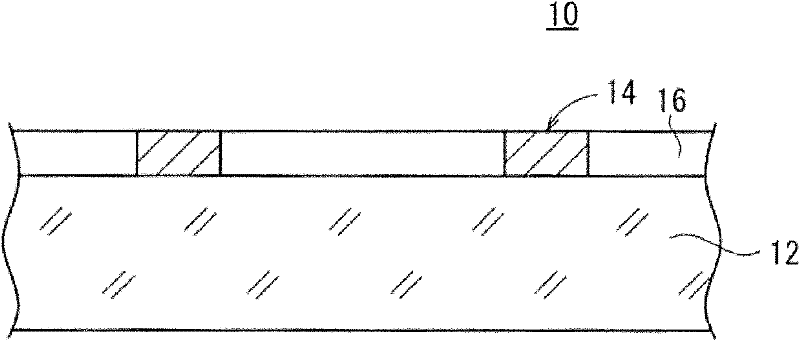

Conductive film, transparent heater, image forming method and recording medium

A conductive film and pattern technology, which is applied in the fields of conductive film, transparent heating element, pattern formation and recording medium, can solve the problems of poor visual recognition of wiring, generation of interference fringes, uneven heat generation, etc., and achieve the elimination of expansion , reduce the number of replacements, improve the effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0218] Hereinafter, the present invention will be described more specifically with reference to examples of the present invention. In addition, the material, usage-amount, ratio, processing content, processing order etc. which are shown in the following Example can be changed suitably unless it deviates from the summary of this invention. Therefore, the scope of the present invention should not be limitedly interpreted to the specific examples shown below.

no. 1 Embodiment

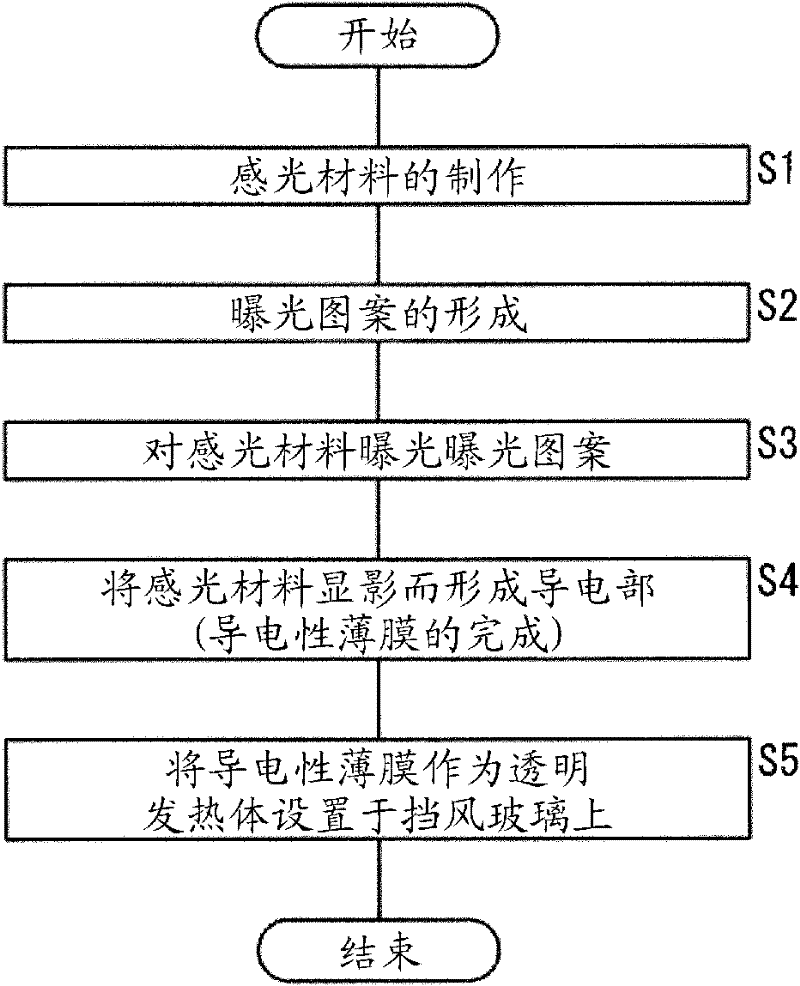

[0220] (Silver halide photosensitive material)

[0221] An emulsion containing 10.0 g of gelatin relative to 60 g of Ag in an aqueous medium containing silver iodobromochloride particles (I=0.2 mol%, Br=40 mol %) having an average spherical equivalent diameter of 0.1 μm was prepared.

