A kind of preparation method of msm photodetector

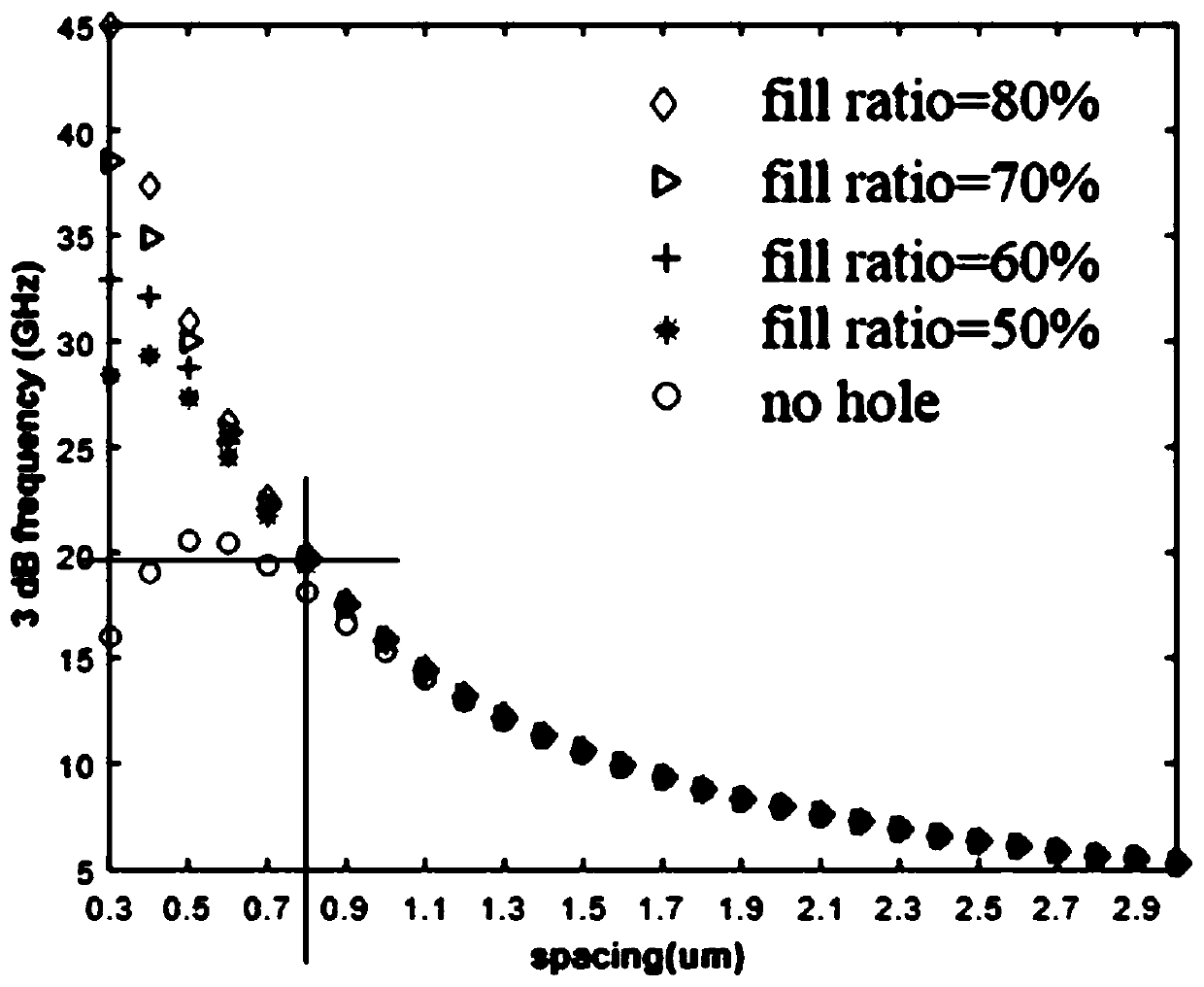

A photodetector and etching technology, applied in the fields of visible light and infrared detection and imaging, can solve problems such as difficult preparation, and achieve the effects of simplified preparation process, fast response speed, and small electrode spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

