Position control mode and force control mode interaction axial friction welding device and friction welding technology

A control mode, friction welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of welding force fluctuation, difficult to accurately control the upsetting cylinder, difficult to accurately control and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

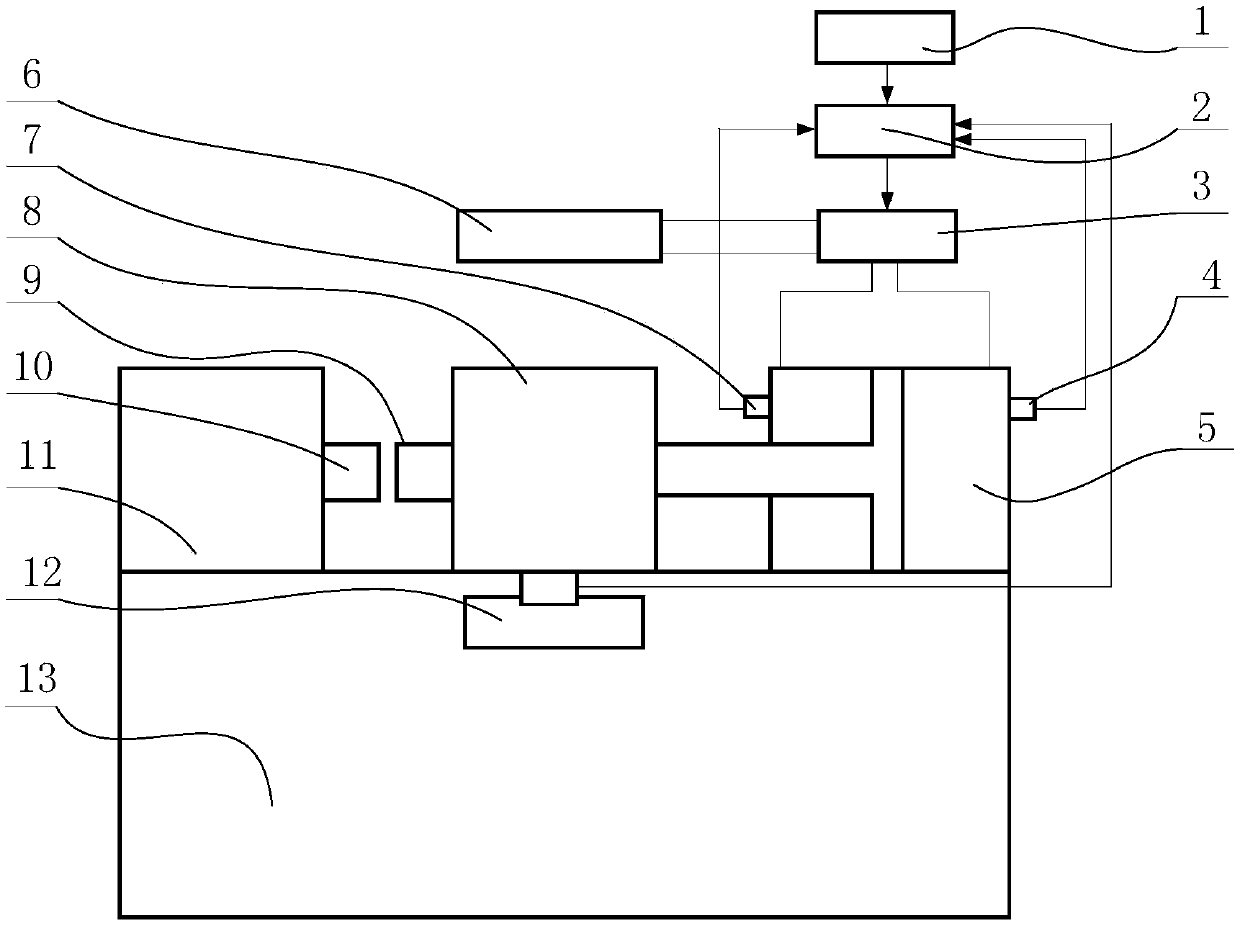

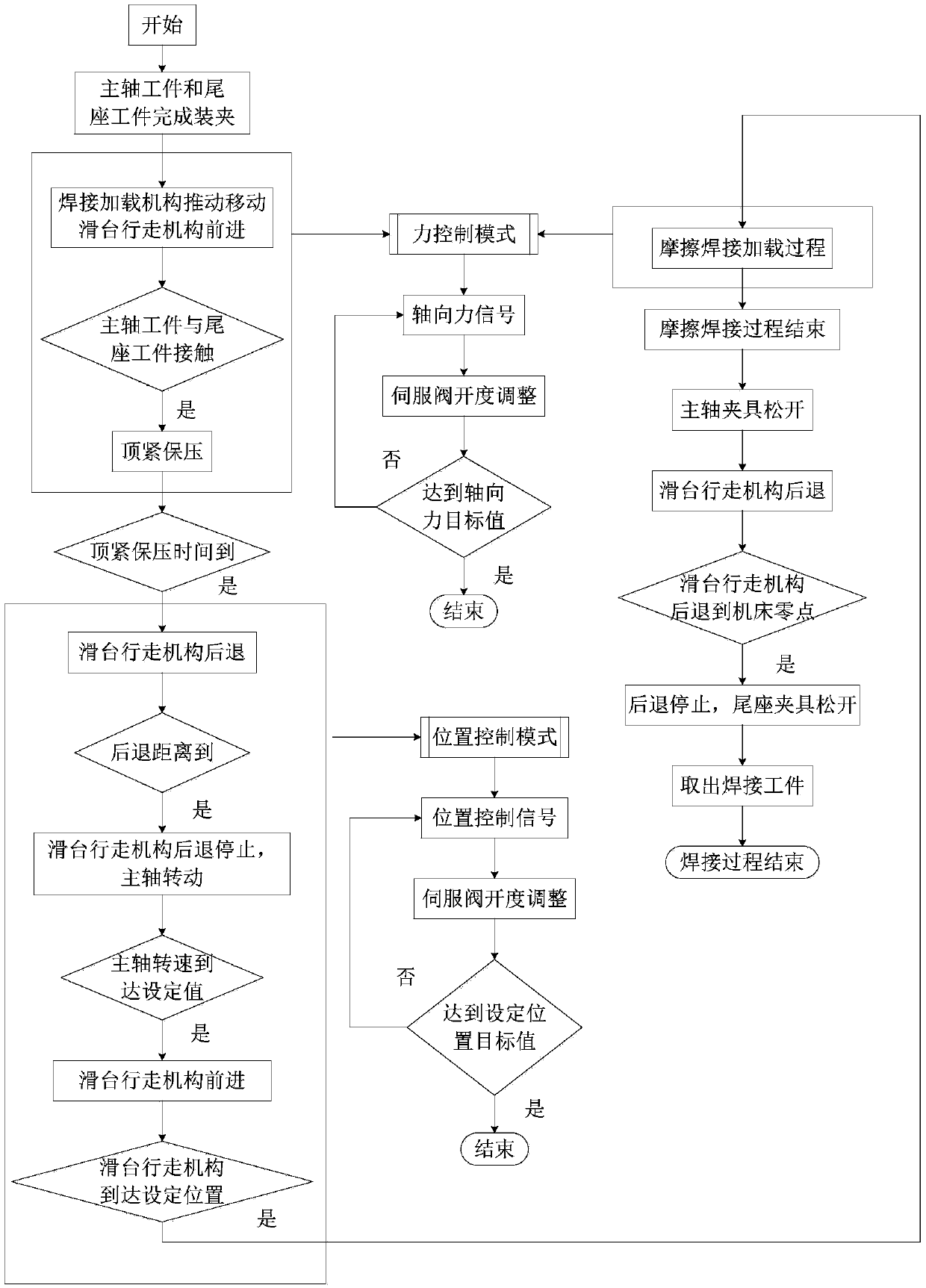

[0033] Such as figure 1 As shown, an axial friction welding device with interaction between position control mode and force control mode is characterized by: hydraulic servo controller 2, hydraulic servo valve 3, axial loading mechanism 5, pressure sensor 4, pressure sensor 7 1. A hydraulic servo welding loading system in a position-force control mode composed of displacement sensors 12.

[0034] The spindle system 11 is fixedly installed on the bed 13, the lower surface of the sliding table running mechanism 8 is equipped with a moving slider, and the upper surface of the bed 13 is equipped with a linear guide rail, and the sliding table running mechanism 8 is indirectly connected to the bed 13 through the moving slider and the linear guide rail structure. connected; the axial loading mechanism 5 is fixedly installed on the bed 13; the hydraulic cylinder is installed on the axial loading mechanism 5, and the piston rod of the hydraulic cylinder is fixedly connected with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com