Low-voltage transparent electrothermal film, preparation process thereof, high-temperature electrothermal sheet and preparation process thereof

An electric heating film and low voltage technology, applied in the field of transparent electric heating film and its preparation, can solve the problems of burning the electric heating film, poor heating uniformity, lowering the use voltage, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

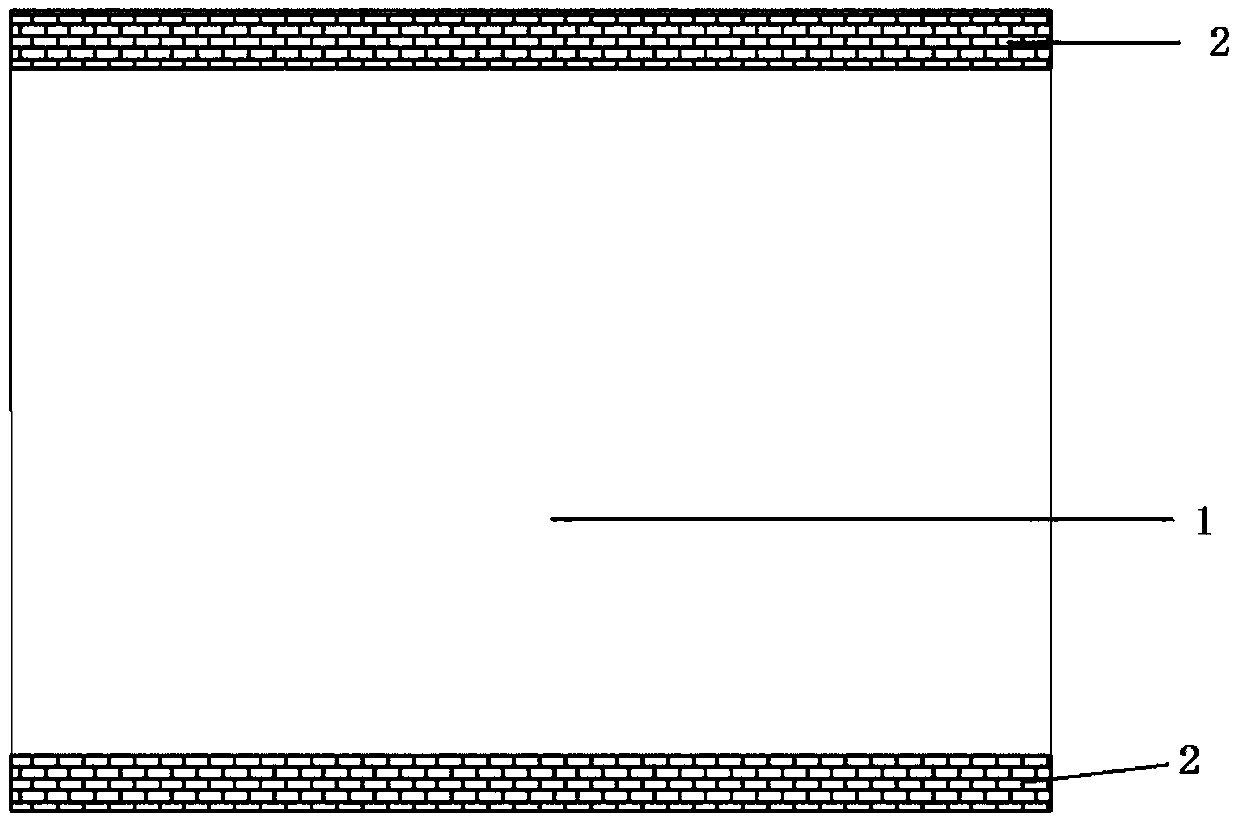

[0193] See figure 2 , 3 As shown, a single-layer graphene is used as a low-voltage transparent electric heating film for heating components, and the electrodes are printed with silver paste.

[0194] The preparation process is as follows:

[0195] 1. Transfer a layer of graphene on PET (transparent substrate) with an area of 150mm×150mm and a thickness of 125μm. The graphene has been doped and the square resistance is 250Ω / □;

[0196] 2. Use screen printing equipment to print the silver paste electrode pattern on the transferred graphene, the pattern shape is like figure 2 As shown, the distance between the inner electrodes is 6mm, the width is 1mm, and the thickness of the silver paste is 25μm;

[0197] 3. Put the printed electrode pattern in an oven and bake to solidify the silver paste. The baking temperature is 130°C and the time is 40 minutes.

[0198] The initial temperature is room temperature (22°C). In this case, connect the leads to the positive and negative electrodes of ...