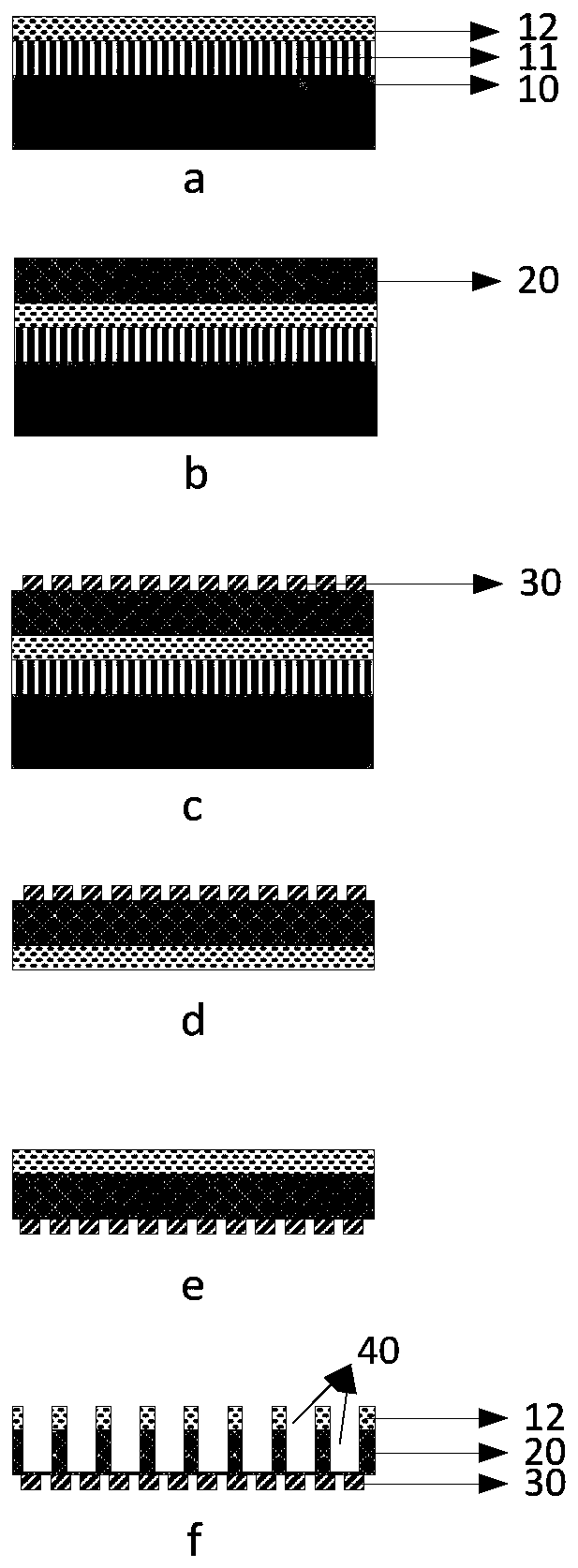

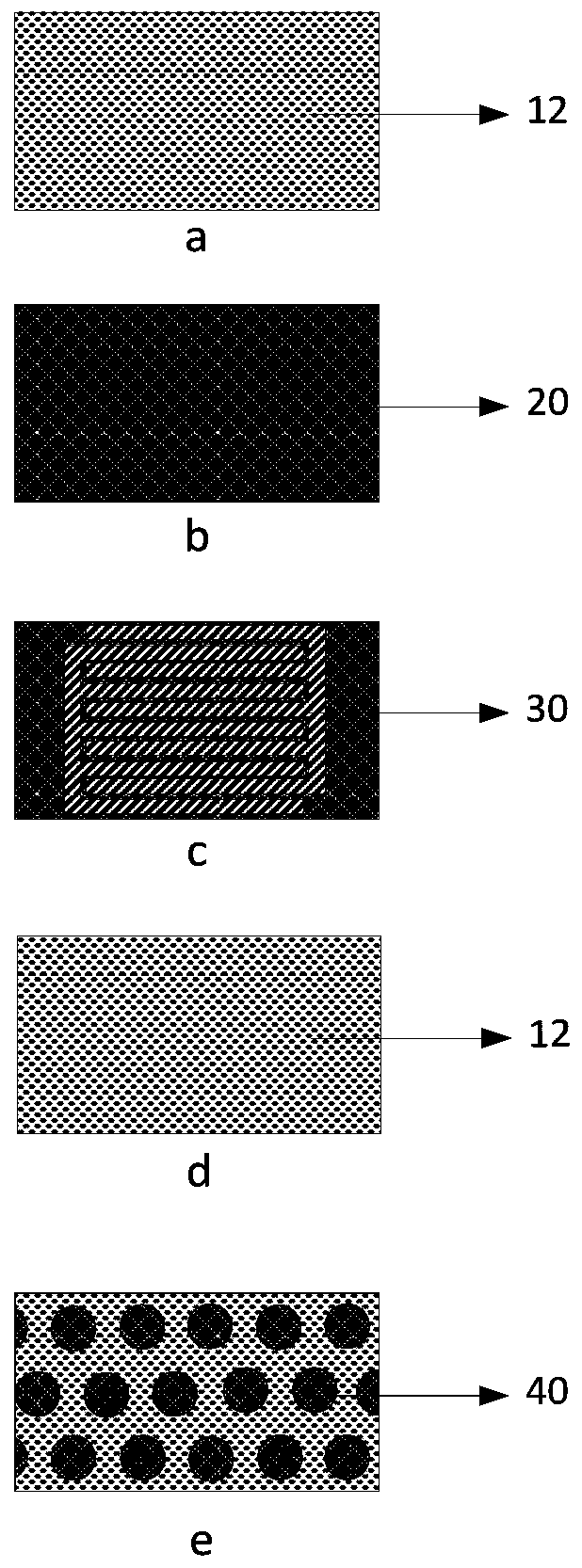

[0031] A kind of preparation method of MSM photodetector, comprises the following steps:

[0032](1) prepare semiconductor thin film 20 on SOI substrate; Wherein, SOI substrate comprises silicon substrate layer 10, silicon dioxide layer 11 and silicon thin film layer 12 that electroplating forms successively from bottom to top, as figure 1 -a with figure 2 As shown in -a, the semiconductor thin film 20 is adhered to the upper surface of the silicon thin film layer 12 by molecular beam epitaxy or metal organic chemical vapor deposition, as figure 1 -b with figure 2 -b shown;

[0033] (2) On the semiconductor thin film 20, adopt magnetron sputtering and patterning to form some interdigital electrodes 30, such as figure 1 -c with figure 2 -c shown;

[0034] (3) adopt buffered hydrofluoric acid solution to corrode silicon dioxide layer 11, make silicon dioxide layer 11 and silicon substrate layer 10 come off from silicon film layer 12, as figure 1 As shown in -d, the ...

Embodiment 1

[0039] Such as figure 1 Shown, a kind of preparation method of high-speed high-efficiency MSM photodetector comprises the steps:

[0040] (1) Select the SOI substrate as the device substrate. The SOI substrate includes a silicon substrate layer 10, a silicon dioxide layer 11 and a silicon thin film layer 12 formed by electroplating sequentially from bottom to top. In the SOI substrate, the silicon substrate layer is 500μm, the silicon dioxide layer thickness is 3μm, and the silicon film layer is 0.25μm. Clean the surface of the SOI substrate to remove contamination, and bake the SOI substrate at 200°C for 30 minutes to remove the water vapor on the surface. Such as figure 1 -a shown;

[0041] (2) Prepare a layer of silicon thin film on SOI substrate by molecular beam epitaxy method, the silicon thickness is 2 μm, such as figure 1 -b shown;

[0042] (3) A metal aluminum film is prepared on a silicon film by magnetron sputtering. The thickness of the film is 50nm. Several...

Embodiment 2

[0049] Such as figure 1 Shown, a kind of preparation method of high-speed high-efficiency MSM photodetector comprises the steps:

[0050] (1) Select the SOI substrate as the device substrate. The SOI substrate includes a silicon substrate layer, a silicon dioxide layer, and a silicon thin film layer formed by electroplating sequentially from bottom to top. The silicon substrate layer in the SOI substrate is 500 μm. The thickness of the silicon oxide layer is 3 μm, and the thickness of the silicon film layer is 0.25 μm. Clean the surface of the SOI substrate to remove contamination, and bake the SOI substrate at 200 ° C for 30 minutes to remove the moisture on the surface;

[0051] (2) Prepare a layer of silicon film on the SOI substrate by metal-organic chemical vapor deposition, and the thickness of the silicon film is 0.5 μm;

[0052] (3) An alloy film of metal bismuth and titanium was prepared on a silicon film by magnetron sputtering. The thickness of the film was 200nm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com