Patents

Literature

211results about How to "Increase the amount of incoming light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

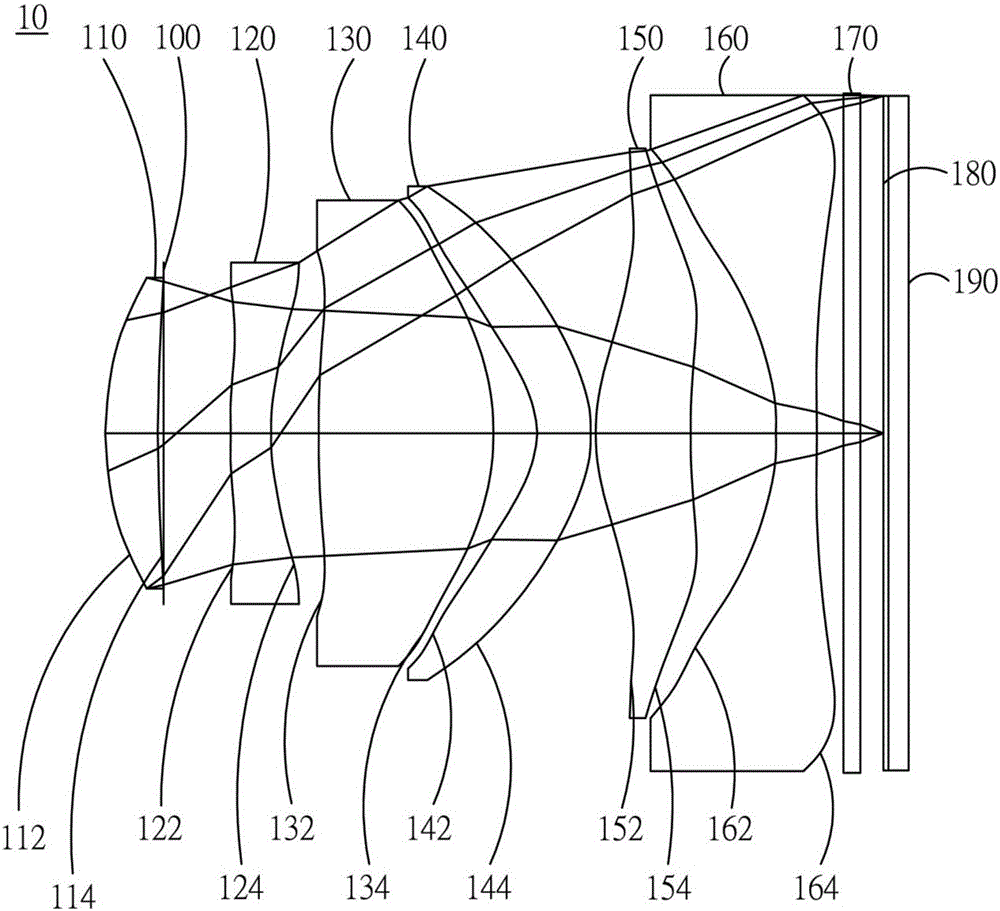

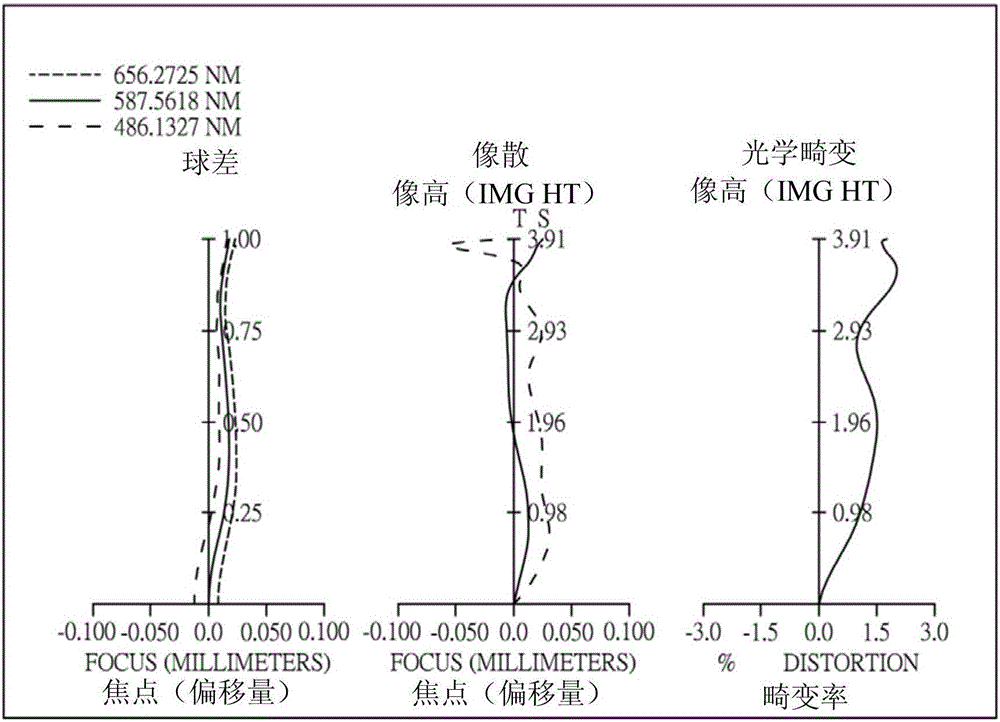

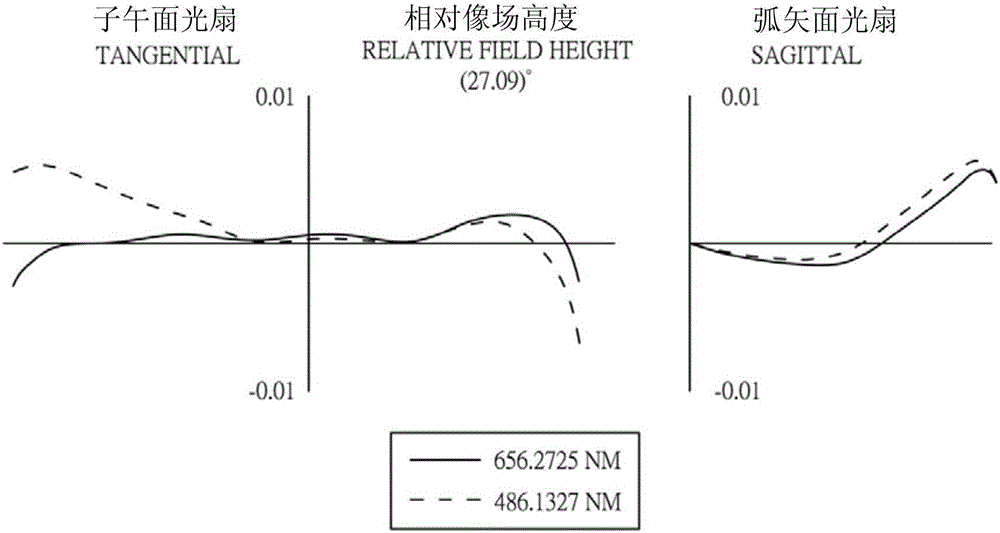

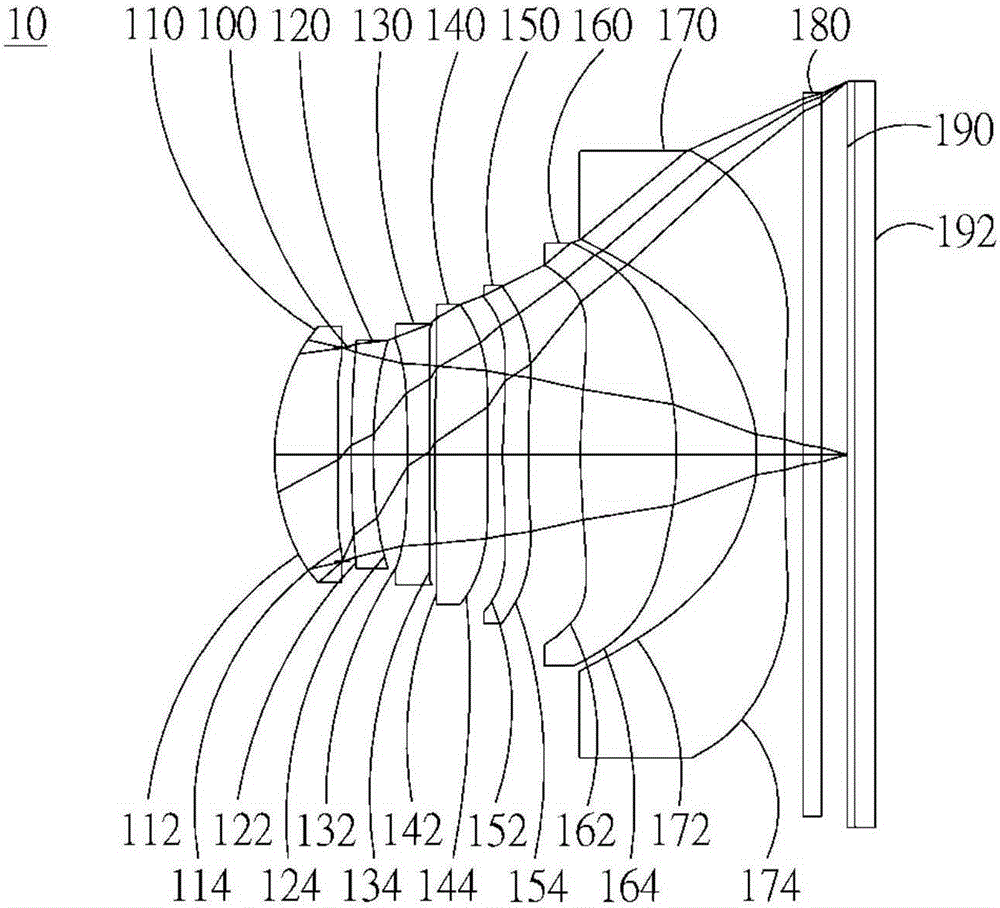

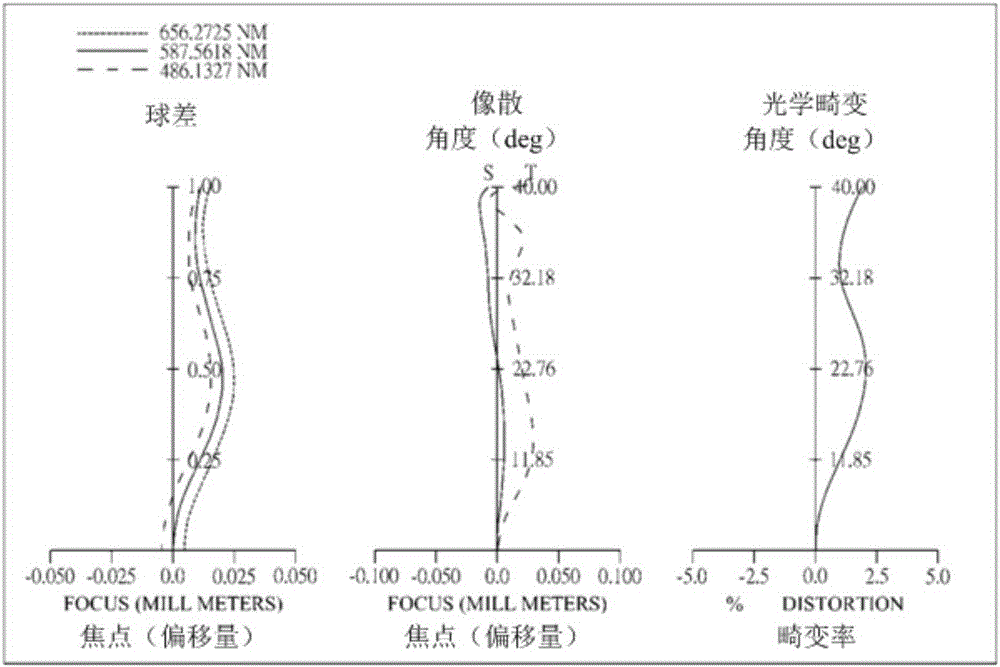

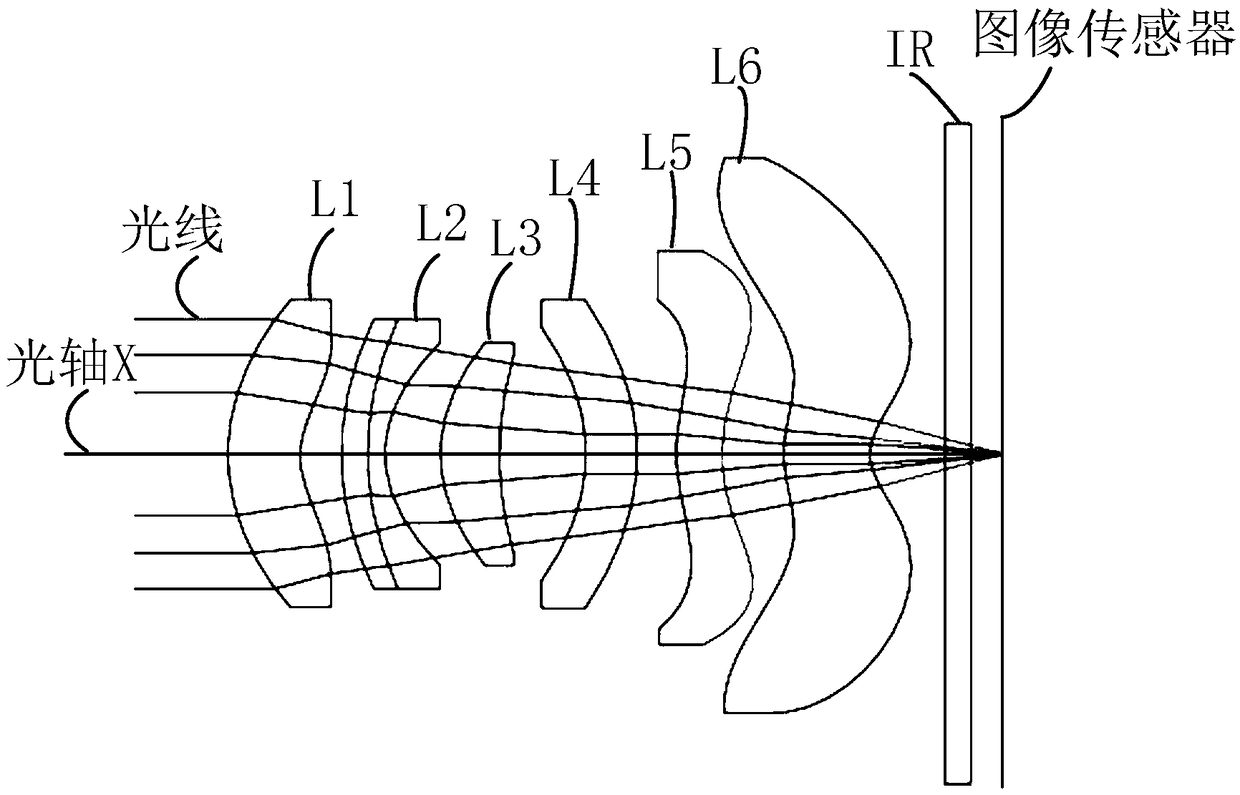

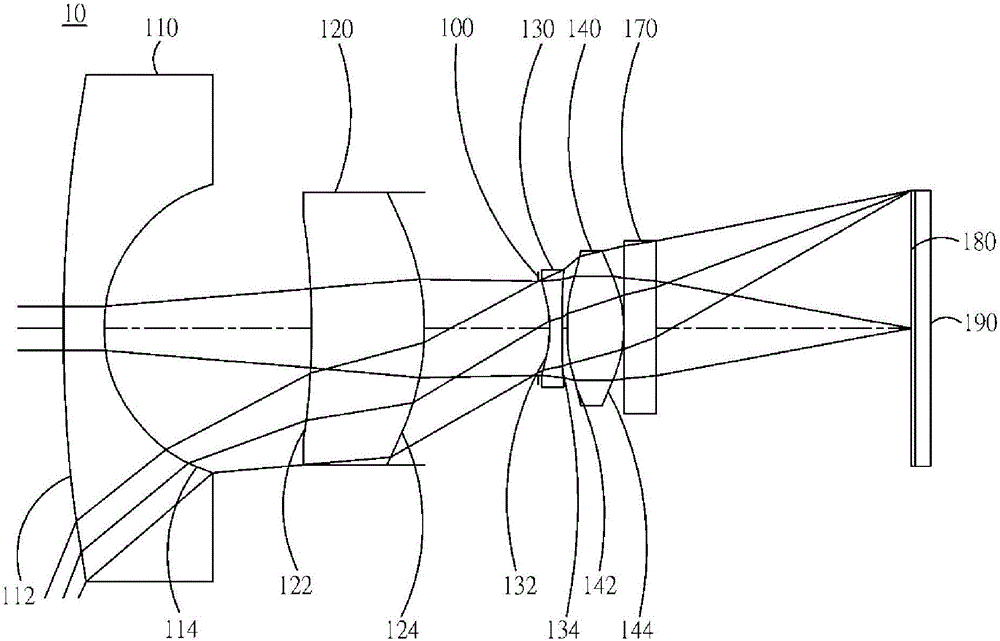

Optical image capturing system

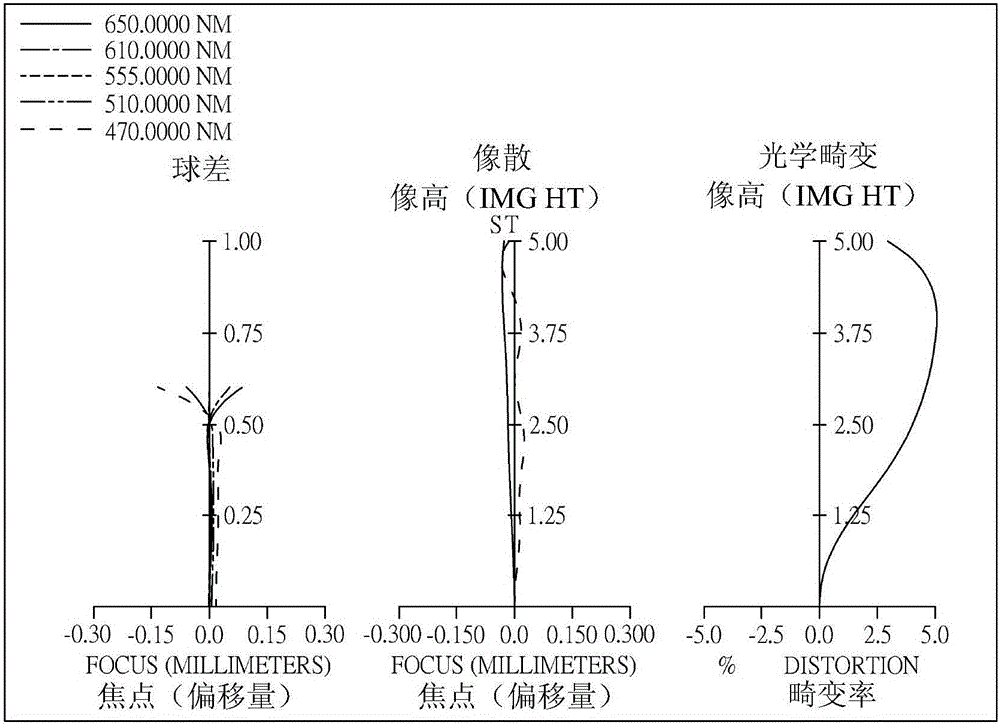

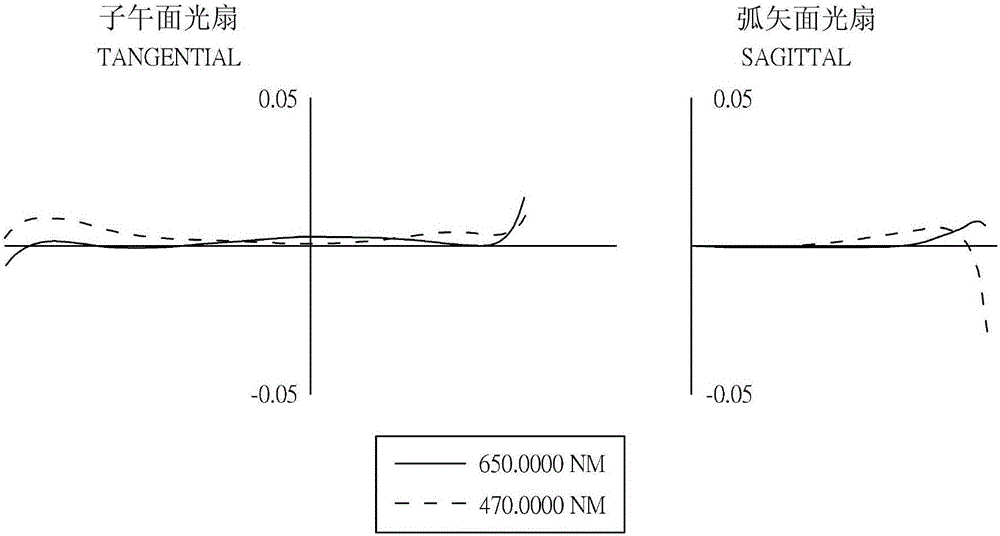

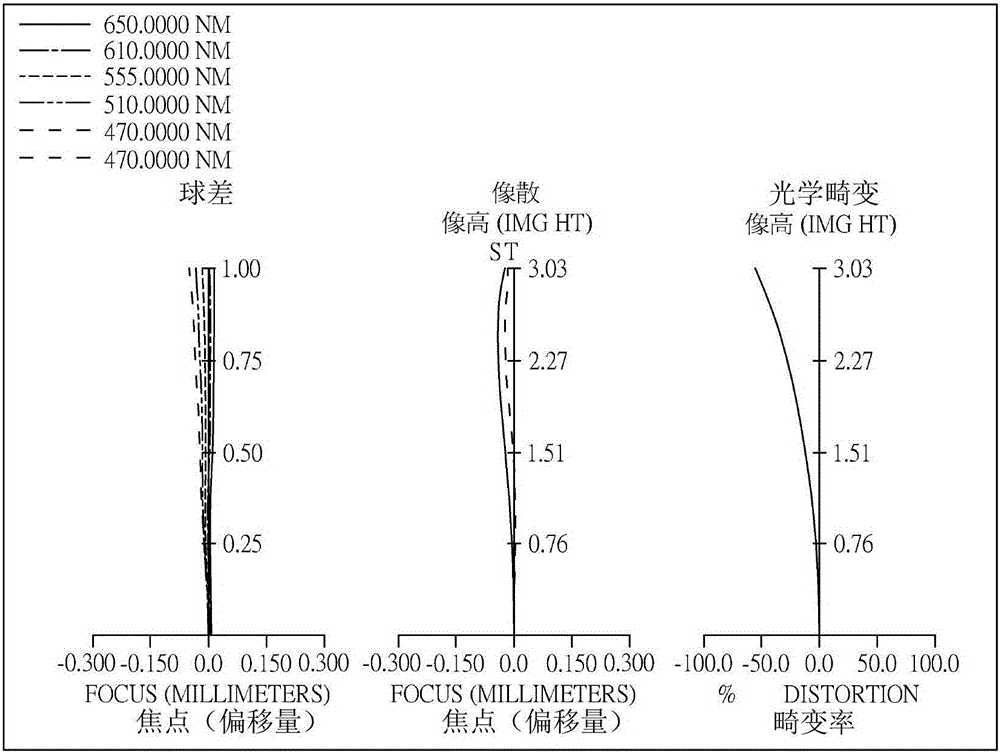

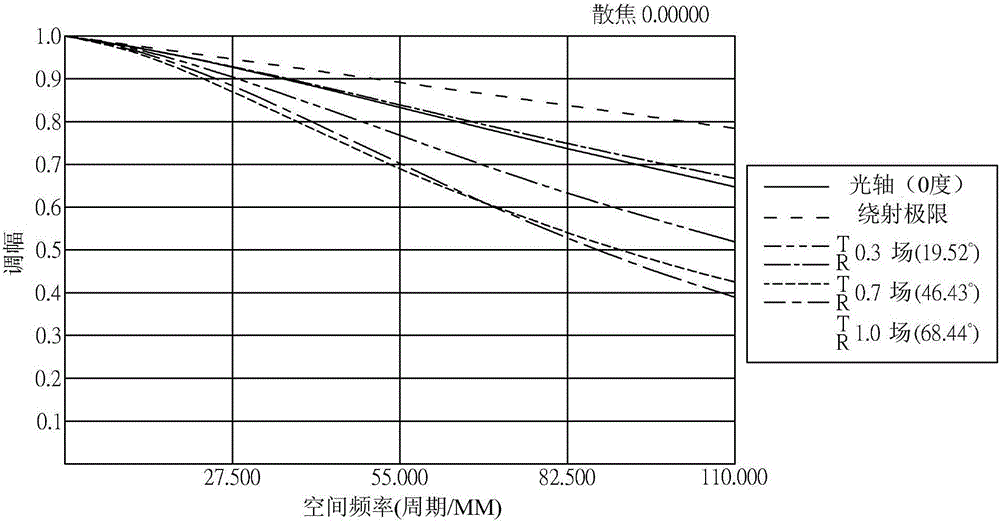

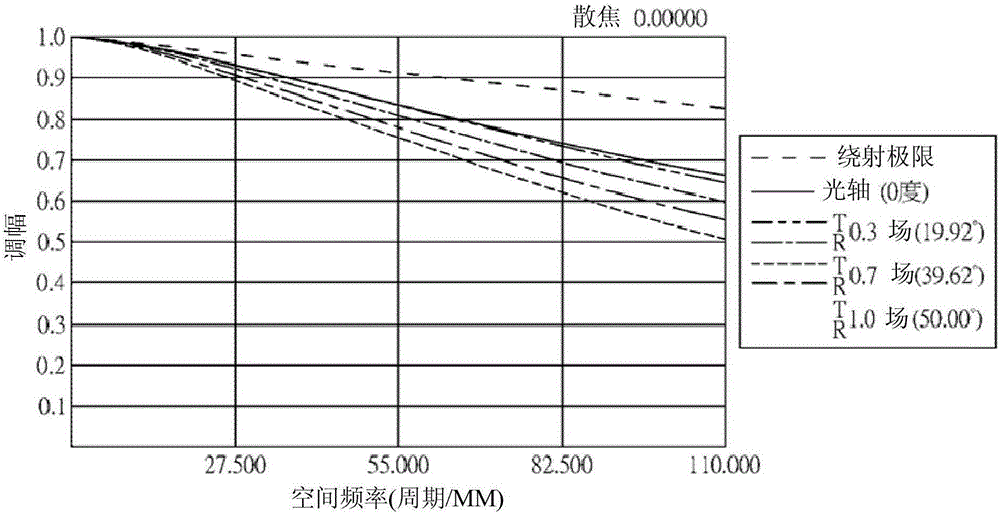

ActiveCN106168700AIncrease the amount of incoming lightImprove image qualityOptical elementsOptical axisImaging quality

