Electrolyzed Hydrogen Oxygen Mixing Device and Preparation Method

A technology of hydrogen and oxygen, which is applied in the direction of electrolysis components, electrolysis process, electrode shape/type, etc., can solve the problems of low degree of separation and integration of gas circuit and electrolysis cell, reduce the purity of hydrogen and oxygen, and complex structure of electrolysis device, etc., to achieve Reduce solution resistance, wide range of use, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with specific embodiments. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

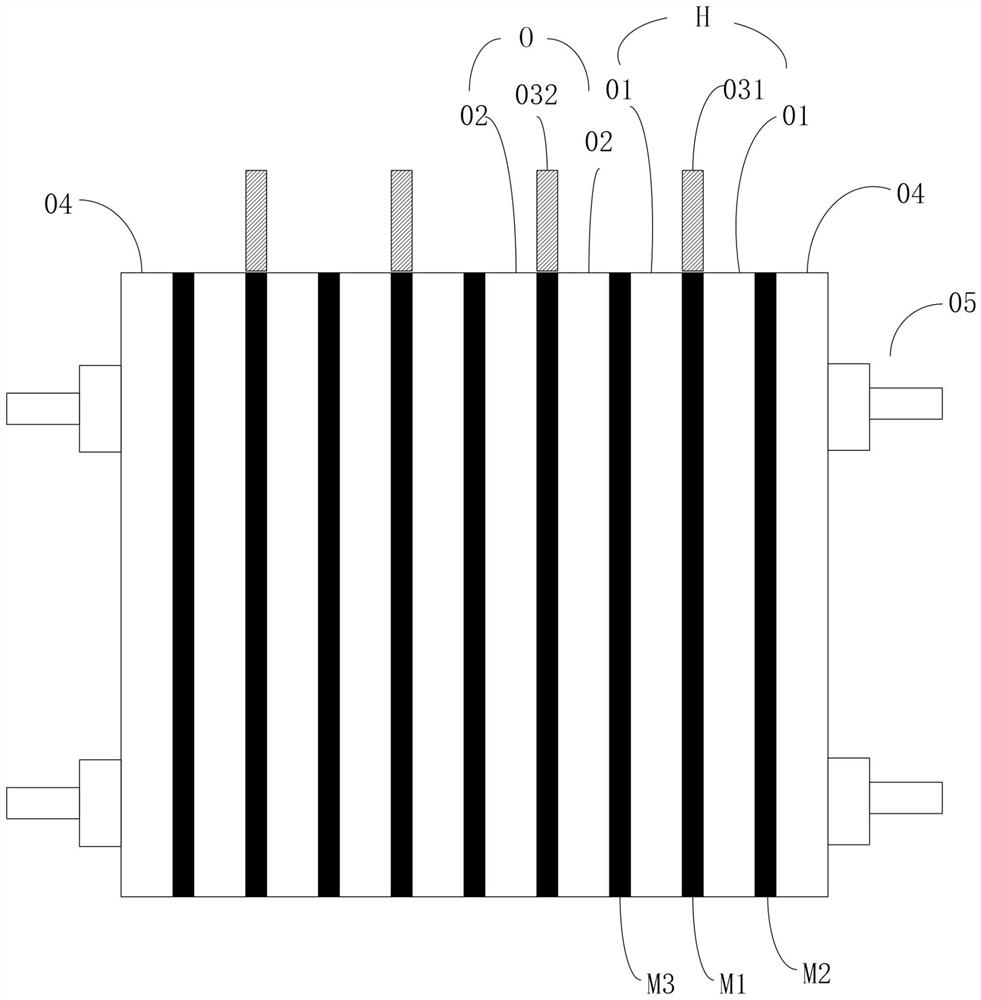

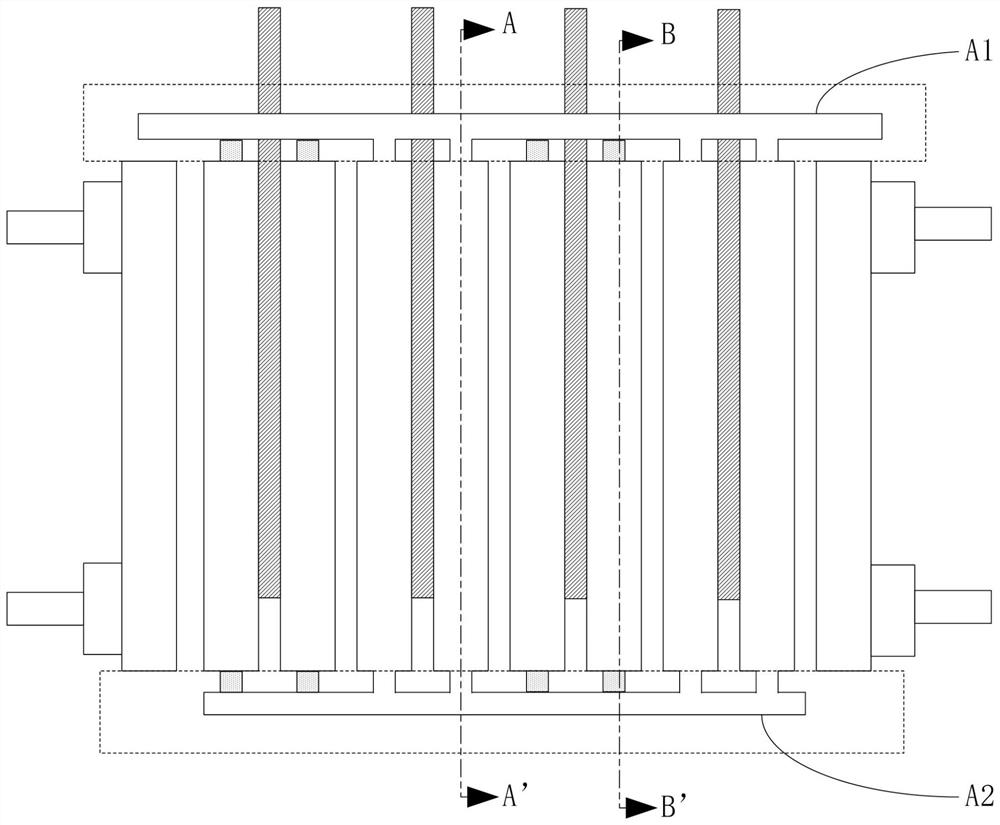

