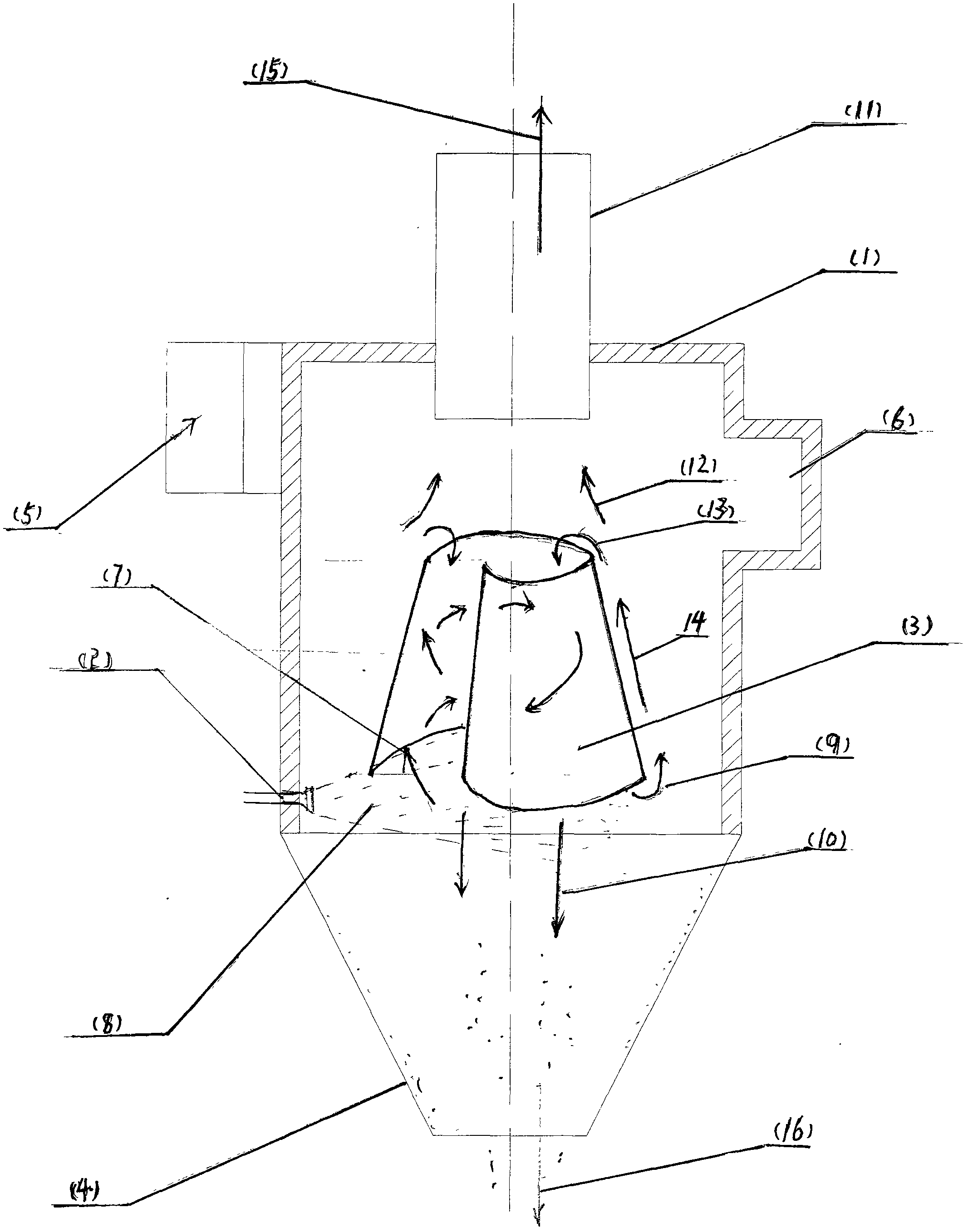

Atomizing spinning dust removing device

A technology of dust removal device and cyclone dust removal, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of affecting the dust removal effect, not being able to undertake one-time dust removal alone, and increasing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The exhaust gas dust shown in the cyclone dust collector (1) enters through the exhaust gas inlet of (5), and through the rotating centrifugal force and the down-spinning centrifugal guide groove (6), it is docked with the secondary spinning inlet (7), and passes through the fan after the pressurization and down-spinning In the atomization layer (8), the small dust particles are combined with water molecules through the atomization layer, and the weight of the dust increases, and the large dust particles after the fan atomization layer (8) formed by the atomization nozzle (2) will pass through the cone The trough (4) falls into the dust box through the direction of the arrows (10) and (16); the other part of the exhaust gas moves upward through the fan atomization layer (8) due to the pressure difference and enters the taper sleeve spinning with the upper and lower transparent openings The dust removal device (3), as shown by the arrows (9), (14), and (13), a part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com