Charging rod constructed by borehole-blasting method

A drilling and blasting method and charging technology, applied in blasting and other directions, can solve the problems of changing, increasing the risk factor, and limited explosive capacity, and achieving the effect of avoiding excessive length, avoiding insufficient length, and simple and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

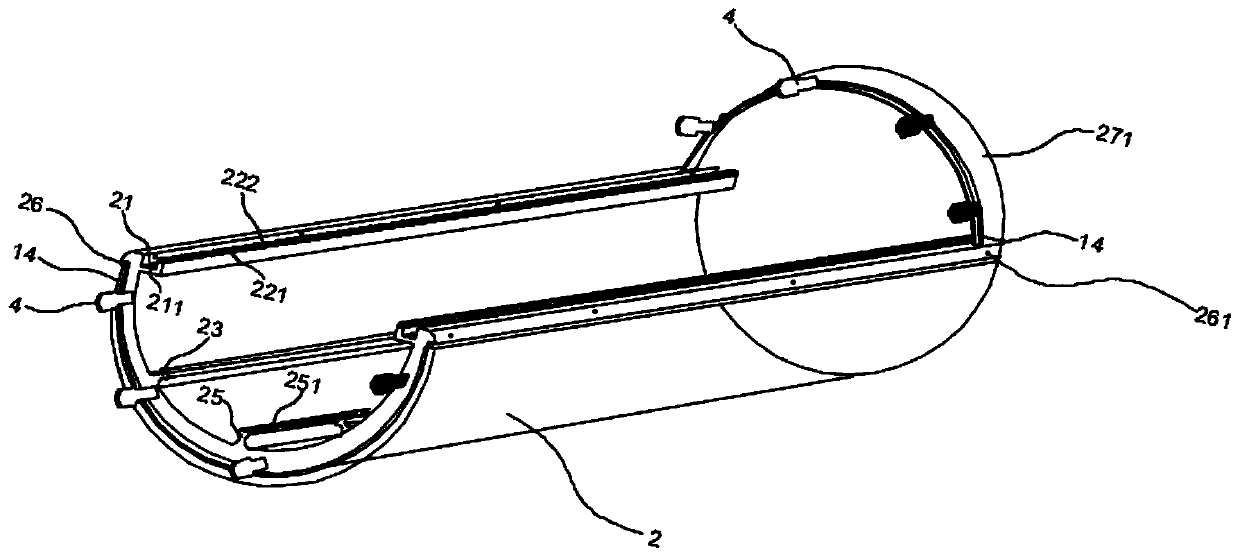

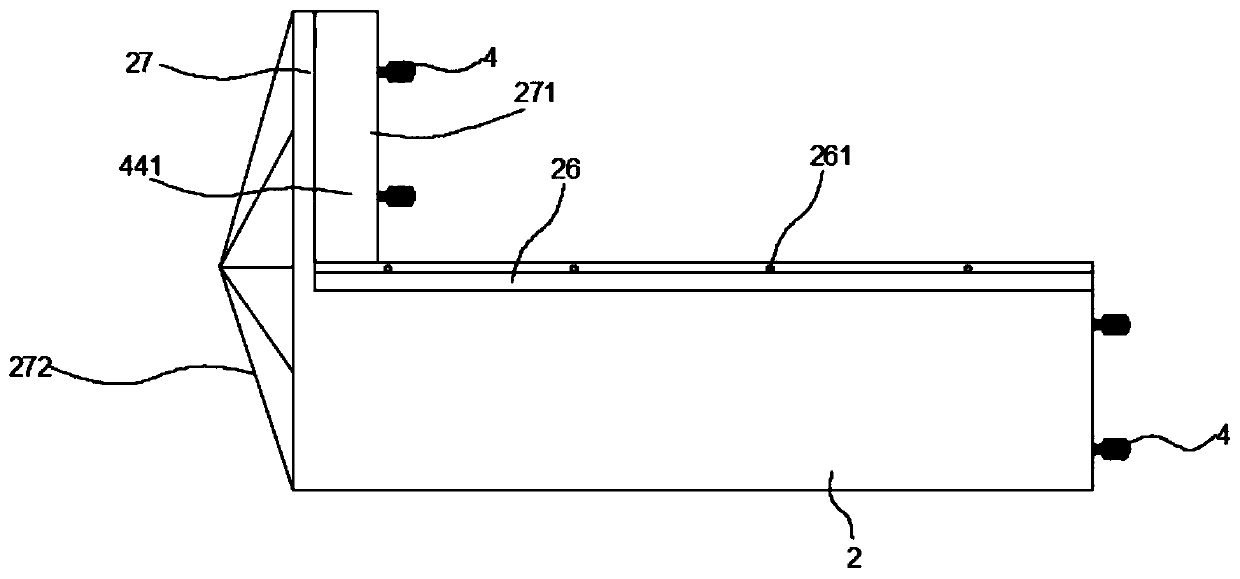

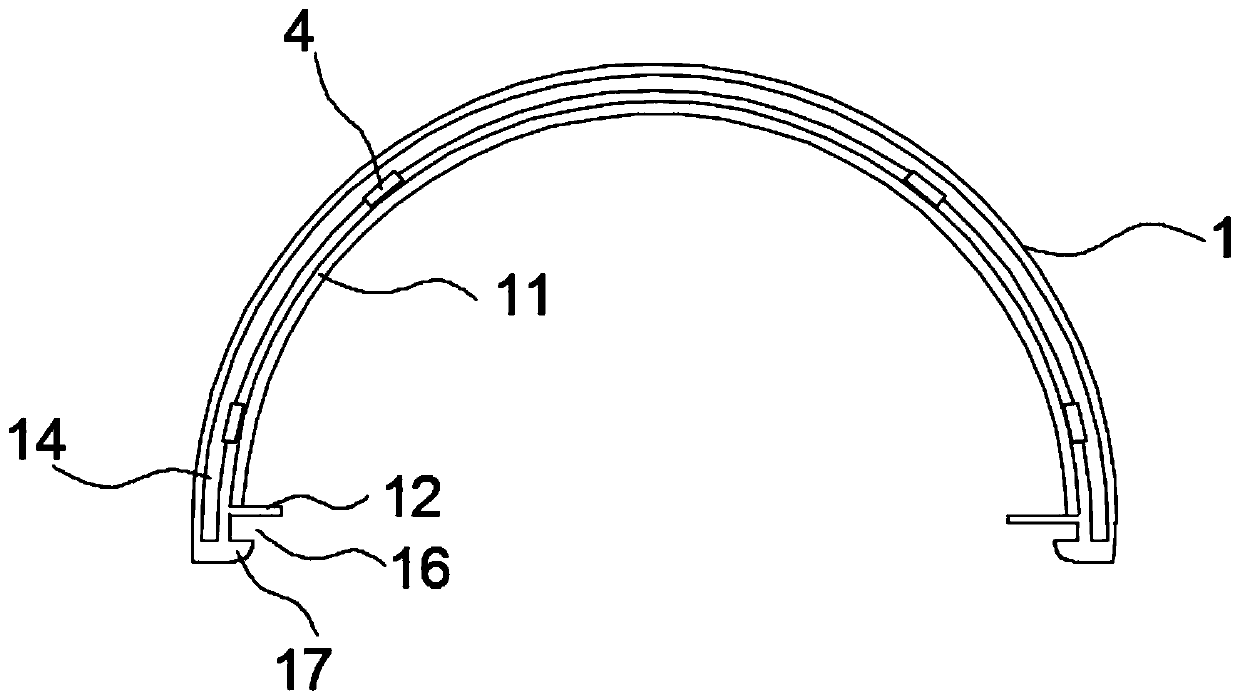

[0055] see Figure 1-Figure 22 As shown, a drilling and blasting construction charge rod includes a front-loading cartridge, an end-loading cartridge and several standard charge-loading cartridges. During construction, the front-end charge-loading At the mouth of the drill hole, the standard charge cartridge is installed between the front end charge cartridge and the end charge cartridge, the front end charge cartridge and the standard charge cartridge, the standard charge cartridge and the standard charge cartridge, the standard charge cartridge The locking device is used to connect with the end-loaded cartridge; and the front-end loaded cartridge, the end-loaded cartridge and the standard loaded cartridge all include an upper cylinder 1 and a lower cylinder 2, and the upper cylinder 1 and the lower cylinder The body 2 is connected by a snap-fitting device; the inner side of the lower cylinder body 2 is equipped with an explosive installation groove 3 for installing explosive...

Embodiment 2

[0074] see Figure 23-Figure 28 , different from Example 1, in order to achieve better connection between the front end cartridge and the standard cartridge, the standard cartridge and the standard cartridge, the standard cartridge and the end cartridge, to prevent loosening, The locking device can also be designed to be as described in the description of the present invention Figure 23-Figure 28 The structure shown is specifically: the locking device includes an upper cylinder locking assembly and a lower cylinder locking assembly with the same structure; the upper cylinder locking assembly and the lower cylinder locking assembly include equidistantly arranged The locking protrusion 5 and the sealing slot 54 on the rear end faces of the upper cylinder body 1 and the lower cylinder body 2, and the locking groove 52 and the sealing protrusion 53 arranged on the front end surfaces of the upper cylinder body 1 and the lower cylinder body 2 ; The locking protrusion 5 on the prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com