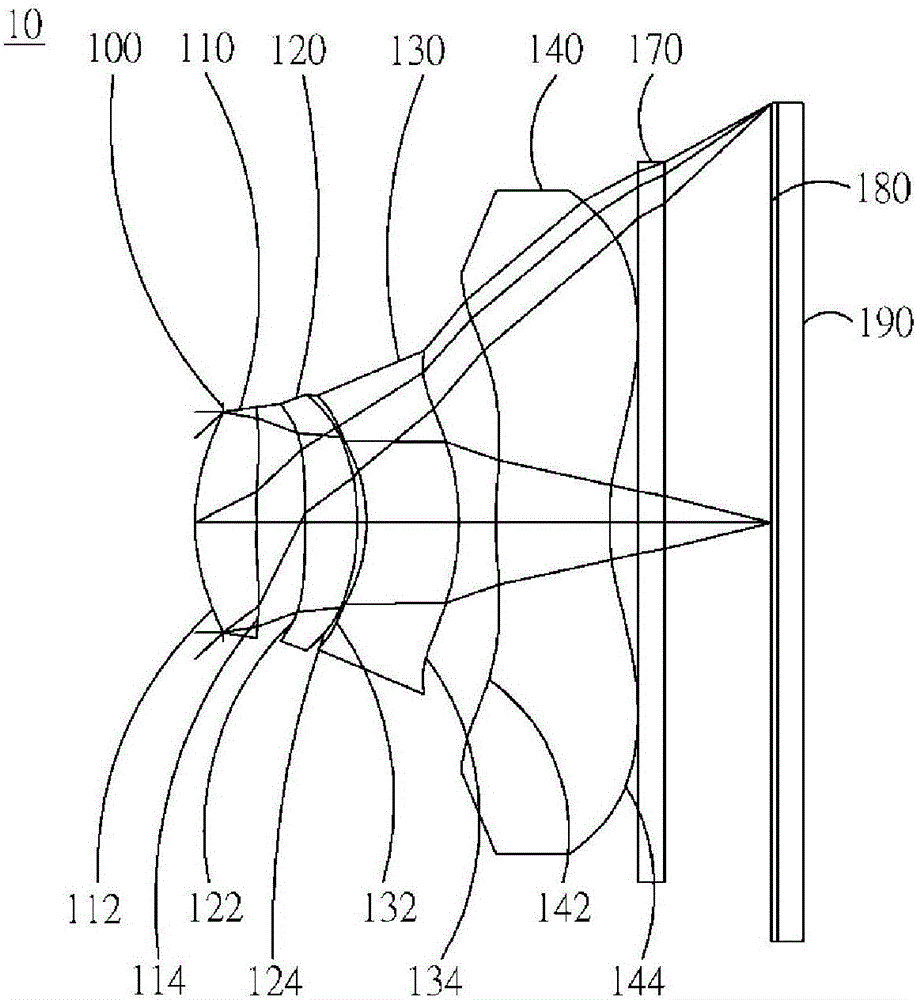

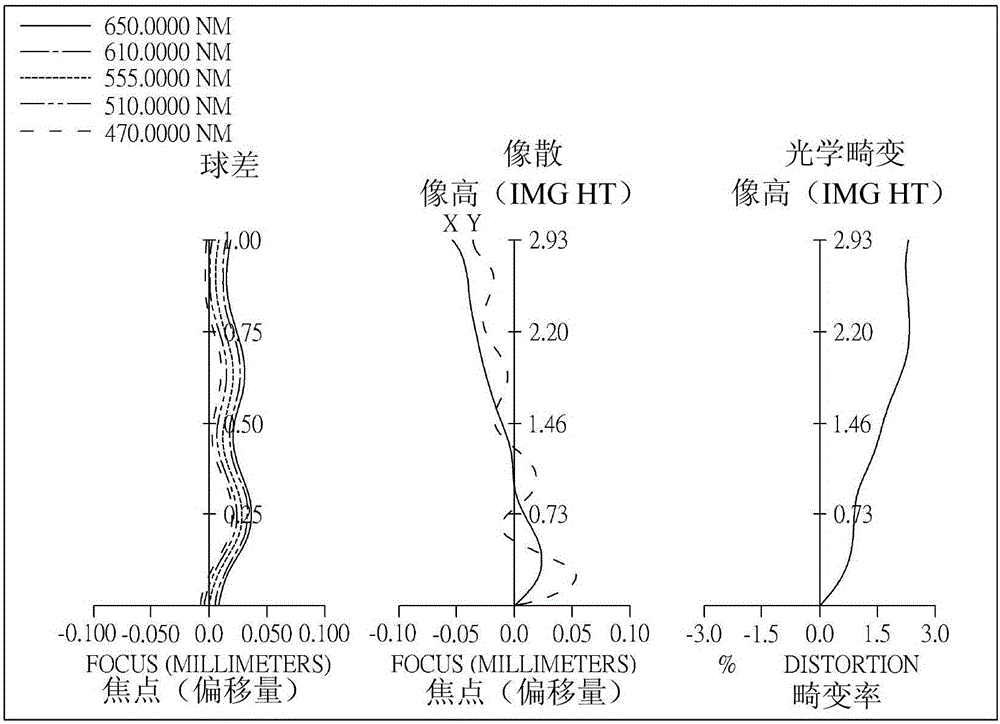

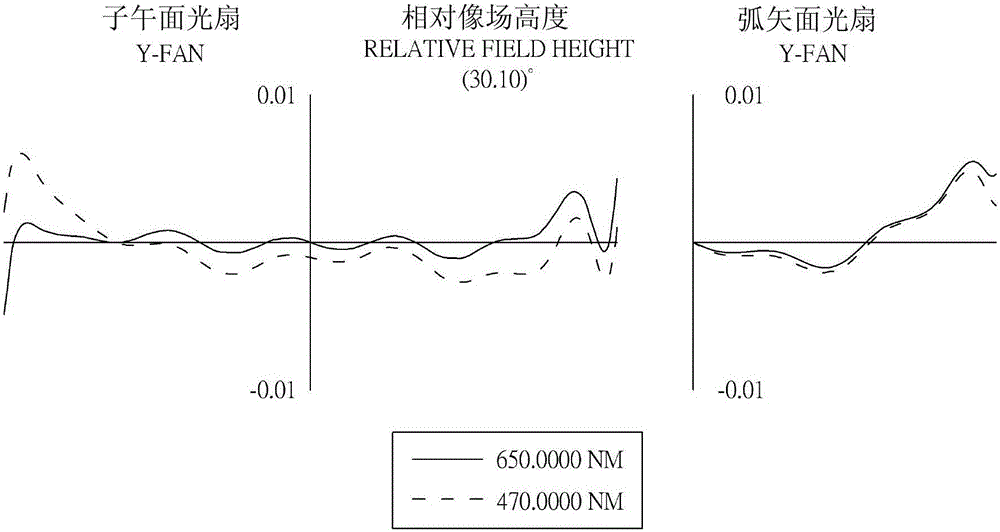

The invention discloses an optical imaging system. In order from an object side to an image side, the optical lens along the optical axis includes a first lens, a second lens, a third lens , a fourth lens, a fifth lens and a sixth lens, wherein at least one lens of the first lens to the fifth lens has positive refractive power, and the sixth lens has negative refractive power. At least one of the image-side surface and object-side surface of each of the six lens elements is aspheric. The optical lens can increase aperture value and improve the imagining quality for use in compact cameras.

Owner:ABILITY OPTO ELECTRONICS TECH

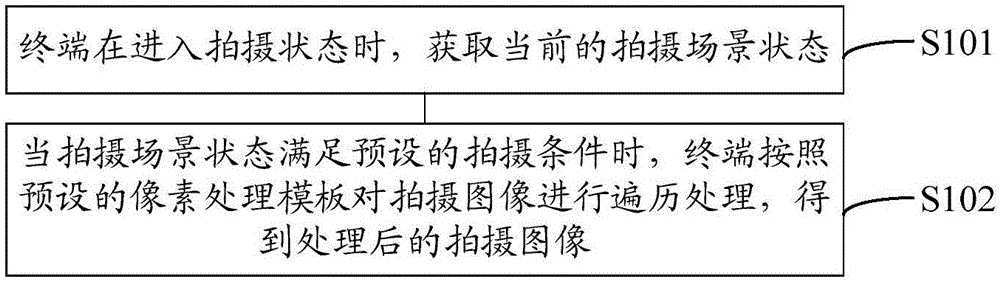

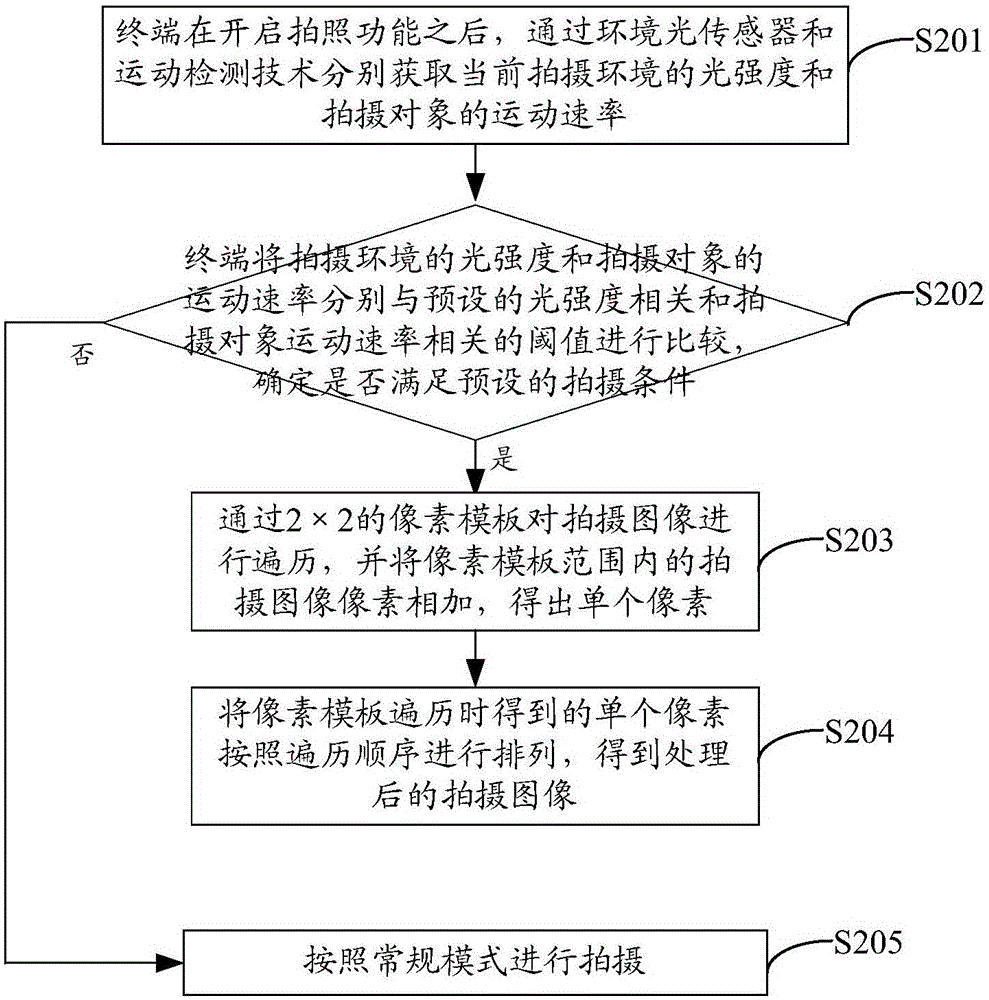

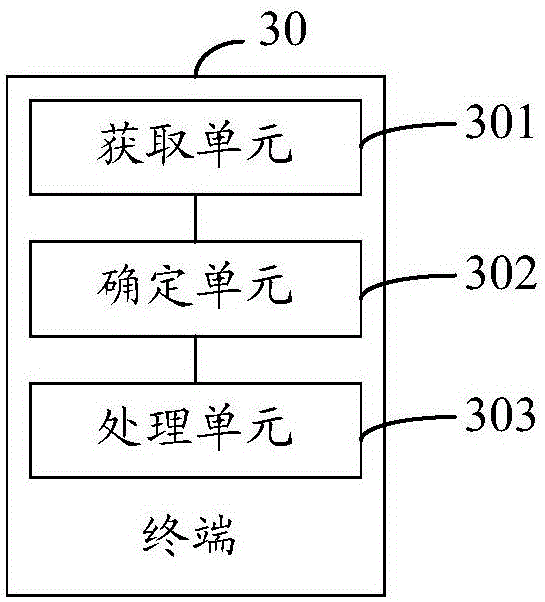

Terminal and method of terminal shooting

ActiveCN106412214AIncrease the amount of incoming lightReduce exposure timeTelevision system detailsColor television detailsComputer graphics (images)Computer vision

An embodiment of the invention discloses a terminal and a method for terminal shooting. The method comprises the steps of acquiring a current shooting scene state when the terminal enters a shooting mode; and when the shooting scene state satisfies a preset shooting condition, combining adjacent pixels in a shot image of the terminal according to a preset pixel processing strategy to obtain the processed shot image.

