Punching sheet painting roller transmission device

A technology of transmission device and paint roller, which is applied to the device of coating liquid on the surface, coating and other directions, which can solve the problems of non-compliance with the thickness of the punched paint film, cumbersome roller maintenance and replacement, reliability, and painting accuracy Poor and other problems, to achieve the effect of ensuring uniformity and consistency, uniform speed and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

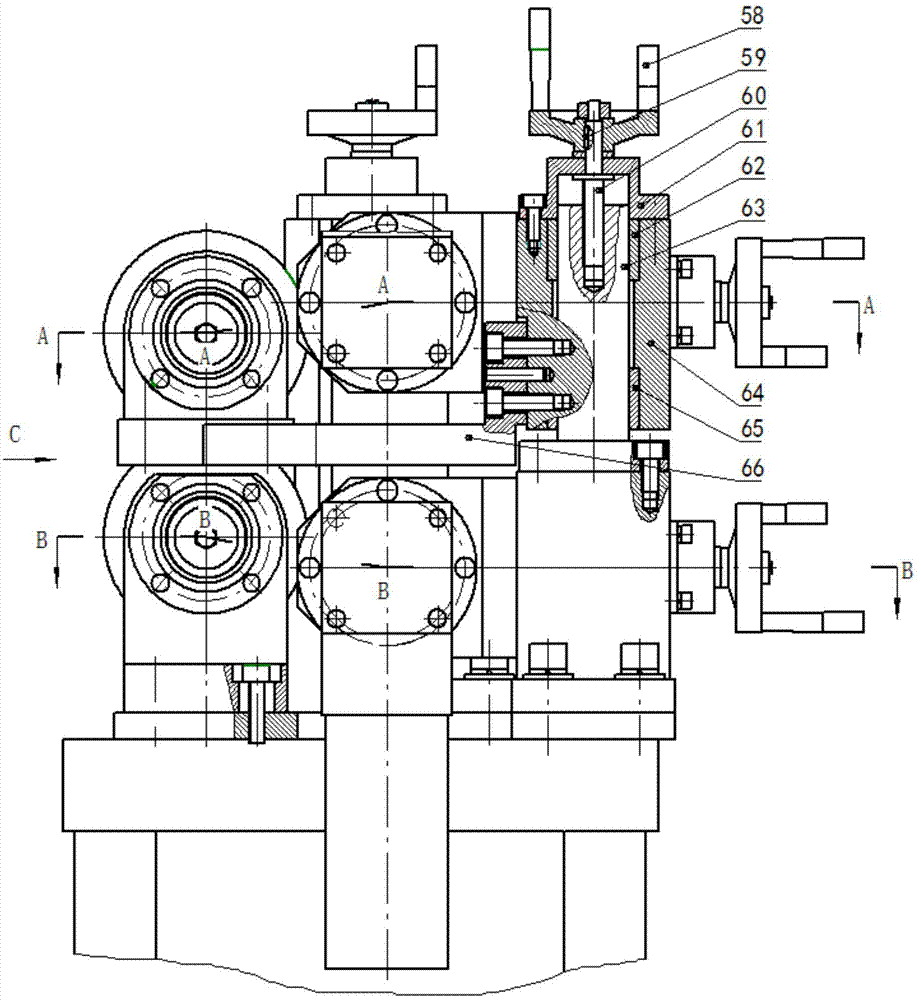

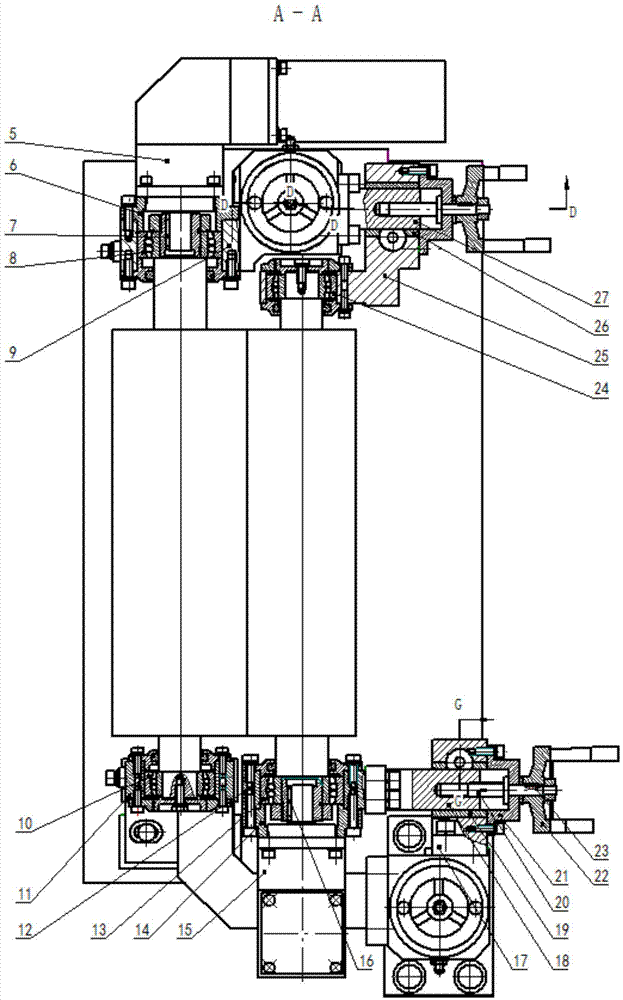

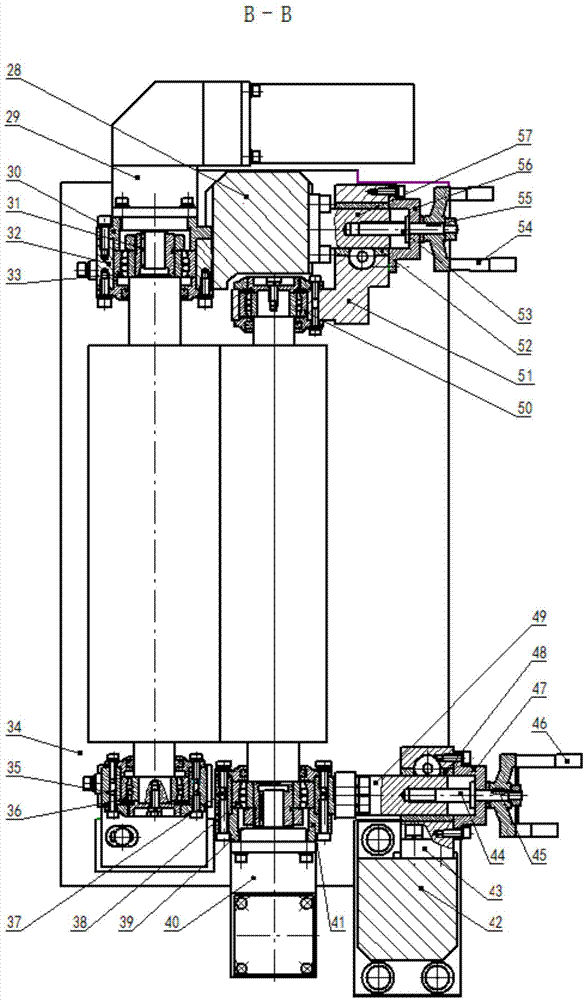

[0017] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown in the figure, a transmission device for film coating rollers, the non-driving ends of the main paint roller I1, the main paint roller II2 and the driving ends of the distribution paint roller I4 and the distribution paint roller II3 are located on one side of the device, the main paint roller I1, the main paint roller The driving end of paint roller Ⅱ2 and the non-driving ends of paint roller Ⅰ4 and paint roller Ⅱ3 are located on the other side of the device; the axes of main paint roller Ⅰ1, paint roller Ⅱ2, paint roller Ⅰ4 and paint roller Ⅱ3 are parallel to each other. Paint roller Ⅰ1 and matching paint roller Ⅰ4 are located above the main paint roller Ⅱ2 and matching paint roller Ⅱ3; , The outer ring of the bearing Ⅱ36 is connected with the inner hole of the bearing seat Ⅰ11 and the bearing seat Ⅱ35, such as figure 1As shown, the bearing seat I11 is connected with the sliding seat I64 through the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com