Precise adjusting mechanism of spacing between rubber roller and steel roller during hot processing of light guide plate

A technology of adjusting mechanism and light guide plate, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of cursor induction interference, pressure climbing at the board seam, rubber roller damage, etc., to improve product yield and improve operability. sex, life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

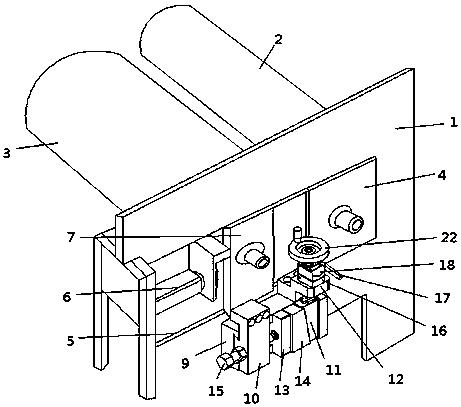

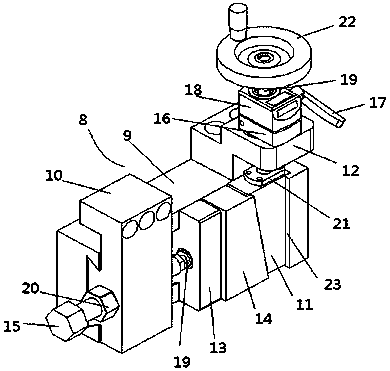

[0036] A specific embodiment of the present invention is as follows:

[0037] The alignment and zeroing process of the adjustment mechanism 8 before work: the dovetail groove 9 is fixed on the assembly frame 1, the rubber roller connecting block 10 is connected to the rubber roller slider 7, and after the rubber roller 3 or steel roller 2 is replaced on the frame 1, turn the hand The rocking wheel 22 resets the visual number in the position display 18 to zero to lower the first wedge block 11 to a certain position, twist the screw mandrel tightening handle 17 to drive the screw mandrel fixing splint 16 to lock the screw mandrel 19, and then connect the rubber roller slider 7 with the Cylinder 6 disengages, pushes the rubber roller 3 to contact the steel roller 2 so that the two are in close contact, at this time, rotate the adjusting screw 15 to make the zero adjustment block 13 push the second wedge block 14 into close contact with the first wedge block 11, then tighten the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com