Owner:ZTE CORP

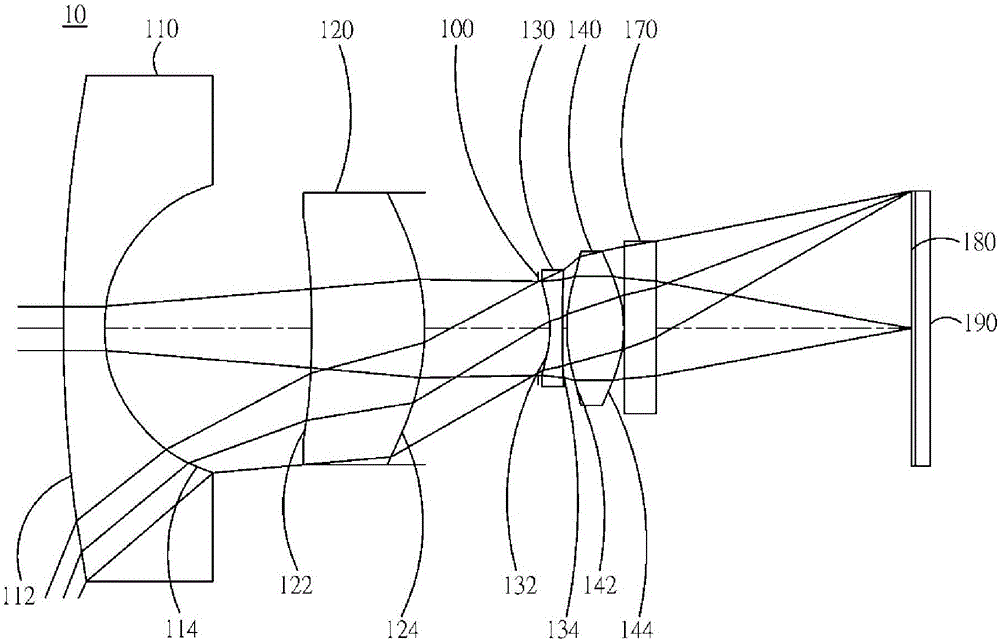

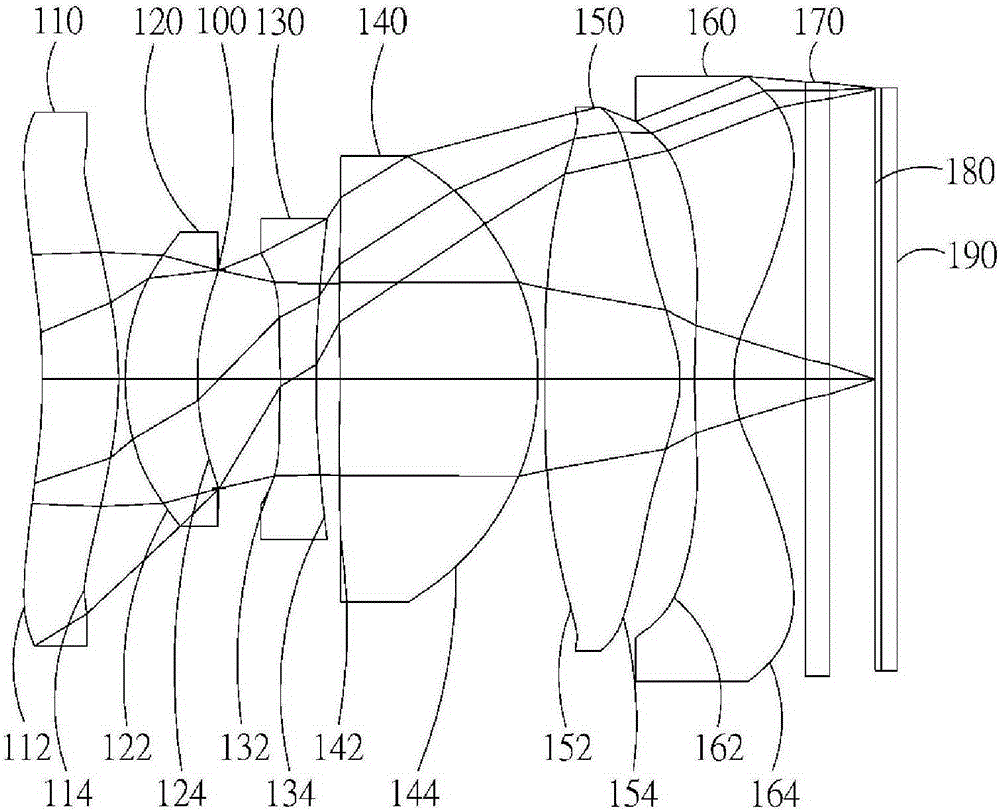

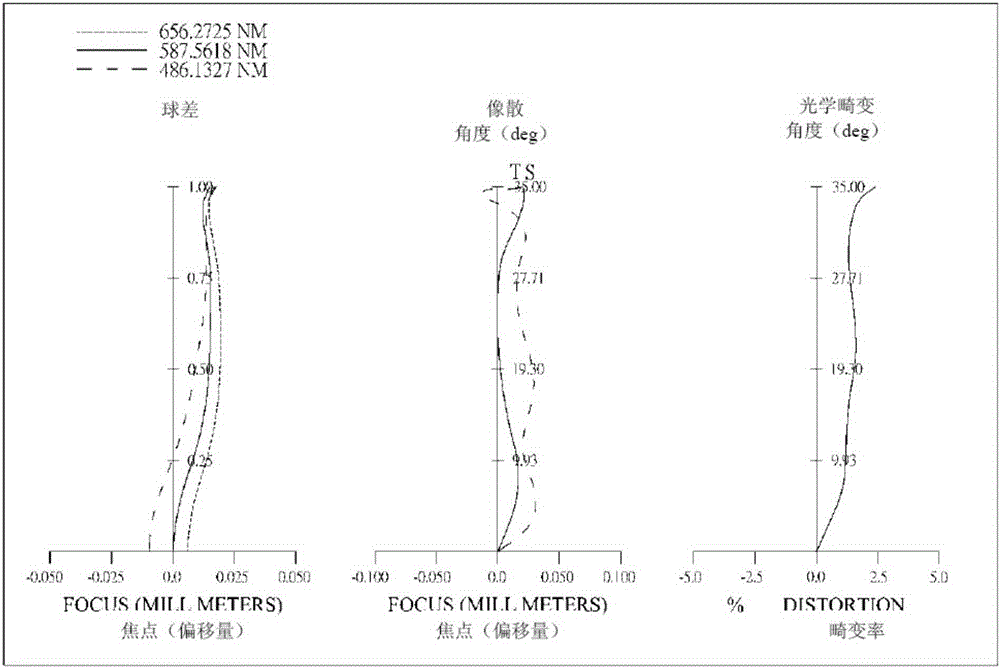

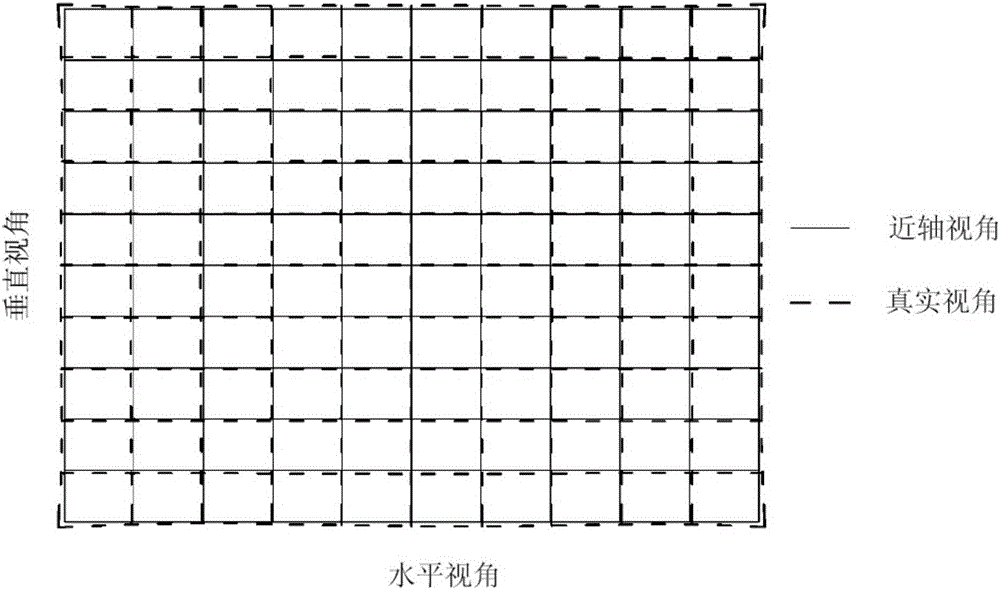

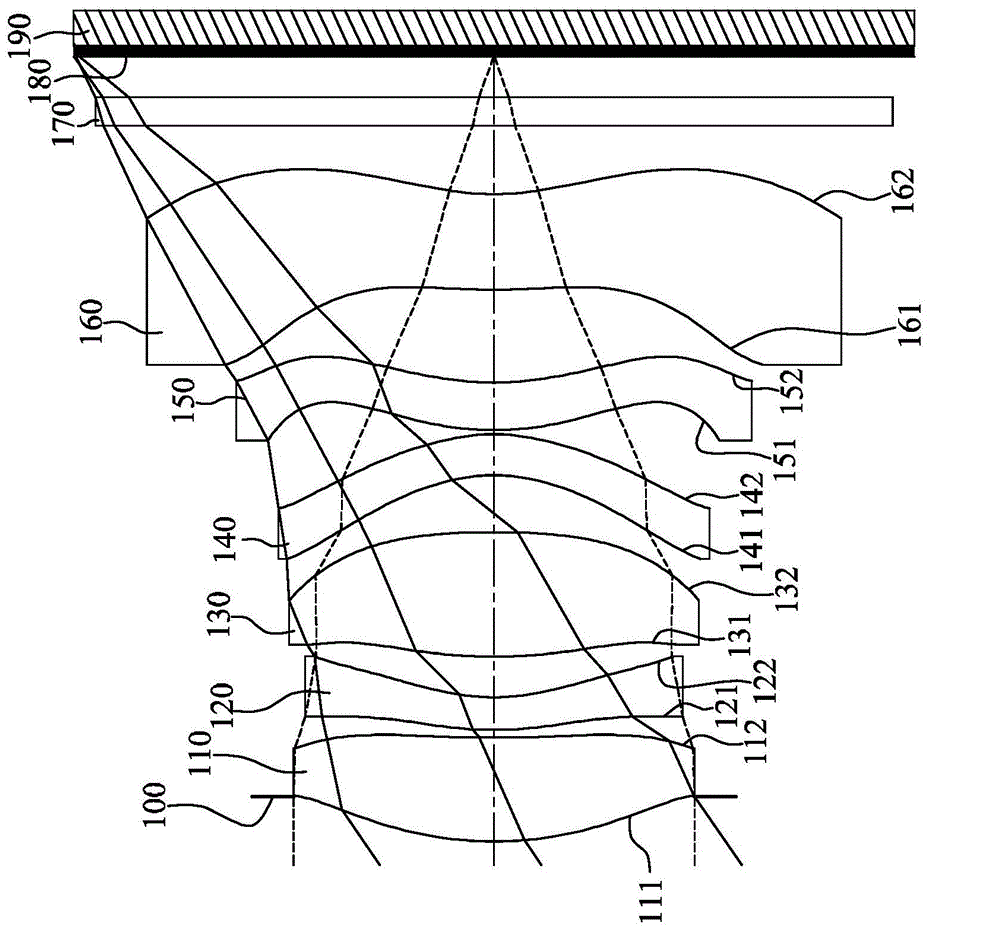

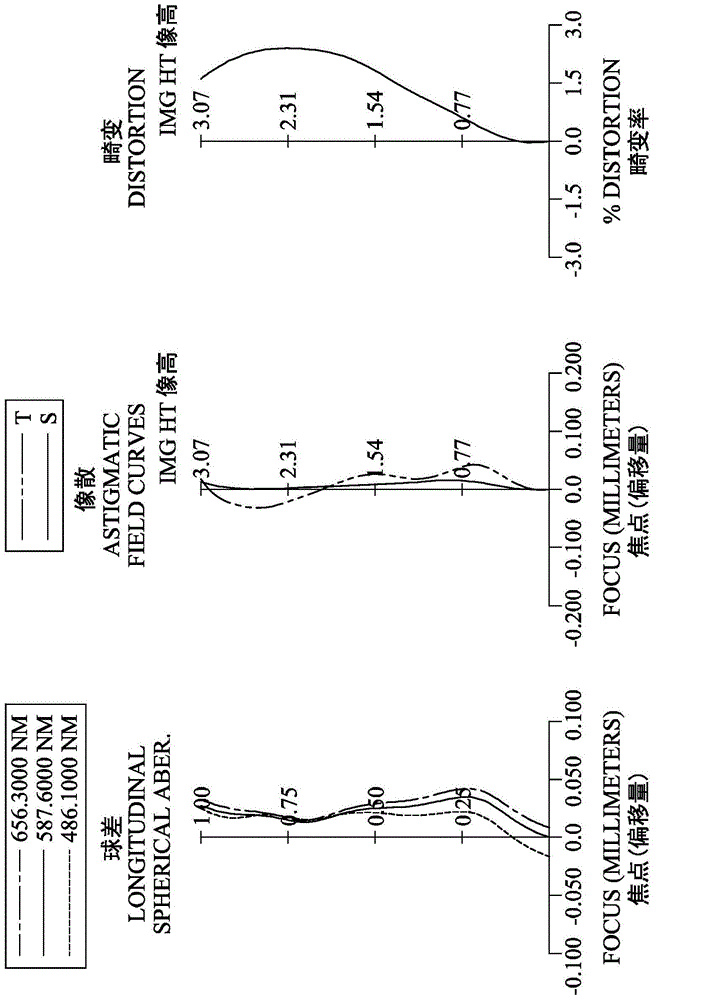

Optical image capturing system

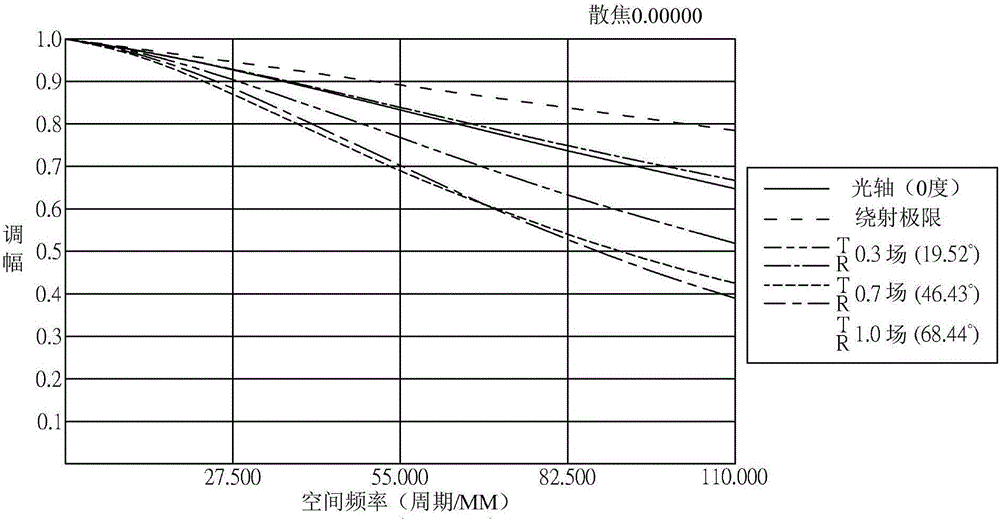

InactiveCN105589176AEffectively adjust the angleImprove image qualityOptical elementsImaging qualityOptical image

An optical image capturing system, from an object side to an image side, comprises a first, second, third, fourth, fifth, sixth, and seventh lens elements. At least one of the first through sixth lens elements has positive refractive power. The seventh lens has negative refractive power. Both of the image-side surface and the object-side surface of the seventh lens element are aspheric and at least one of the two surfaces has inflection points. The second through seventh lens elements of the optical image capturing system have refractive power. When specific conditions are satisfied, the optical image capturing can have a large aperture value and a better optical path adjusting ability, so as to improve imaging quality.

Owner:ABILITY OPTO ELECTRONICS TECH

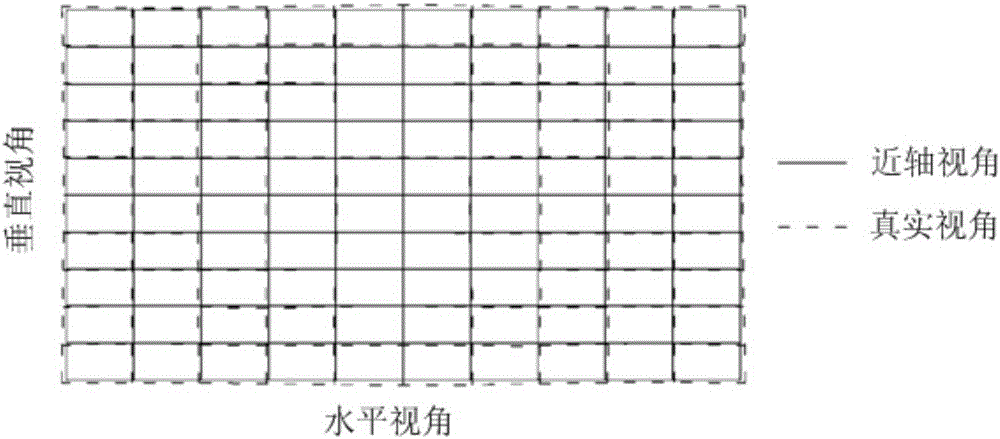

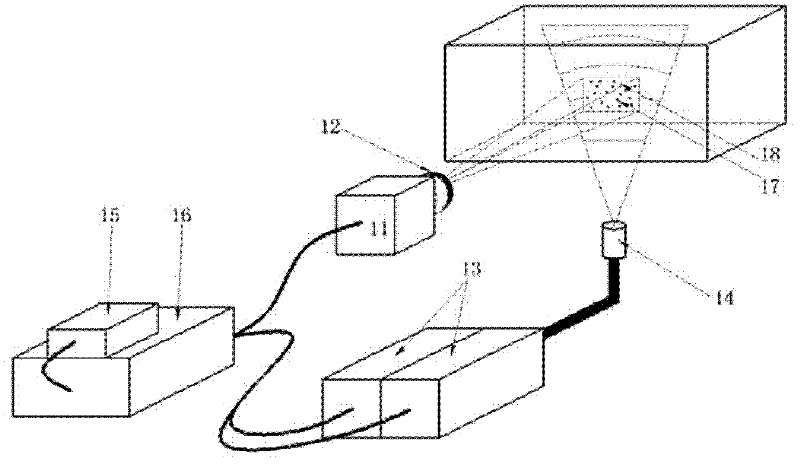

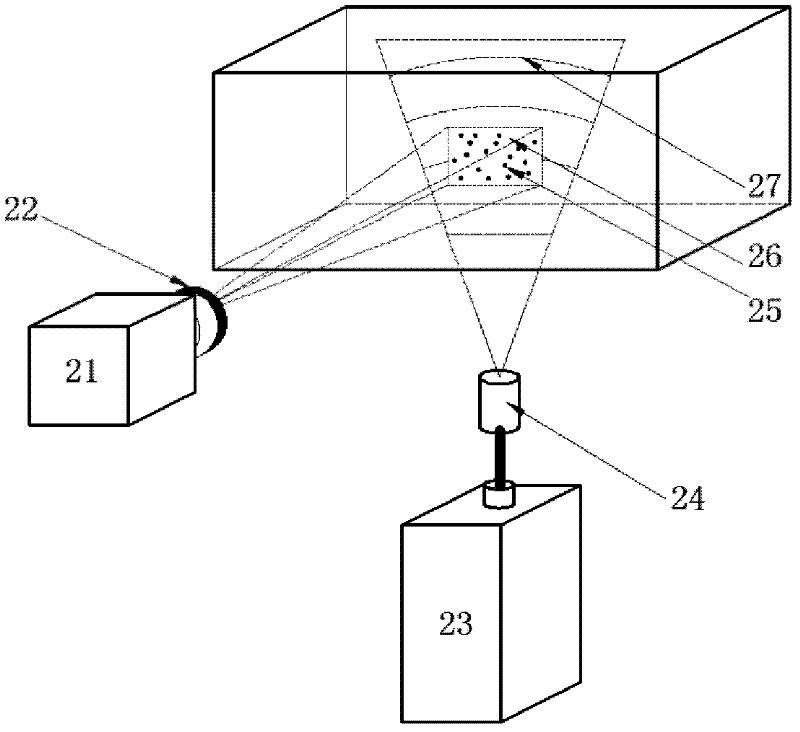

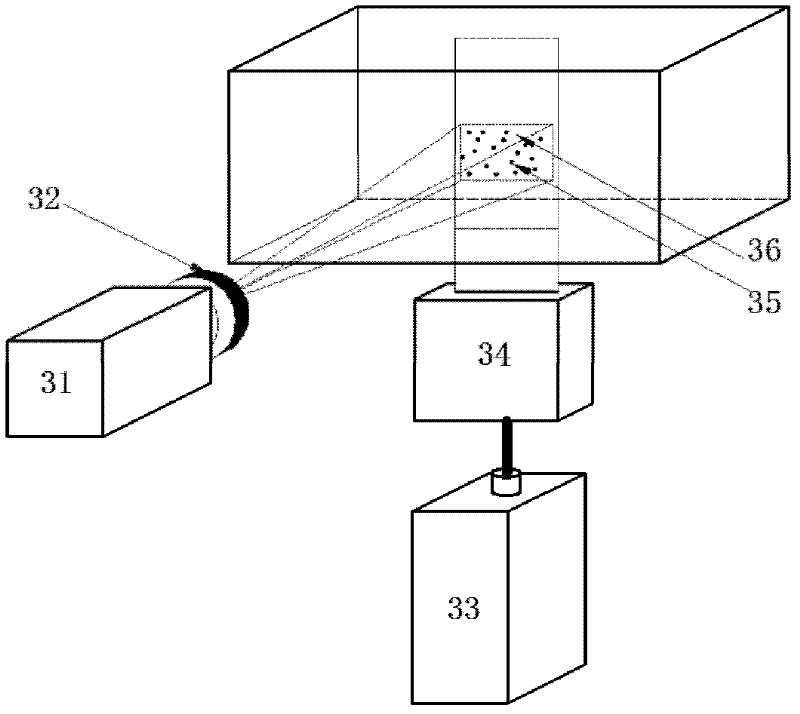

High frequency image acquisition system for measuring flow rate

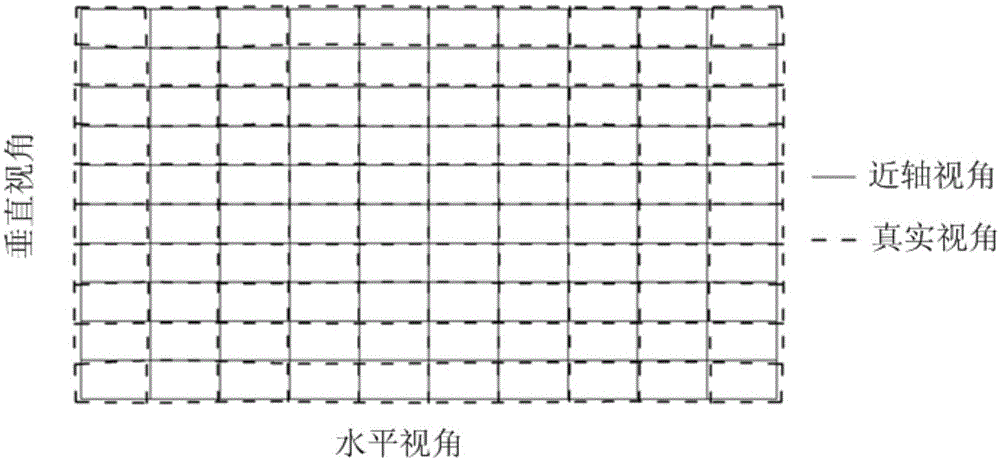

InactiveCN102393193AFast samplingIncrease profitPhotogrammetry/videogrammetryFluid speed measurementOptoelectronicsCaliber

The invention relates to a high frequency image acquisition system for measuring a flow rate, and belongs to the technical field of water conservancy measurement. The system comprises a high speed camera, a lens, a continuous laser and a combination lens, and is characterized in that: the high speed camera is provided with a 50mm large-caliber lens adaptor; the lens has an F1.0 / 50mm large-caliberaperture; the continuous laser is a low-power continuous laser with the maximum power of 2-5W; and the combination lens can convert light beams emitted by the laser into 1mm-thickness rectangular plane light. The system can acquire images economically and safely at high frequency and high quality so as to continuously measure the flow rate of an open channel or a pipeline.

Owner:TSINGHUA UNIV

Optical image capturing system

ActiveCN106154497AEffectively adjust the angleImprove image qualityOptical elementsOphthalmologyImaging quality

An optical image capturing system, sequentially including a first lens element, a second lens element, a third lens element and a fourth lens element from an object side to an image side, is provided. The first lens element has positive refractive power. The second through third lens elements have refractive power. The fourth lens element has negative refractive power. At least one of the image side surface and the object side surface of each of the four lens elements are aspheric. The optical lens elements can increase aperture value and improve the imagining quality for use in compact cameras.

Owner:ABILITY OPTO ELECTRONICS TECH

Image sensor, imaging device, mobile terminal and imaging method

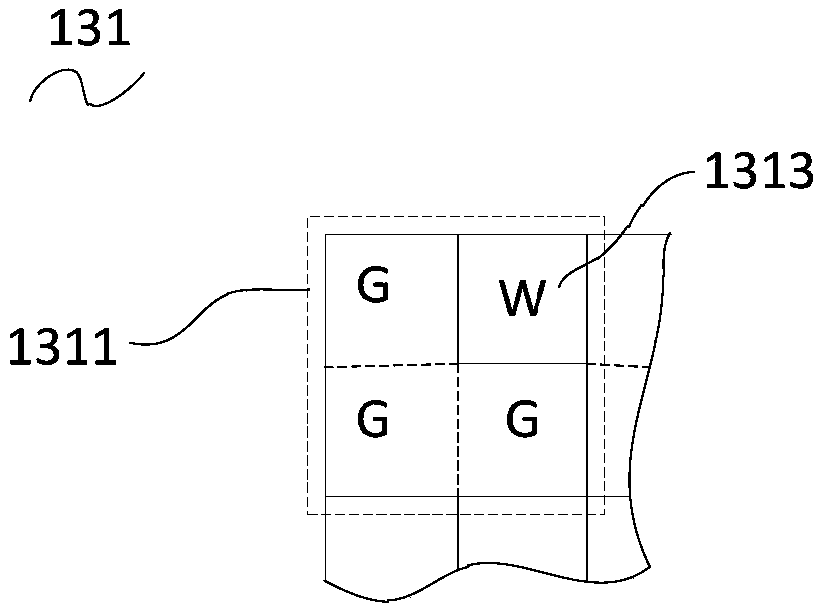

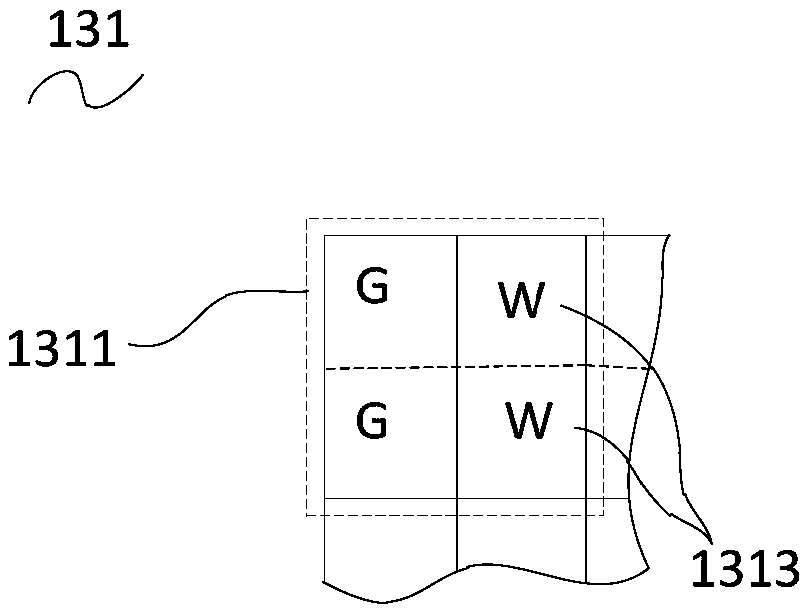

ActiveCN105516697AReduce noiseIncrease the amount of incoming lightTelevision system detailsSolid-state devicesSignal-to-noise ratio (imaging)Computer terminal

The invention discloses an image sensor, an imaging device, a mobile terminal and an imaging method. The image sensor comprises a photosensitive pixel array and an optical filter arranged on the photosensitive pixel array, wherein the optical filter comprises a photosensitive unit array provided with a plurality of filtering units, wherein each filtering unit covers N photosensitive pixels; some filtering units at least include white filtering areas; the white filtering areas cover at least one photosensitive pixel in N photosensitive pixels, wherein a combined pixel is formed by the N photosensitive pixels covered by one filtering unit, and N is a positive integer. According to the image sensor disclosed by the embodiments of the invention, the while filtering areas are embedded into some filtering units, so that the light quantity can be increased, so that higher signal to noise ratio, brightness and definition can be obtained at low illumination, and an image with fewer noisy points can be generated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

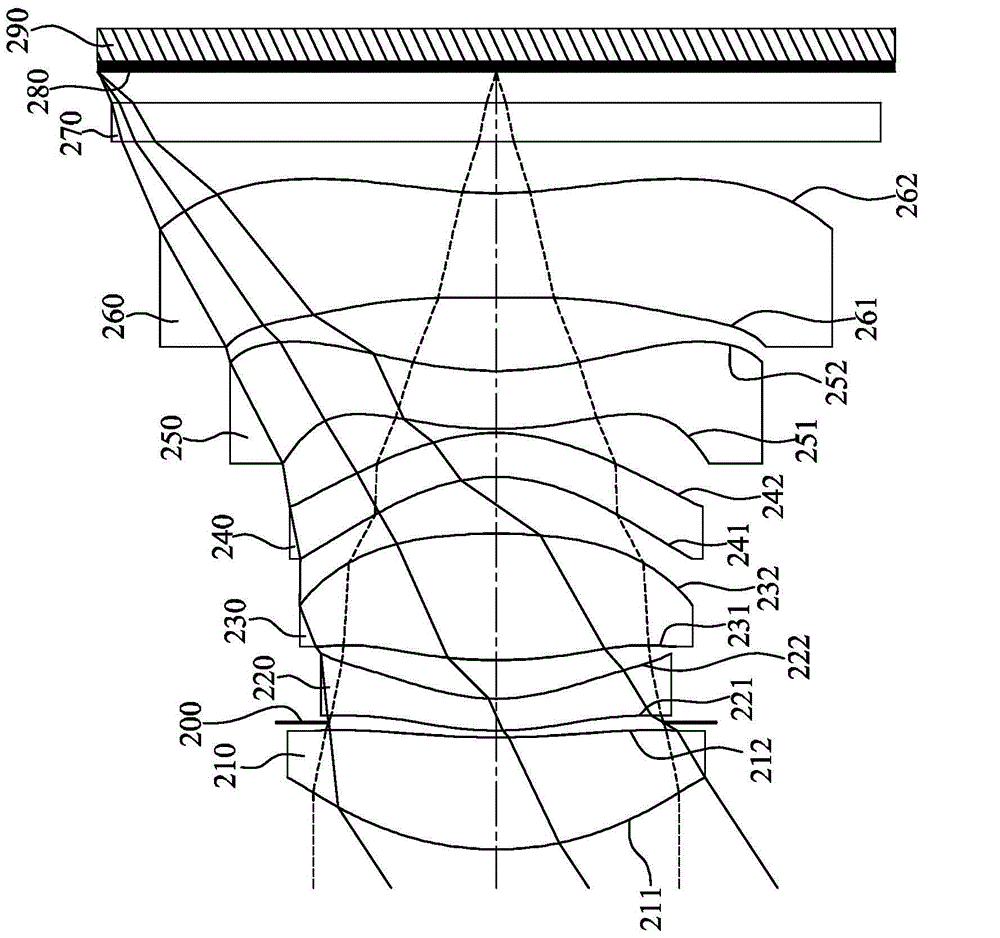

Optical Image Capturing System

InactiveCN106054353AEffectively adjust the angleImprove image qualityOptical elementsRefractive errorImaging quality

The present disclosure discloses an optical image capturing system. The optical image capturing system includes a first lens with refractive power, a second lens with refractive power, a third lens with refractive power, a fourth lens with refractive power, a fifth lens with refractive power, a sixth lens with refractive power and a seventh lens with refractive power sequentially arranged from an object side to an image side along the optical axis. At least one of the first through sixth lens has positive refractive power. The seventh lens may have negative refractive power and both image side and object side surfaces of the seventh lens are aspheric. The optical image capturing system can increase aperture value and improve the imagining quality for the application of compact cameras.

Owner:ABILITY OPTO ELECTRONICS TECH

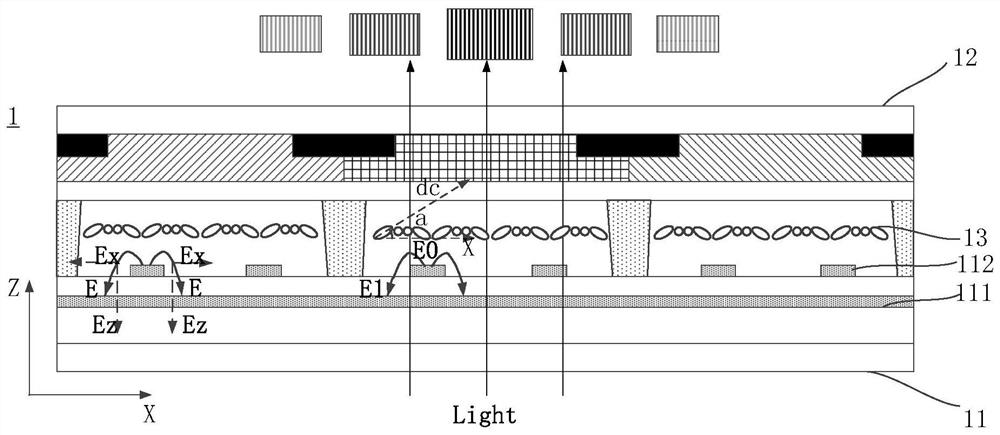

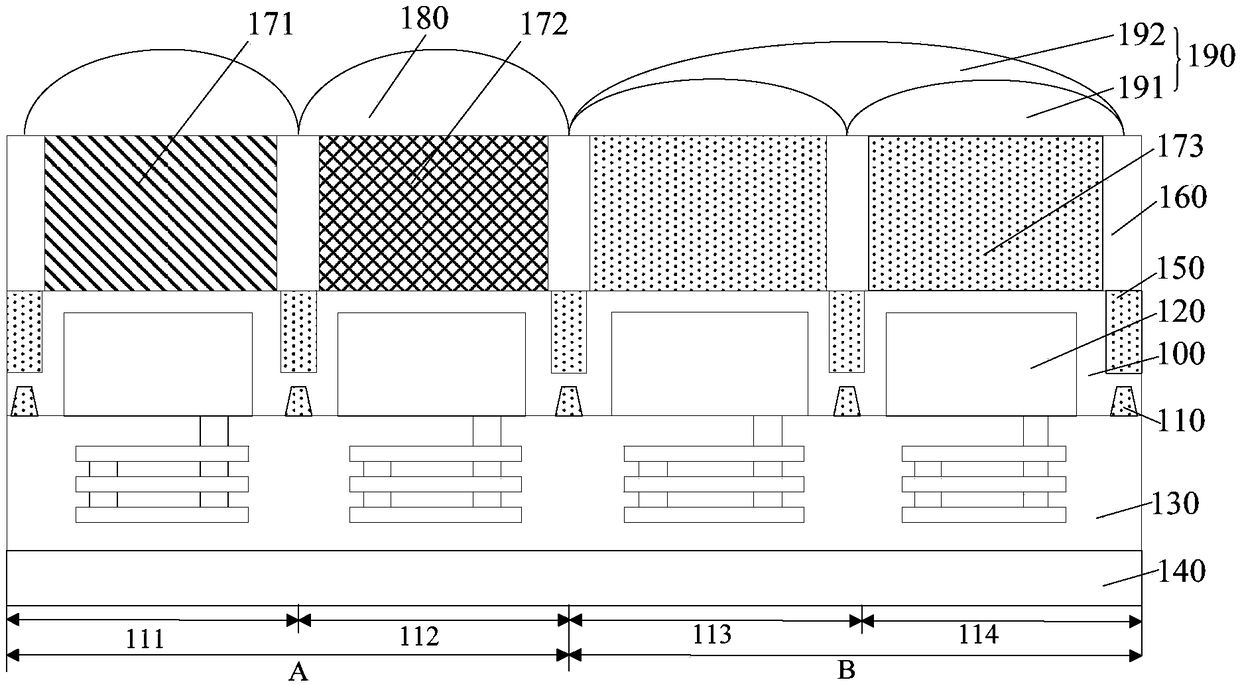

Liquid crystal display panel, manufacturing method thereof and display device comprising liquid crystal display panel

ActiveCN105676526AIncreasing the thicknessIncrease the amount of incoming lightNon-linear opticsLiquid-crystal displayDisplay device

The invention relates to a liquid crystal display panel, a manufacturing method thereof and a display device comprising the liquid crystal display panel, and aims to solve the problem that although the utilization rate of a backlight source is increased by arranging a quantum rod layer in a polarizing plate, the thickness of a display panel is increased, and moreover a quantum rod has a limited effect of light conversion. The liquid crystal display panel comprises an array substrate, an opposite substrate, a polarized light structure and a polarizing film, wherein the polarized light structure is arranged on one side, back on to the opposite substrate, of the array substrate, and is capable of emitting linearly polarized light; the polarizing film is arranged on the opposite substrate; the polarized light structure comprises a first electrode layer, a second electrode layer and a quantum rod layer positioned between the first electrode layer and the second electrode layer; the quantum rod layer is adopted to emit linearly polarized light of which the polarization direction is parallel to the absorbing axis of the polarizing film when voltage is loaded. As the polarized light structure in the liquid crystal display panel can emit linearly polarized light, a backlight source and a lower polarizing film are not needed, and thus the thickness of the display panel can be reduced; meanwhile the emitted linearly polarized light can directly enter the electrode layers, a liquid crystal layer and the like, so that the utilization rate of light can be increased.