Embodiment 2

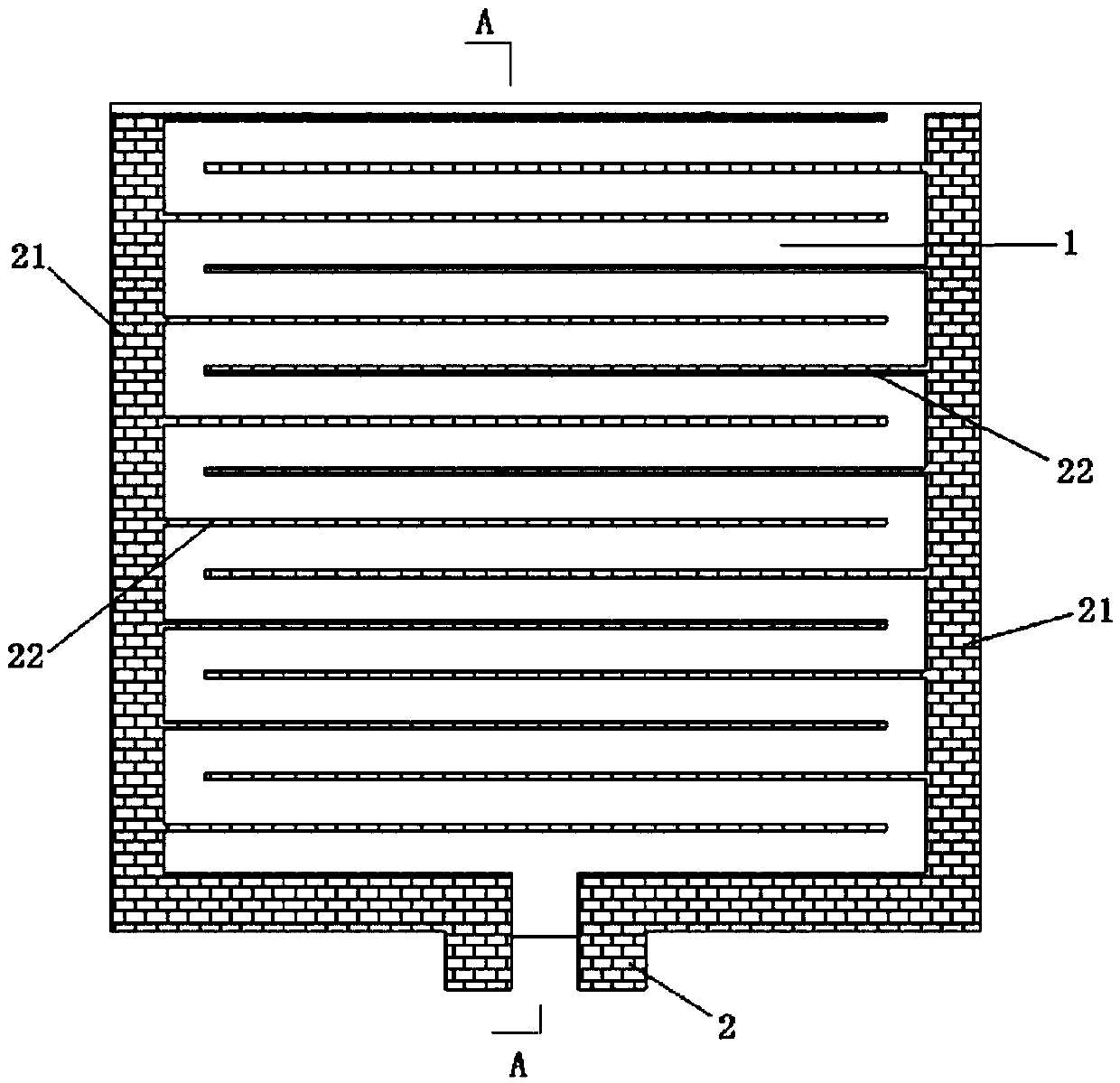

[0209] In this embodiment, two layers of graphene are used as the low-voltage transparent electric heating film of the heating member, and the electrodes are printed with silver paste.

[0210] 1. Transfer two layers of graphene on PET (transparent substrate) with an area of 120mm×120mm and a thickness of 125μm. The graphene has been doped and the square resistance is 120Ω / □;

[0211] 2. Use screen printing equipment to print the silver paste electrode pattern on the transferred graphene, the pattern shape is like Figure 4 As shown, the outer diameter of the bus bar is 96mm, the longest inner electrode is 73mm, and the distance between the inner electrodes is 6mm. A total of 17 gaps are generated. The width is 1mm and the width of the bus bar is 8mm. On the bus bar, the first inner electrode reaches the end. The length of an inner electrode stop is 130mm, and the thickness of silver paste is 25μm;

[0212] 3. Put the printed electrode pattern in an oven and bake to solidify the si...

Embodiment 3

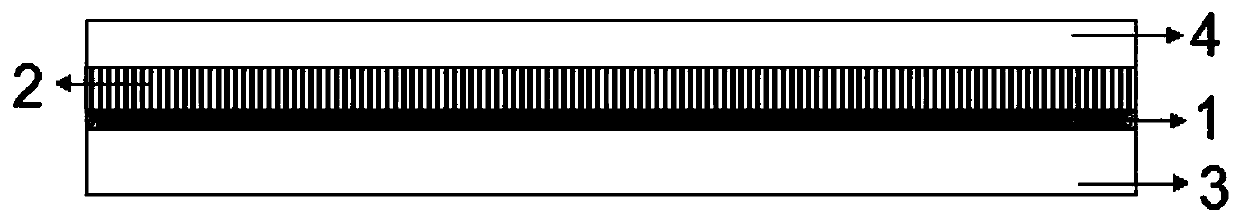

[0225] See Figure 5 As shown, the low-voltage transparent electric heating film with single-layer graphene as the heating member is prepared as follows:

[0226] 1. The copper foil with well-grown graphene (graphene is doped, the square resistance is 250Ω / □) and the PET with the size of 150mm×300mm and the thickness of 125μm are bonded together through UV glue. The copper foil size is 140mm×280mm. , The thickness is 25μm;

[0227] 2. Curing the UV glue with a wavelength of 365nm and an energy of 1000mJ / cm 2 ;

[0228] 3. Use screen printing equipment to print a peelable mask on the bonded copper foil, the pattern shape is like Figure 5 As shown, at this time, it is equivalent to the electric heating film being divided into two, forming the effect of connecting the left and right electric heating films in series. The actual utilization voltage is halved. The internal electrode spacing is 3mm, the length is 108mm, and the width is 1mm. There are 32 strips in total. Generate 30 inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com