Manufacturing method of semiconductor photoelectronic device

A technology for optoelectronic devices and manufacturing methods, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the non-radiative recombination rate of devices, reducing the usable area of Micro-LED devices, color distortion, etc., and eliminating optical crosstalk of devices. problems, improve the luminous efficiency of the device, and improve the effect of the effective use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

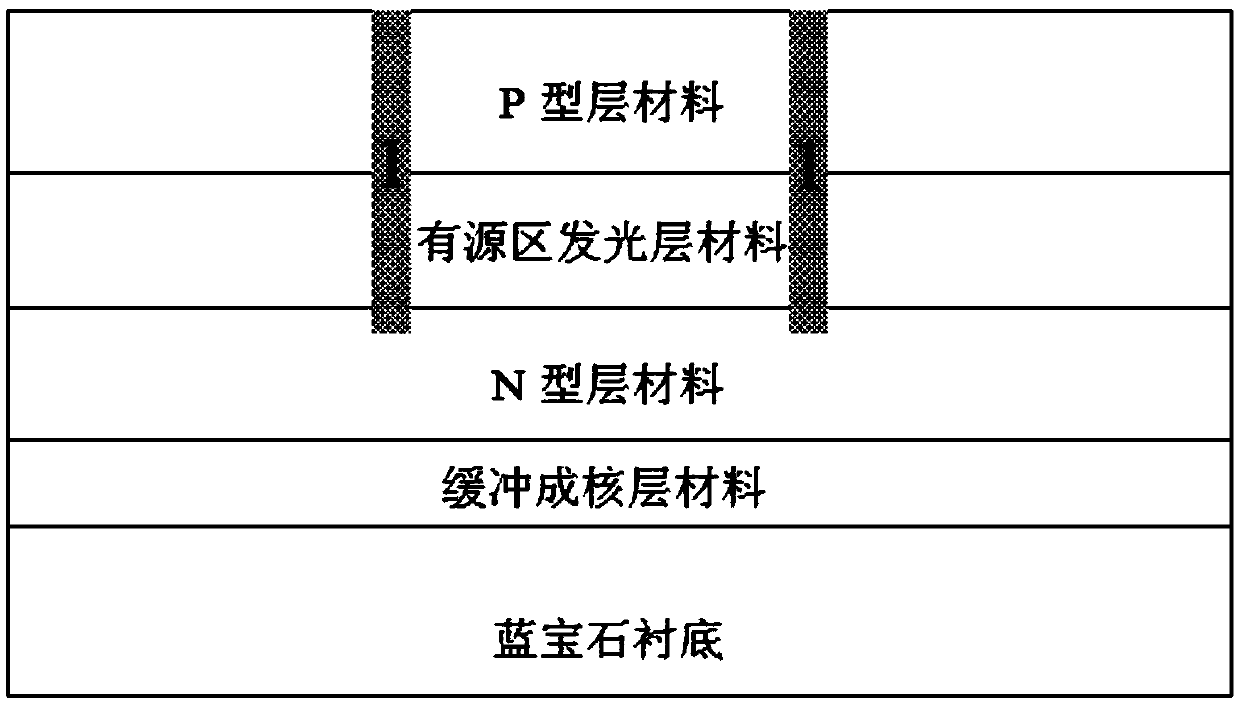

[0051] Example 1: Micro-LED formal installation structure

[0052] see reference Figure 1-5 , a Micro-LED chip front-loading structure based on ion implantation. The specific preparation process steps are as follows:

[0053] Step 1: Using MOCVD (metal organic chemical vapor deposition) on the sapphire substrate material to epitaxially grow the buffer nucleation layer material, N-type layer material, active region light-emitting layer material and P-type layer material to form an LED structure;

[0054] Step 2: Use a photoresist (or silicon dioxide, silicon nitride, metal aluminum, etc.) mask to define an ion implantation region, and form a high-resistance implantation isolation region 1 by hydrogen (or helium, nitrogen, fluorine) ion implantation, Adjust the energy and dose of implanted ions to precisely control the ion implantation depth, so that the implanted isolation region 1 penetrates the P-type layer and the light-emitting layer in the active region, so as to enter t...