Owner:BOE TECH GRP CO LTD

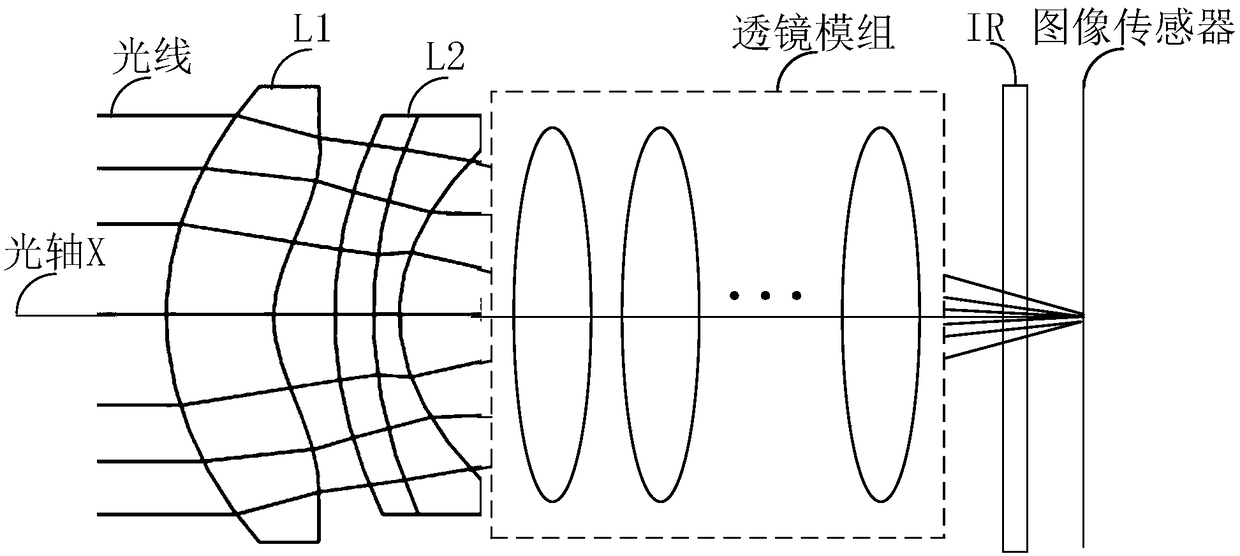

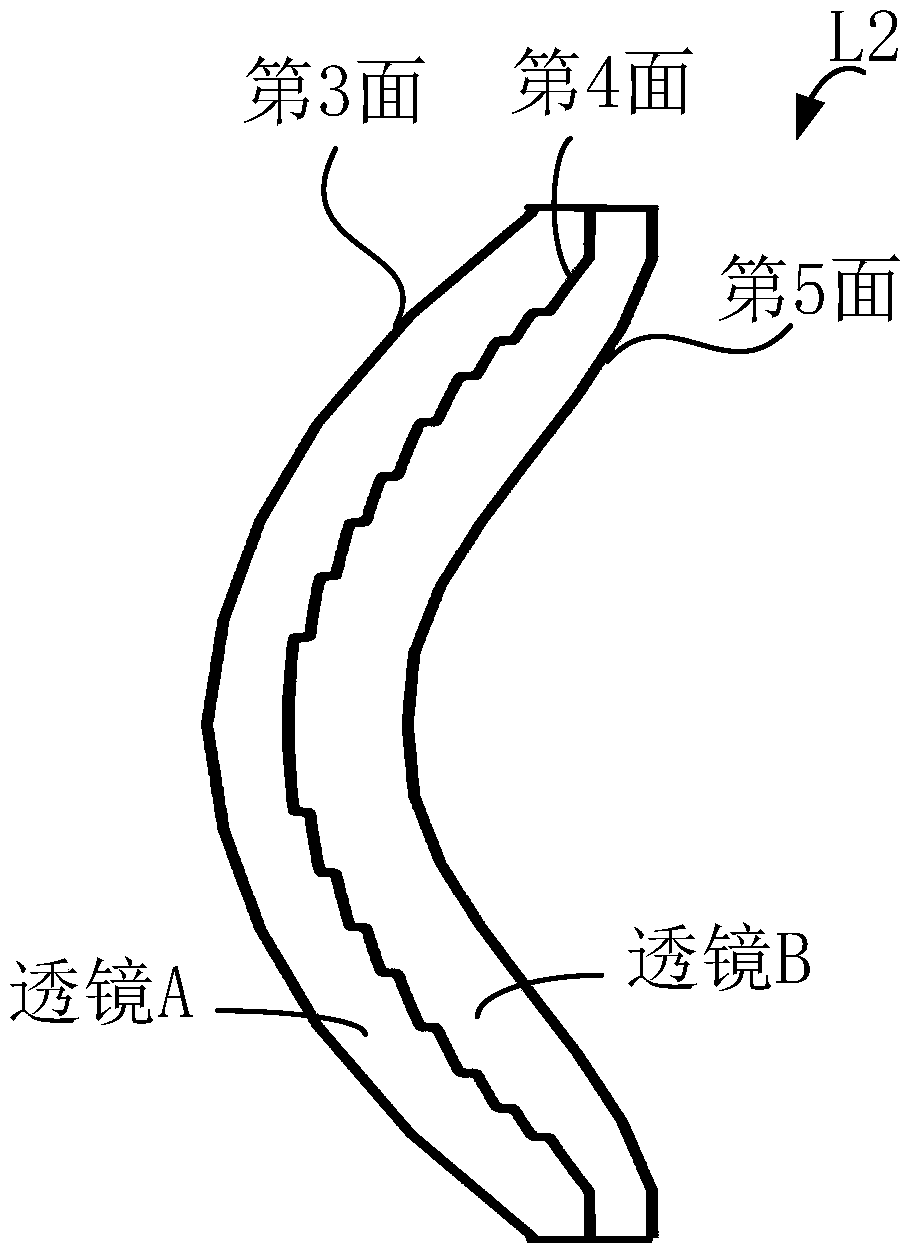

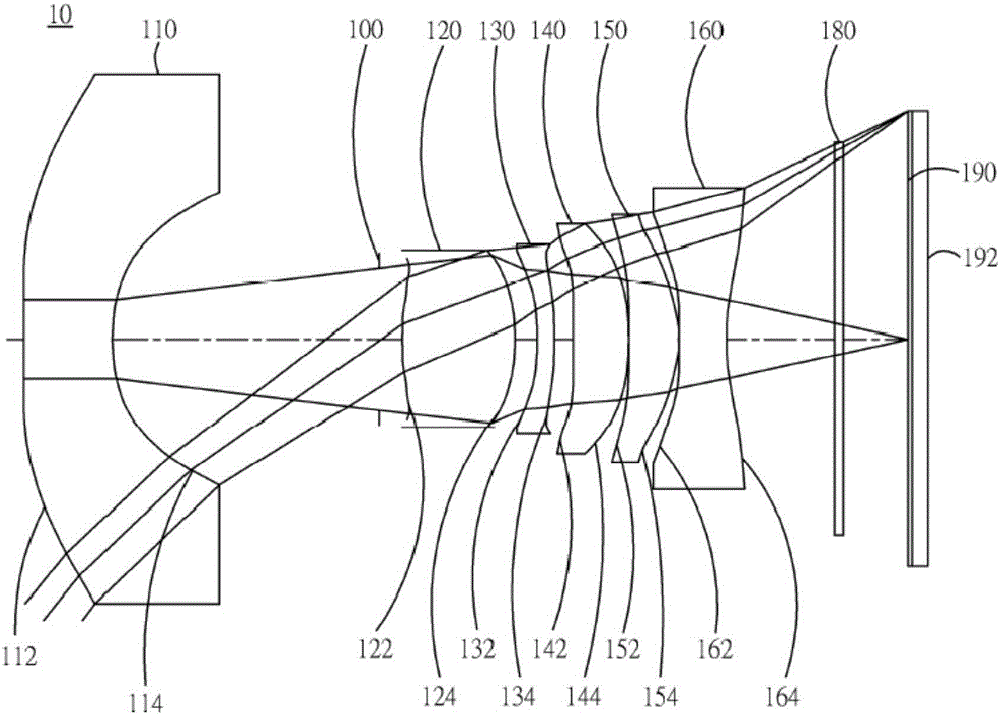

Camera lens, camera module and terminal

ActiveCN109031592AImprove image qualityMeet miniaturization needsTelevision system detailsColor television detailsCamera lensSize increase

The application provides a camera lens, a camera module, and a terminal. The camera lens includes a first lens, a diffractive optical element, and a lens module along an optical axis from the object surface to the image surface; the surface of the first lens facing the object surface is a convex surface at the optical axis, and the surface facing the image surface is a concave surface, having a positive focal power; the diffractive optical element has a positive focal power and includes a surface facing the object surface, a surface facing the image surface, and a diffractive surface between the two surfaces, the surface facing the object surface is a convex surface at the optical axis, and the surface facing the image surface is a concave surface at the optical axis; the lens module includes N lenses, at least one of the surface facing the object surface and the surface facing the image surface of each of the N lenses is an aspheric surface, and the lens module has a positive focal power. The camera lens provided by the application can meet the requirements of miniaturization and high image quality, and meet the demand for size increase of the image sensor.

