Textile dust collecting device for textile device

A textile equipment and collection device technology, which is applied in the field of textile dust collection devices for textile equipment, can solve the problems of shortening, inability to spun wadding, and dust-proof partition collection service life, etc., and achieves the effect of simple structure and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

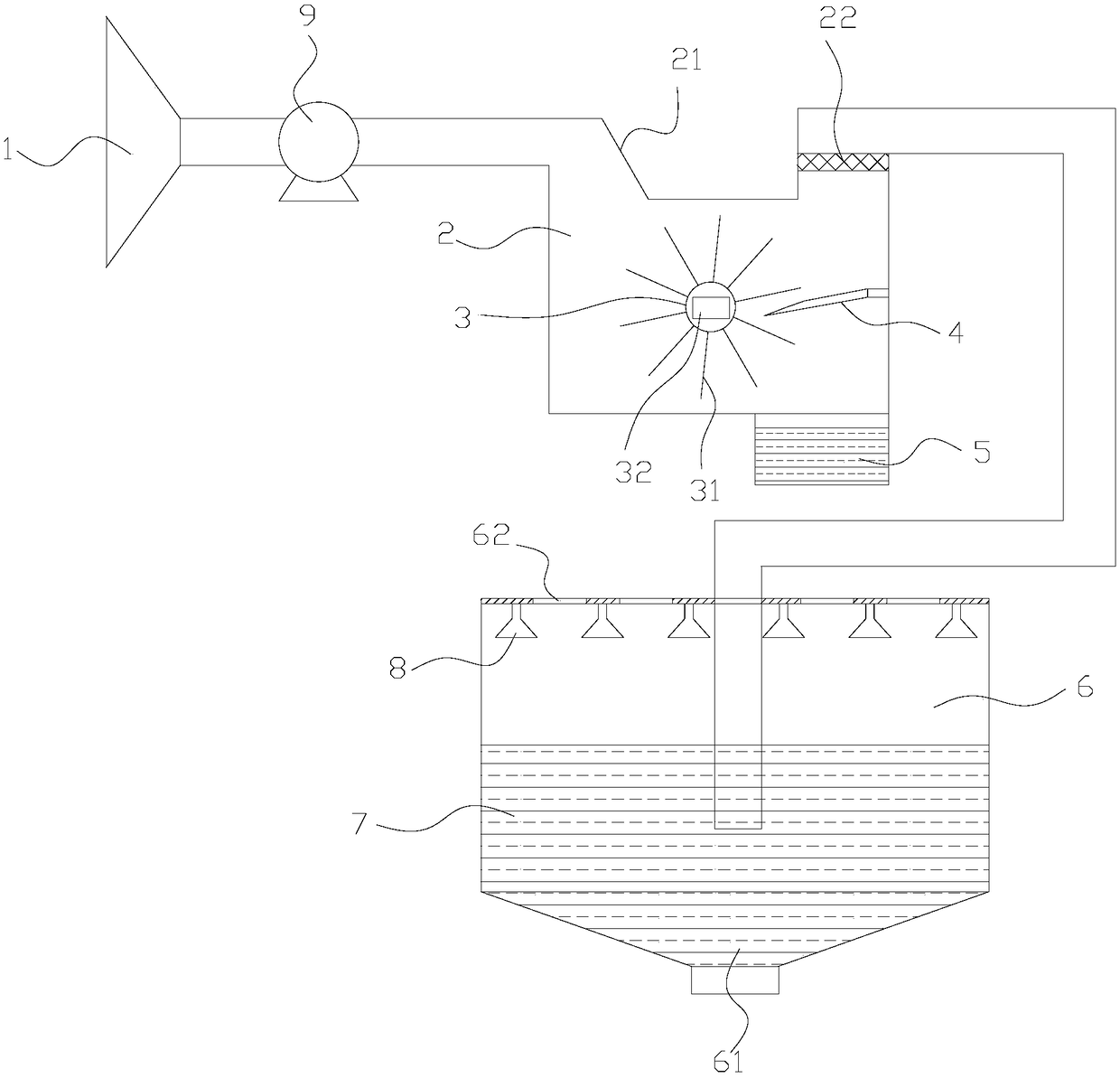

[0026] In order to solve the technical problem that the existing textile dedusting device cannot separate and collect spun wadding and dust, resulting in shortened service life. Embodiment 1 of the present invention provides a textile dust collection device for textile equipment, such as figure 1 As shown, it includes a dust collection hood 1 , a flocculation chamber 2 , a flocculation roller 3 , a scraper comb 4 , a flocculation bucket 5 , a dust collection chamber 6 , a water reservoir 7 and a spray head 8 .

[0027] Such as figure 1 As shown, the dust collection cover 1 is designed in a bucket shape, which is convenient for absorbing and placing the dust flocs raised by the equipment in a wider range, and the smaller diameter end of the dust collection cover 1 is connected to the suction port of a negative pressure suction pump 9 Connected, through the size design that the diameter of the vacuum hood 1 gradually decreases, the intensity of negative pressure adsorption is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com