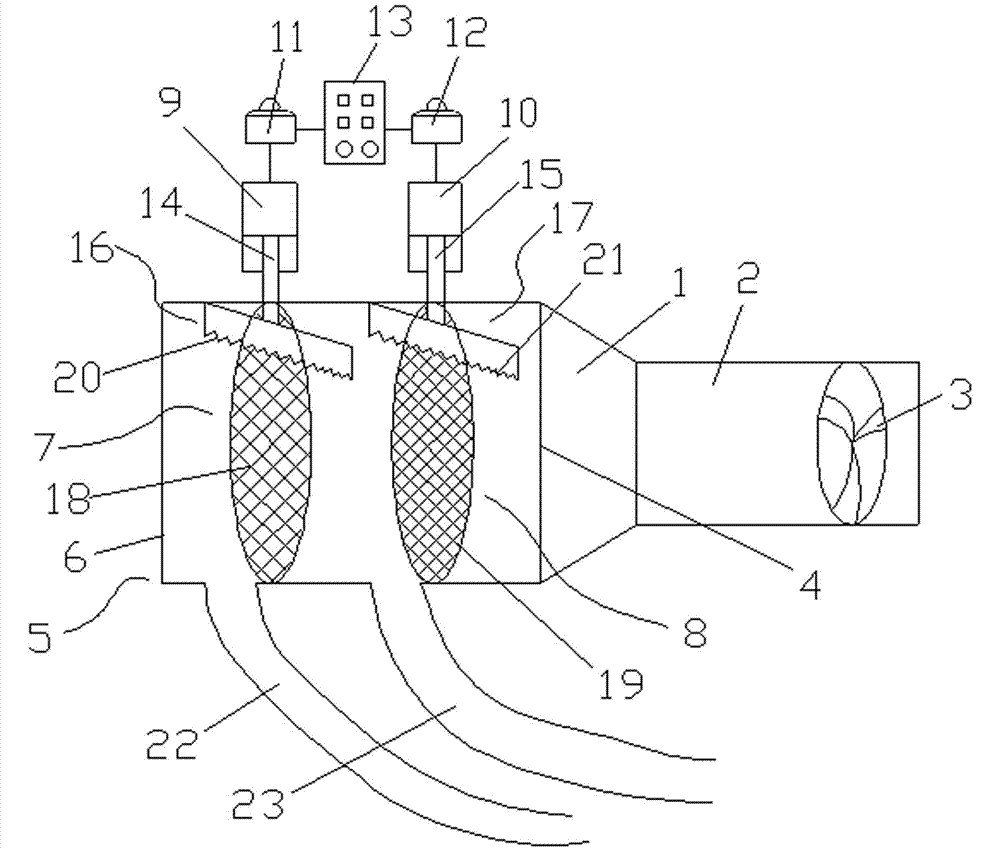

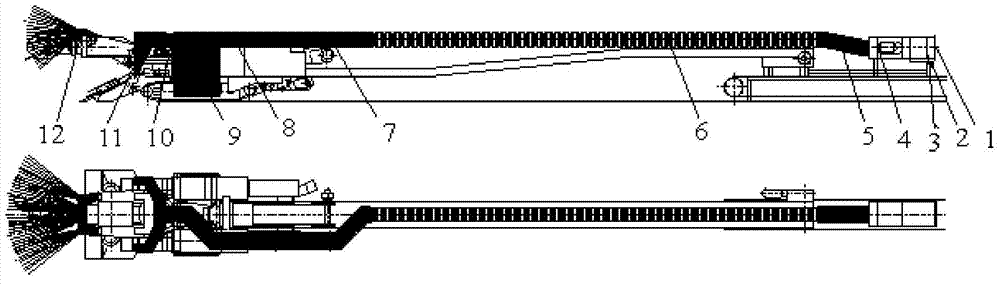

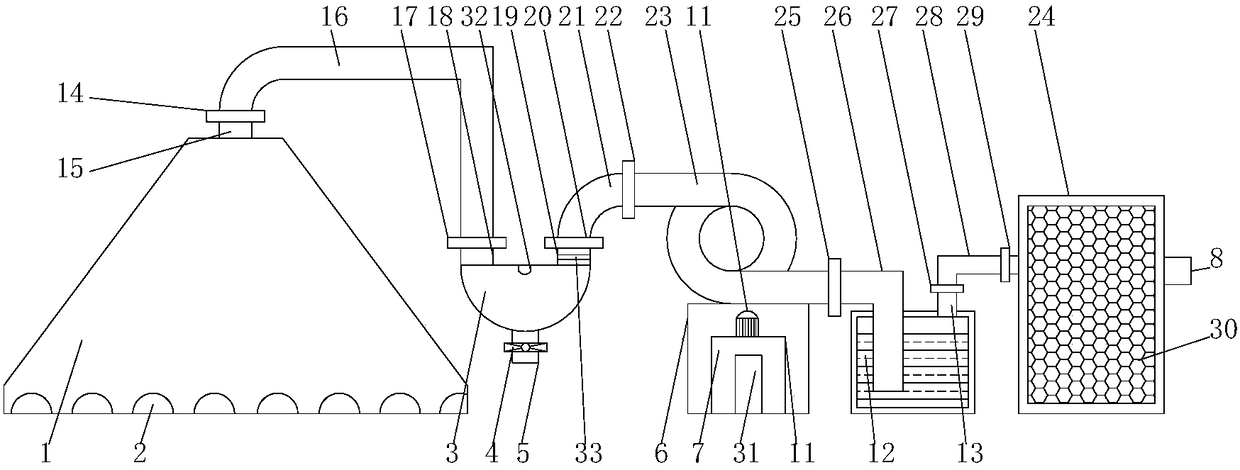

Ultrasonic atomization and vibration spinning dust-removing device of heading machine