Owner:HUAWEI TECH CO LTD

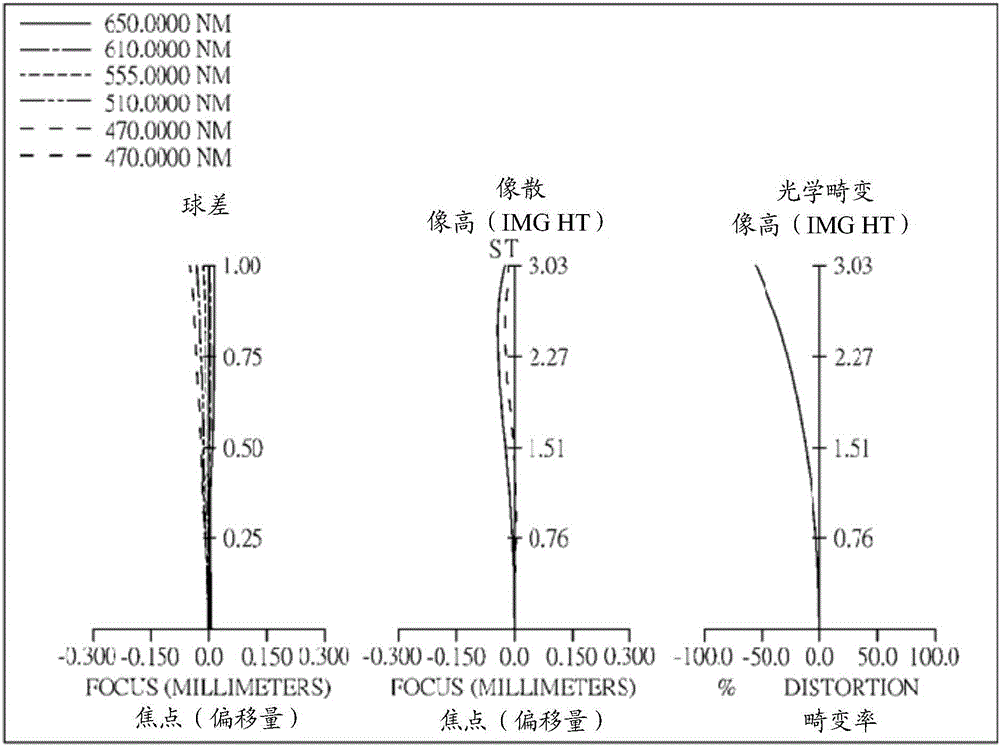

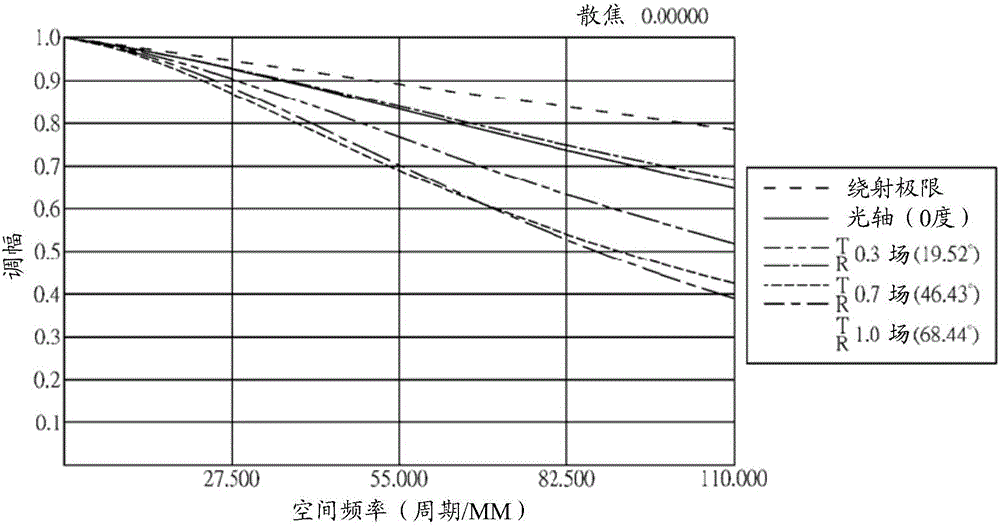

Optical image capturing system

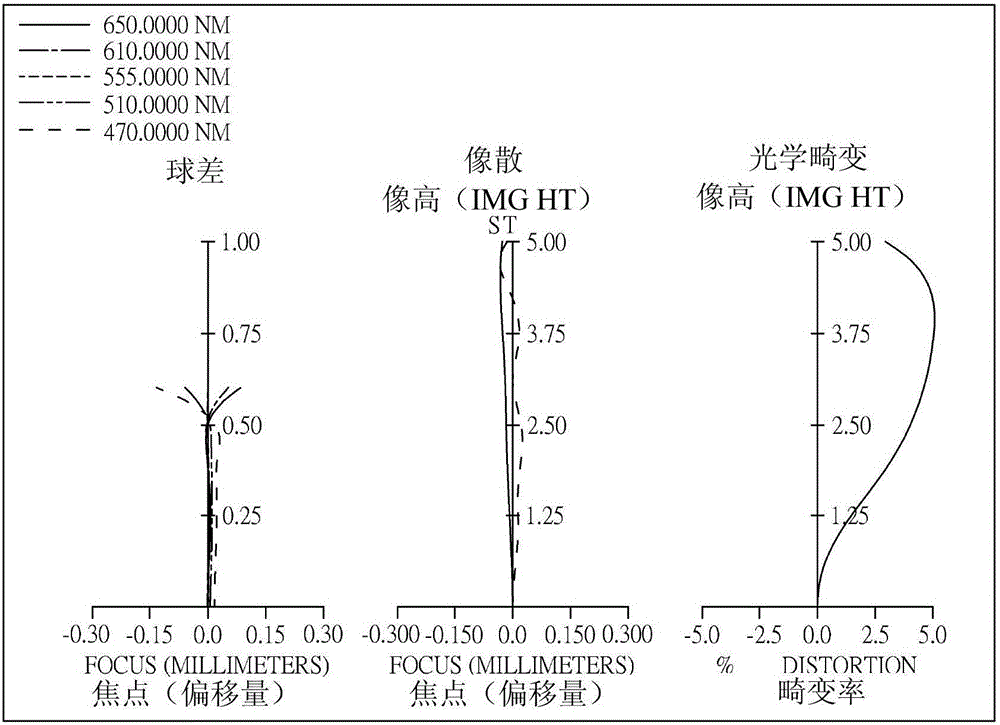

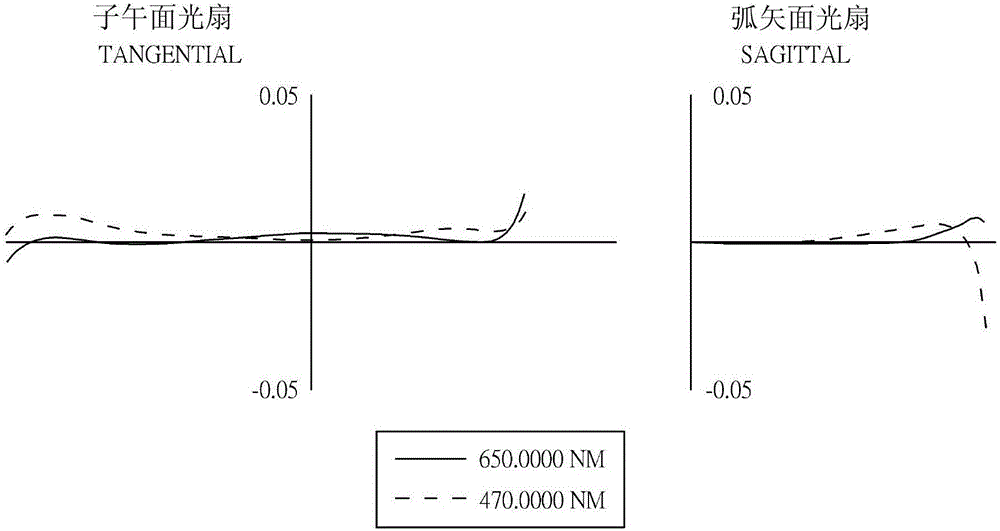

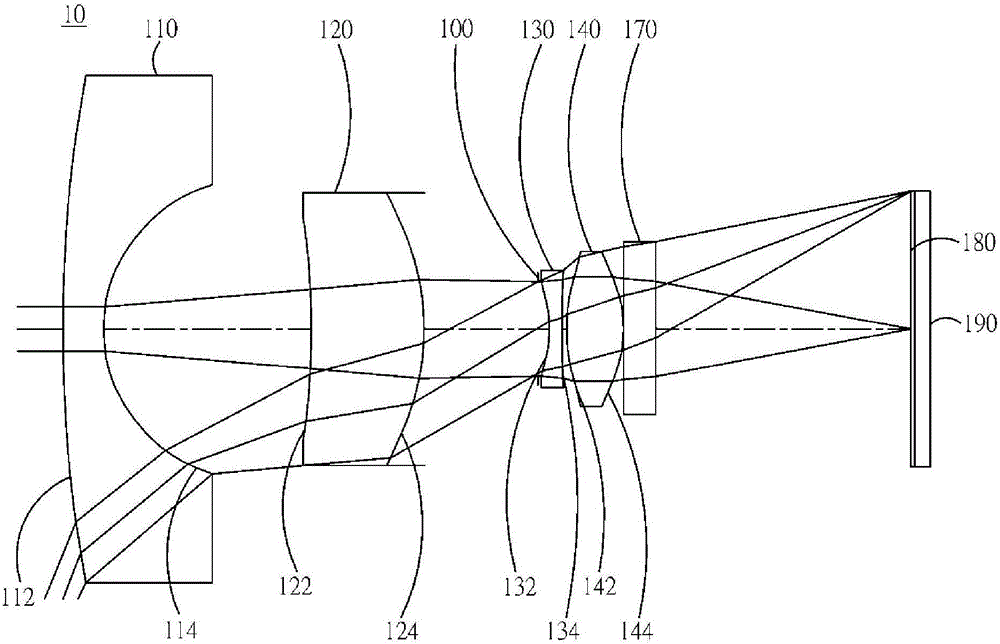

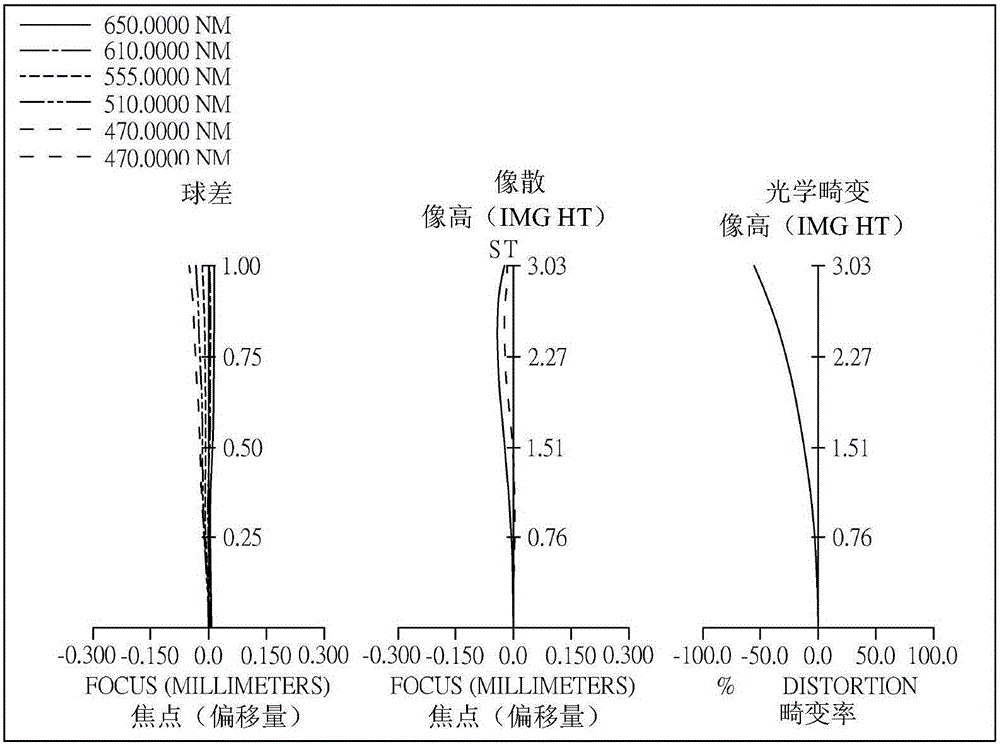

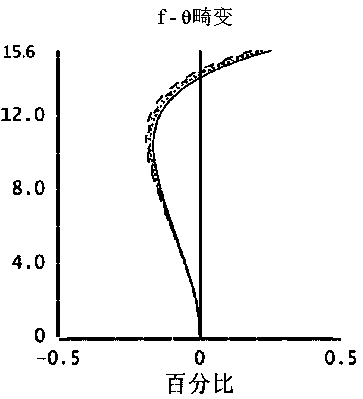

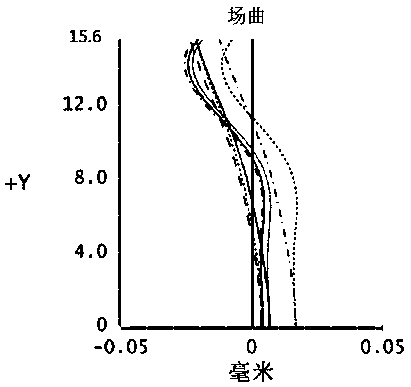

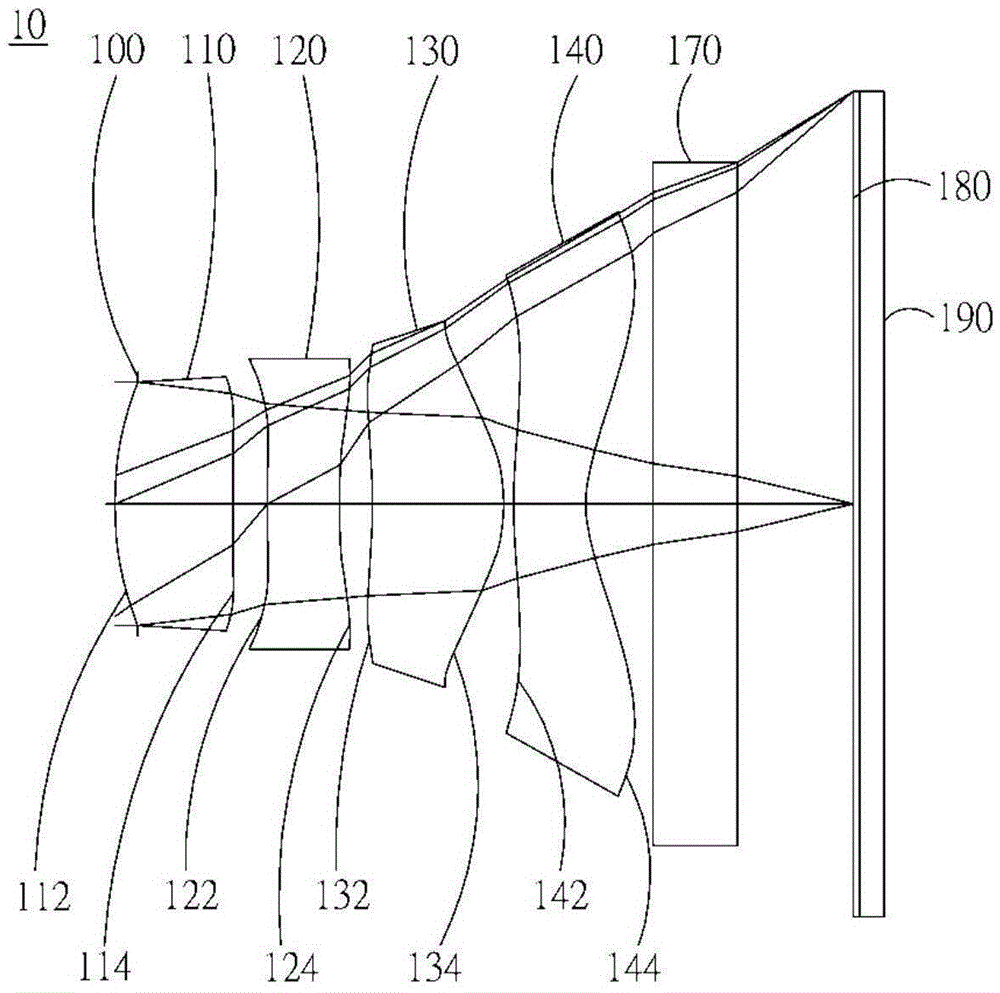

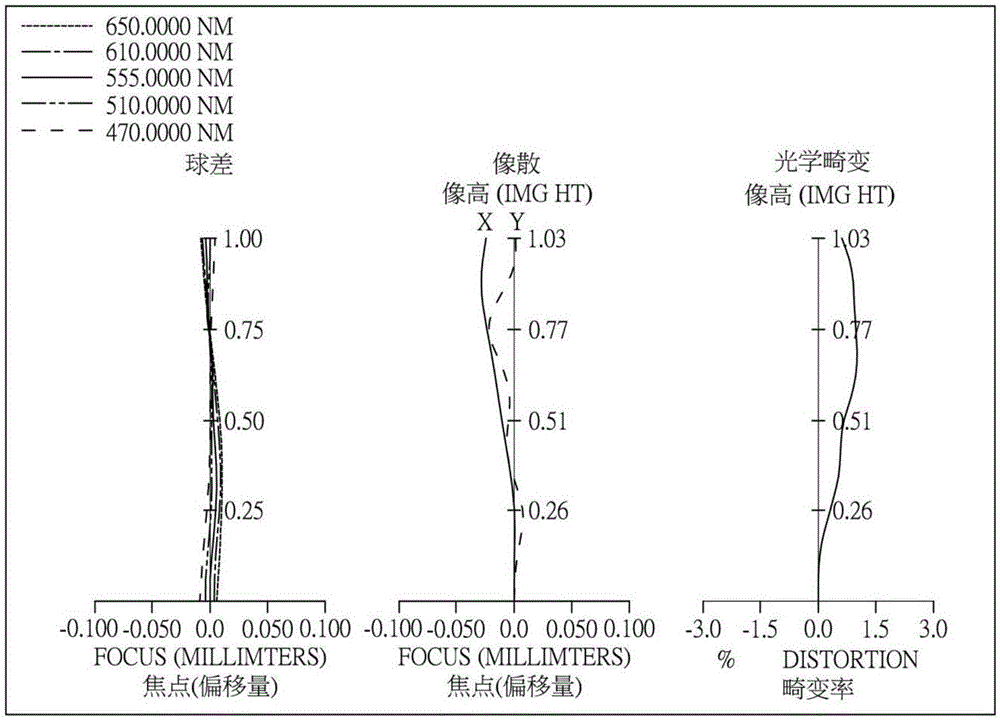

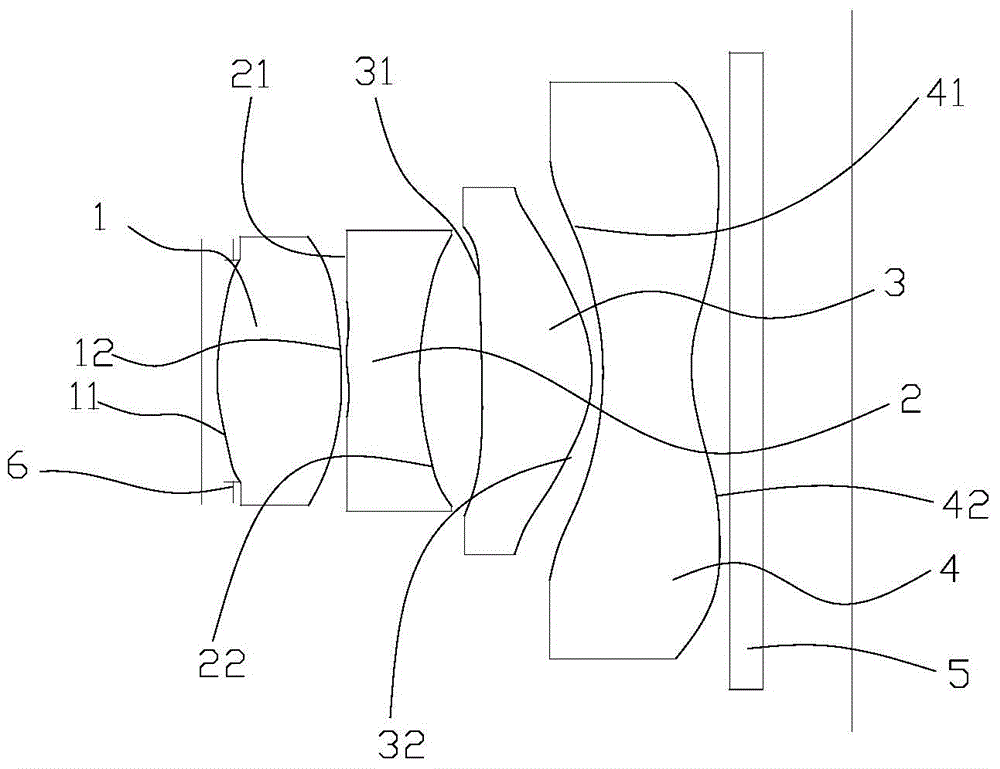

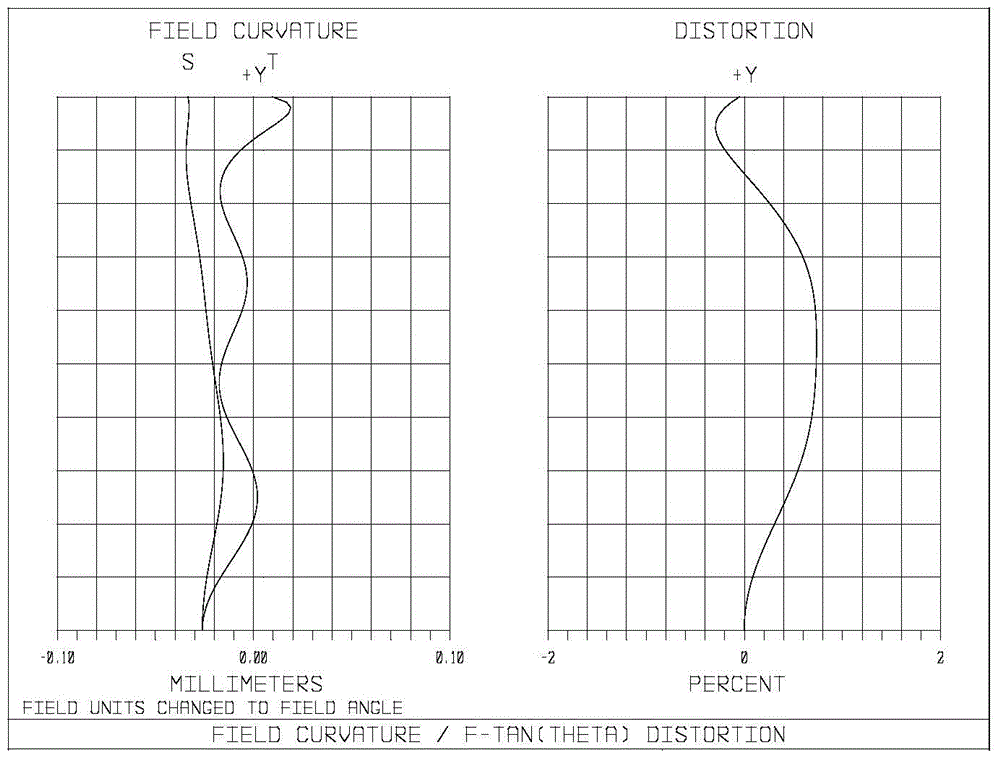

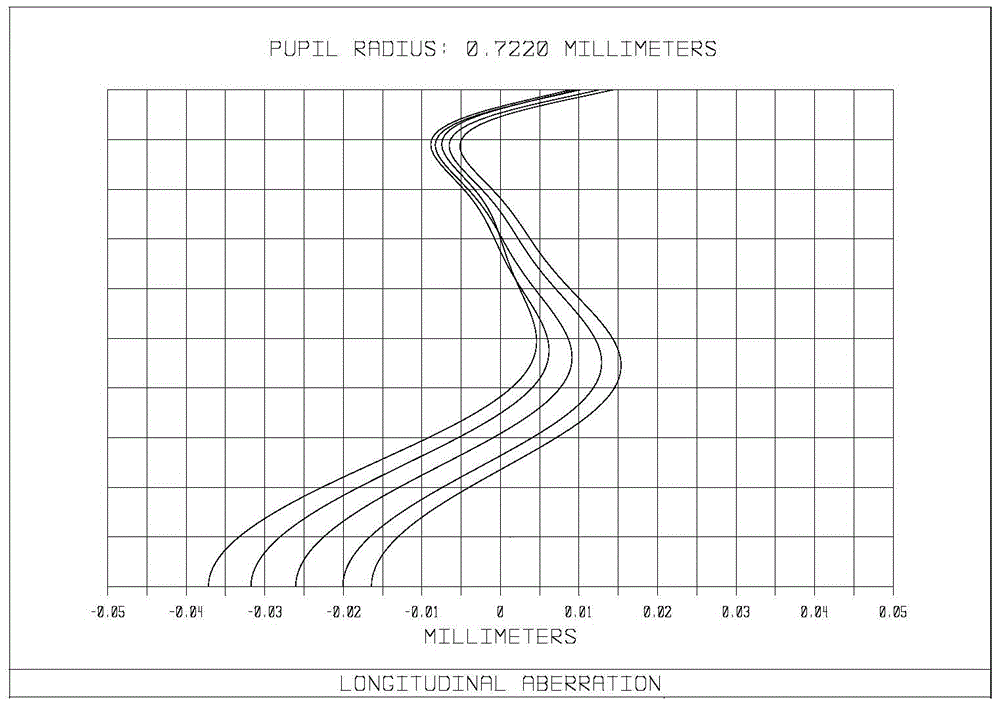

ActiveCN106443964AIncrease the amount of incoming lightImprove image qualityOptical elementsImaging qualityImage quality

The invention discloses an optical image capturing system. The first lens, the second lens, the third lens, the fourth lens, the fifth lens, and the sixth lens are sequentially included from the object side to the image side. At least one of the first lens to the fifth lens has a positive refractive power. The sixth lens may have a negative refractive power, both surfaces being aspherical, wherein at least one surface of the sixth lens has a counter-point. The lens with the refractive power in the optical imaging system is the first lens to the sixth lens. When the specific conditions are met, it is possible to have greater light collection and better optical path adjustment capability to improve the image quality.

Owner:ABILITY OPTO ELECTRONICS TECH

Optical image capturing system

ActiveCN105425361AEffectively adjust the angleGood light path adjustment abilityOptical elementsImaging qualityPhysics

The present invention discloses an optical image capturing system, comprising, from an object side to an image side, a first lens with positive refractive power having a convex object-side surface; a second lens with refractive power; a third lens with refractive power; a fourth lens with refractive power; a fifth lens with refractive power; and a sixth lens with negative refractive power having a concave image-side surface, wherein both surfaces of the all lenses are aspheric surfaces, and at least one surface of the sixth lens has an inflection point. In the optical image capturing system, the first to sixth lenses have refractive power. When a specific condition is met, a greater light receiving ability and a better optical path adjusting ability are achieved, so as to improve imaging quality.

Owner:ABILITY OPTO ELECTRONICS TECH

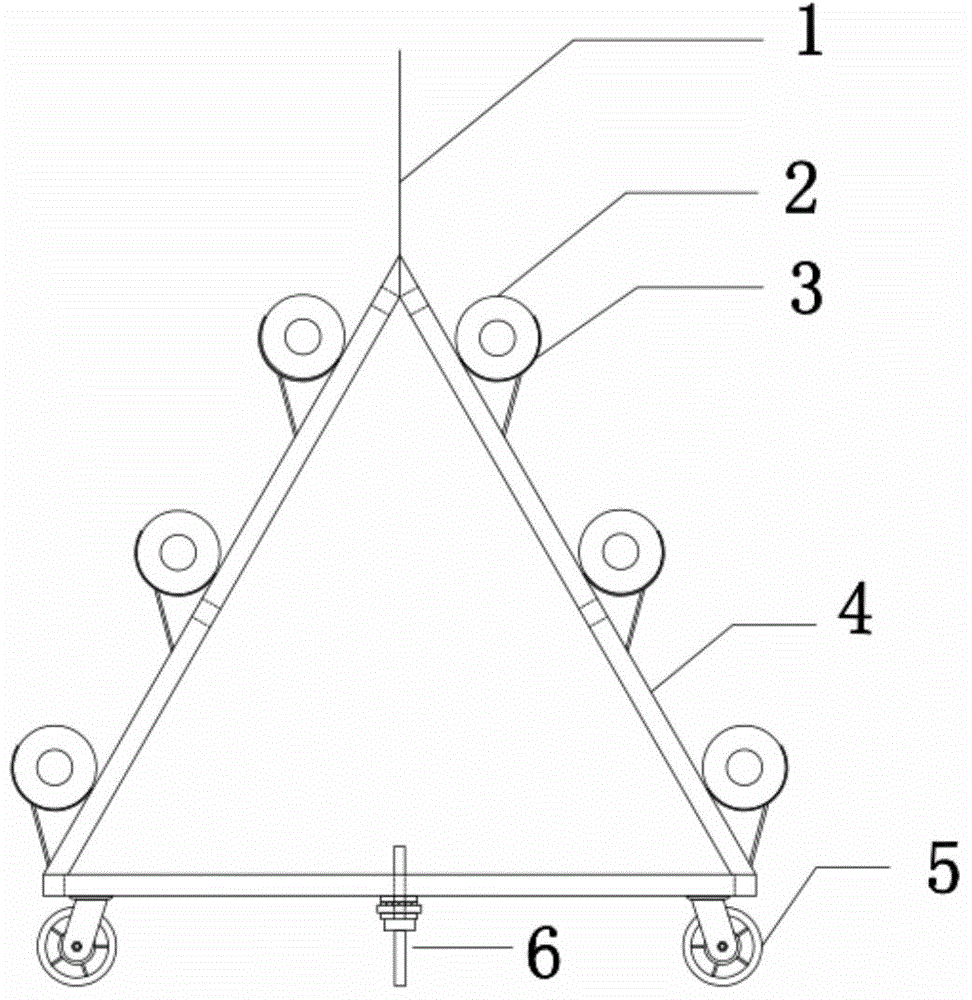

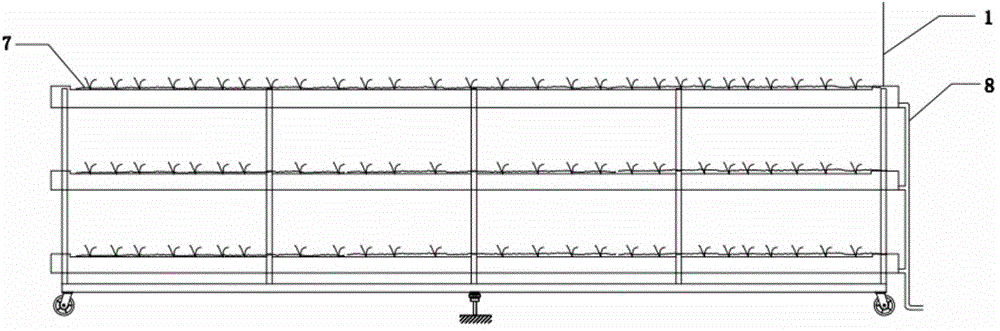

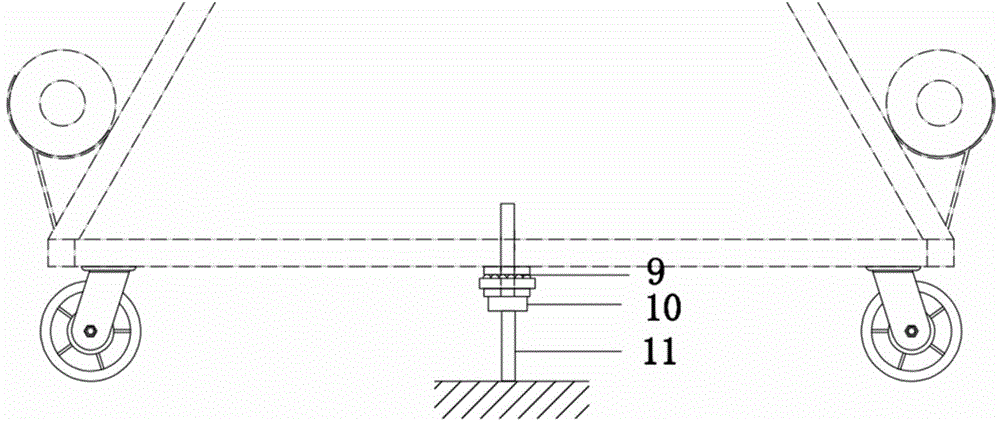

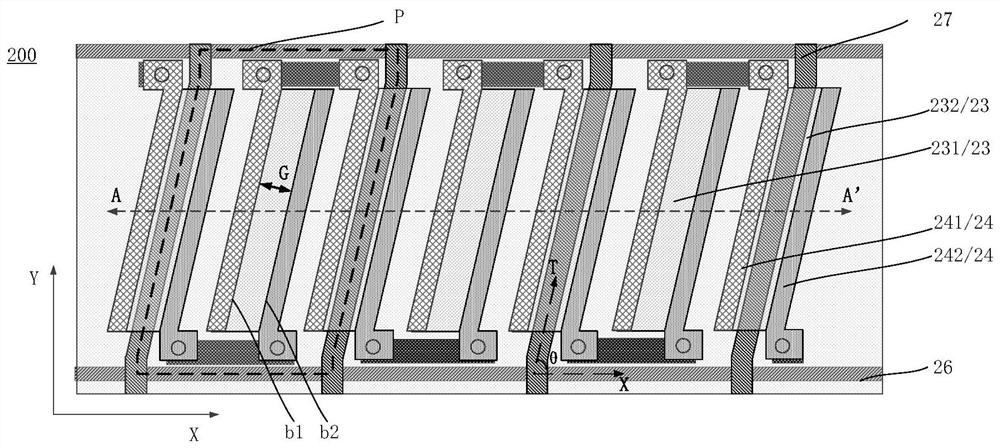

Automatic sun-oriented multiplayer stereoscopic strawberry cultivation system and application method thereof

InactiveCN104429699APromote photosynthesisIncrease productionAgriculture gas emission reductionCultivating equipmentsAutomatic controlGreenhouse

The invention relates to a cultivation system, in particular to a sun-oriented multiplayer stereoscopic strawberry cultivation system capable of automatically rotating and particularly provides an automatically-rotatable automatic sun-oriented multiplayer stereoscopic strawberry cultivation system and an application method thereof. According to local longitude and latitude of a greenhouse and changes of solar azimuth in main lighting time in a day, an automatic control cabinet controls a motor in different lighting time periods to drive a crank connecting rod to rotate a cultivation frame by a reasonable angle to enable strawberries to be exposed to sunlight to the greatest extent, so that the problems about lighting uniformity and shading are solved. The automatic sun-oriented multiplayer stereoscopic strawberry cultivation system has the advantages that light inlet quantity of the cultivation system is increased effectively, photosynthesis of the strawberries can be improved effectively, yield can be increased and quality can be improved; the strawberry cultivation system is simple in structure and low in cost, and the adjusting process is controlled completely automatically, so that labor is saved greatly, simplicity and convenience in operation are achieved, operation effect is good, and energy conservation and practicability are realized.

Owner:CHINA AGRI UNIV

Optical image capturing system

ActiveCN106324801AEasy to adjustEffectively adjust the angleOptical elementsOphthalmologyImaging quality

An optical image capturing system, sequentially including a first lens element, a second lens element, a third lens element and a fourth lens element from an object side to an image side, is disclosed. The first lens element has negative refractive power, and the object side may be convex. The second through third lens elements have refractive power. Two surfaces of said lenses can be aspheric surfaces. The fourth lens element has positive refractive power, and two surfaces thereof are aspheric surfaces. At least one surface of the fourth lens has an inflection point. The first to fourth lenses of the optical image capturing system have refractive power. If all specific conditions are satisfied, the optical system can increase light gathering and optical path adjusting ability, thus improving the imagining quality.

Owner:ABILITY OPTO ELECTRONICS TECH

Optical image capturing system

ActiveCN106405791AEffectively adjust the angleGood light path adjustment abilityOptical elementsImaging qualityPhysics

An optical image capturing system sequentially comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens from the object side to the image side. At least one of the first lens, the second lens, the third lens, the fourth lens and the fifth lens has positive refractive power. The sixth lens can have negative refractive power, and two surfaces of the sixth lens are aspheric surfaces. At least one surface of the sixth lens has inflection points. The first lens, the second lens, the third lens, the fourth lens, the fifth lens and the sixth lens in the optical image capturing system have refractive power. When a specified condition is satisfied, the optical image capturing system has a better light-receiving and optical path adjusting capacity, thereby improving the imaging quality.

