Textile machine spinning dust collecting device

A machine-woven dust collection device technology, which is applied in the field of textile manufacturing, can solve the problems of secondary pollution of dust collection, easy blockage of filter devices, and affecting the normal use of dust collectors, so as to prevent secondary pollution and reduce the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

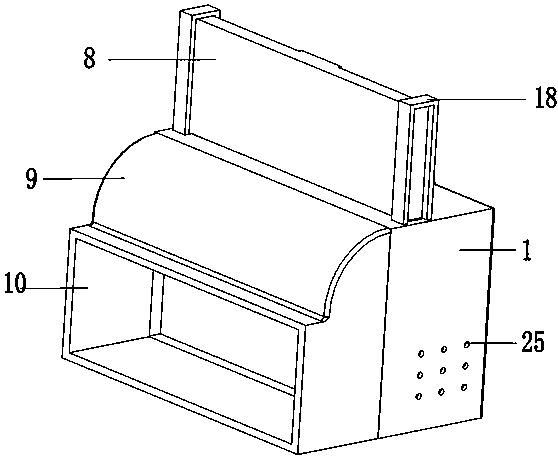

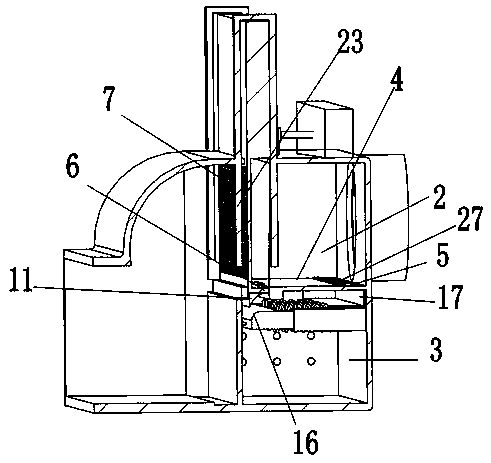

[0028] The present invention provides such as Figure 1-5 A kind of weaving machine weaving dust collecting device shown, comprises main box 1, as figure 1 As shown, the top of the main box 1 is fixedly installed with a solid plate 8 and a limit groove 18, the limit groove 18 limits the solid plate 8, the solid plate 8 can slide up and down in the limit groove 18, and the bottom of the solid plate 8 is installed Dust collection net 7 is arranged, and this dust collection net 7 selects high-strength polyurethane material for use, and intensity is high, and service life is long, and scraper 14 is not easy to be damaged when scraping off dust collection with the lamination movement with it; One side of solid plate 8 is fixedly installed with suction Air box 9, the side wall of suction box 9 is provided with suction port 10, and the air sucked in by suction hole 10 can enter in the air intake box 2 by air inlet 23, and the size of solid plate 8 is the same as the size of air inlet...

Embodiment 2

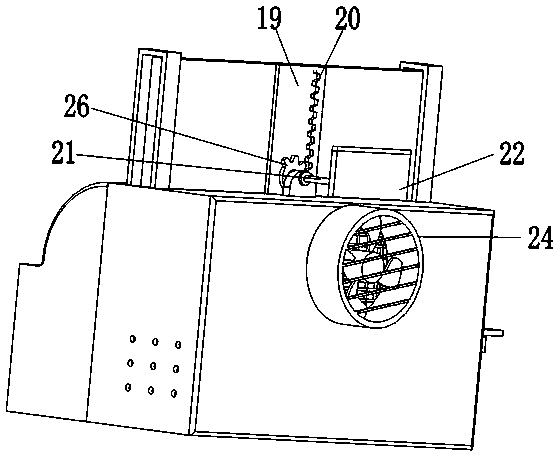

[0032]The controller can be set to control the forward and reverse rotation time and interval length of the stepper motor 22 according to the cleaning time cycle. When the dust removal time is reached, the controller starts the stepper motor 22 to rotate forward, and the stepper motor 22 is driven by the connecting shaft The gear 26 rotates, the gear 26 drives the rack 20 to move, the rack 20 drives the solid plate 8 and the collecting net 7 to move downward, the end plate 6 and the upper arc plate 11 below the collecting net 7 move downward, and when the upper arc plate 11 When in contact with the lower arc-shaped plate 16, the lower arc-shaped plate 16 squeezes the extruded plate 13 connected with it, and the extruded plate 13 moves into the fixed sleeve 12, and at the same time compresses the spring 15, the upper arc-shaped plate 11 and the end plate After 16 passes through the lower arc-shaped plate 16 in turn, the extrusion plate 12 and the spring 15 lose the extrusion for...

Embodiment 3

[0034] When the collection net 7 moved to the lowermost position in the material receiving box 3, the scraper 14 hung up all the textile dust of the collection net 7, and now the solid plate 8 blocked the air inlet 23, because the size of the solid plate 8 and The size of the air inlet 23 is the same, the air in the air intake box 10 is isolated and no longer enters the air intake box 2, and along with the air in the air intake box 2 is continuously discharged by the suction fan 24, the air in the air intake box 2 The air pressure is smaller than the air pressure in the receiving box 3. Under the action of the air pressure in the receiving box 3, the cover plate 27 on the ventilation slot 5 is opened, and the air enters the receiving box 3 from the round hole 25, and passes through the receiving box 17. The dust-collecting bag on the top is then passed into the air intake box 3 through the long ventilation slot 5, and then discharged by the suction fan 24. During this process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com