InactiveCN103498677ACover and block drift pathsImprove dust removal efficiencySlitting machinesEngineeringUltrasonic atomization

The invention provides an ultrasonic atomization and vibration spinning dust-removing device of a heading machine. According to the ultrasonic atomization and vibration spinning dust-removing device, an ultrasonic atomizer is fixedly connected with wet type vibration spinning equipment by a connection part, wherein the ultrasonic atomizer comprises an ultrasonic impulse device, a driving exhaust opening, a flexible connection piece, a reversible hoisting shielding screen, an ultrasonic atomization assembly and a fog-dust mixing cavity; the ultrasonic impulse device is connected with the driving exhaust opening; the impulse device is fixedly connected with the driving exhaust opening; the ultrasonic atomization assembly and the driving exhaust opening are connected together by the flexible connection piece; the ultrasonic atomization assembly is connected with the fog-dust mixing cavity; the reversible hoisting shielding screen is fixedly arranged on the driving exhaust opening; the connection part comprises a connection air barrel and a fixed bracket; the wet type vibration spinning equipment comprises a vibration spinning flow guide separator, a wet type draught fan and a reducing connector; the connection air barrel is used for connecting the ultrasonic atomizer with the wet type vibration spinning equipment; the connection air barrel is fixedly connected with the wet type draught fan by the reducing connector; the wet type draught fan is fixedly connected with the vibration spinning flow guide separator; the vibration spinning flow guide separator is provided with a clean air outlet and a coal slime outlet.

