Insulating glass element, especially for a refrigerated enclosure

a technology of insulating glass and refrigerating enclosure, which is applied in the direction of heater elements, refrigeration devices, building components, etc., can solve the problems of condensation or frost at the periphery of the glazed surface, moisture to the skin, and reduction of the field of vision through, so as to prevent the appearance of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

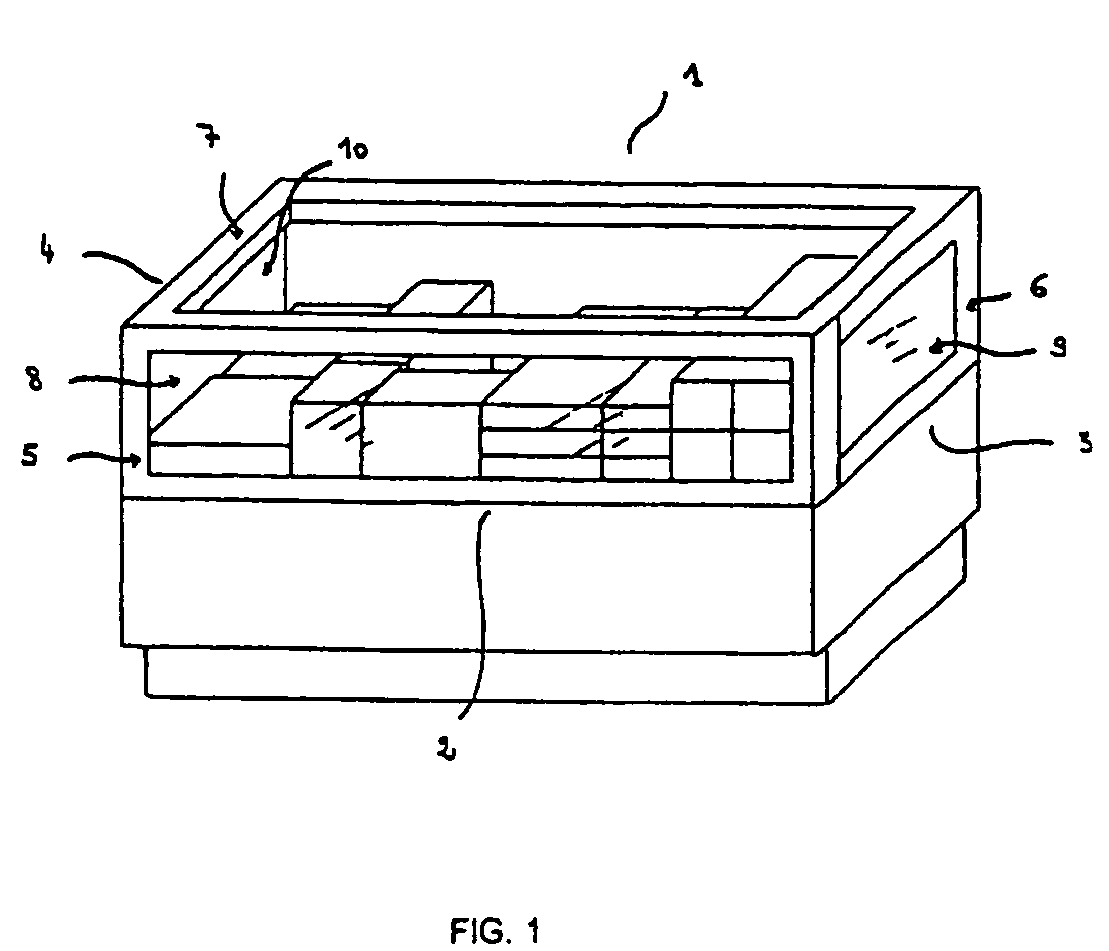

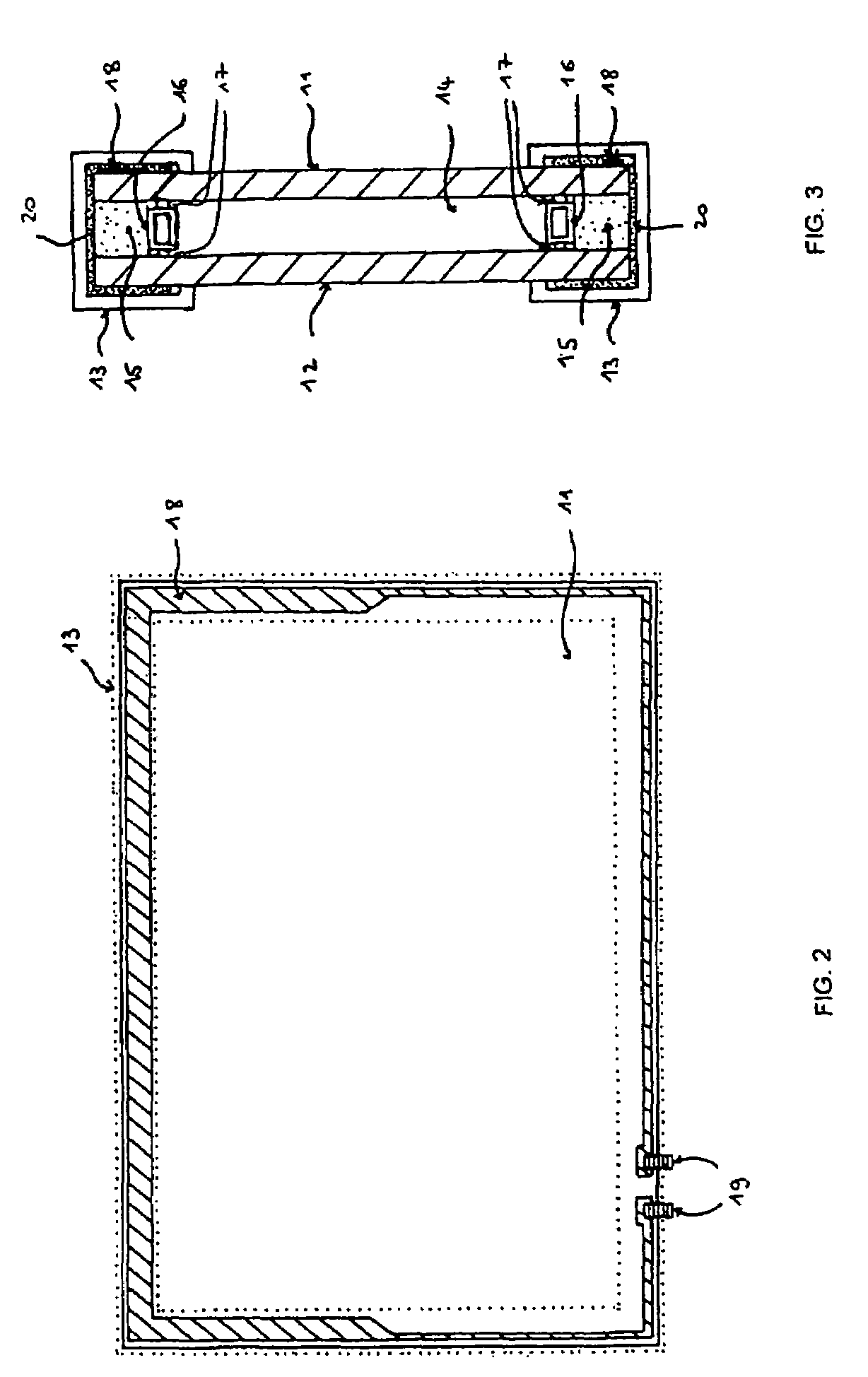

[0047]FIG. 2 shows a front view of a glazed element according to the invention.

