Transparent glass with heating coating

A window glass and coating technology, applied in the field of transparent window glass, can solve problems such as opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

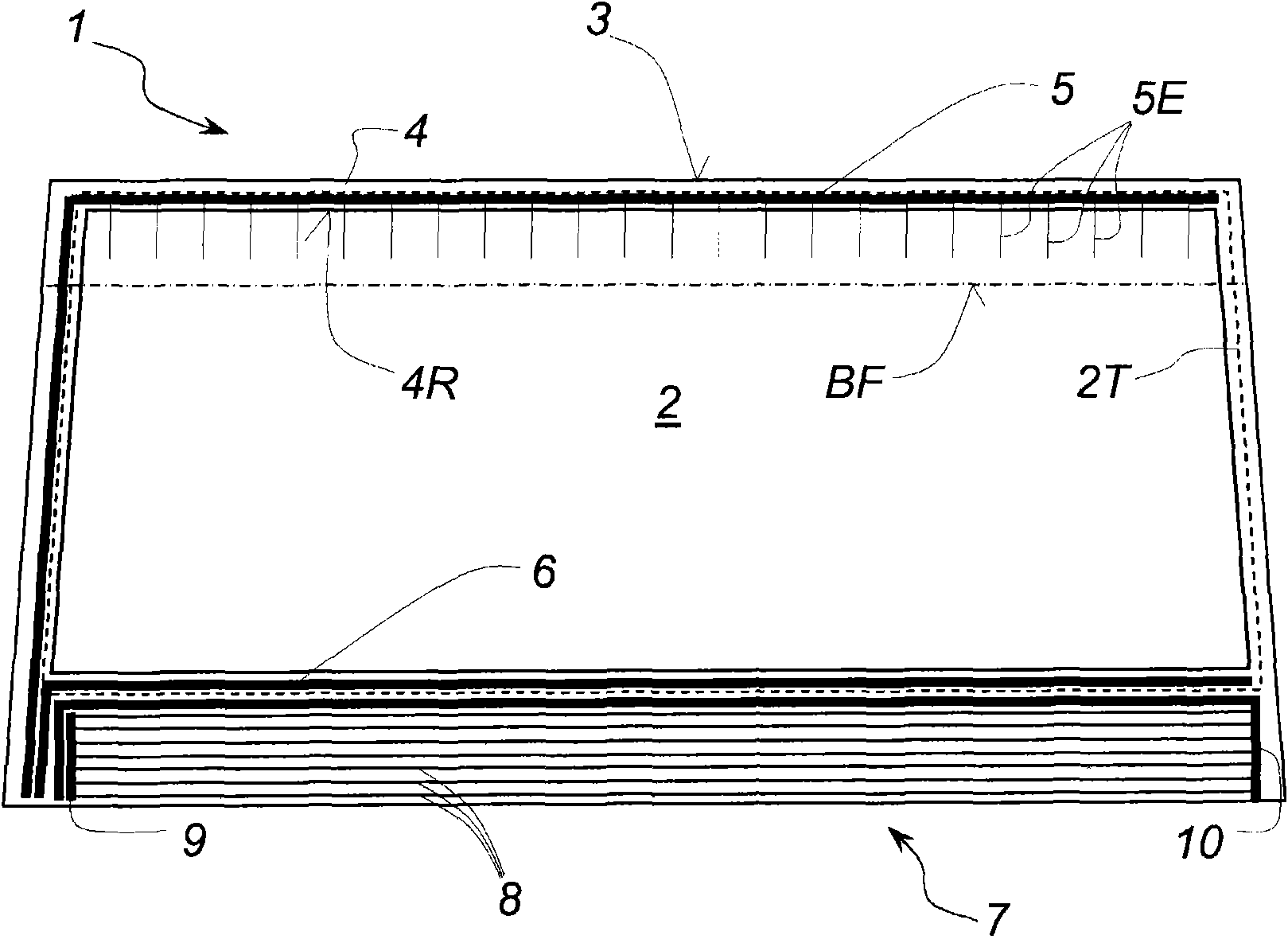

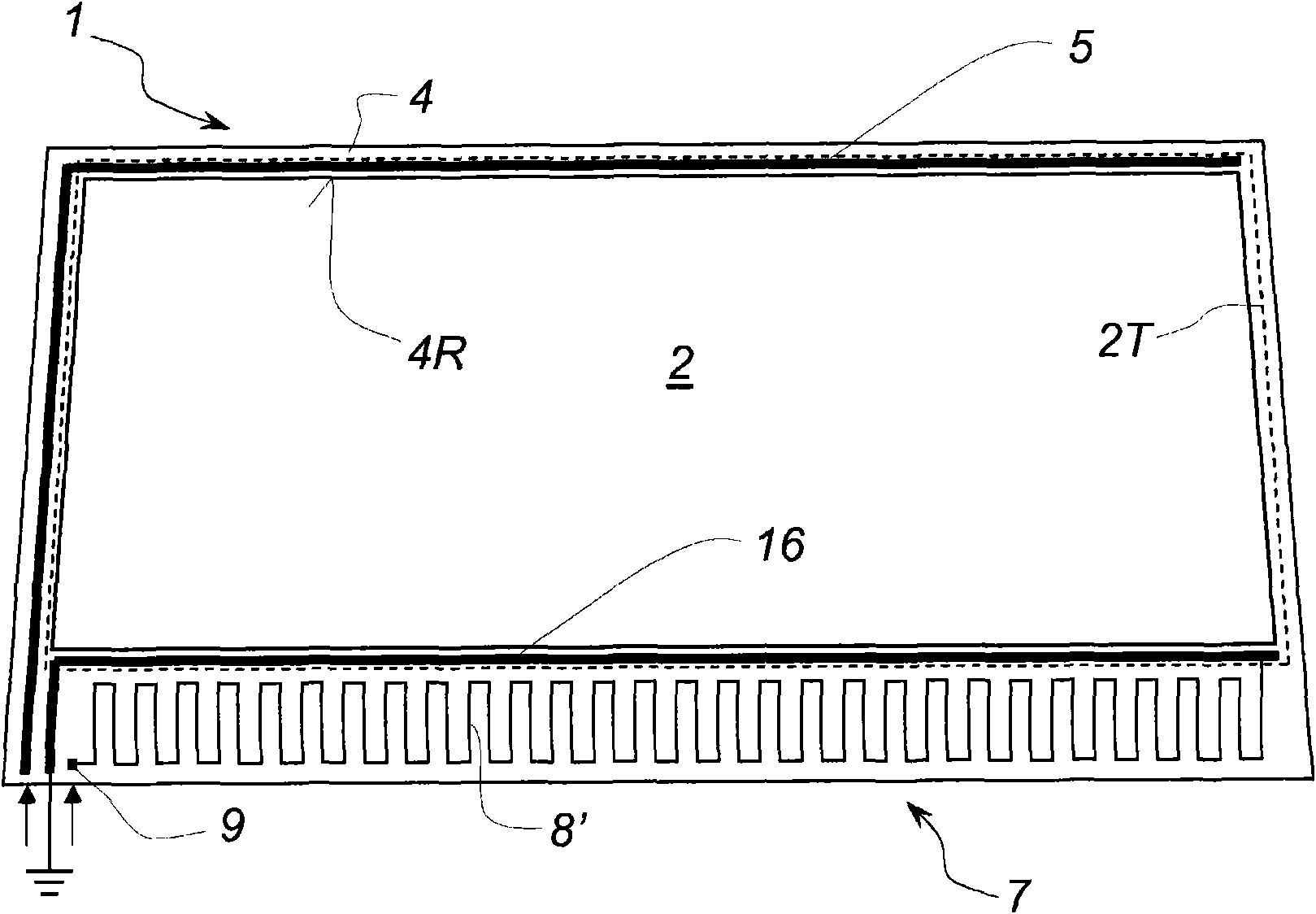

[0034] according to figure 1 , an electrically conductive and completely transparent coating 2 is incorporated in a substantially trapezoidal heated composite glazing 1 in a manner known per se.

[0035] The dashed line marked 2T indicates that on all sides the outer edge of the continuously covered surface tapers slightly inwards with respect to the outer edge 3 of the composite glazing 1 or that the edge band is spaced from the entire coating. In this way, electrical insulation from the outside is obtained on the one hand, and the coating is protected from corrosion from the outer edges on the other hand. By masking the substrate during deposition of the coating, removing the coating along the edge of the glazing, or also by drawing a perimeter dividing line through the coating along the outer edge of the glazing, a shrinkage 2T of the outer edge can be caused, which satisfies Insulation and protection against corrosion.

[0036] The coating itself preferably and in a mann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com