Owner:SUZHOU HUAAN MINING TECH

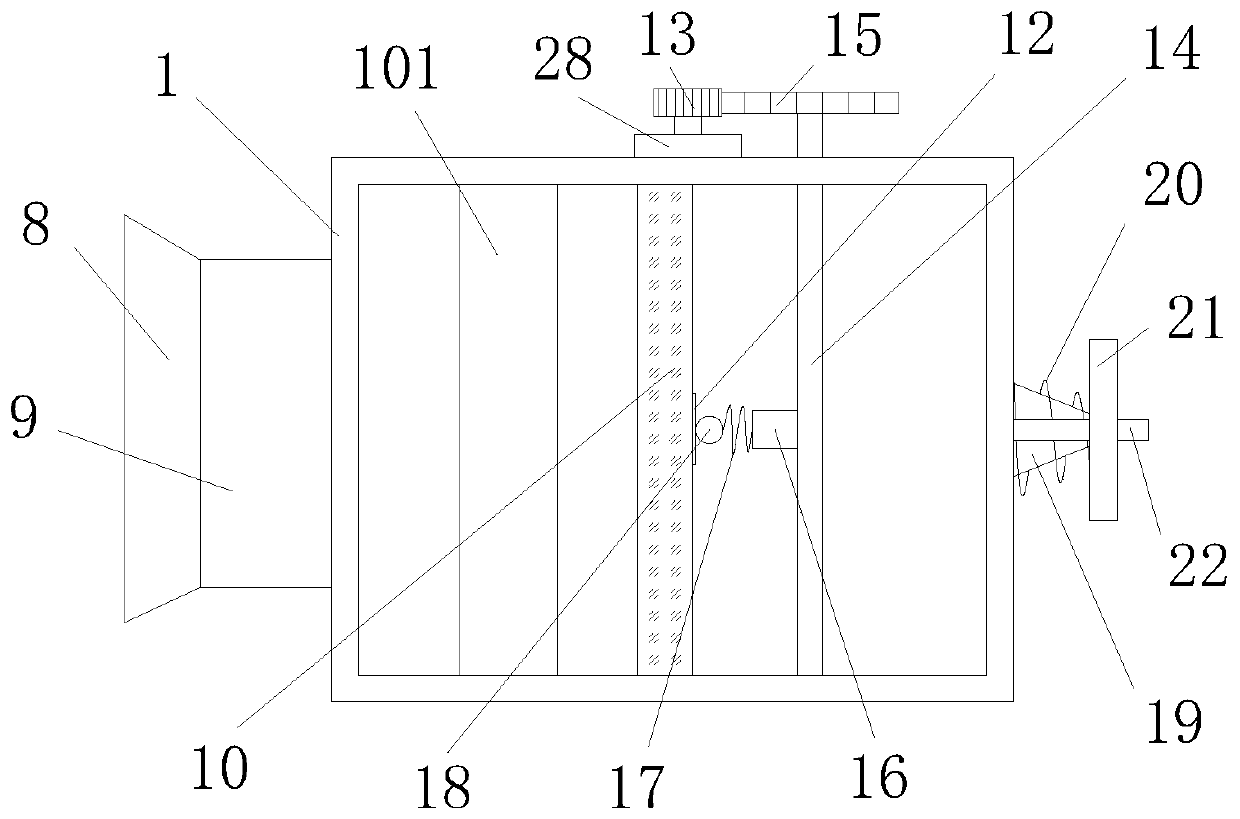

Textile machine spinning dust collecting device

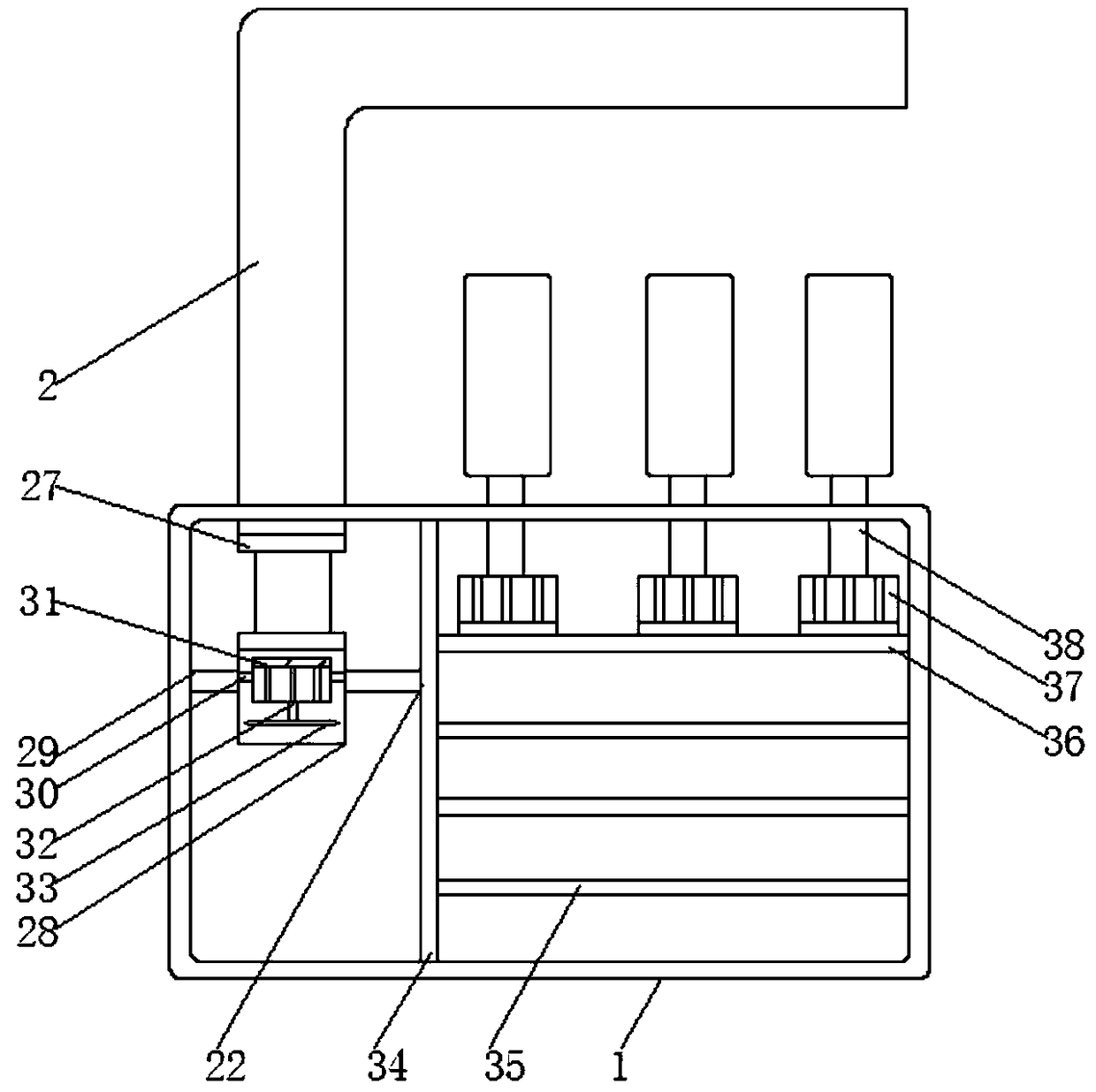

ActiveCN110270175AAvoid cloggingTo achieve the effect of collecting dustDispersed particle filtrationTransportation and packagingEngineeringSpinning dust

A textile machine spinning dust collecting device comprises a main box, a gas inlet box and a material collecting box. A collecting net and a solid plate are arranged in the main box. A lifting plate is arranged on one side of the solid plate. A rack and a gear are arranged in an inner cavity of the lifting plate. A partition plate is arranged between the gas inlet box and the material collecting box. A ventilating long groove is formed in one side of the partition plate. An upper arc-shaped plate is fixed to the bottom of the collecting net. A fixed sleeve and a squeezing plate are fixed to the inner wall of the material collecting box. A spring is arranged between the outer wall of the squeezing plate and the inner wall of the material collecting box. A lower arc-shaped plate is arranged on the top of the squeezing plate. A material collecting groove is formed in the upper side of the fixed sleeve. An air suction fan is fixed to the side wall of the gas inlet box. A scraper is fixed to the inner wall of the material collecting box. A round hole is formed in the side wall of the material collecting box. By means of the textile machine spinning dust collecting device, spinning dust on the collecting net can be automatically cleaned away in time, and blockage is prevented; meanwhile, the spinning dust can be secondarily collected into a dust collecting cloth bag, secondary contamination during processing is prevented, labor intensity is lowered, and the dust removal effect is improved.