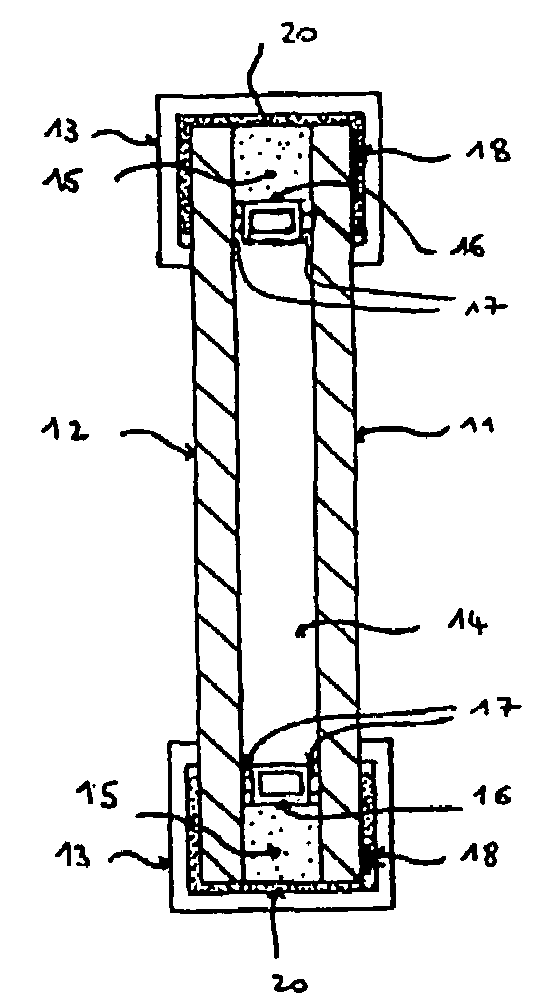

[0048]FIG. 3 is a vertical section through this same element.

[0049]According to this embodiment, the glazed element comprises two glass sheets 11, 12, provided with a heating border 18, supported by a frame having the shape of the section 13. In FIG. 2, the section 13 is represented by dotted lines in order to show the heating border 18 more clearly.

[0050]The glass sheets 11, 12 are separated from each other by a space 14 and joined at the periphery by a seal 15, which is watertight. Into the space 14, at a small distance from the edge of the sheets 11, 12, is inserted a hollow section 16 containing a desiccating agent, which is fixed to the glass by an adhesive bead 17. The outer sheet 11 is provided, on its external face, with a heating border 18 of variable width which extends over the four sides of the sheet, the ends of which bear a terminal 19 for the electrical supply. A heat-conducting seal 20 pro...

second embodiment

[0051]FIG. 4 shows a front view of a glazed element according to the invention and FIG. 5 is a vertical cross section through this element.

[0052]As above, the element consists of glass sheets 11, 12 supported by the section 13, also shown in dotted lines in FIG. 4. The glass sheets 11, 12, separated by the space 14, are joined at the periphery by the seal 15. The space 14 comprises the hollow section 16 containing the desiccating agent and the adhesive bead 17 (not shown). In this case, the outer sheet 11 bears, on the internal face, two different heating borders 21, 22, of the same width and of a length substantially equal to the sides of the sheet 11, the ends of which bear terminals 19. Intermediate elements 23 are attached to the borders 21, 22 by adhesive bonding or by welding at the end 24, the end remaining free 25 itself being folded toward the sheet 11 and lying in a plane substantially parallel to the thickness of the sheet. The entire surface of the end 25 is thus exposed...

third embodiment

[0053]FIG. 6 shows a front view of a glazed element according to the invention and FIG. 7 is a vertical section through this element.

[0054]In this case, the elements consist of three sheets of glass 11, 12, 26 supported by the section 13, also shown in dotted lines in FIG. 6. The glass sheets 11, 12, 26, separated by the spaces 14, 27, are joined at the periphery by the seal 15. Each space 14, 27 contains the hollow section 16 containing the desiccating agent and the adhesive bead 17 (not shown). In this case, the intermediate sheet 12 bears, on the external face, a heating border 28, formed from upper 29 and lower 30 strips connected together at one side, whose ends provided with terminals 19 are located on the side of the sheet away from the previous side.

[0055]In this case, the intermediate element 31 is a T-section, whose web 32 is fastened to the strip 29 of the heating border 28 and whose flanges 33 lie in a plane substantially perpendicular to the plane of the sheet 26 bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com