Owner:ABILITY OPTO ELECTRONICS TECH

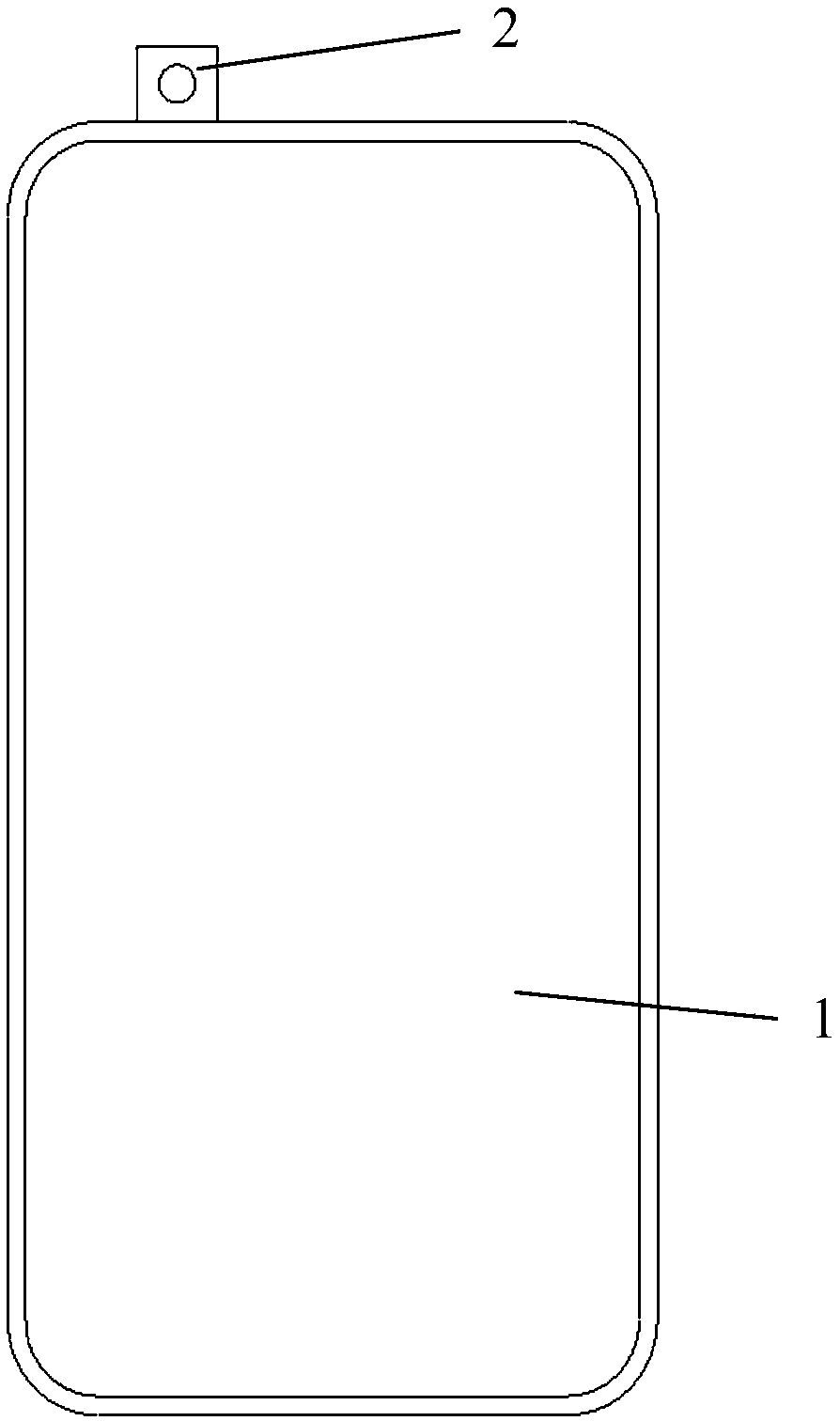

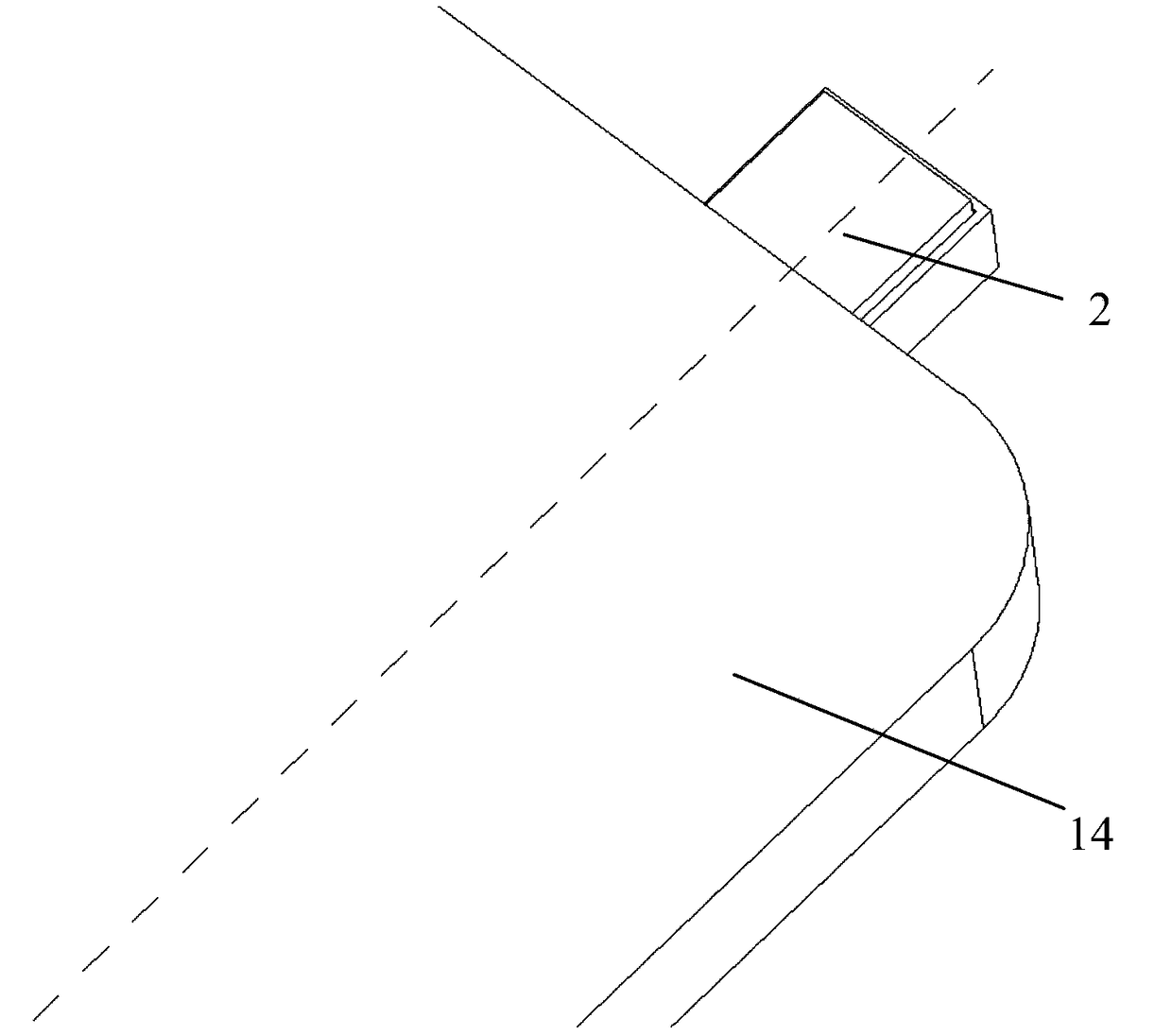

A mobile terminal and a photographing control method

ActiveCN109040538AReduce the overall heightIncrease the amount of incoming lightTelevision system detailsColor television detailsCamera moduleComputer science

The invention provides a mobile terminal and a photograph control method, wherein the mobile terminal comprises: a housing with a through hole on one side; a camera module comprising a base structure,an optical sensor arranged on the base structure, a camera body and a first moving driving structure connecting the base structure and the camera body. The camera module is connected with the housingthrough a second movement driving structure, wherein the camera module comprises a first state arranged in the interior of the housing and a second state moved relative to the housing and protrudingfrom the housing through the through hole through the second movement driving structure; Through the first moving driving structure, the relative distance between the camera body and the base structure is driven to be larger or smaller, so as to increase the light incoming amount of the lens and improve the shooting effect.

Owner:VIVO MOBILE COMM CO LTD

Optical image capturing system

ActiveCN106353877AEasy to adjustEffectively adjust the angleOptical elementsOptical axisImaging quality