Owner:胡俏俊

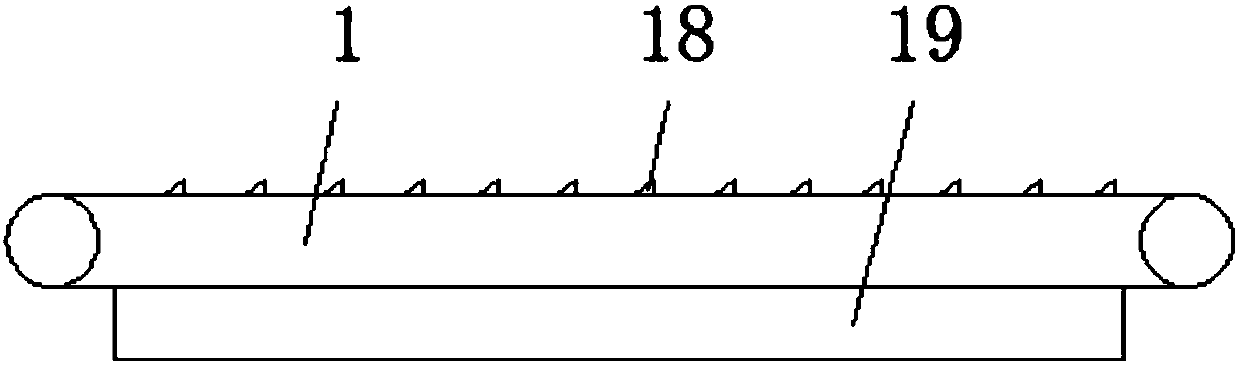

Spinning brush

The invention discloses a spinning brush which comprises a brush handle and bristles, wherein the brush handle is made of oil-proof wood materials, the bristles are made by corrosion-resistant hair, a fastening needle is arranged at one end of the bristles, a moving slide rail is arranged on the brush handle, and a telescopic slide rail is arranged in the middle of the brush handle. The spinning brush can be conveniently used for brushing certain additives during spinning as well as sweeping dust. The bristles are made of special materials and have a dust-proof function. The length can be adjusted in four directions. The spinning brush adopting a novel design scheme has the advantages of simple structure, skillful and novel design, wide range of applications and extreme flexibility, and is favorable to popularization and use.

Owner:KUNSHAN JIEMING TEXTILE

Textile machine spinning dust removal device

InactiveCN107653557AClean thoroughlyTo achieve dust removalAuxillary apparatusKnittingCouplingEngineering

The invention discloses a textile machine spinning dust removal device, which comprises an inverted funnel-shaped collector. The upper port of the collector is welded with a collecting pipe in an inverted gib-shaped structure; the internal bolt at the lower port of the collector is connected with an external filter screen; one end where the collecting pipe and the collector are connected is weldedwith a fixing support; the other end of the collecting pipe is internally provided with a sliding groove along a horizontal direction; a dust collecting box is in sliding connection inside the sliding groove; one side of the dust collecting box is fixed with a baffle, and the other side of the dust collecting box is welded with a handle; the position, close to the middle, inside a transverse pipeline of the collecting pipe is sleeved with an internal filter screen; the upper bolt, close to the internal filter screen, of the collecting pipe is connected with a motor; one side, close to the internal filter screen, of the motor is fixedly sleeved with a coupling; and the coupling in the vertical direction is fixedly sleeved with a screw rod. Through arranging the motor, the coupling, the screw rod, a moving rod and a brush to form a transmission cleaning device, cotton matters accumulated on the internal filter screen can be cleaned, the device can better achieve a dust absorption role,the dust removal efficiency is improved, and dust and cotton matters in the air can be reduced.

Owner:JIAXING YUNYUN TEXTILE

Textile dust collecting device for textile device

InactiveCN109468715ASimple structureImprove dust removal effectTextiles and paperSpinning dustWaste management

The invention discloses a textile dust collecting device for a textile device, which comprises a dust suction hood, a wadding collecting cavity and a dust collecting cavity, wherein the wadding collecting cavity is communicated with the dust suction hood through a dust suction pipeline, a wadding roller is arranged in the wadding collecting cavity, a plurality of metal wadding rolling teeth whichare densely and uniformly distributed on the circumferential roller surface of the wadding roller and extend radially, a scraping comb is arranged on one side of the wadding roller, opposite to an airoutlet of the wadding collecting cavity, and the scraping teeth of the scraping comb extend into the metal wadding teeth and are arranged at intervals relative to the metal wadding teeth; the dust collecting cavity is communicated with the air outlet of the wadding collecting cavity through a dust collecting pipeline, a water tank is arranged in the dust collecting cavity, and the air outlet of the dust collecting pipeline extends into the water tank. The textile dust collecting device for the textile device is simple in structure and good in dust removing effect, and can be used for separating and adsorbing spinning wadding and spinning dust at the same time.

