Ultrasonic atomization and vibration spinning dust-removing device of heading machine

A technology of ultrasonic atomization and ultrasonic atomizer, which is applied in the field of dust removal for mining equipment, can solve the problems of limited installation position, inability to handle dust, poor atomization effect, etc., and achieve the effect of convenient use, reasonable structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

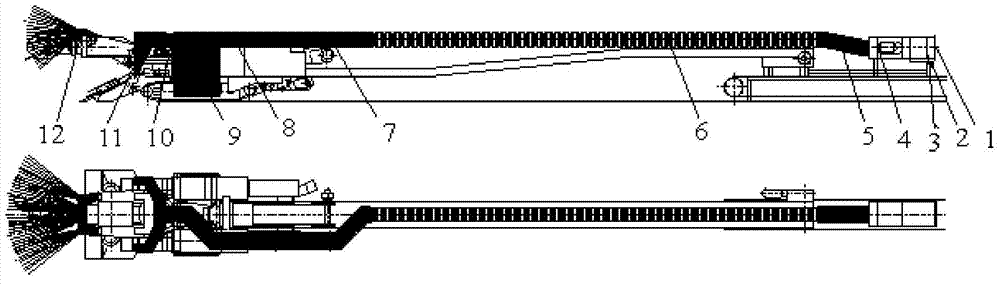

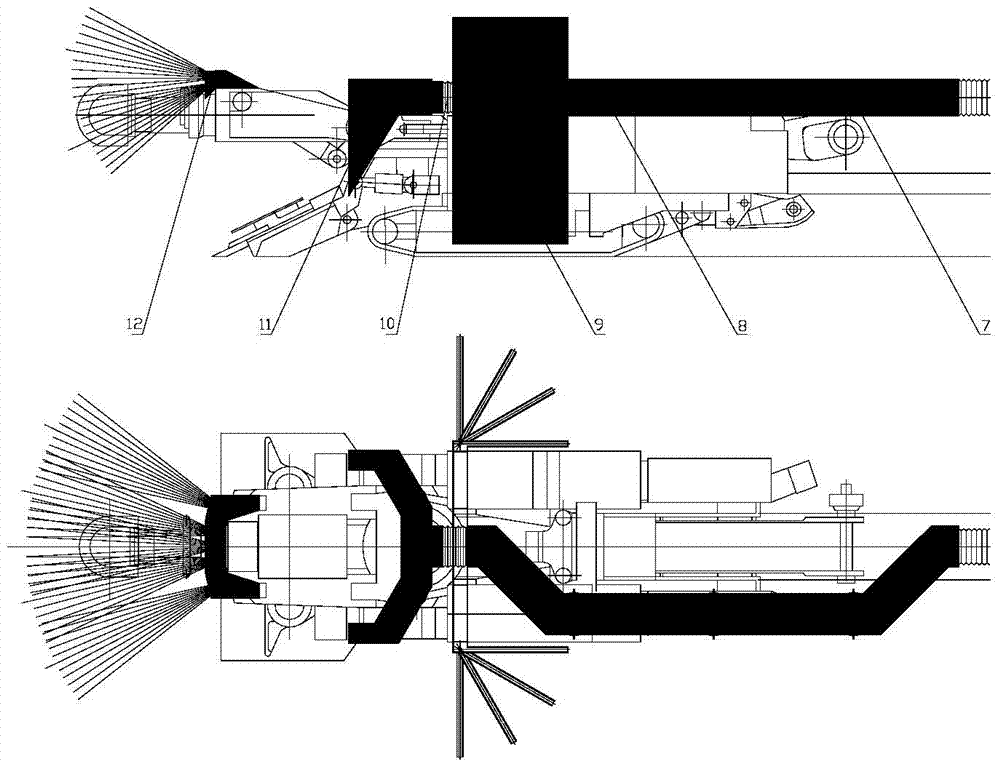

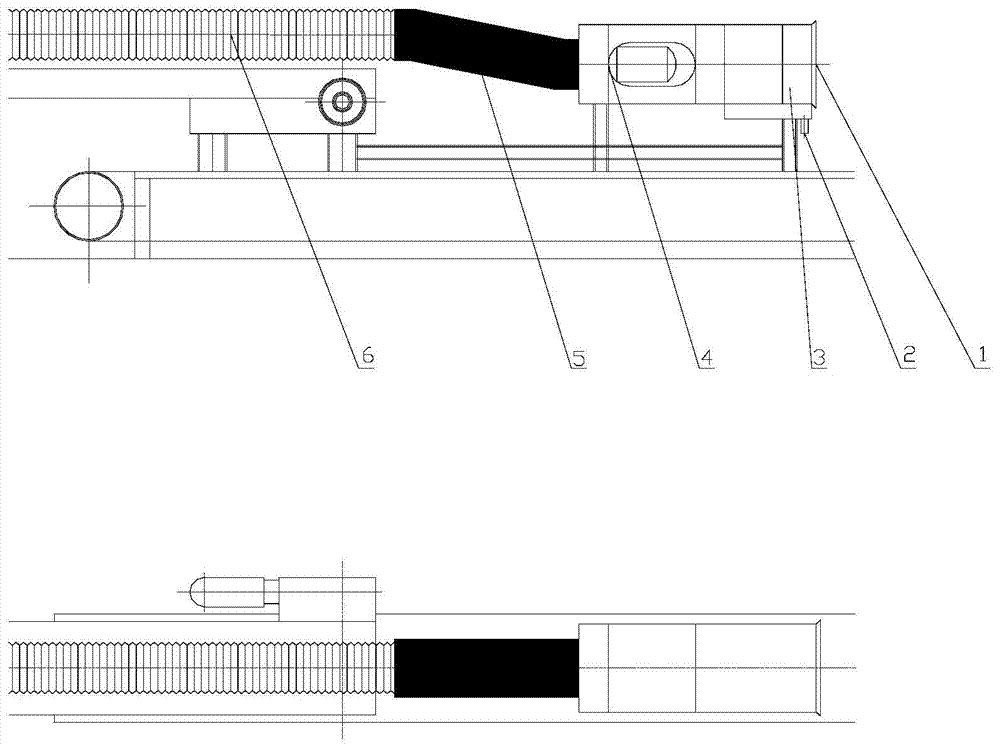

[0025] Such as figure 1 The ultrasonic atomization and vibrating dust removal device of the roadheader shown includes an ultrasonic atomizer, connecting parts, and wet vibrating equipment. The ultrasonic atomizer is fixedly connected to the wet vibrating equipment through the connecting parts. The ultrasonic atomizer includes an ultrasonic impulse device 12 , active air suction port 11, flexible connector 10, reversible lifting screen 9, ultrasonic atomization component 8, fog and dust mixing chamber 7, such as figure 2 As shown, the ultrasonic impulse device 12 is connected to the active air suction port, the impulse device and 12 are fixedly connected to the active air suction port 11, the ultrasonic atomization assembly 8 and the active air suction port 11 are connected together through a flexible connector 10, and the ultrasonic atomization assembly 8 It is connected with the fog and dust mixing chamber 7, and the reversible lifting screen 9 is fixed on the active air suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com