Owner:ABILITY OPTO ELECTRONICS TECH

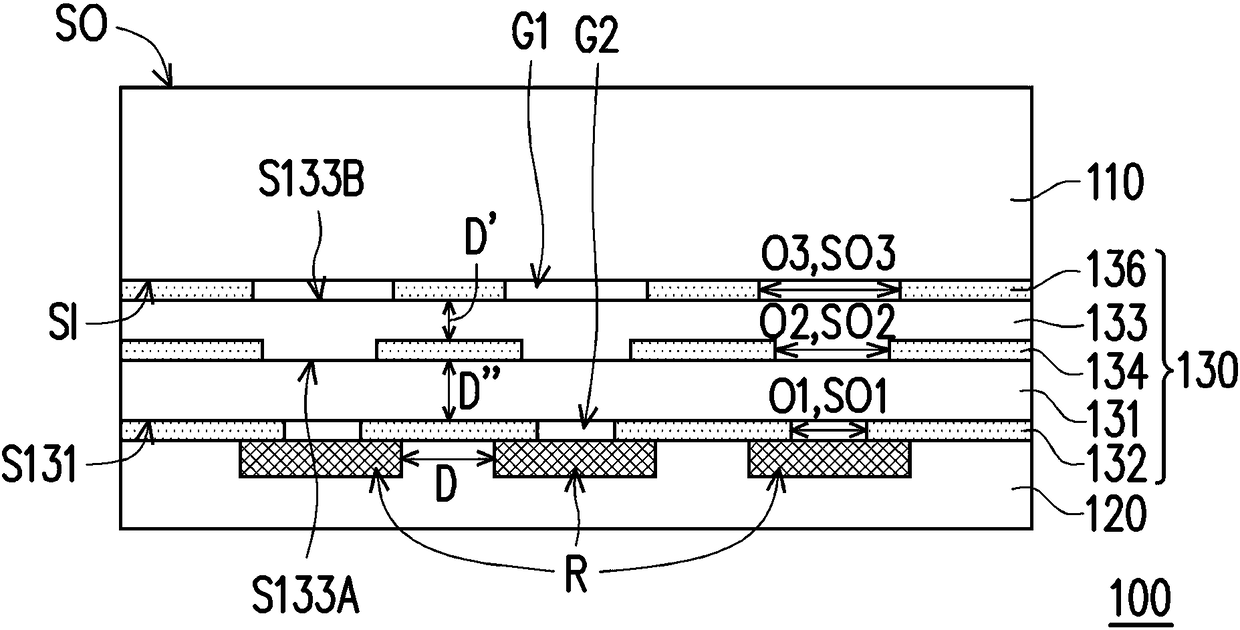

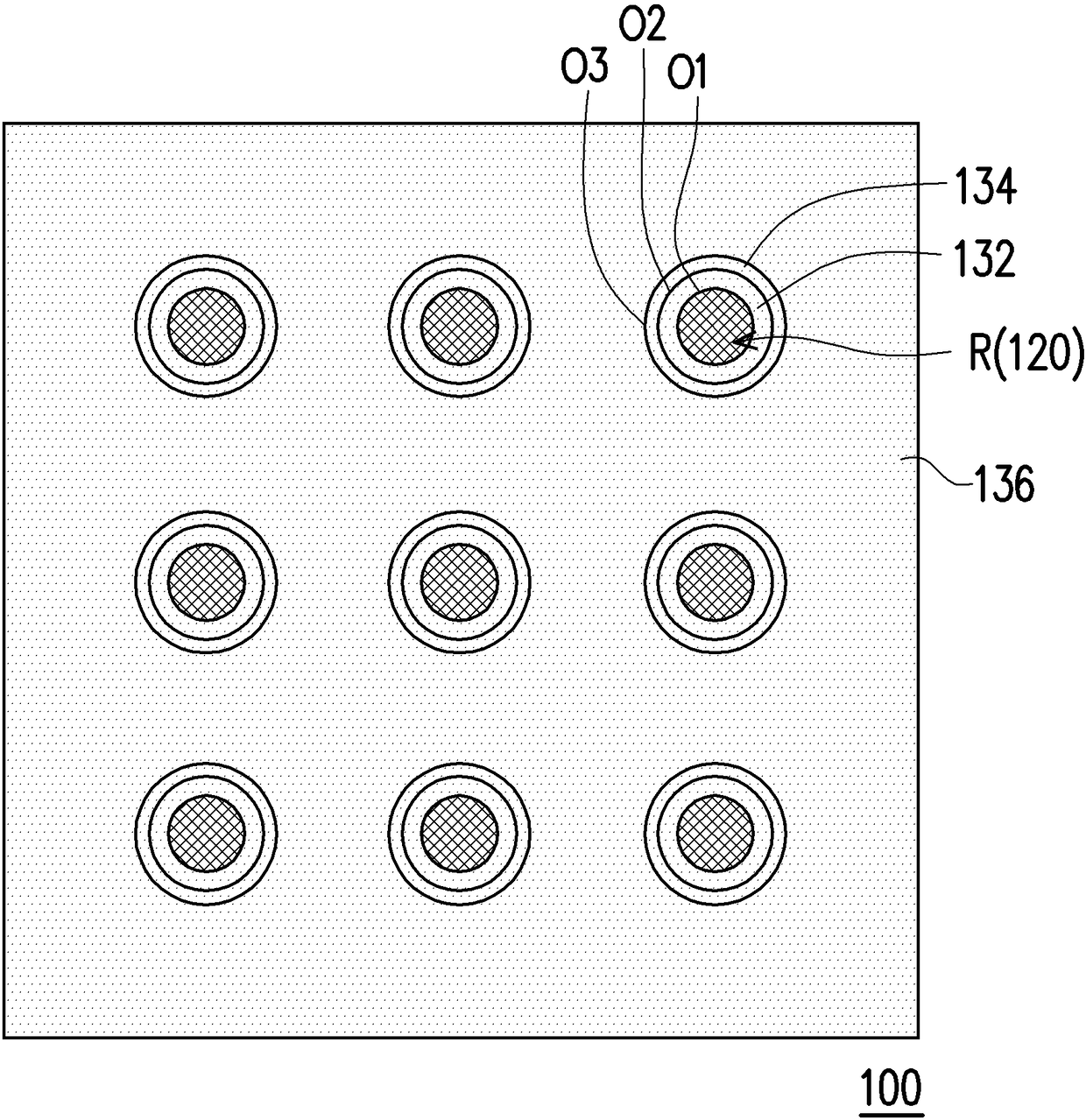

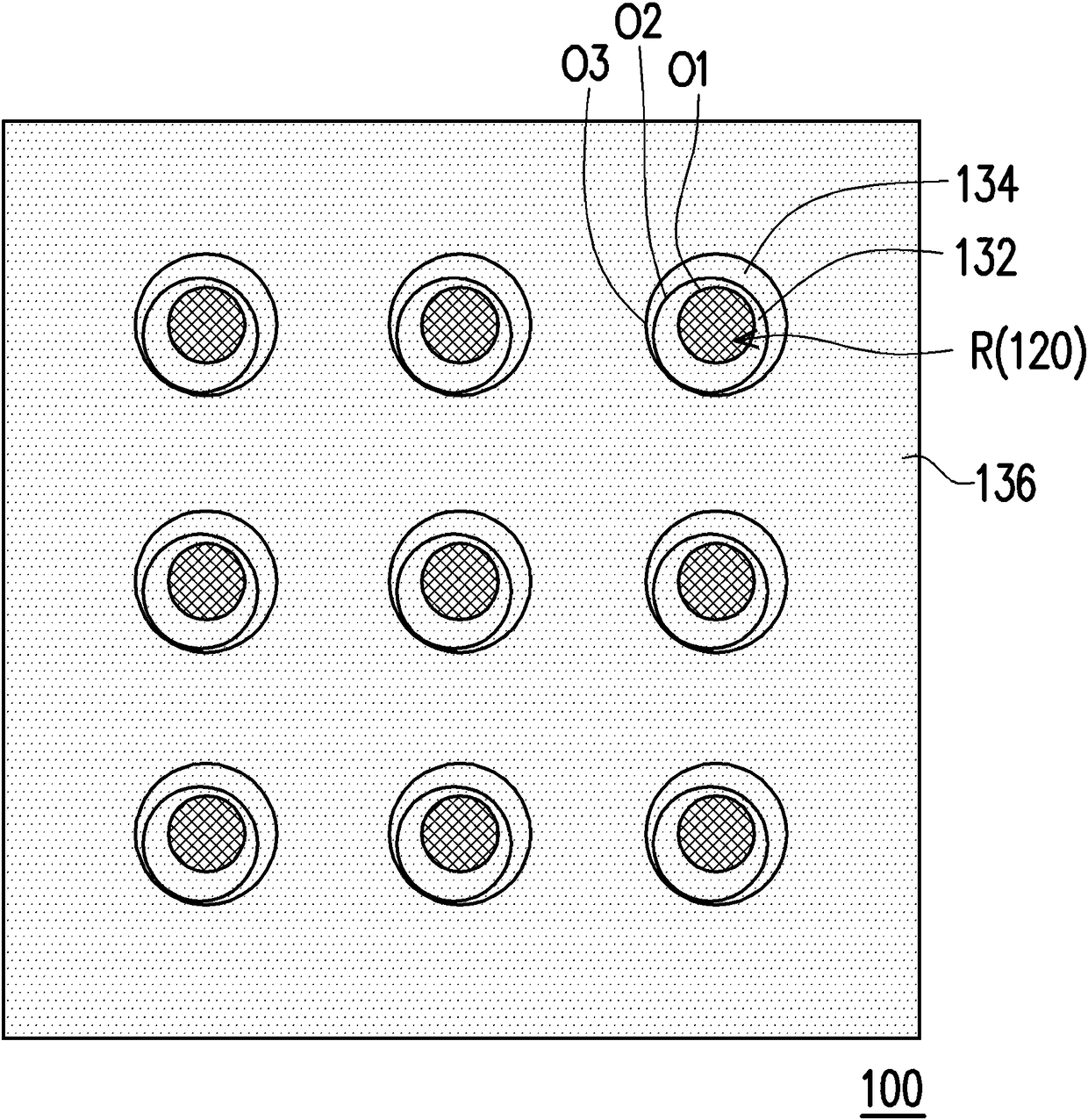

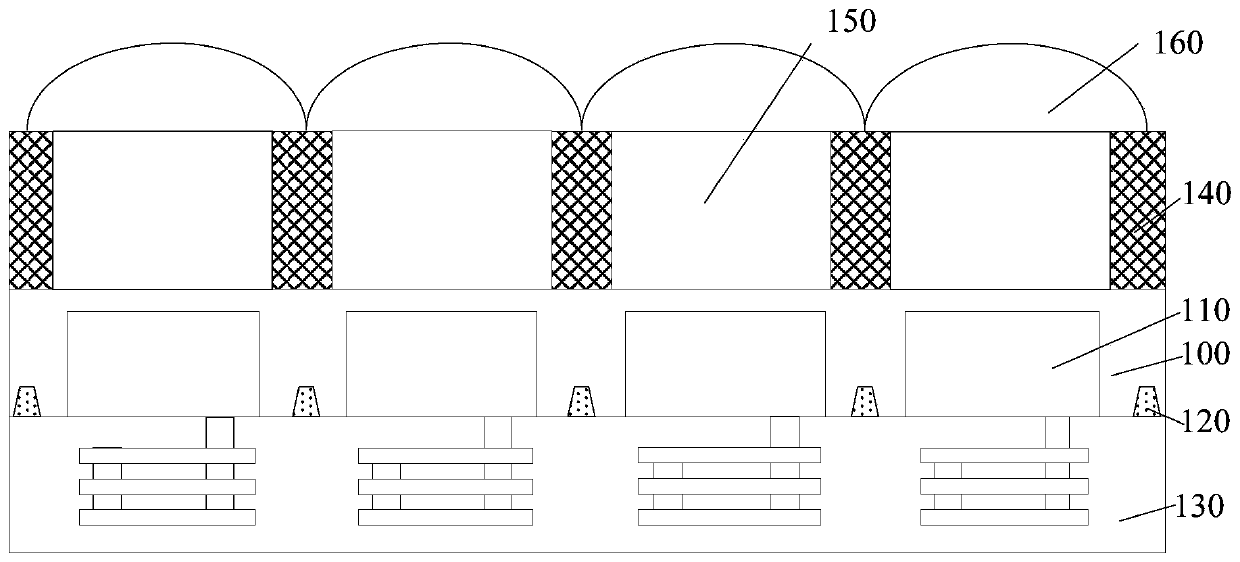

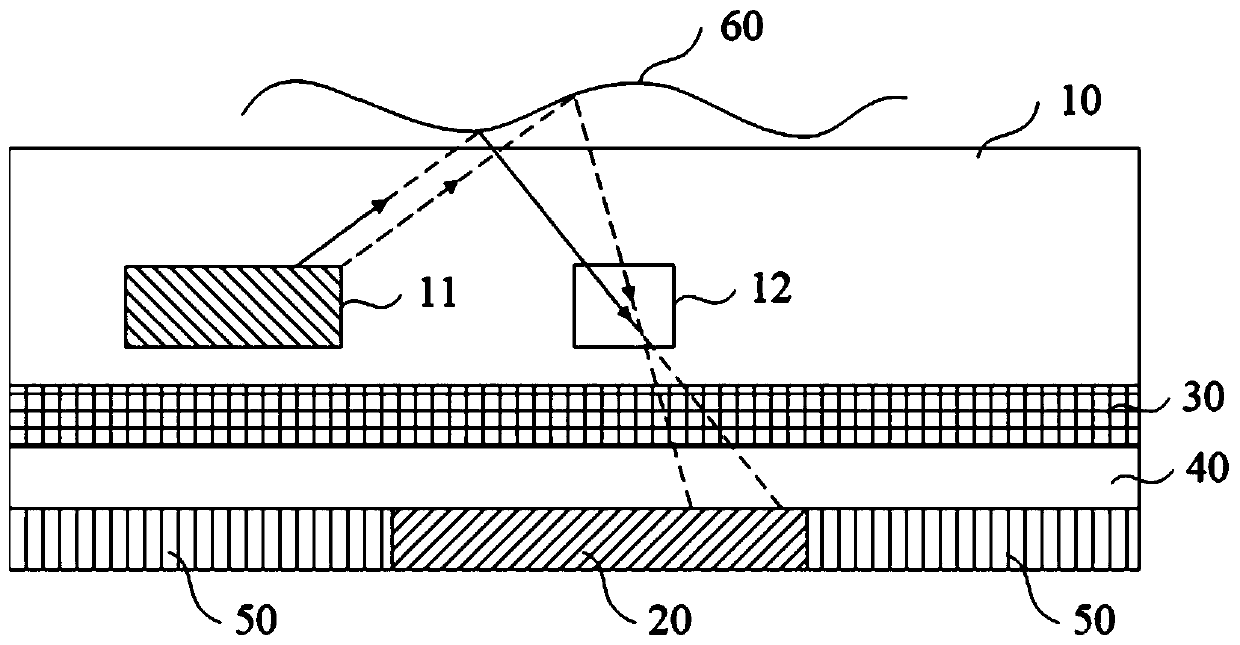

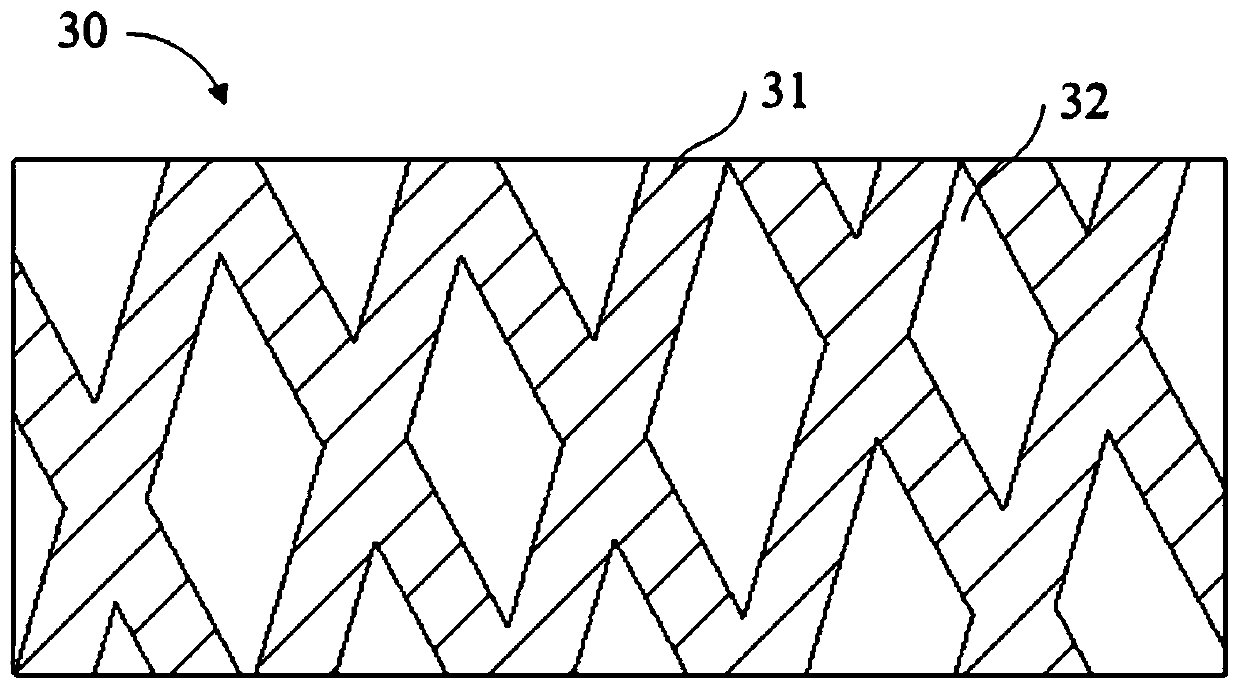

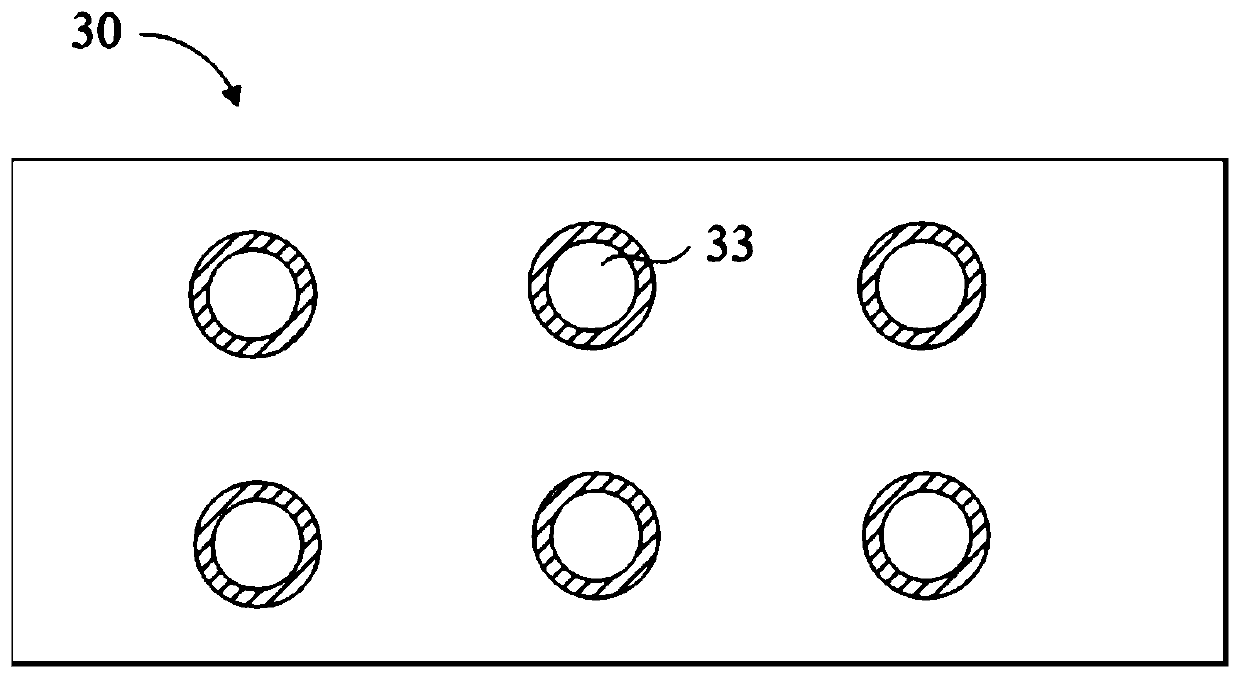

Image capture apparatus

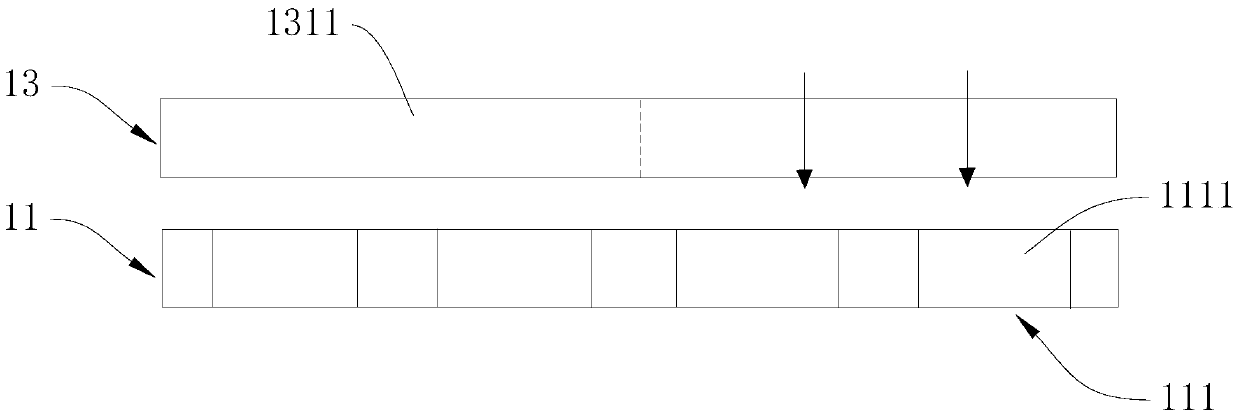

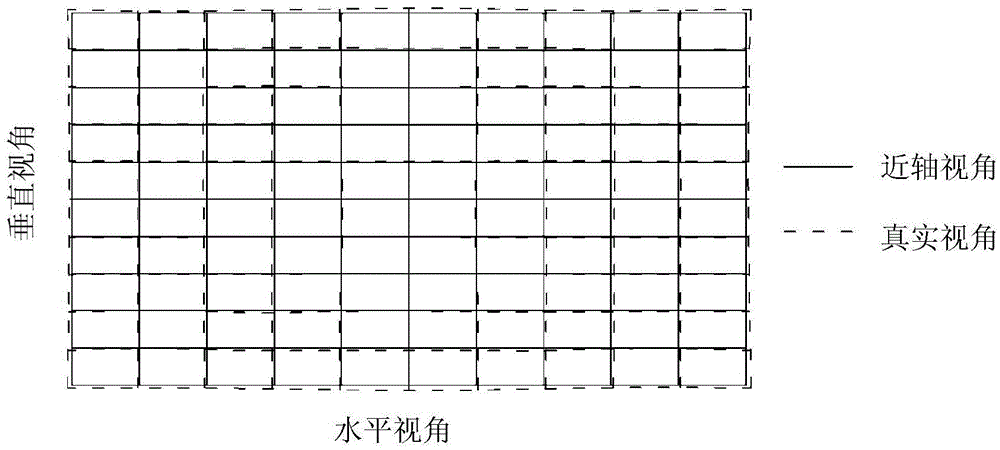

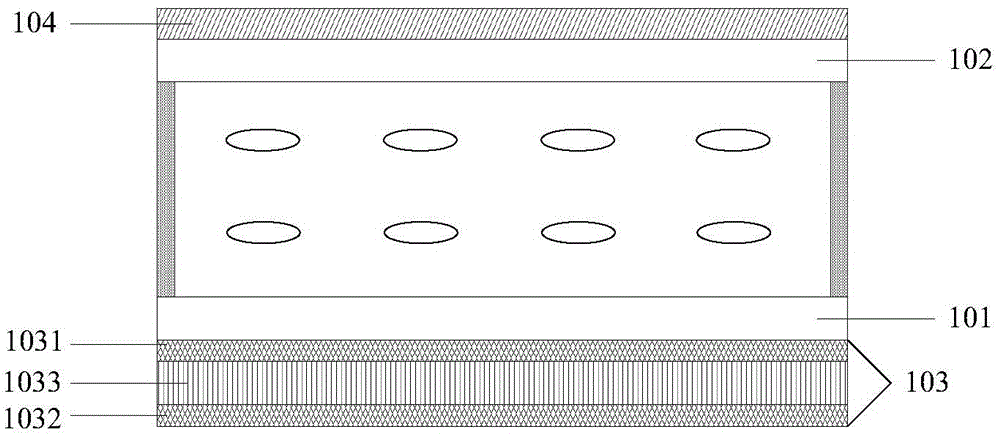

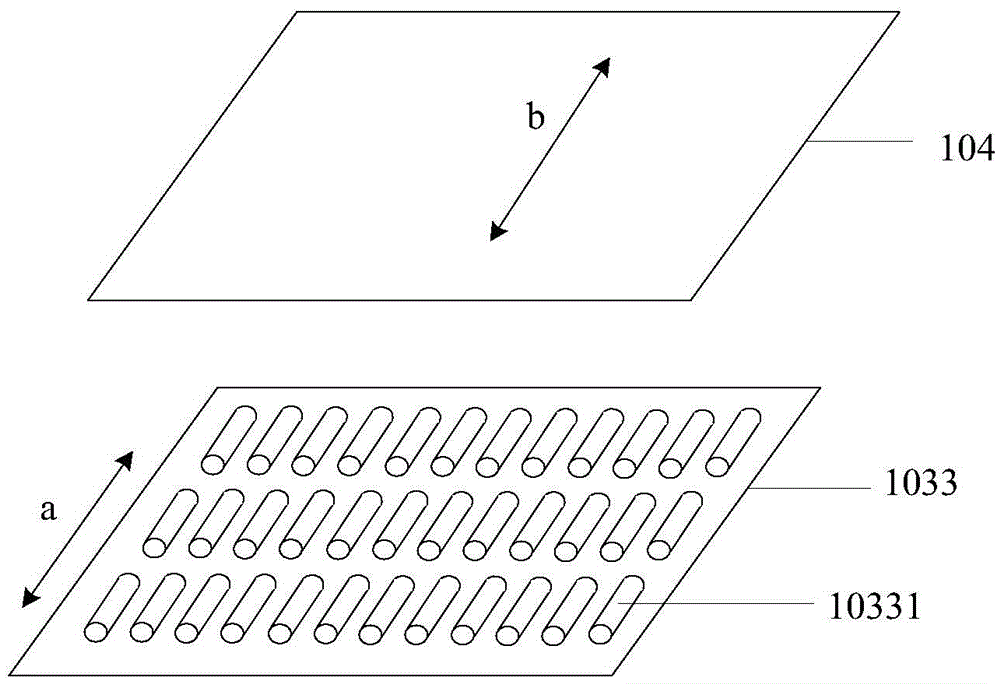

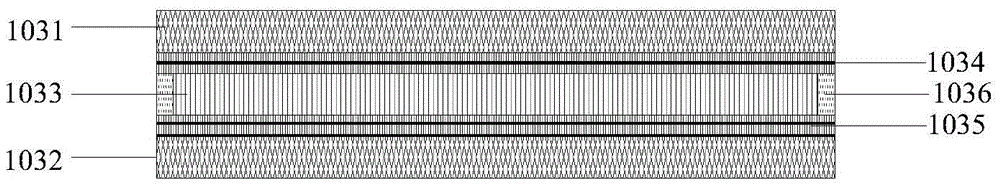

ActiveCN109389108AIncrease the amount of incoming lightIncoming light limitCharacter and pattern recognitionOptical elementsImage captureLight transmission

An image capture apparatus includes a cover plate, a sensor, and an optical collimator. The optical collimator is disposed between the cover plate and the sensor and includes a first light shielding pattern layer, a second light shielding pattern layer, and a third light shielding pattern layer that overlap each other. The first, second, and third light shielding pattern layers respectively have aplurality of first, second, and third light transmission openings. The size of each of the third light transmission openings is greater than or equal to the size of each of the second light transmission openings, and the size of each of the second light transmission openings is larger than the size of each of the first light transmission openings. Alternatively, the size of each of the third light transmission openings is larger than the size of each of the second light transmission openings, and the size of each of the second light transmission openings is greater than or equal to the size of each of the first light transmission openings.

Owner:GINGY TECH

Image sensor and forming method thereof

InactiveCN109860219AIncrease the amount of incoming lightImprove performanceRadiation controlled devicesEngineeringImage sensor

The invention discloses an image sensor and a forming method thereof. The method comprises the steps that a substrate is provided, wherein the substrate comprises a pixel region and an isolation region, the pixel region is adjacent to the isolation region, and the isolation region surrounds the pixel region; a photosensitive structure is formed in the pixel region of the substrate; an initial gridlayer is formed on the surface of the isolation region of the substrate, wherein an initial groove exposed out of the pixel region is formed in the initial grid layer; and the side wall of the initial grid layer is thinned, so that a grid layer is formed on the surface of the isolation region, and a groove exposed out of the pixel region is formed in the grid layer. Through the method, the performance of the image sensor is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

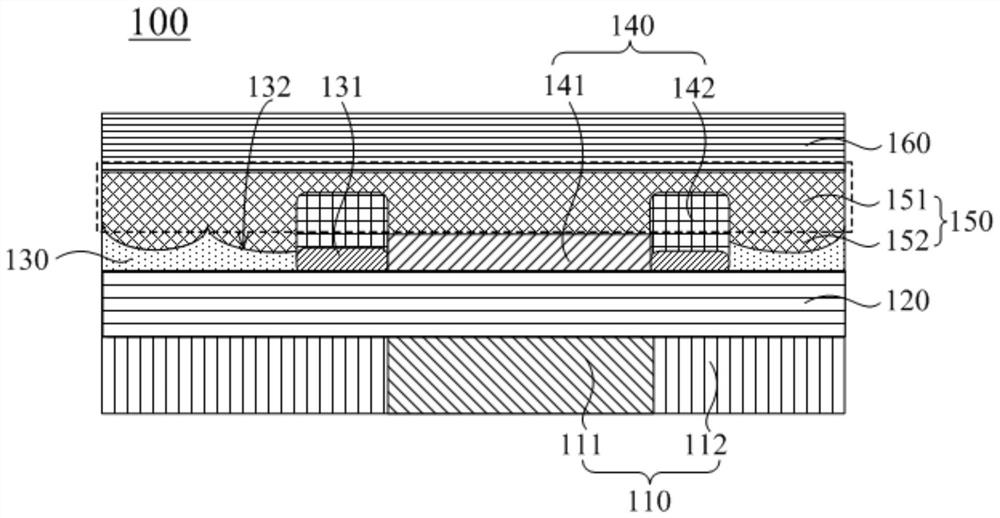

Display panel and display device

ActiveCN113009739AUniform transmittanceImprove transmittanceNon-linear opticsDisplay deviceMaterials science

The invention provides a display panel and a display device. The display panel comprises a first display area, the first display area comprises a plurality of sub-pixel units, a protruding part is arranged in the first display area, the orthographic projection of the protruding part on the display panel is overlapped with the sub-pixel units, the protruding part is provided with a first side edge and a second side edge, a first driving electrode is arranged on the first side edge, and a second driving electrode is arranged on the second side edge; in the same sub-pixel unit, the first driving electrode and the second driving electrode are alternately arranged, and when different potential signals are applied to the first driving electrode and the second driving electrode, a horizontal electric field is formed between the first driving electrode and the second driving electrode; the liquid crystal molecules in the liquid crystal layer rotate in the horizontal electric field, the liquid crystal molecules do not generate obvious periodical inclination and torsion arrangement, the diffraction phenomenon generated by periodical arrangement of light through liquid crystal deflection is greatly weakened, and therefore the imaging effect is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

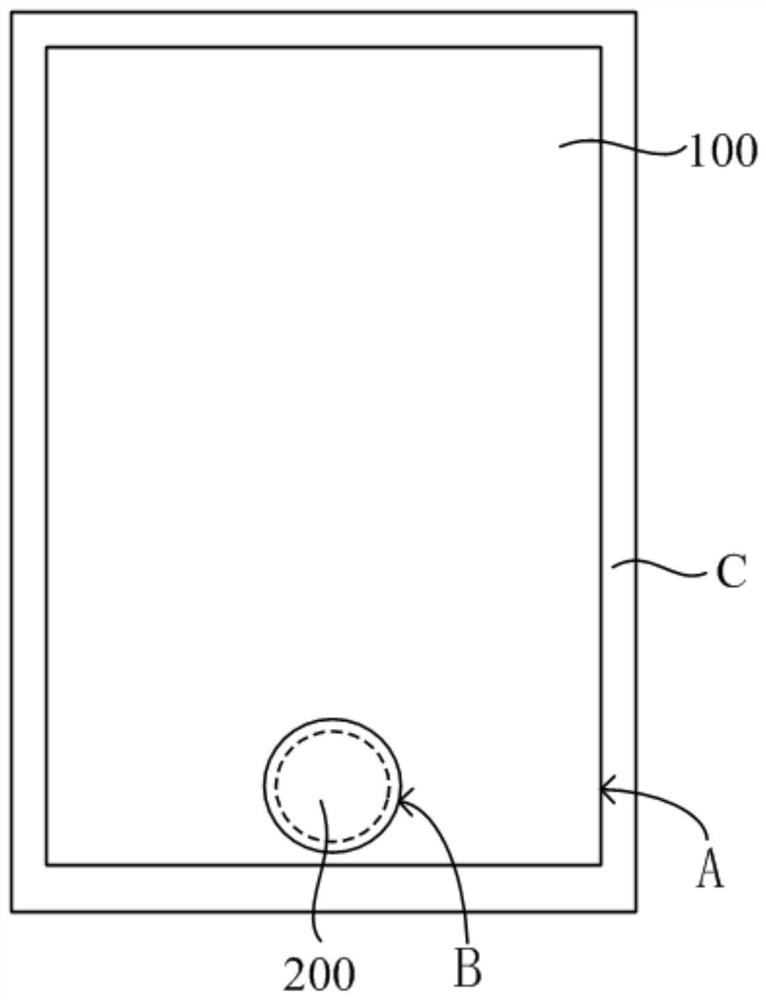

Display device for under-screen fingerprint identification

ActiveCN109712527AImprove flatnessImprove aestheticsCharacter and pattern recognitionIdentification meansDisplay deviceFingerprint

The invention provides a display device for under-screen fingerprint identification. The display device includes a display panel and a fingerprint module, a support layer is arranged between the display panel and the fingerprint module and extends along the joint face of the display panel and the fingerprint module, and at least part of the support player is located at the joint between the display panel and the edge of the fingerprint module. By adopting the display device for under-screen fingerprint identification, pressure generated when the display panel fits the fingerprint module can beeffectively relieved; the situations are avoided that fingerprint module profile impressions appear on the display panel, and the display panel deforms; the surface flatness and attractiveness of thedisplay panel are improved, the light inlet amount of the fingerprint module is increased, and the fingerprint identification accuracy is improved.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Optical Image Capturing System

InactiveCN105589184AEffectively adjust the angleGood light path adjustment abilityOptical elementsImaging qualityPhysics

An optical image capturing system, from an object side to an image side, comprises a first, second, third, fourth, fifth and sixth lens elements. The first through fifth lens elements have refractive power and both of an object-side surface and an image-side surface of the fifth lens elements are aspheric. The sixth lens with negative refractive power may have a concave image-side surface. Both of the image-side surface and the object-side surface of the six lens elements are aspheric and at least one of the two surfaces has inflection points. Each of the six lens elements may have refractive power. When specific conditions are satisfied, the optical image capturing system can have a large aperture value and a better optical path adjusting ability to acquire better imaging quality.

Owner:ABILITY OPTO ELECTRONICS TECH

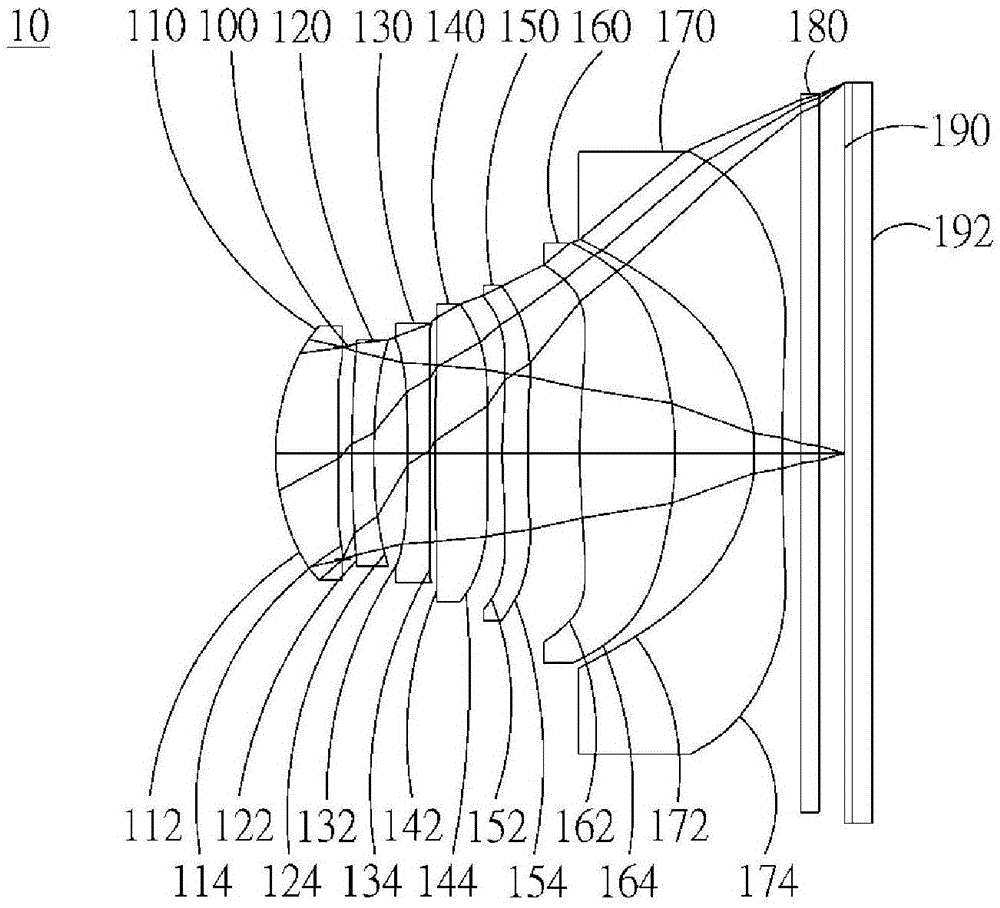

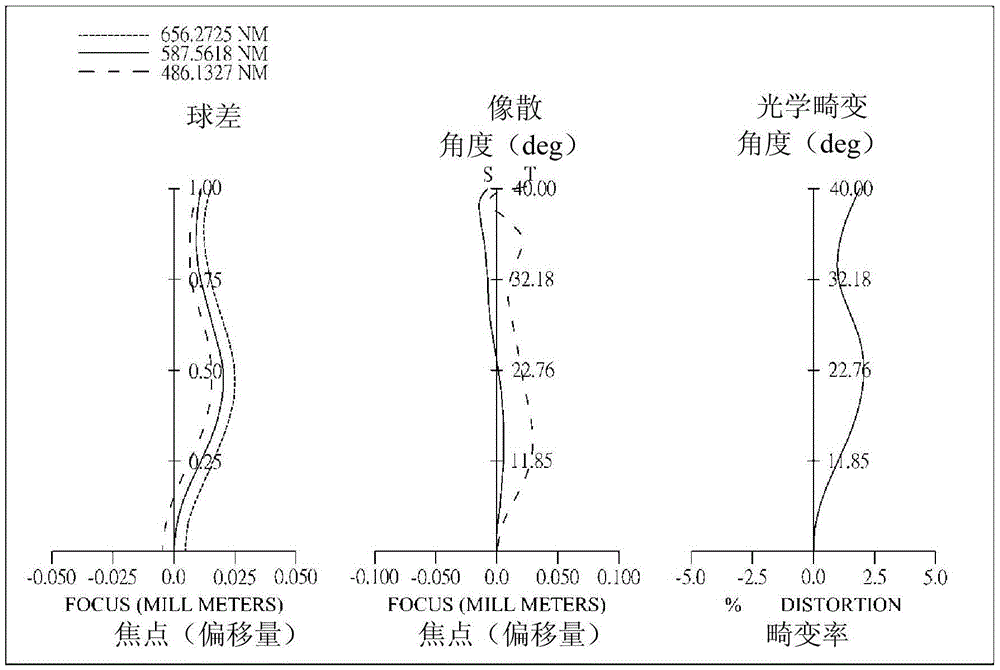

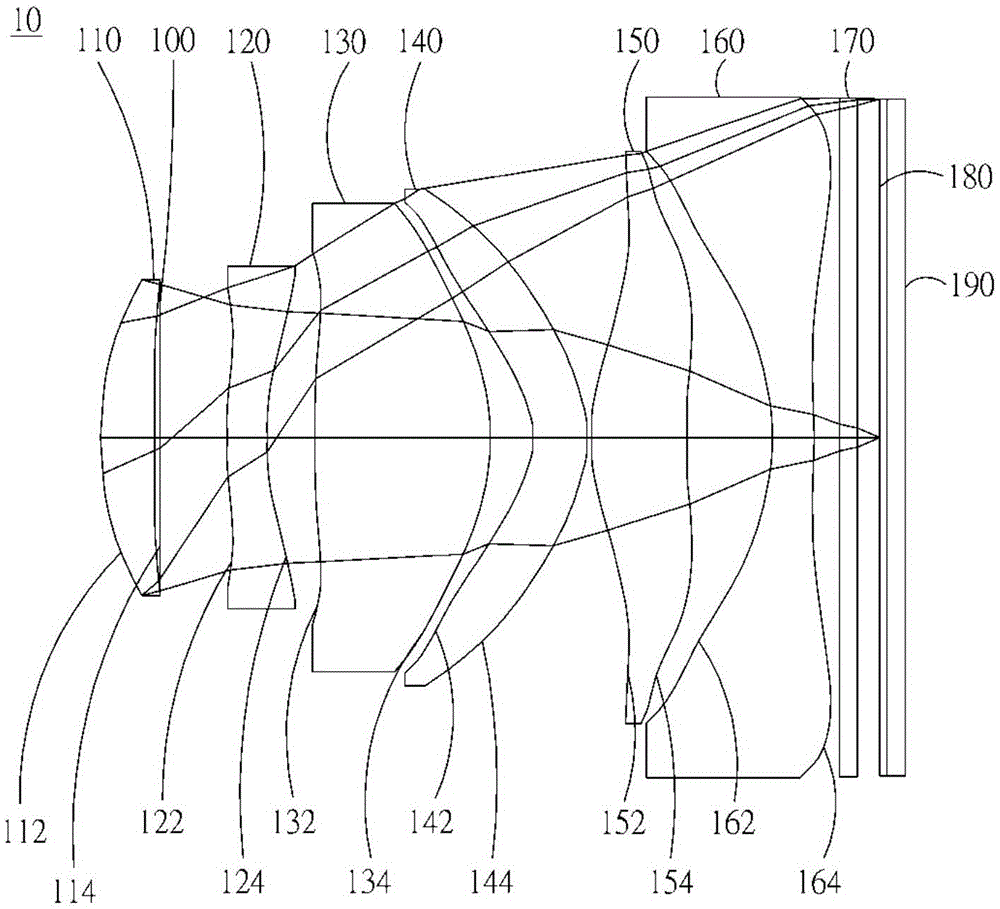

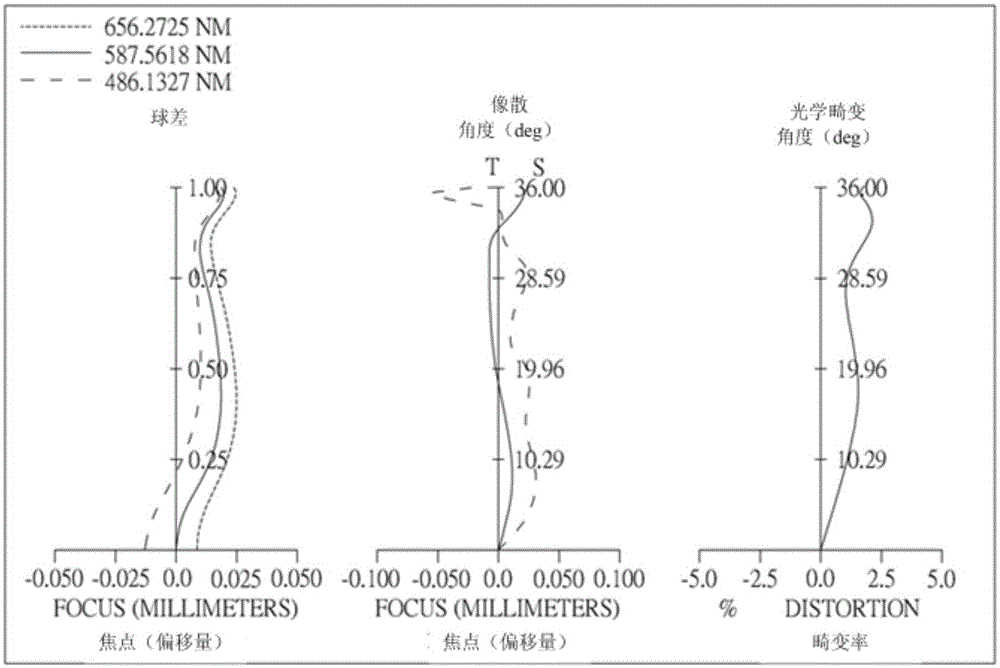

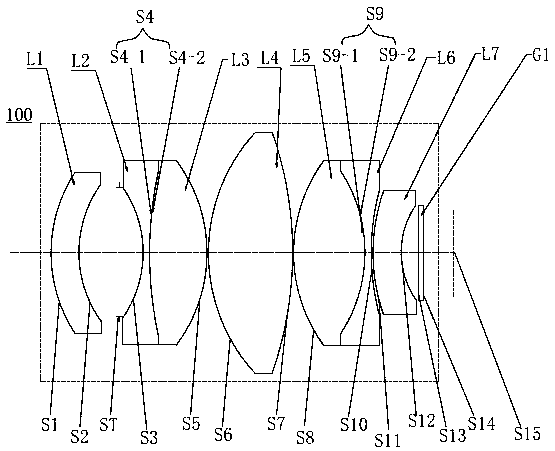

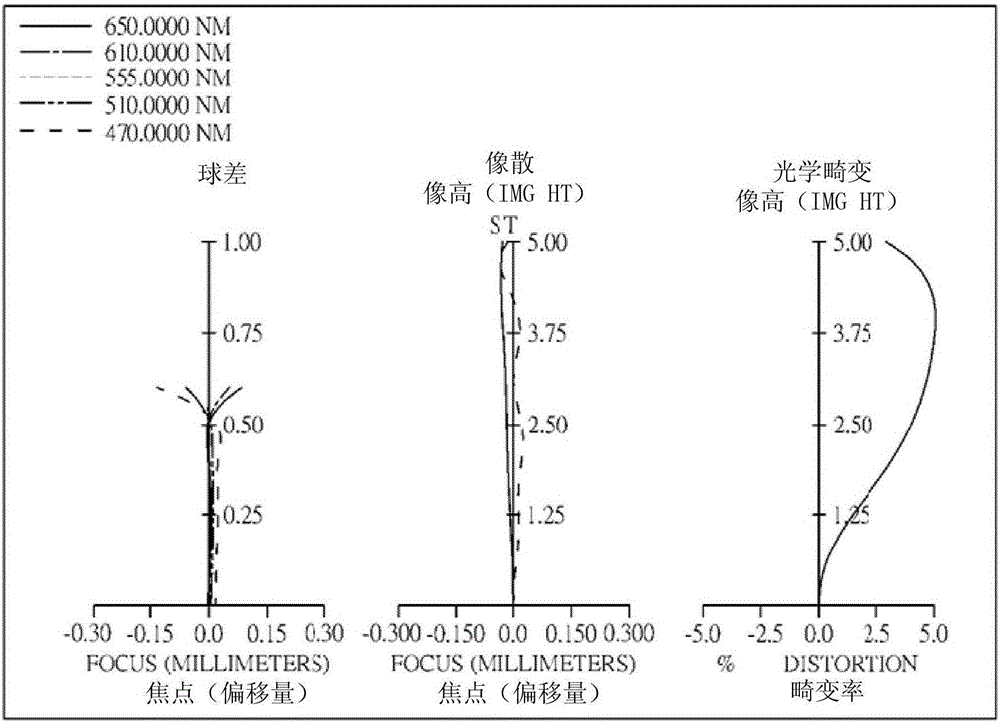

Optical imaging lens and imaging equipment

ActiveCN110632743ACompact structureDimensional ConstraintsOptical elementsCamera lensImage resolution