Owner:WUHAN POLYTECHNIC

Textile machine spinning dust collection device

InactiveCN105664623AReduced activityAvoid cloggingUsing liquid separation agentWater storage tankWastewater

The invention relates to the textile field, and in particular relates to a textile machine spinning dust collection device. The device can be used for collecting spinning dust in a workshop, thereby improving work environment in the workshop. The device structurally comprises a flat plate, wherein rollers are arranged at the bottom of the flat plate, a water storage tank is arranged above the flat plate, a water sunction pump is arranged above the water storage tank, the bottom of the water sunction pump is communicated into the water storage tank via a water suction pipe, a water outlet of the water sunction pump is connected with a vertical water spray pipe, an atomization head is arranged at the top end of the water spray pipe, a waste water collection tank is arranged at one side of the water storage tank, a conical collection funnel is arranged above the water storage tank and the waste water collection tank via a support, the water spray pipe penetrates through the bottom of the conical collection funnel, a drain pipe is arranged at one side of the water spray pipe, and the lower end of the drain pipe is communicated into the waste water collection tank. The textile machine spinning dust collection device is simple to operate and convenient to use, and is applicable to various textile workshops.

Owner:苏州市合庆纺织贸易有限公司

Textile machine spinning dust collecting device

InactiveCN108866700AIncrease the function of cleaning the dust on the surface of the textile machinePractical to useAuxillary apparatusArchitectural engineeringMotor shaft

The invention discloses a textile machine spinning dust collecting device. The device comprises a device pedestal, the top of a left end of the front side of the device pedestal is provided with a circular hole, a drawstring is fixedly connected inside the circular hole, a clamping plate is arranged at the right end of an outer side of the drawstring, the bottom of the drawstring is fixedly connected with a handle, a motor is installed inside the handle, the bottom of the handle is connected with a motor shaft, the handle runs through the bottom of the motor shaft, the left and right sides andrear and back sides of the motor shaft are all provided with cleaning brush hair, a division plate is installed inside the device pedestal, and the top of the right side of the division plate is provided with a fixing plate. By arranging the handle and the motor shaft on the device pedestal and arranging the cleaning brush hair on the motor shaft, the collecting device additionally has a functionfor cleaning the surface dust of a textile machine, is relatively small and can clean various dead corners, and the textile machine spinning dust collecting device is conducive to be more practicallyused, relatively practical and suitable for being widely popularized and used.

Owner:JIAXING YUNYUN TEXTILE

Spinning dust collecting device of spinning machine

The invention discloses a spinning dust collecting device of a spinning machine, and relates to the technical field of spinning machines. The spinning dust collecting device comprises a spinning room,a first connecting pipe is fixedly connected to the middle of the upper surface of the spinning room, the upper surface of the first connecting pipe is located outside the spinning room and fixedly connected with a suction fan, the lower surface of the first connecting pipe penetrates through the middle of the upper surface of the spinning room and is in buckled connection with the upper surfaceof a filter net layer, a second connecting pipe is connected to the lower surface of the filter net layer through attaching, and the front surface of the first connecting pipe is fixedly connected with the front surface of the second connecting pipe through connecting ribs. According to the spinning dust collecting device of the spinning machine, on one hand, a sucking pipe and branch pipes are located over a working table and used for sucking by starting the suction fan when the spinning machine on the working table works and dust starts to spread through air, and the dust enters the suckingpipe through the branch pipes, and is sucked to the filter net layer under suction force of the suction fan.

Owner:湖州新爱品纺织有限公司

Counter-current-proof type spinning dust-removing device

InactiveCN105903275ASimple structureWorking principle is clearDispersed particle separationWorking environmentEngineering

The invention provides a counter-current-proof type spinning dust-removing device, belonging to the technical field of spinning machining machinery. The counter-current-proof type spinning dust-removing device comprises a rack, a dust collection hood arranged on the rack, and a dust collection pipeline arranged above the dust collection hood, wherein a dust falling hole is formed in the tail end of the dust collection pipeline; a dust falling box is arranged under the dust falling hole, and is fixedly connected with the dust falling hole through a dust falling pipeline; stopping separation plates are arranged at the upper ends of inner walls of the two sides of the dust falling box; a dust collection draught fan is arranged on the inner wall of one side under the stopping separation plates; and a dust collection hole is formed in the inner wall on the other side under the stopping separation plates. The counter-current-proof type spinning dust-removing device is simple and reasonable in structure and has a clear working principle; the device works by adopting a manner of combining the dust collection hood and the draught fan; the dust falling box is innovatively added and the stopping separation plates are arranged in the dust falling box, so that backflow of spinning dust is prevented through the stopping separation plates; the operation is extremely convenient and a working environment of operators is improved; and relatively good protection on body health of the operators is formed.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

Spinning dust removing device

InactiveCN105327559APlay the role of dust removalAchieve the effect of active dust removalDispersed particle filtrationEngineeringHigh pressure

The invention relates to the field of spinning, in particular to a spinning dust removing device. The spinning dust removing device has the advantages of being capable of performing active sucking dust removing and high-pressure removing, thorough in dust removing, simple in structure, low in use cost, easy to clean and the like. The spinning dust removing device structurally comprises a shell, a first filter net and a fan blade. The shell is of a cylindrical hollow structure. The first filter net is of a cylindrical hollow structure, is arranged inside the shell and is concentric with the shell. The fan blade is fixed to the supporting rod through a fixing shaft, and the supporting rod is fixed to the inner wall of an air outlet pipe. A motor is connected to the lower portion of the fan blade through the fixing shaft. The air outlet pipe is arranged at the upper end of the shell, is communicated with the first filter net inside the shell and is of a cylindrical hollow structure. An air storage tank is arranged at the upper portion of the outer side of the shell, surrounds the periphery of the shell and is of a circular ring structure. The spinning dust removing device is suitable for the field of spinning.

