Support coal-discharging-port negative-pressure atomizing dust settling device

A technology for atomizing dust and coal discharge, which is used in safety devices, dust-proofing, mining equipment, etc., can solve the problems of easy blockage, low life, unreasonable installation position, poor atomization effect, etc., and achieves high dust removal efficiency and fog The effect of good chemical efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

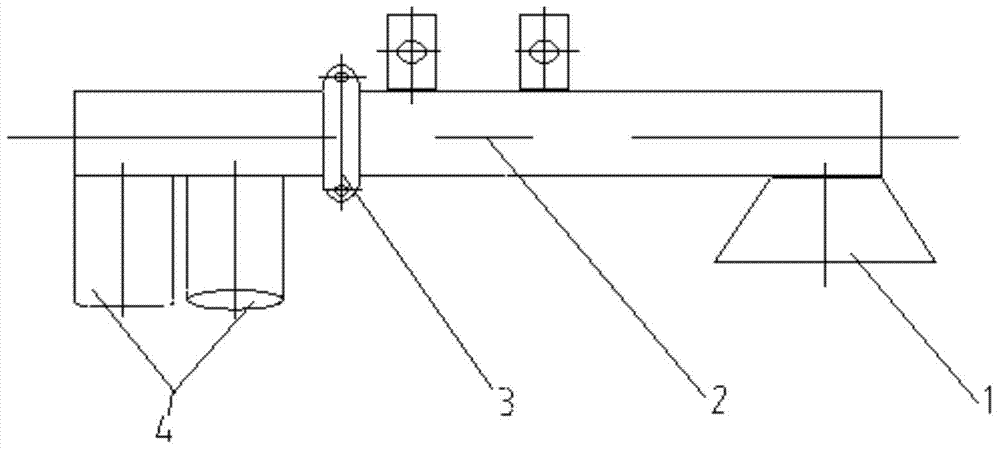

[0014] A negative pressure atomization and dust suppression device for a support coal outlet, including an air induction pipe, an air suction port, a U-shaped body, and a jet air-inducing body. One end of the U-shaped body is closed and the other end is open. The cavities are connected; the air suction port is perpendicular to the U-shaped body. One end of the air-introduction pipe is closed, and the other end is open, and the U-shaped body is connected to the open end of the air-induction pipe through a cardan at the open end as a whole; There are two air-introducing pipes arranged in a fan shape in the jet-inducing air body. Such as figure 1 shown.

[0015] The above structure manufacturing method,

[0016] (1) The suction port is made into a funnel shape by welding four trapezoidal steel plates, and then the funnel-shaped structure is welded to one end of the "U"-shaped steel pipe, and its direction is perpendicular to the "U"-shaped steel pipe and completely communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com