Textile machine dust removing device with spraying structure

A technology of dust removal device and textile machine, which is applied in the direction of dust removal, combination device, and separation of dispersed particles. It can solve the problems of dust backflow, health hazards of operators, and insufficient dust removal effect, so as to achieve health protection, convenient operation, Eliminate the effect of dust backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

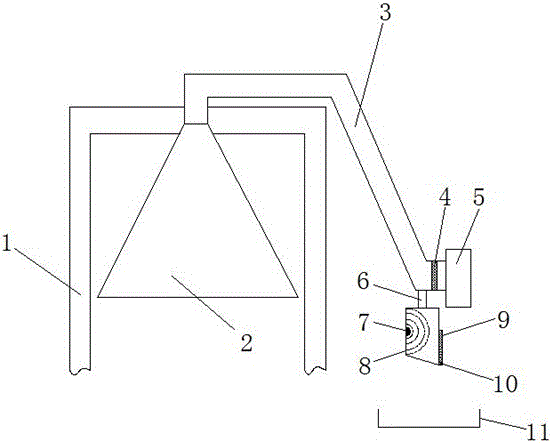

[0017] Such as figure 1 As shown, a textile machine dust removal device with a spray structure includes a frame 1, a collection cover 2 arranged on the frame 1, a collection pipe 3 arranged above the collection cover 2, and a drip tank 11; the collection pipe 3 A fan 5 is provided at the end of the fan, a first filter screen 4 is provided between the collection pipe 3 and the fan 5, and a dust suppression box 8 is provided on the lower left side of the first filter screen 4, and the dust suppression box 8 is fixedly connected with the collection pipe 3 through the dust collection pipe 6. , the inner wall of the dust suppression box 8 is provided with a spray head 7, the bottom of the dust suppression box 8 is provided with a dust outlet 10, the dust outlet 10 is provided with a second filter screen 9, and the dripping tank 11 is arranged below the dust suppression box 8.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Top diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com