Owner:SUZHOU BUWU JIAXIANG TEXTILE TECH CO LTD

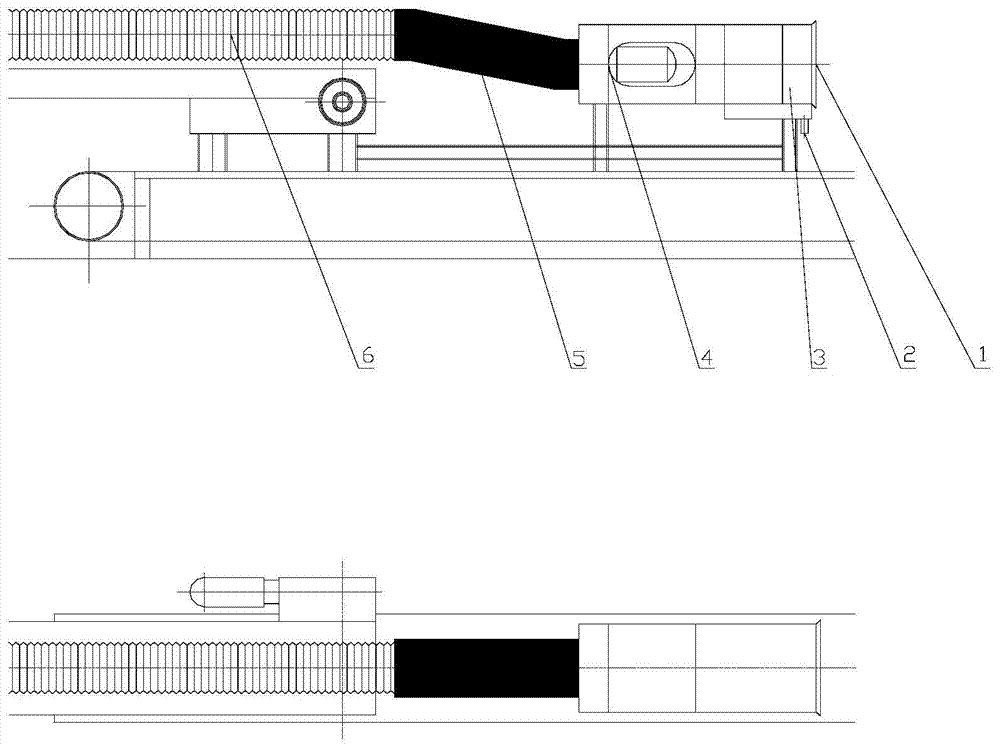

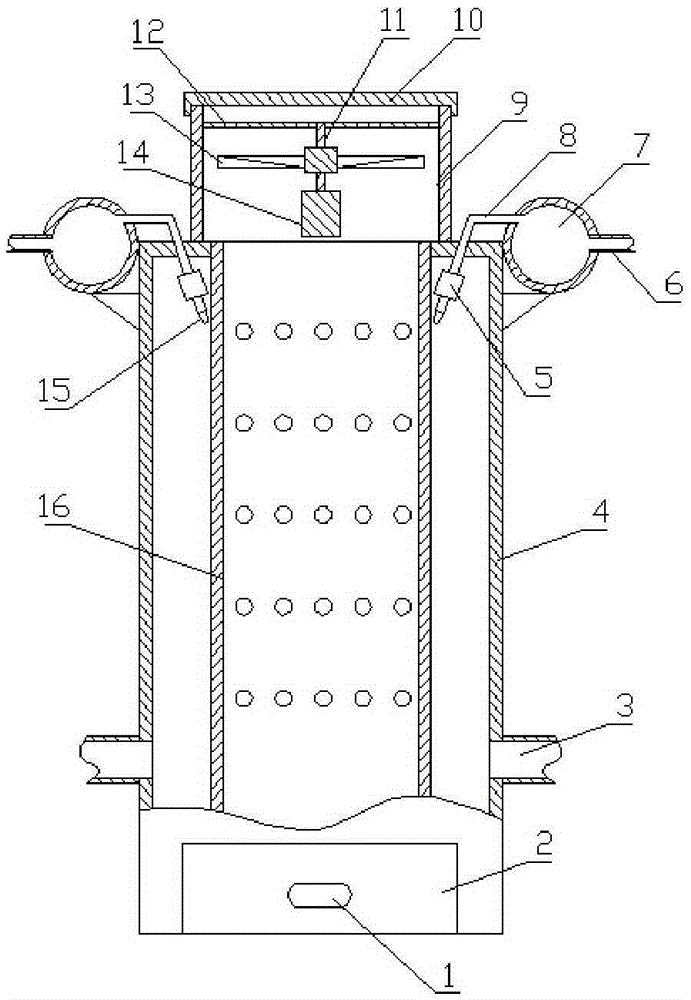

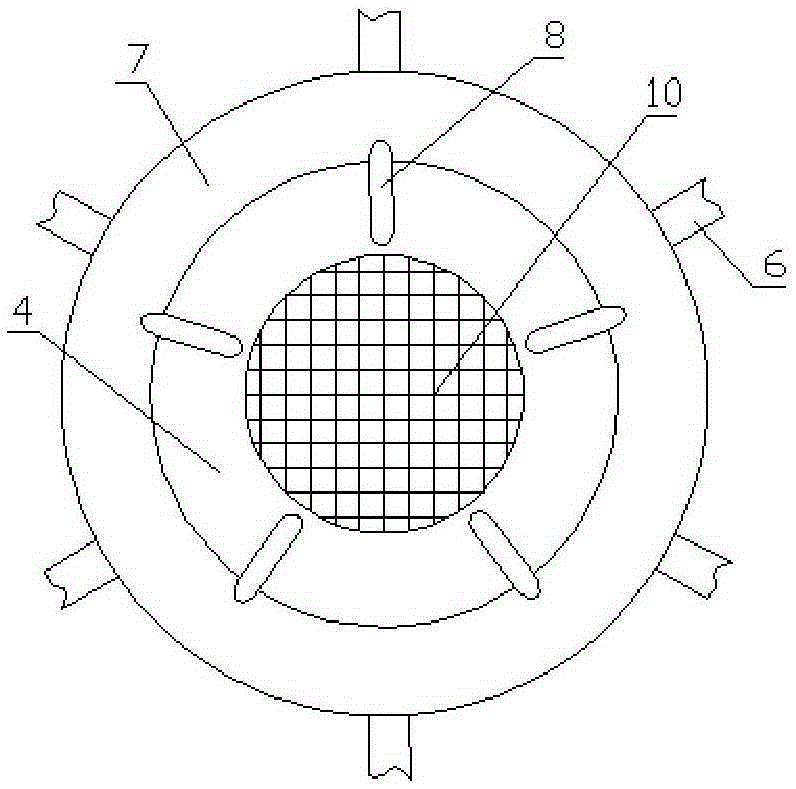

