Textile machine spinning dust collection device

A technology of woven dust and collection devices, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents. It can solve problems such as unfavorable health and affect the working environment of the workshop, so as to achieve good promotion and utilization value and prevent blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

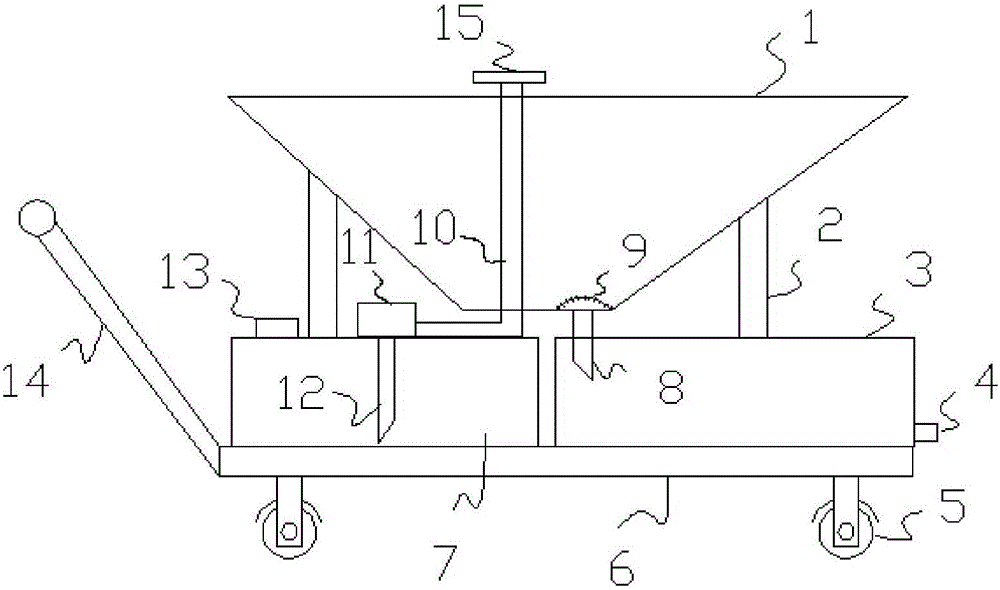

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

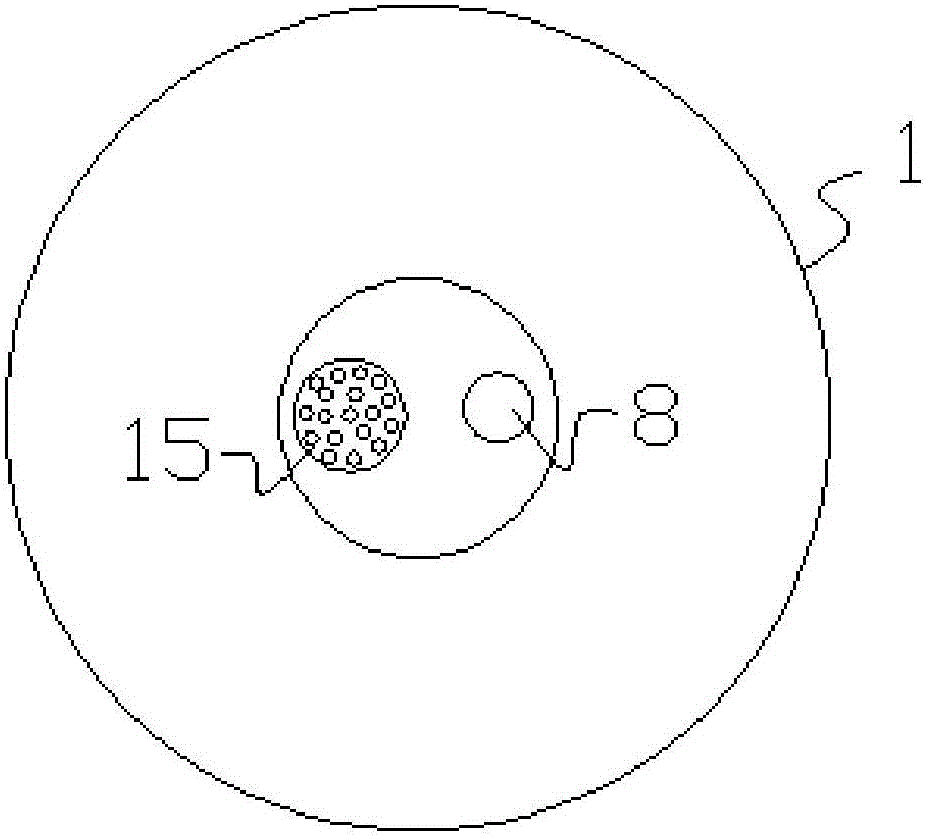

[0022] Such as figure 1 , figure 2 As shown, the structure of this kind of weaving machine weaving dust collection device includes a flat plate 6, the bottom of the flat plate 6 is provided with a roller 5, the top of the flat plate 6 is provided with a water storage tank 7, and the top of the water storage tank 7 is provided with Water suction pump 11, the bottom of water suction pump 11 communicates with the inside of water storage tank 7 through water suction pipe 12, and the water outlet of water suction pump 11 is connected with a vertically arranged water spray pipe 10, and an atomizing spray pipe is arranged on the top of water spray pipe 10. The head 15 and the atomizing head 15 are known technologies and are well known to those skilled in the art, and their structures will not be repeated here. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com