Spinning dust removing device

A technology of dust removal device and shell, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of affecting the health of workers, increasing the cost of enterprises, and the ineffective filtering effect of floating objects such as fibers, etc. To achieve the effect of significant dust removal, uniform gas delivery, and improve dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

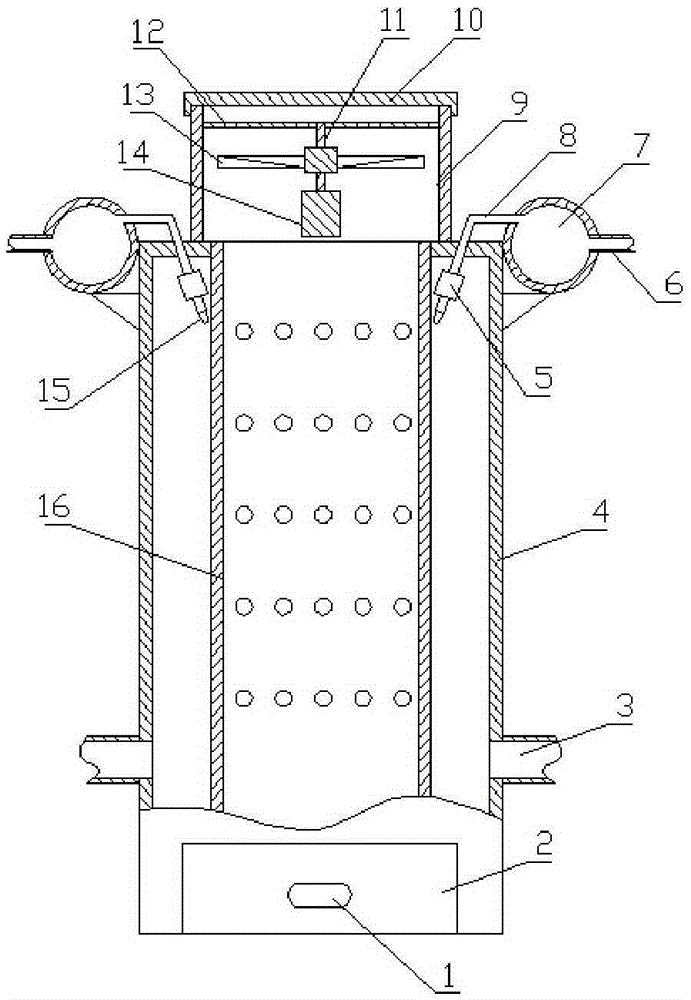

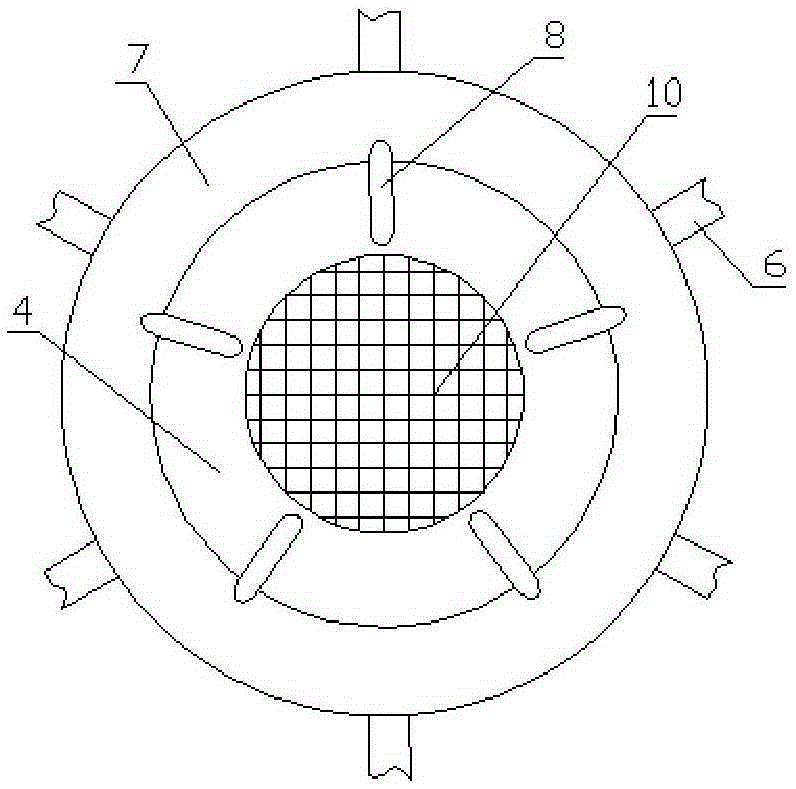

[0027] Such as figure 1 , figure 2 As shown, the structure of this kind of textile dust removal device includes a housing 4, a first filter screen 16 and a fan 13; the housing 4 is a cylindrical hollow structure, and when in use, the housing 4 is light in weight and easy to disassemble. installation and maintenance; the first filter screen 16 is a cylindrical hollow structure, and the first filter screen 16 is located inside the housing 4 concentrically with the housing 4. When in use, the first filter screen 16 can remove fibers, wool Floats such as wadding are blocked on the outside of the filter screen to play the role of dust removal; the fan blade 13 is fixed on the support rod 12 through the fixed shaft 11; the support rod 12 is fixed on the inner wall of the air outlet pipe 9; The above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com