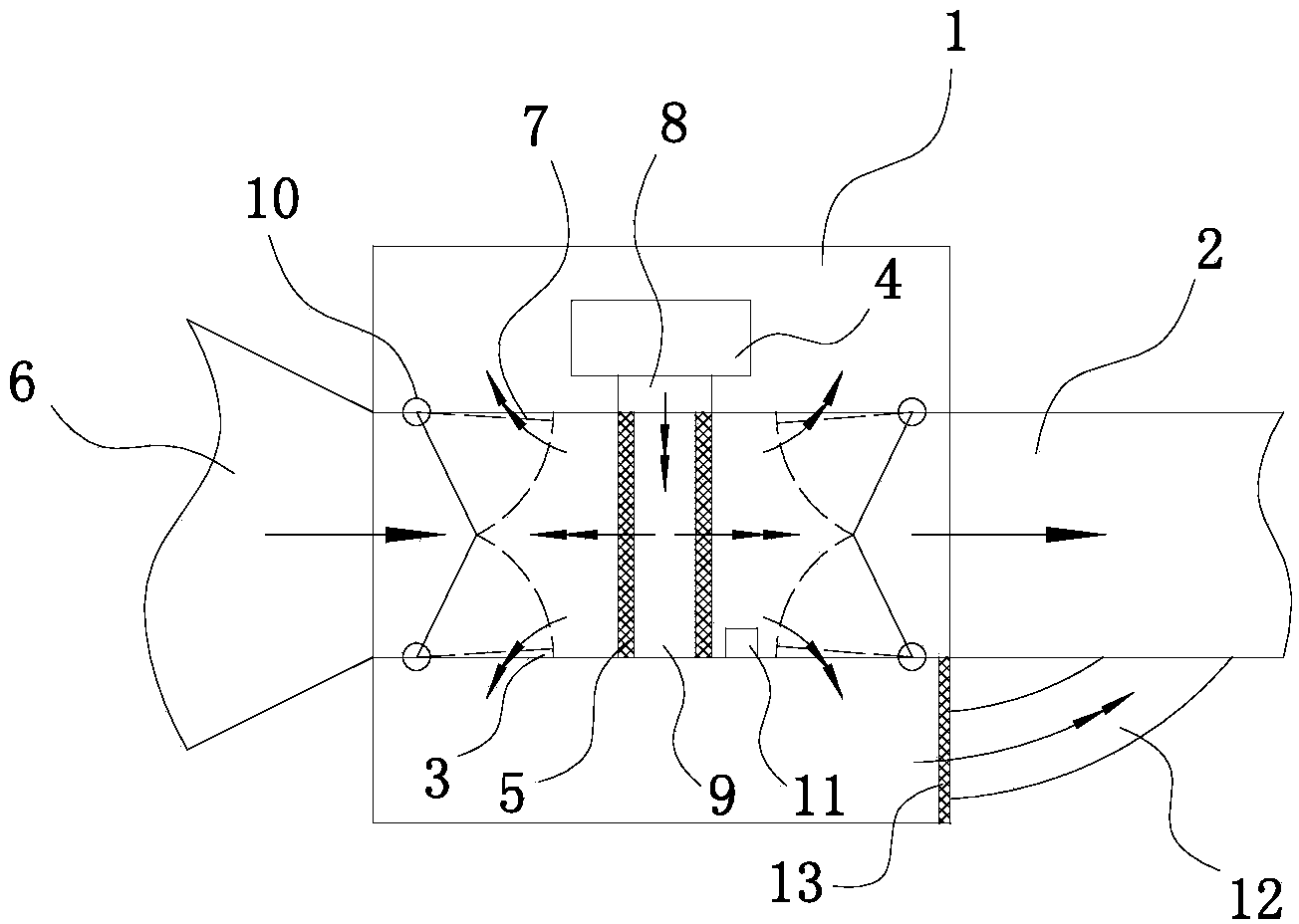

Dustproof pipeline structure for spinning dust removal

InactiveCN104164716AShorten the cleaning cycleReduce replacement cycleTextiles and paperSpinning dustPressure sensor