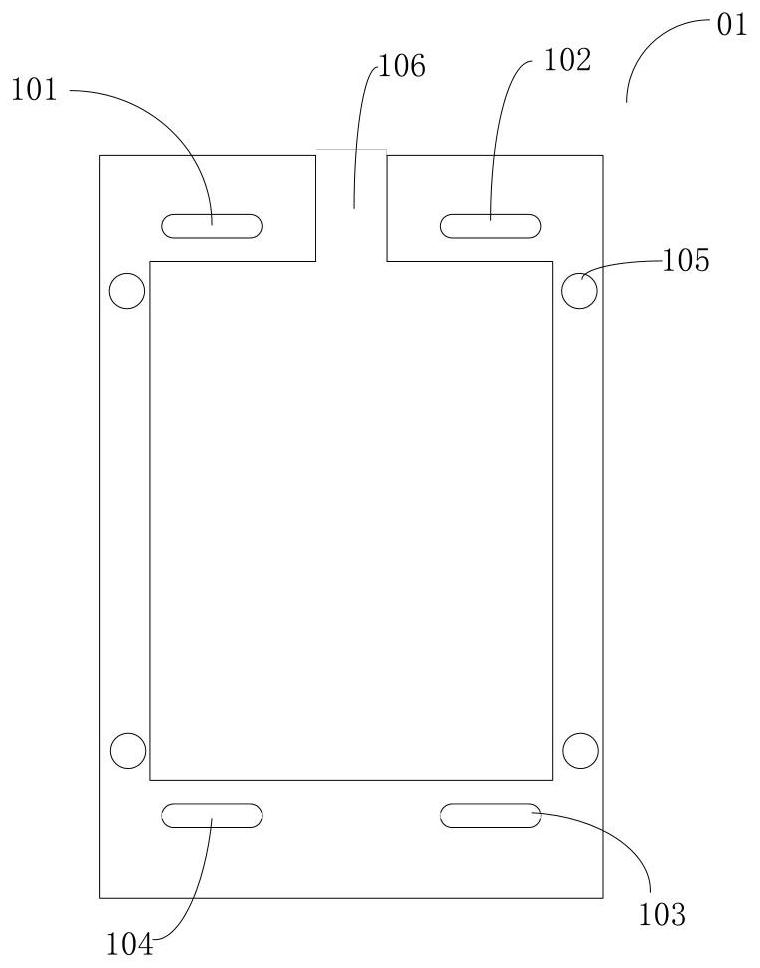

[0055] The electrolytic hydrogen and oxygen production device of the present invention includes stacked hydrogen production units and oxygen production units. The two gas channels are respectively the hydrogen production channel and the oxygen production channel. These two channels both penetrate the top of the hydrogen production unit and the top of the oxygen production unit, and the hydrogen production gas channel is connected with the hydrogen production unit. The channel is connected with the oxygen production unit; and the two liquid channels include a hydrogen pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com