Lifting type suspension drying machine

A dryer, lift-type technology, applied in the direction of dryers, paper machines, textiles and paper making, etc., can solve the problems of paper breakage, unsuitable drying, unfavorable paper drying, etc., achieve good drying effect and reduce tension , to prevent the effect of excessive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

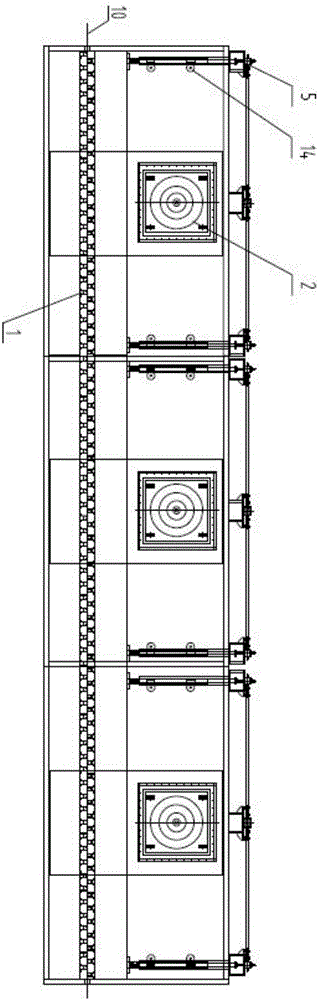

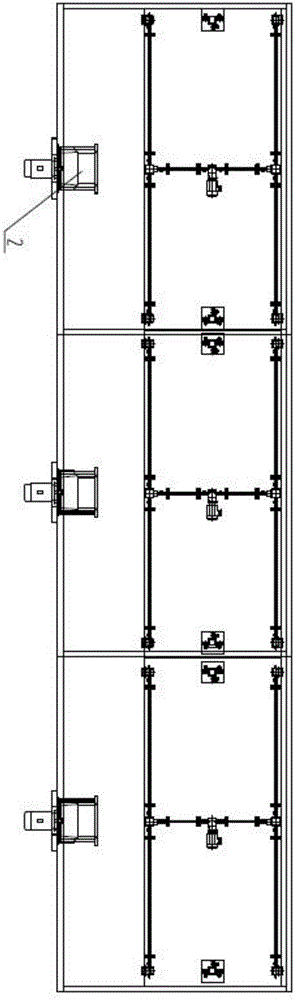

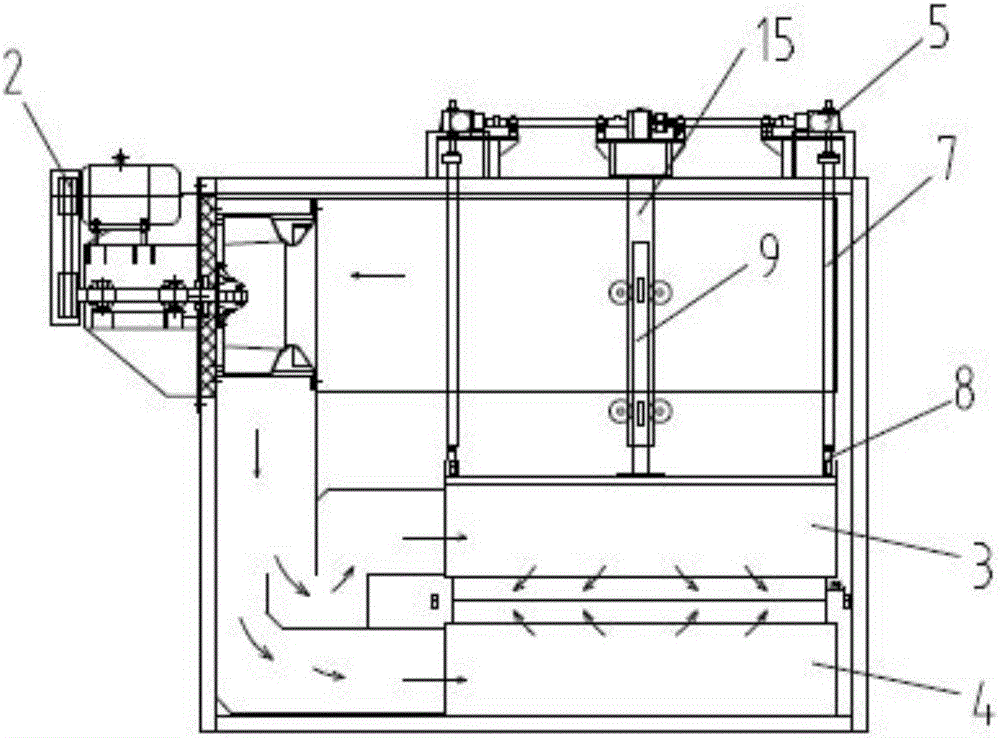

[0017] Such as Figure 1~5 As shown, the present invention comprises frame, and it also comprises elevating mechanism, air nozzle 1, bellows; The lower end inside of frame is provided with transmission mechanism, and paper runs from left to right through transmission mechanism; Bellows are installed in the frame; the bellows are divided into upper bellows 3 and lower bellows 4; upper bellows 3 and lower bellows 4 are respectively arranged at the upper end and lower end of the transmission mechanism;

[0018] The lower end of the upper bellows 3 and the upper end of the lower bellows 4 are connected to a row of air nozzles 1; the air nozzles 1 are made according to the Coanda effect, so that the air flows along the curved surface, reducing the tension on the paper and making the paper not easy to break ;The upper and lower air nozzles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com