The invention relates to a dustproof pipeline structure for spinning dust removal. The dustproof pipeline structure comprises filters which are arranged between an air collection pipe and an air pipe in parallel. A reverse dedusting gap is formed between the two filters. A cleaning fan is mounted on the outer wall of the air pipe. An air guide pipe of the cleaning fan is communicated with the reverse dedusting gap. The side walls, on the two sides of the filters, of the air pipe are respectively provided with a dust guide door, and the dust guide doors are symmetric. One end of each dust guide door is connected with the air pipe through a spring, and an opening gap is kept between the other end of each dust guide door and the air pipe. A dust collection pipe is further arranged on the outer wall of the air pipe. The dust collection pipe is communicated with the air pipe through a connecting pipe. A dustproof filter plate is arranged between the dust collection pipe and the connecting pipe. A wind pressure sensor is mounted on the inner wall of the air pipe between the filters and a dust removing device. The wind pressure sensor controls the cleaning fan by detecting the magnitude of wind pressure. The dustproof pipeline structure shortens the replacement and cleaning cycle of the filters and improves dust removal efficiency.

Owner:SUZHOU KAIFENGRUI ELECTRONICS SCI & TECHCO

Multifunctional spinning dust remover

InactiveCN108325990ASolve the single functionAffect qualityDispersed particle filtrationDirt cleaningSpinning dustWaste heat

The invention discloses a multifunctional spinning dust remover. The multifunctional spinning dust remover comprises a collecting hopper and is characterized in that a dust discharge pipe at the top end of the collecting hopper is connected with a first connecting pipe through a first connector, the other end of the first connecting pipe is connected with a second connecting pipe on the left of the top end of a spinning dust temporary storage tank through a second connector, a third connecting pipe on the right of the top end of the spinning dust temporary storage tank is connected with a fourth connecting pipe through a third connector, the other end of the fourth connecting pipe is connected with the air inlet end of a fan through a fourth connector, the air outlet end of the fan is connected with a fifth connecting pipe through a fifth connector, and the other end of the fifth connecting pipe is arranged inside a cooling water tank. By the multifunctional spinning dust remover whichis high in practicality, the problem that an existing spinning dust remover is single in function can be solved, air in a spinning workshop can be purified effectively, the waste heat and waste humidity of the air in the spinning workshop can be removed, and the quality of textile products can be increased.

Owner:响水县嘉禾纺织制衣有限公司

Spinning machine spinning dust collecting device for spinning

InactiveCN109224742AReduce labor intensityEasy to useCombination devicesEngineeringMechanical engineering

The invention discloses a spinning machine spinning dust collecting device for spinning. The spinning machine spinning dust collecting device for spinning comprises an air inlet, a collecting hopper,an air pumping box and a water tank. The air inlet is connected with the air inlet of the collecting hopper through a first ventilating pipe. The interior of the collecting hopper is provided with a collecting cavity. The collecting cavity is internally provided with an inclined filter screen. The bottom end of the collecting cavity is connected with a dust discharging pipe. The air outlet of thecollecting hopper is connected with the air inlet of the air pumping box through a second ventilating pipe. The interior of the air pumping box is provided with an internal cavity. The interior of theinternal cavity is fixedly provided with an exhaust fan through a bolt. The air outlet of the air pumping box is connected with one end of a third ventilating pipe. The other end of the third ventilating pipe passes through the side wall of the water tank and is extended into the water tank. The top end of the water tank is provided with the air outlet. The top end of the water tank is further fixedly provided with a group of motor. The spinning machine spinning dust collecting device for spinning has the advantages of good dedusting effect, easy cleaning and the like, and can be extensivelypopularized and applied.

Owner:SUZHOU CHENHAO TEXTILE TECH CO LTD

Spinning dust-collecting device

The invention relates to the technical field of spinning, and discloses a spinning dust-collecting device. The spinning dust-collecting device comprises a bearing main board, wherein the upper end ofthe bearing main board is equipped with a storage device; one side of the storage device at the upper end of the bearing main board is equipped with a spraying device in a penetrating mode; the upperend of the storage device is equipped with a transmission tube I; the upper part of the other side of the storage device is equipped with a connecting plate; one side of the transmission tube I at theupper end of the connecting plate is equipped with a centrifugal fan; one side of the centrifugal fan is equipped with a transmission tube II; the outer side of the transmission tube II is equipped with a handheld holding handle; and each of one side of the transmission tube II and one side of the handheld holding handle is equipped with a connecting device. The spinning dust-collecting device can conveniently clear collected dust through the storage device, capacity of stored dust can be improved through the spraying device, a suction nozzle can be conveniently replaced by the connecting device, and movement is more convenient through a placing device.

Owner:湖州拉杜拉塔服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com