Fully-automatic fixed-position conveying, fixed-point mold conveying and fixed-point mold pushing production line

A fully automatic, assembly line technology, applied in conveyor objects, transportation and packaging, unloading devices, etc., can solve the problems of low degree of automation, unsmooth operation, low efficiency, etc., and achieve the effect of high degree of automation and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

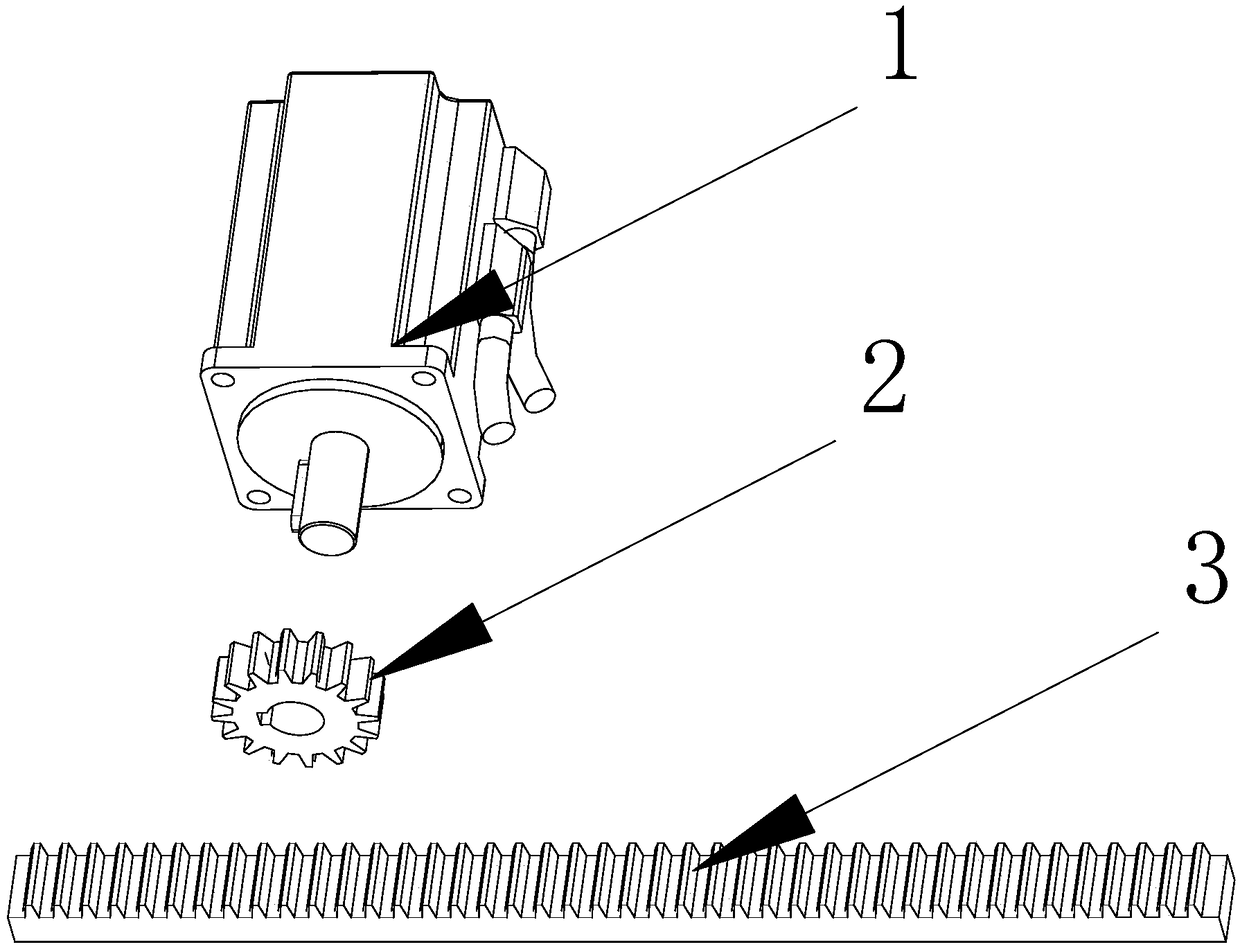

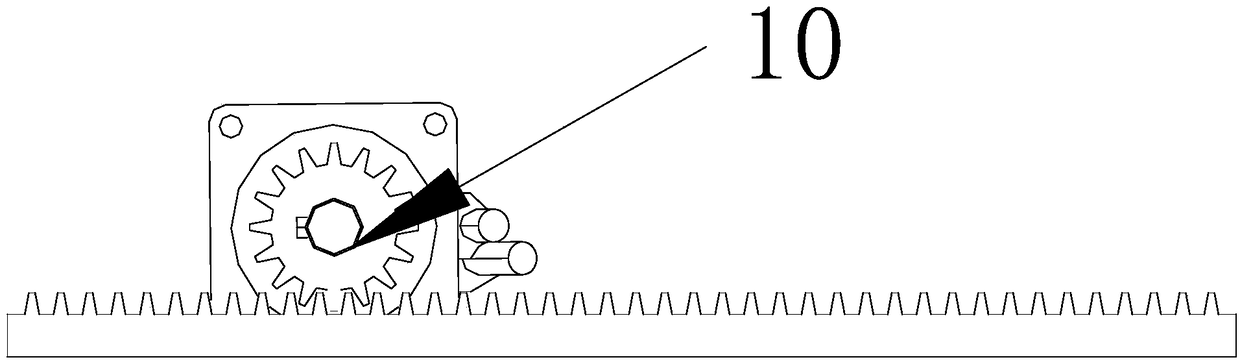

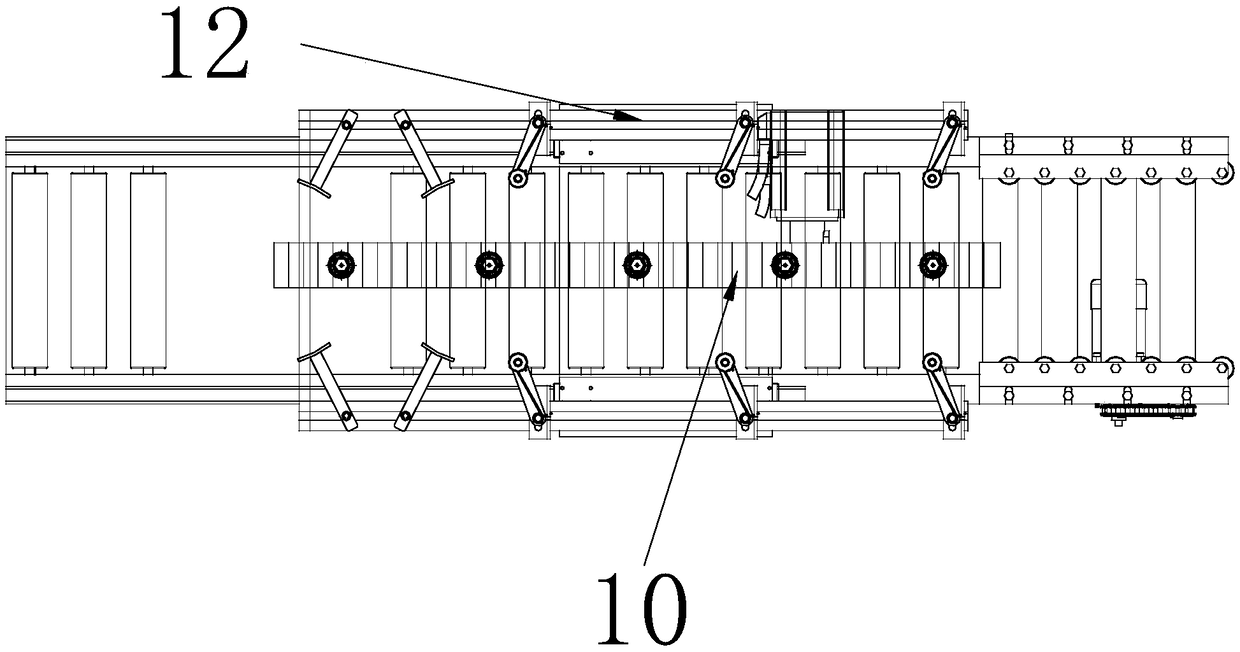

[0060] see Figure 1-Figure 13, a fully automatic positioning and conveying fixed-point mold delivery and fixed-point push mold assembly line, including a roller press 5, a plaster mold 6, a plaster mold bucket 7, a gear row module 10, a mold conveying mechanism 11, a pushing mechanism 12, a conveying motor 21, Mold guide shaft 22, slide table 23, optical axis guide rail 24, chain 25, one-way roller 26, conveying main body 27, pushing mechanism main body 31, pushing mold positioning 32, preparatory mold positioning 33 and mold adjustment spacing positioning 34, the gear The servo motor 1 is fixedly installed on the rack module 10. The front end of the servo motor 1 fixes the gear 2 through the key bar. The gear 2 meshes with the rack 3. The back of the mold conveying mechanism 11 is fixed with the rack 3 through the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com