Embodiment 2

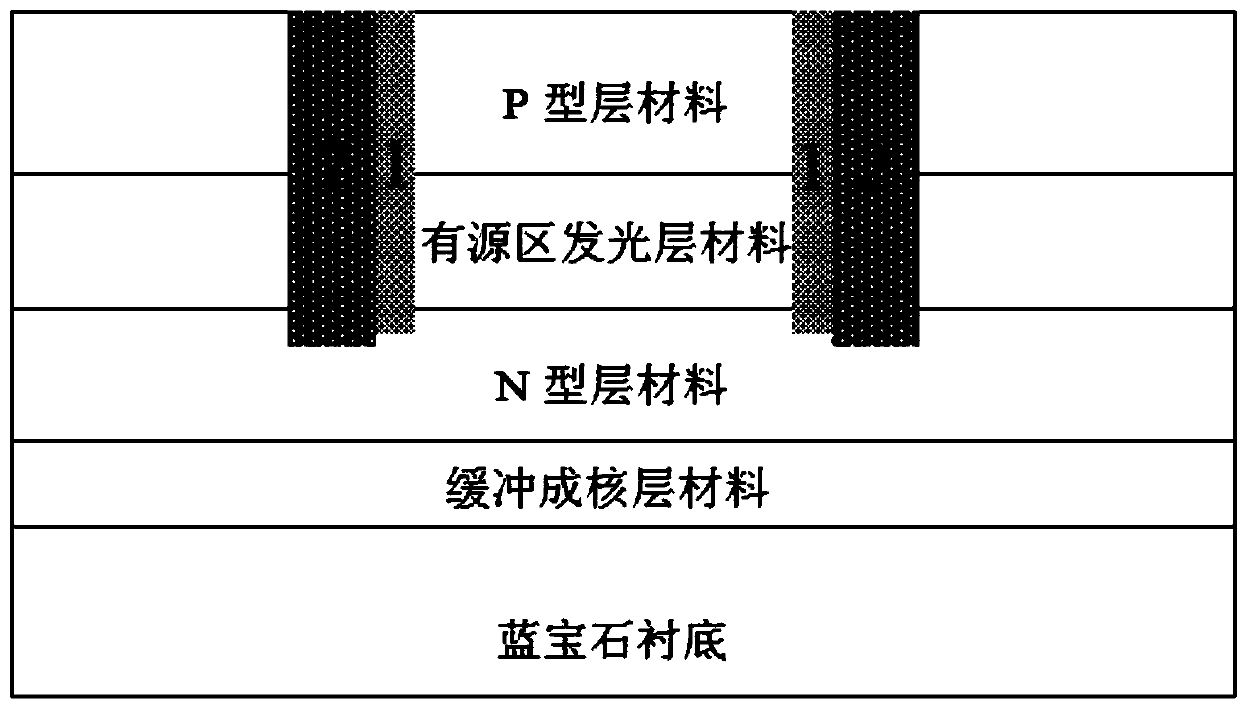

[0060] Example 2: Micro-LED formal installation structure

[0061] Please refer to Figure 6-7 , a Micro-LED chip front-loading structure based on ion implantation. The specific preparation process steps are as follows:

[0062] Step 1: On the sapphire substrate, use MOCVD (metal organic chemical vapor deposition) to epitaxially grow buffer nucleation layer material, high resistance layer material, N-type layer material, active region light-emitting layer and P-type layer material to form LED structure;

[0063] Step 2: use a photoresist (or silicon dioxide, silicon nitride, metal aluminum, etc.) mask to define an ion implantation region, and form a high-resistance implantation isolation region 4 by hydrogen (or helium, nitrogen, fluorine) ion implantation, Adjust the energy and dose of implanted ions to precisely control the ion implantation depth, so that the implanted isolation region 4 penetrates the P-type layer and the material of the light-emitting layer in the active...

Embodiment 3

[0069] Example 3: Micro-LED vertical structure

[0070] Please refer to Figure 8-9 , the specific preparation process steps of the vertical structure of the Micro-LED chip based on ion implantation are as follows:

[0071] Step 1: Using MOCVD (metal organic chemical vapor deposition) to epitaxially grow N-type layer material, active region light-emitting layer and P-type layer material in sequence on GaN or SiC substrate to form an LED structure;

[0072] Step 2: Use a photoresist mask to define the ion implantation area, form a high-resistance ion implantation isolation area 7 through hydrogen (or helium, nitrogen, fluorine) ion implantation, adjust the energy and dose of implanted ions to precisely control the ion implantation depth , so that the depth of the implanted isolation region 7 completely penetrates the GaN or SiC substrate, forming an isolation for the LED device;

[0073] Step 3: Further performing secondary ion implantation on the ion implantation isolation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com