Large-aperture low-sensitiveness optical lens assembly

A technology of optical lenses and lens components, applied in the field of optical lenses, can solve the problems of high-pixel lens quality, low production yield, etc., achieve the effect of optical total length, improve resolution and illumination, field curvature and magnification chromatic aberration correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

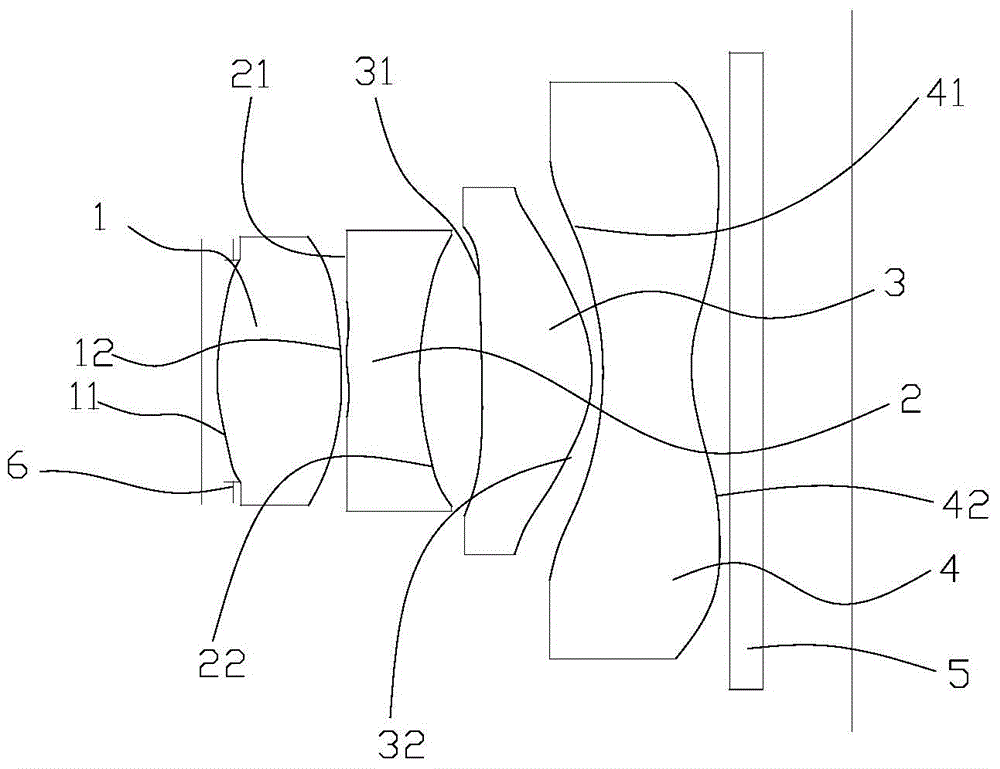

[0031] refer to figure 1 , the large-aperture low-sensitivity optical lens assembly of the present invention is composed of four plastic (resin) aspherical lenses, including a first lens 1, a second lens 2, and a lens arranged in sequence from the object side to the imaging side. The third lens 3 , the fourth lens 4 , the optical filter 5 , and the aperture 6 , wherein the aperture 6 is arranged on the object side of the first lens 1 , and adopts the way of the aperture in front. The first lens 1 has positive refractive power, and the image side is convex; the second lens 2 has negative refractive power, and the object side is concave; the third lens 3 has an aspheric surface and has positive refractive power; the fourth lens 4 has an object side It is a concave surface, and both the object side and the image side are aspherical.

[0032] Wherein, the lens assembly, the first lens 1, the second lens 2, the third lens 3, and the fourth lens 4 satisfy the following relational e...

Embodiment 2

[0042] refer to Figure 4 , different from Embodiment 1, in the large-aperture low-sensitivity optical lens assembly, the lens assembly, the first lens 1, the second lens 2, the third lens 3, and the fourth lens 4 satisfy the following relationship:

[0043] 0.350, Vd2<30; 0.1

[0044] Wherein, F is the focal length of the lens assembly; F1 is the focal length of the first lens 1; D2 is the thickness of the second lens 2 on the optical axis; D3 is the thickness of the third lens 3 on the optical axis; R1 is the first lens 1 The radius of curvature of the surface on the object side; R2 is the radius of curvature of the surface of the image side of the first lens 1; R3 is the radius of curvature of the surface of the second lens 2 on the object side; R4 is the radius of curvature of the surface of the second lens 2 on the image side; R7 is the radius of curvature of the surface of the second lens 2 on the image side; The radius of curvature of the four-lens 4 object...