The invention provides an optical imaging lens and imaging equipment, and the optical imaging lens comprises, in order from the object side to the image side, the following parts of a first lens having focal power, wherein the object side is convex, and the image side is concave; a second lens having negative focal power, wherein the object side is concave, and the image side is concave; a third lens having positive focal power, wherein the object side is convex, and the image side is convex; a fourth lens having positive focal power, wherein the object side is convex, and the image side is convex; a fifth lens having positive focal power, wherein the object side is convex, and the image side is convex; a sixth lens having negative focal power, wherein the object side is concave, the imageside is concave, and the fifth lens and the sixth lens constitutes a cemented body; a seventh lens having a negative focal power, wherein the object side is concex, and the image side is concave; anda diaphragm. The optical imaging lens provided by the invention has the characteristics of a large aperture, a long focal length, high resolution, and the like, and can meet the requirements of a small field of view and a high resolution lens in the automotive field.

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

Optical imaging system

ActiveCN105892008AEffectively adjust the angleImprove image qualityOptical elementsImaging qualityPhysics

Owner:ABILITY OPTO ELECTRONICS TECH

Phase focusing image sensor and forming method thereof

InactiveCN109449174AImprove performanceIncrease the amount of incoming lightSolid-state devicesRadiation controlled devicesSemiconductorAbsorption layer

The invention discloses a phase focusing image sensor and a forming method thereof. According to the method, a semiconductor substrate, a first photosensitive structure and a first filter layer are provided, wherein the semiconductor substrate comprises a phase focusing area and has a first surface and a second surface opposite to the first surface; the first photosensitive structure is located inthe phase focusing area of the semiconductor substrate; the first photosensitive structure comprises a first surface and a second surface opposite to the first surface; the first photosensitive structure comprises an absorption layer which is used for absorbing near infrared light; the first surface of the first photosensitive layer is exposed from the absorption layer; the first filter layer islocated on the second surface of the phase focusing area of the semiconductor substrate; and natural light passes through the first filter layer. The performance of the phase focusing image sensor isimproved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

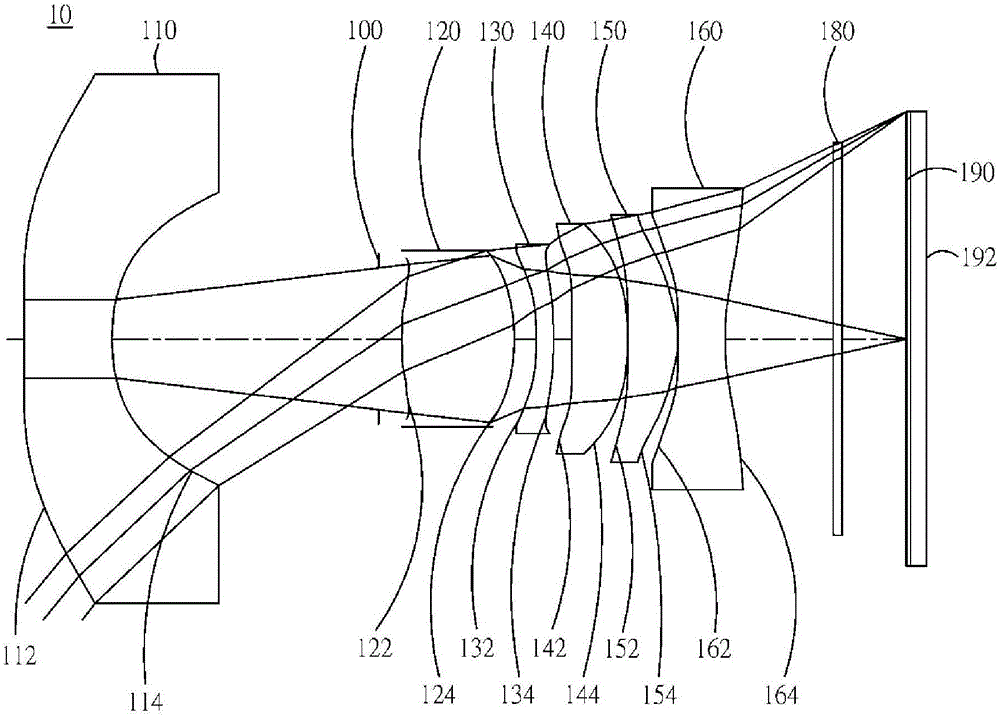

Optical imaging system, image-taking device, and electronic device

ActiveCN105807406AGuaranteed miniaturizationIncrease the amount of incoming lightOptical elementsOptical axisElectron

The present invention discloses an optical imaging system, an image-taking device, and an electronic device. The optical imaging system orderly comprises a first lens having refractive power, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens from an object side to an image side. The first lens has positive refractive power, and the object side surface of the first lens is a convex surface near an optical axis. The second lens has refractive power. The third lens has positive refractive power. The fourth lens has refractive power. The fifth lens has refractive power, the image side surface is a concave surface near the optical axis, and the object side surface and image side surface are aspheric surfaces. The sixth lens has refractive power, the image side surface is a concave surface near the optical axis, and the object side surface and the image side surface are aspheric surfaces. The first lens, the second lens, the third lens, the fourth lens, the fifth lens and the sixth lens have no relative movement in the optical axis. The optical imaging system also comprises an aperture arranged between an imaged object and the third lens.

Owner:LARGAN PRECISION

Optical image capturing system

ActiveCN106324805AIncrease the amount of incoming lightWiden perspectiveOptical elementsOphthalmologyImaging quality

An optical image capturing system, sequentially including a first lens element, a second lens element, a third lens element and a fourth lens element from an object side to an image side, is disclosed. The first lens element has negative refractive power, and the object side may be convex. The second through third lens elements have refractive power. Two surfaces of said lenses can be aspheric surfaces. The fourth lens element has positive refractive power, and two surfaces thereof are aspheric surfaces. At least one surface of the fourth lens has an inflection point. The first to fourth lenses of the optical image capturing system have refractive power. If all specific conditions are satisfied, the optical system can increase light gathering and optical path adjusting ability, thus improving the imagining quality.

Owner:ABILITY OPTO ELECTRONICS TECH

Optical image capturing system

ActiveCN106468823AIncrease the amount of incoming lightImprove image qualityOptical elementsImaging qualityPhysics

The invention discloses an optical image capturing system comprising a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens in order from an object side to an image side. At least one of the first lens to the fifth lens has a positive refractive power. The sixth lens may have a negative refractive power and both surfaces thereof are aspherical, wherein at least one surface of the sixth lens has an inflexion point. The lenses with the refractive power in the optical image capturing system are the first lens to the sixth lens. When the specific conditions are met, greater optical reception and better optical path adjustment capability can be achieved to improve the imaging quality.

Owner:ABILITY OPTO ELECTRONICS TECH

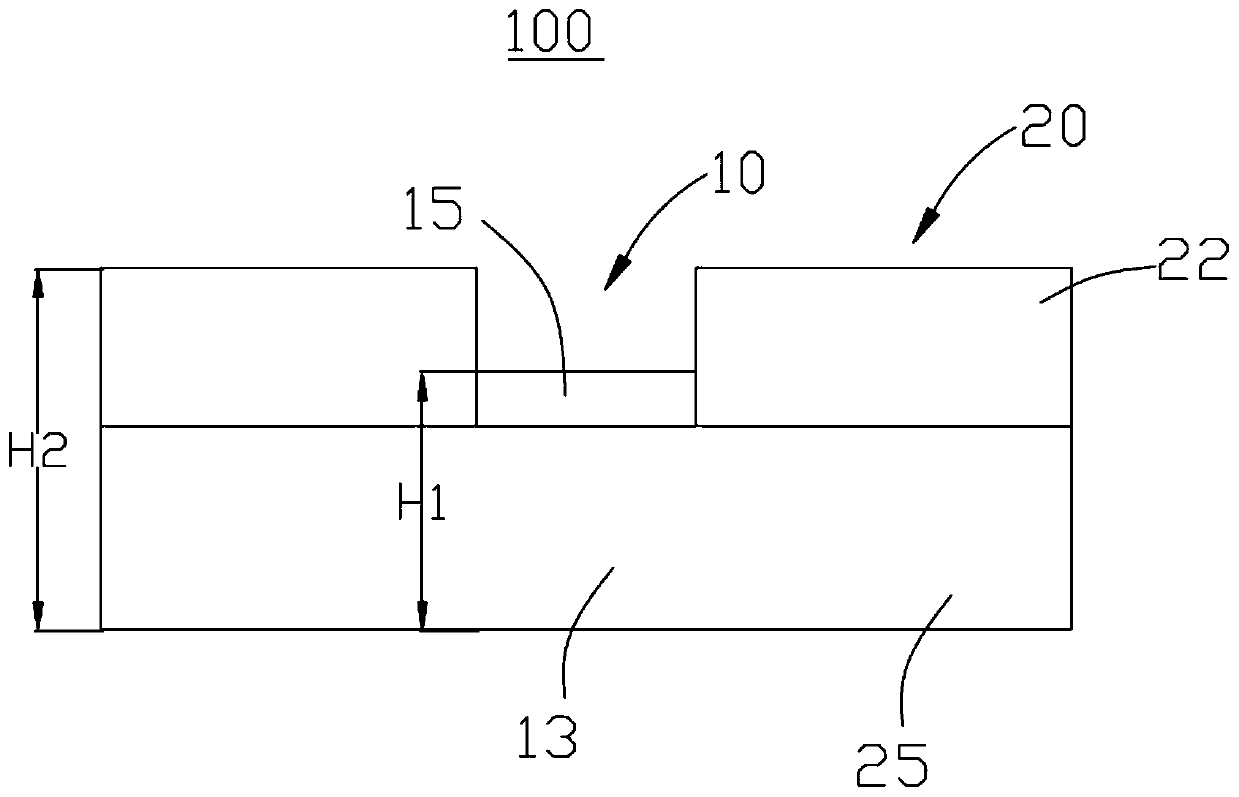

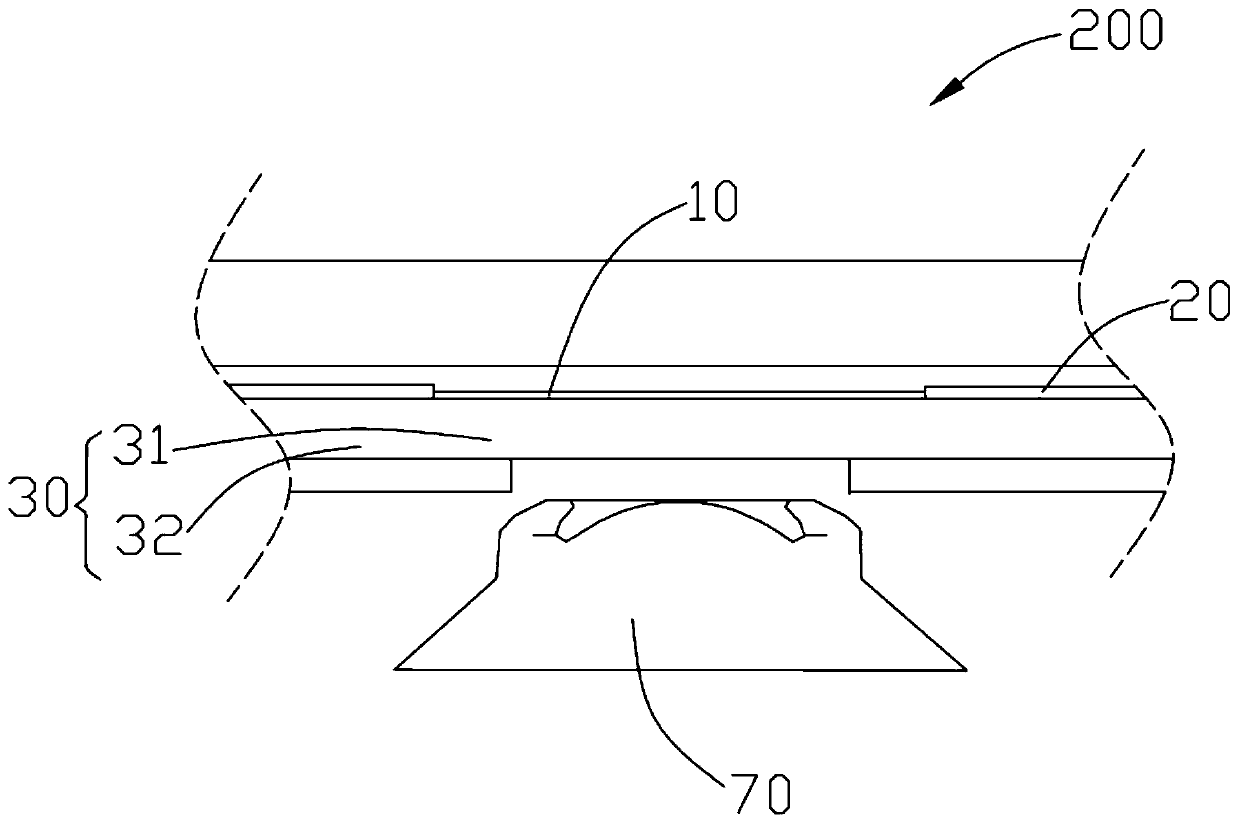

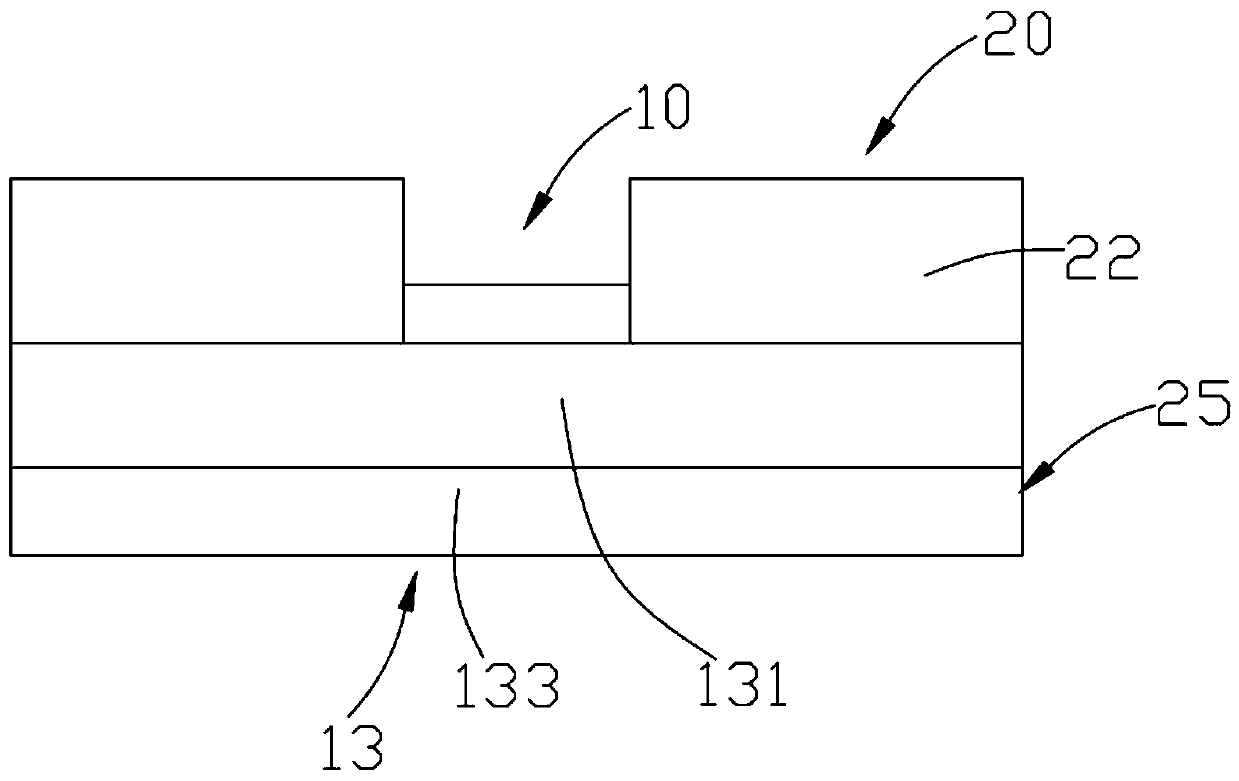

Polaroid, display module and mobile terminal

ActiveCN110133787AImprove transmittanceIncrease the amount of incoming lightPolarising elementsTransmittanceComputer terminal

The invention provides a polaroid, adapting to a display screen, wherein the display screen comprises a light transmitting area and a display area surrounding the light transmitting area, the polaroidis used for covering the light transmitting area and the display area, the polaroid comprises a first lamination portion and a second lamination portion, the first lamination portion is used for covering the light transmitting area, and the first lamination portion has a first height; the second lamination portion is used for covering the display area, the second lamination portion has a second height, wherein the first height is smaller than the second height, and the light transmittance of the first lamination portion is greater than that of the second lamination portion. The polaroid provided by the invention is provided with the first lamination portion, and the height of the first lamination portion is smaller than the height of the second lamination portion, so that glue filling package can be facilitated, and the light intake quantity of a camera can be improved, which is conducive to improving the camera shooting quality. The invention further provides a display module and a mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Large-aperture low-sensitiveness optical lens assembly

The invention relates to a large-aperture low-sensitiveness optical lens assembly which comprises a first lens, a second lens, a third lens and a fourth lens. The first lens is provided with positive light focal power, and the image side face of the first lens is a convex face. The second lens is provided with negative light focal power, and the object side face of the second lens is a concave face. The third lens is provided with an aspheric face and positive light focal power. The object side face of the fourth lens is a concave face, and the object side and the image side face are aspheric faces. The lens assembly meets the following relational expression: 0.3<F1 / TLT<1.0, 0.7<F / TTL<1.3, and D3 / D2<3. By means of the structure, when specific conditions are met, the lens assembly is beneficial for reducing the sensitivity of a system, promotes periphery resolution and illuminance, and improves the imaging effect.

Owner:GUANGDONG XUYE OPTOELECTRONICS TECH

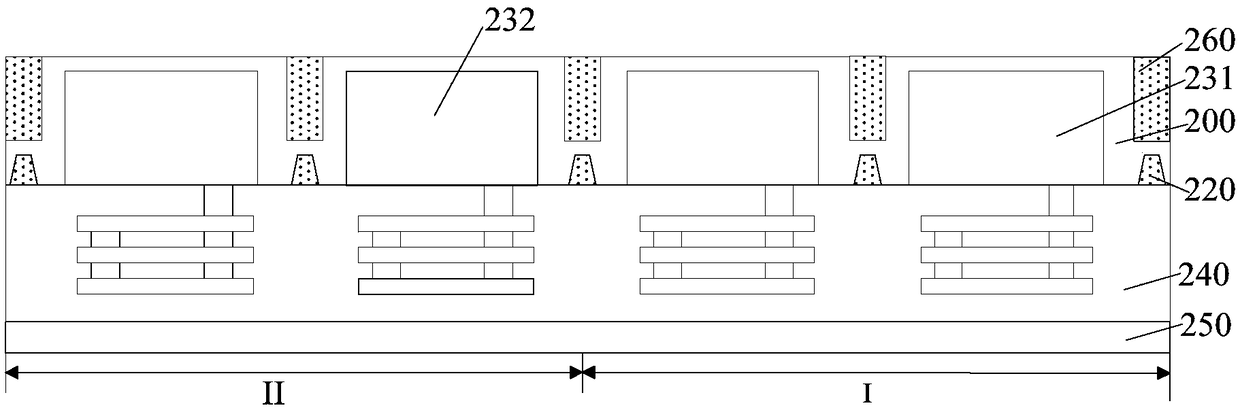

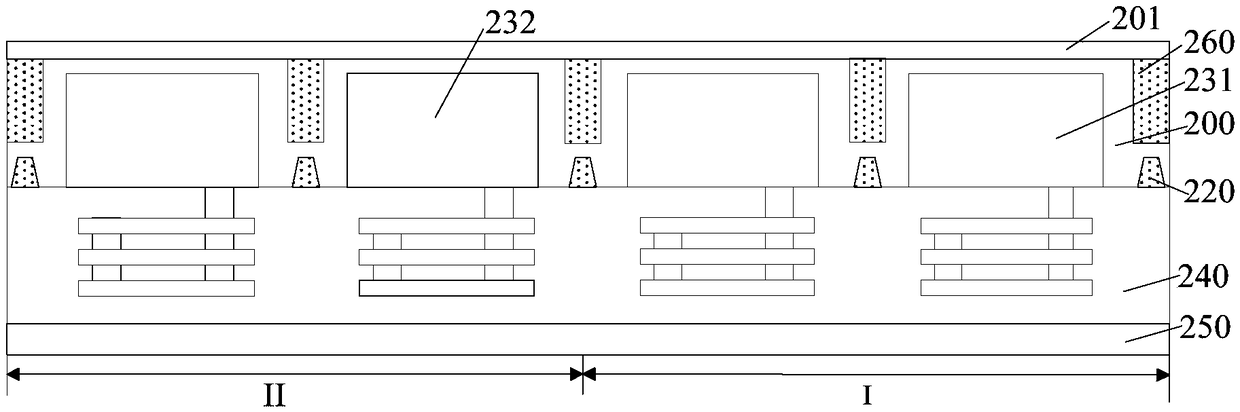

Display panel and display device

ActiveCN113394260AIncrease the screen ratioIncrease the amount of incoming lightSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a display panel and a display device, relates to the technical field of electronic equipment, and is used for solving the technical problem that the screen-to-body ratio of the display panel and the shooting effect of a camera module are difficult to consider at the same time, and the display panel comprises a main screen area and an auxiliary screen area; the display panel comprises a display layer, a touch control layer and a light-transmitting layer which are sequentially arranged in a stacked mode. The display layer comprises a plurality of light-emitting units and a pixel limiting layer for isolating the light-emitting units; and the side, close to the touch control layer, of the light transmitting layer located in the auxiliary screen area comprises at least one first lens part, the first lens part corresponds to the pixel limiting layer located in the auxiliary screen area and protrudes towards the touch control layer, the touch control layer comprises a first concave part embedded with the first lens part, and the refractive index of the first lens part is smaller than that of the touch control layer. Light can enter the touch layer with the large refractive index from the first lens part with the small refractive index, the first lens part with the protruding structure enables the area below the auxiliary screen area to receive more light, and the shooting effect of the camera module is improved.

Owner:HEFEI VISIONOX TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com