[0222] Additionally, adding K to this emulsion 3 Rh 2 Br 9 and K 2 IrCl 6 , so that the concentration is 10 -7 (mol / mol silver), Rh ions and Ir ions are doped in silver bromide grains. Add Na to this emulsion 2 PdCl 4 , and then use chloroauric acid and sodium thiosulfate to carry out gold-sulfur sensitization, and then apply it to polyethylene terephthalate (PET) together with gelatin hardening agent, so that the coating amount of silver is 1g / m 2 . At this time, the Ag / gelatin volume ratio was 1 / 2.

[0223] On a 30 cm wide PET support body, 20 m of width of 25 cm was applied, and both ends were cut off by 3 cm to leave 24 cm of the coated central part to obtain a roll-shaped silver...

no. 2 Embodiment

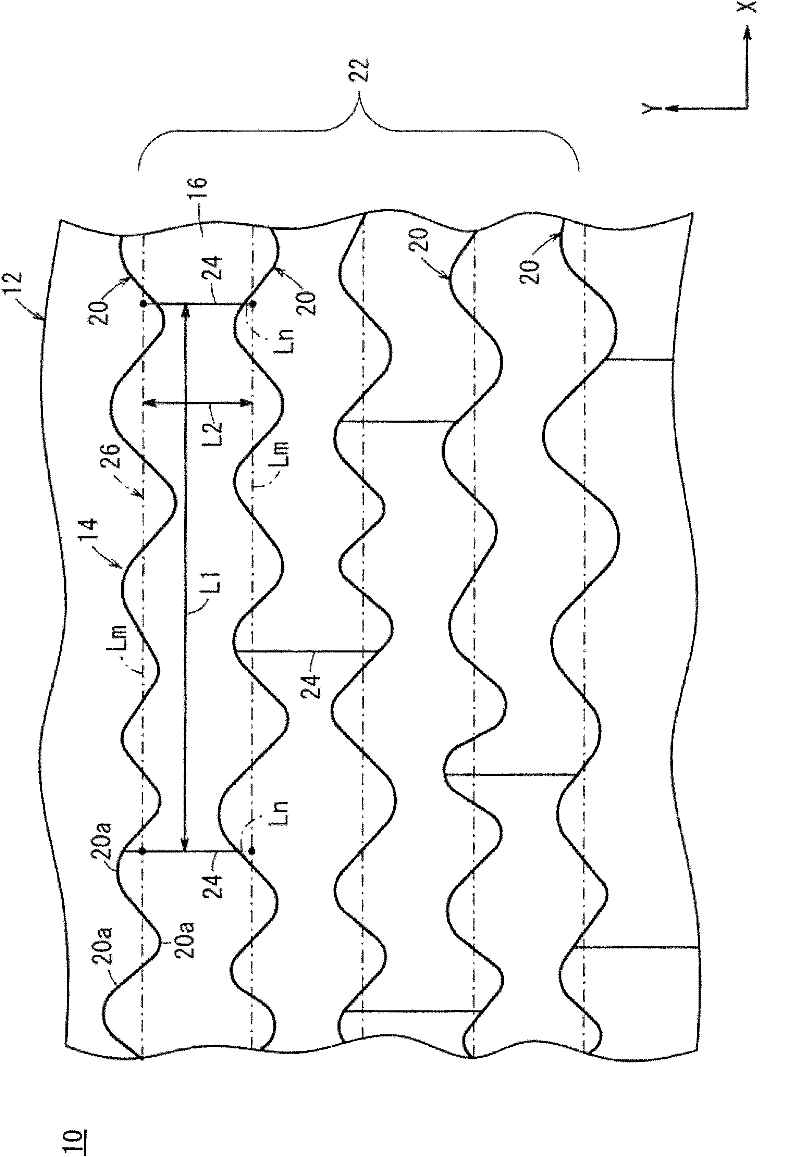

[0260] Next, adjust Figure 4 ~ Figure 6 In the pattern forming process shown in , various changes are made to the ratio (L1 / L2) of the length L1 of the first side to the length L2 of the second side of the closed area (quadrilateral), and six kinds of patterns are obtained in the same manner as in the first embodiment. Conductive film (samples 1 to 6). The details of samples 1 to 6 are as follows: Figure 11 As shown, the ratio (L1 / L2) of sample 1 is 1, the ratio (L1 / L2) of sample 2 is 2.5, the ratio (L1 / L2) of sample 3 is 5, and the ratio (L1 / L2) of sample 4 is 10 , the ratio (L1 / L2) of sample 5 is 50, and the ratio (L1 / L2) of sample 6 is 100.

[0261] About samples 1-6, the sensory evaluation of the diffraction image and wiring visibility was performed by 4 evaluators. The evaluation results are shown in Figure 11 . Figure 11 In the graph of , the horizontal axis represents the ratio (L1 / L2), and the vertical axis represents the evaluation score. The evaluation resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com