Device for collecting spinning dust of spinning machine

A machine-woven dust collection device technology, applied in textiles, textiles, papermaking, knitting, etc., can solve the problems of harmful operators' health, reduced dust collection efficiency, dust flying, etc. The effect of purifying air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

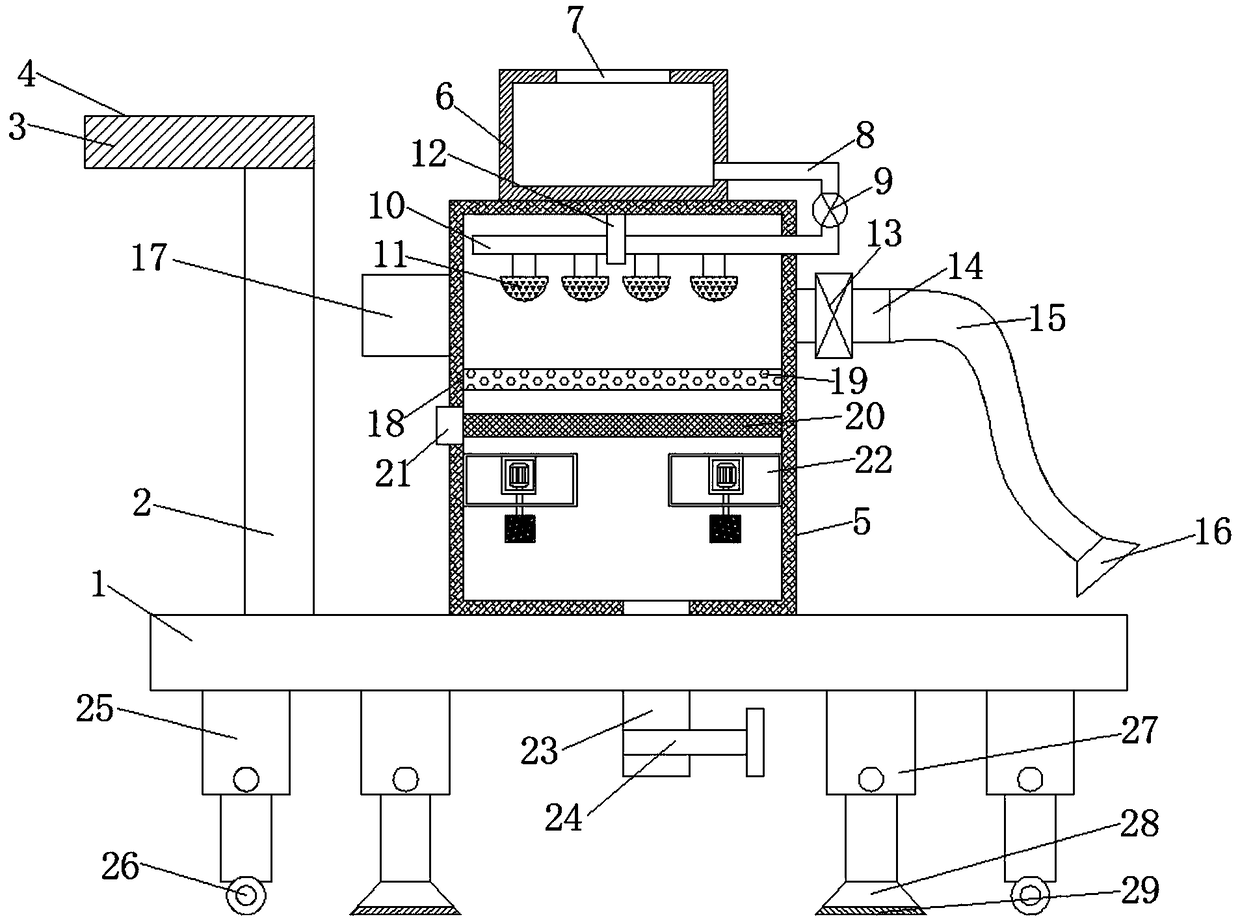

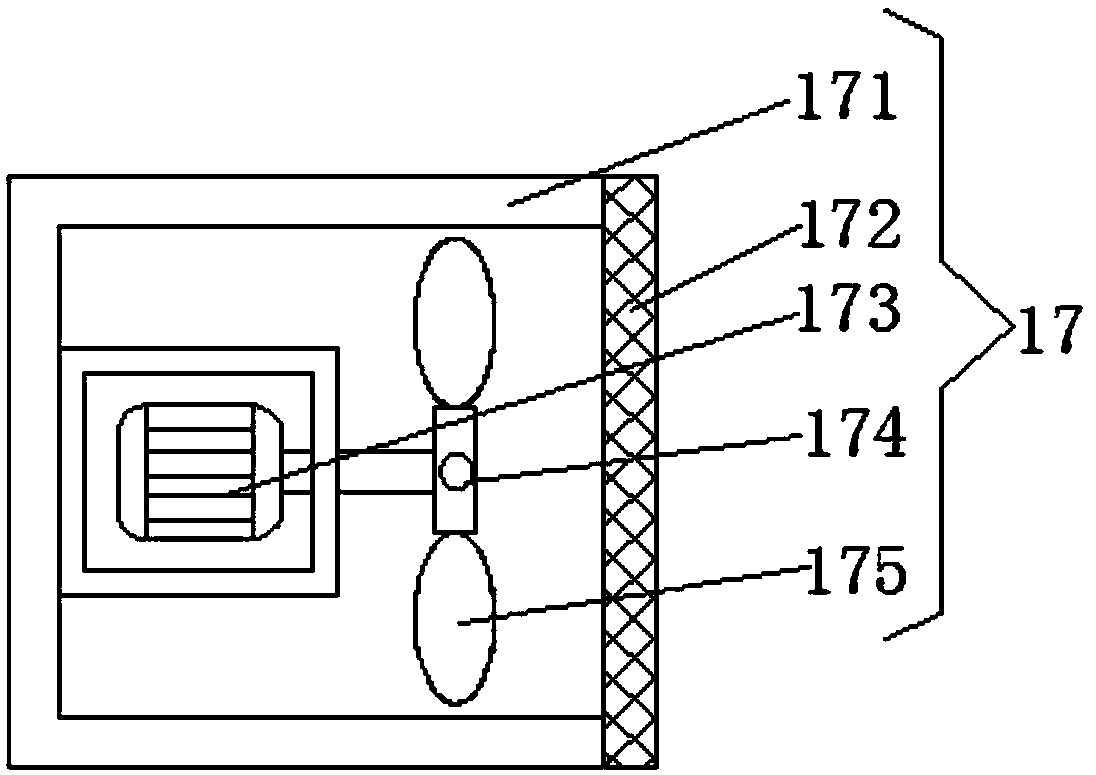

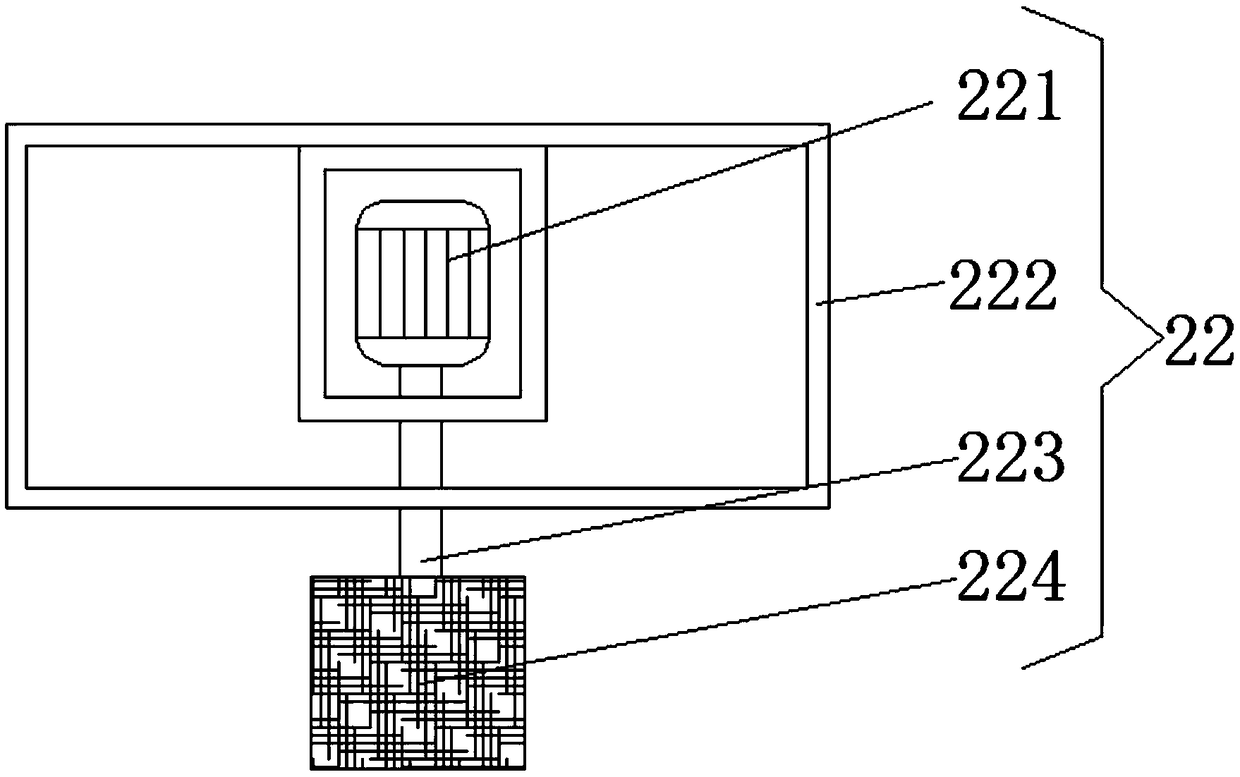

[0023] The embodiment of the present invention provides a textile dust collection device for a textile machine, such as Figure 1-3 As shown, the base 1 is included. The bottom of the base 1 is fixedly installed with a first electric telescopic rod 25, and the bottom of the first electric telescopic rod 25 is fixedly installed with a movable wheel 26. The movable wheel 26 is provided to facilitate the movement of the device and is suitable for various workshops. The use greatly improves the practicability. The number of moving wheels 26 is no less than four. The bottom of the base 1 is fixedly installed with a second electric telescopic rod 27. By setting the first electric telescopic rod 25 and the second electric telescopic rod 27, The staff can adjust the height of the device ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com