Embodiment 3

[0053] refer to Figure 7 , different from Embodiment 2, in the aspheric formula of the large aperture and low sensitivity optical lens assembly, the specific data of each parameter is shown in Table 3 (F=3.21mm, FNO=2.2, FOV=75.2°)

[0054] Table 3 Data sheet of each lens of the lens assembly

[0055]

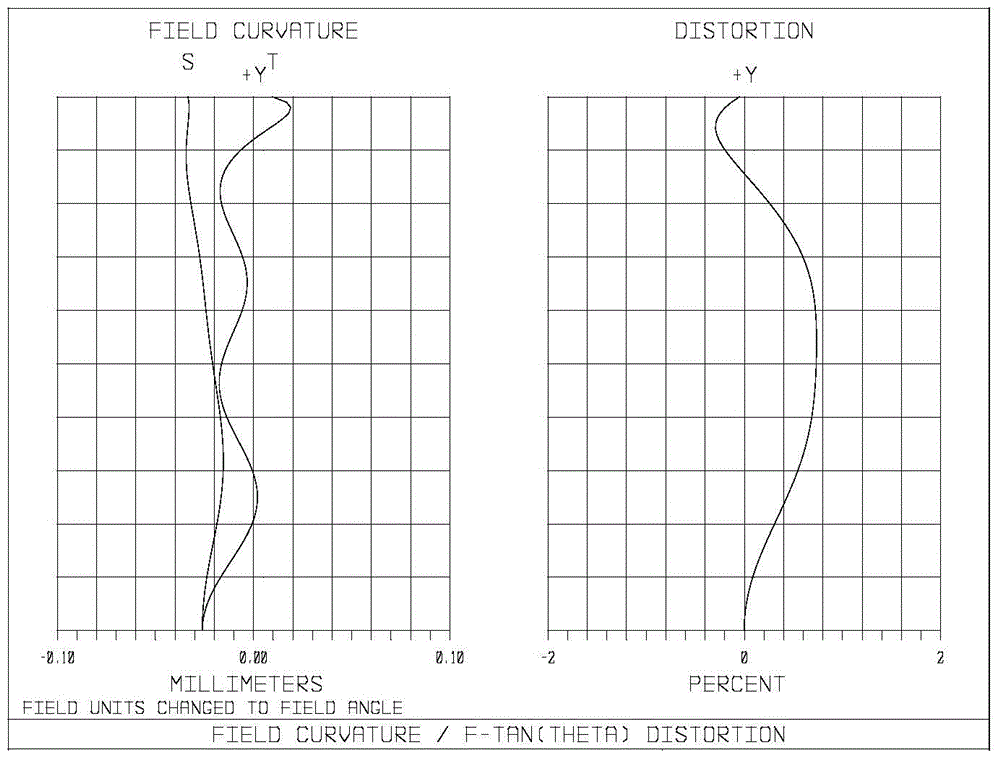

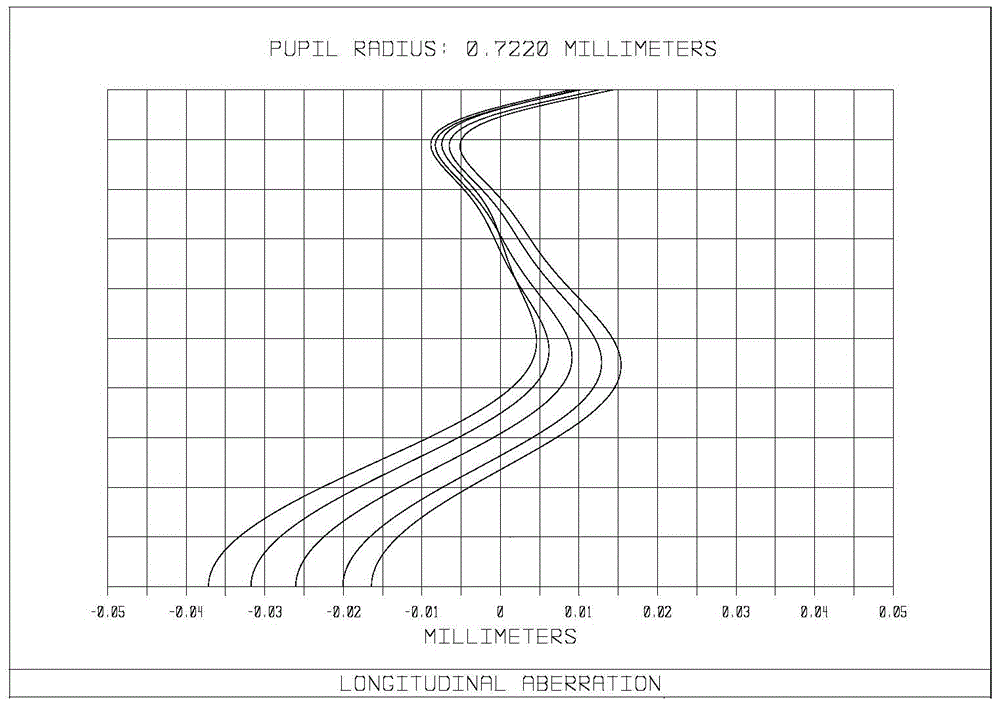

[0056] According to the above parameters, the field curvature and distortion curve of the lens assembly, refer to Figure 8 ;Spherical aberration curve reference Figure 9 . Depend on Figure 8 It can be seen that the optical distortion of the lens assembly is less than 1.5%, the field curvature is less than 0.1mm, and the distortion of the imaging picture is small and the definition is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com