Dustproof pipeline structure for spinning dust removal

A pipe and dust collection pipe technology, which is applied in the field of dust removal pipes in textile workshops, can solve the problems of affecting the dust removal effect, low dust removal efficiency, cumbersome cleaning and replacement operations, etc., to achieve good cleaning effect, improve filtering effect, and shorten cleaning and replacement cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

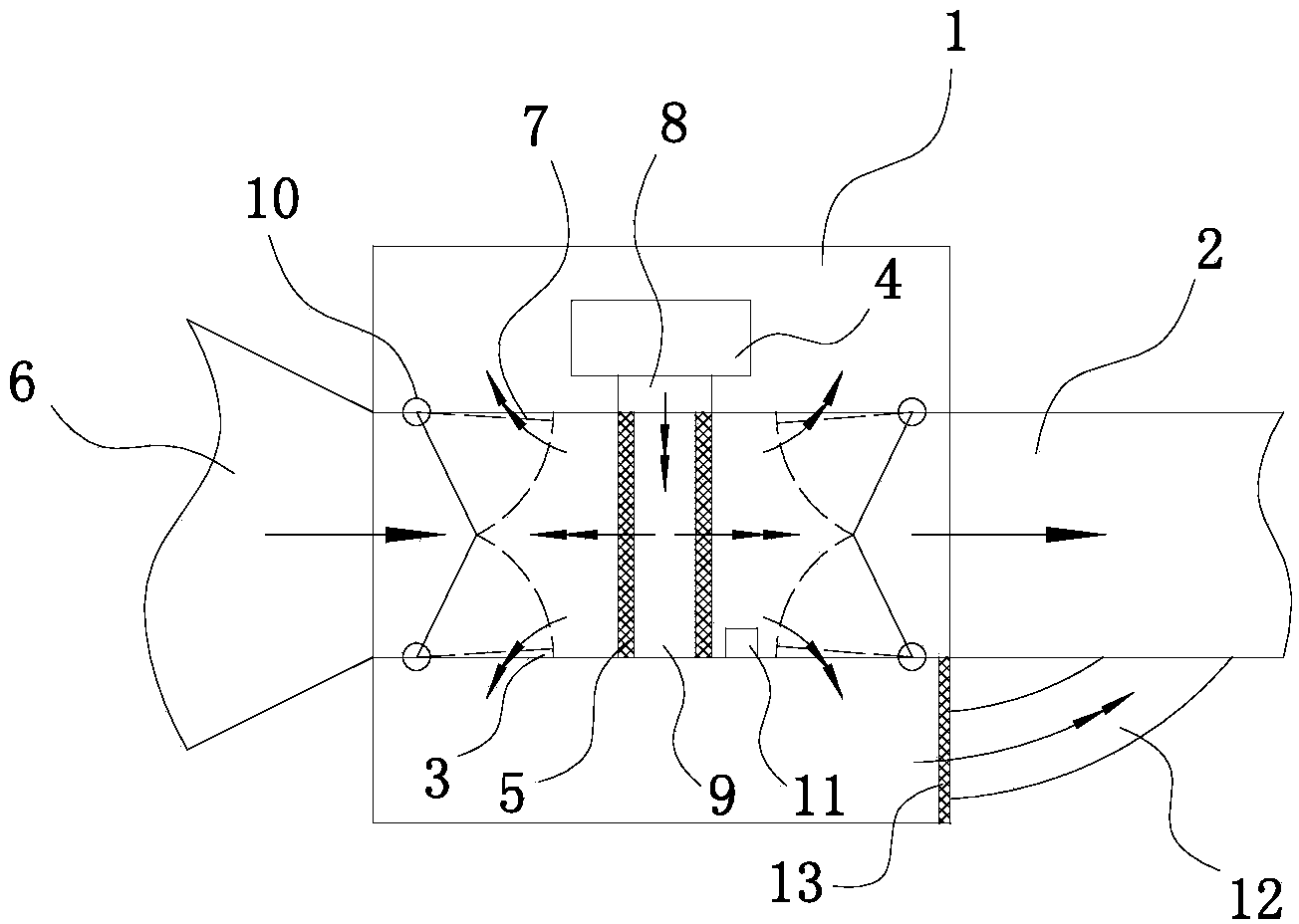

[0015] Such as figure 1 and figure 2 As shown, the dust removal pipeline structure used for textile dust removal in this embodiment includes the filter sheet 5 installed between the air collection pipe 6 and the air pipe 2, and the filter sheet 5 is installed in parallel between the air collection pipe 6 and the air pipe 2, and the two filters There is an anti-dust removal gap 9 between the sheets 5; a cleaning fan 4 is installed on the outer wall of the air duct 2, and the air guide pipe 8 of the cleaning fan 4 communicates with the anti-dust removal gap 9; the side walls of the air duct 2 on both sides of the filter sheet 5 are symmetrical There is a dust guide door 7, one end of the dust guide door 7 is respectively connected to the air duct 2 by means of a spring buckle 10, and an opening gap 3 is maintained between the other end and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com