Outer rotor direct driving type permanent magnet synchronous torque servo motor

A technology of permanent magnet synchronous and servo motors, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, motors, etc., can solve the problem of unavoidable motor temperature rise or excessive local temperature rise, small size , Increase the cost of the motor and other issues, achieve good application prospects, easy process, and reduce the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

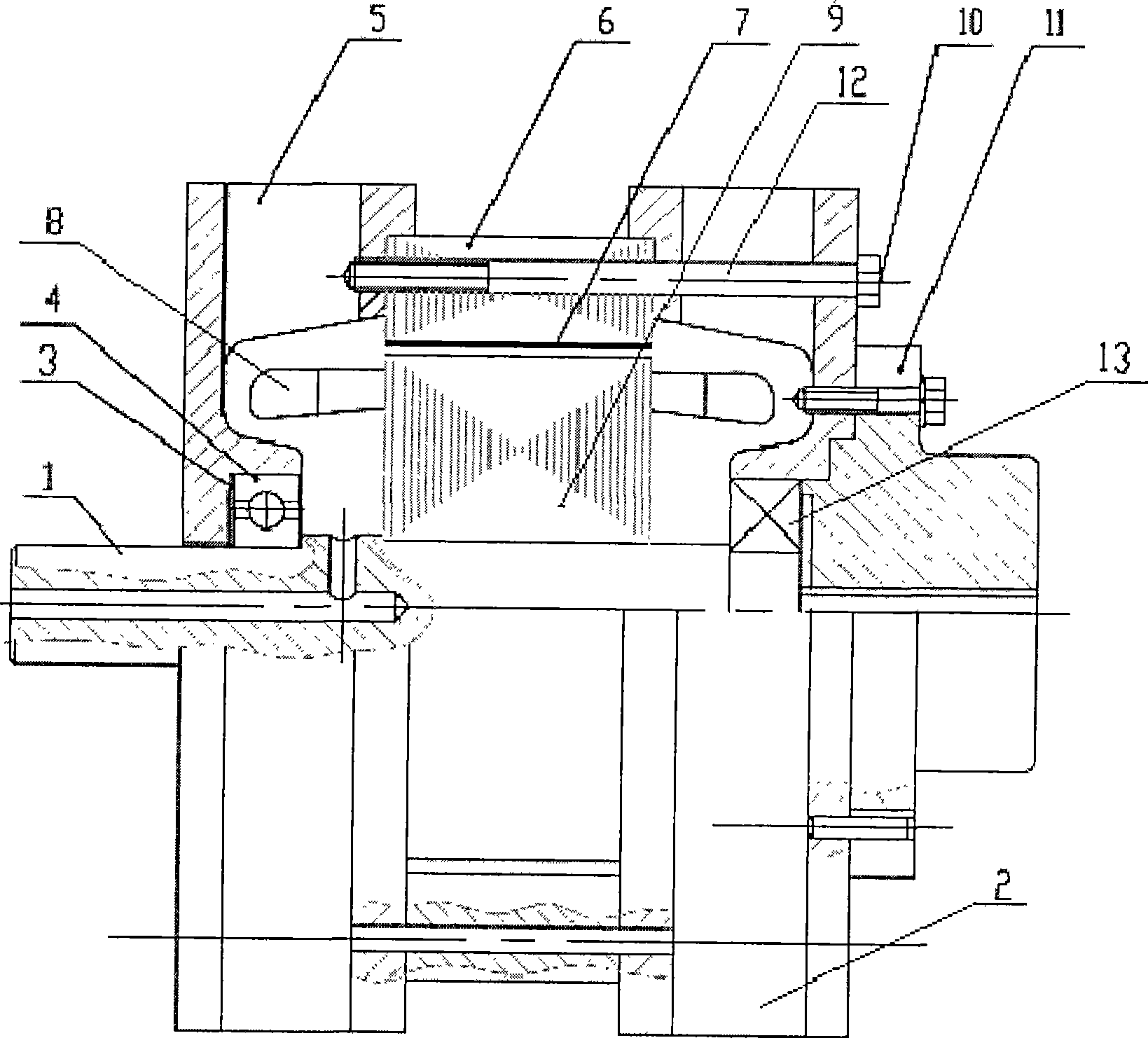

[0022] The embodiments will be described in detail below in conjunction with the accompanying drawings.

[0023] figure 1 It is a schematic diagram of the longitudinal section structure of the motor of the present invention. The motor shaft 1 is covered with a stator core 9, and the stator core 9 is provided with a stator winding 8. The motor shaft 1, the stator winding 8, and the stator core 9 together form a motor stator.

[0024] A rotor core 6 is arranged above the stator core 9 , and a permanent magnet 7 is placed on the surface of the rotor core 6 close to the stator core 9 . A front end cover 2 and a rear end cover 5 are sleeved on the motor shaft 1 respectively, the rotor core 6 is located between the two end covers, and the two end covers are respectively connected to the motor shaft 1 through the front bearing 13 and the rear bearing 4 . Wave spring sheets 3 are installed on the outer sides of the two bearings to apply prestress to the bearings, reduce the noise of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com