A self-aligned in-situ characterization chip and its preparation and use method

A self-aligning, in-situ technology, applied in material analysis using radiation, material analysis using radiation diffraction, and material analysis using wave/particle radiation, etc., can solve problems such as hindering sample observation, and achieve easy learning and The effect of promotion, simple use method and good material compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

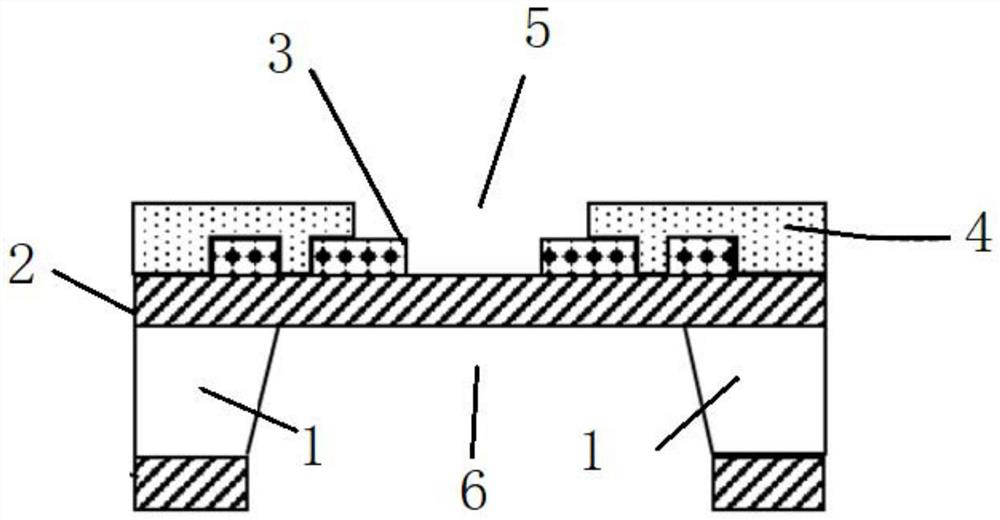

[0038] The first embodiment A self-aligned in-situ characterization chip for background observation

[0039] Such as figure 1 Shown is a self-aligned in-situ characterization chip according to the first embodiment of the present invention, which is used for in-situ observation of a sample to be tested, including a substrate layer 1, the front and back of the substrate layer 1 A first insulating layer 2 and a second insulating layer 2' are provided respectively. Wherein, the substrate layer 1 is used to support structures such as the first insulating layer 2 and the second insulating layer 2', and the material of the substrate layer 1 is silicon, silicon carbide or gallium nitride. In this embodiment, the substrate layer 1 is a circular silicon wafer with a thickness of 400-500 μm.

[0040] The first insulating layer 2 has a front side away from the substrate layer 1, a functional layer 3 and a third insulating layer 4 are arranged on the front side of the first insulating la...

no. 2 example

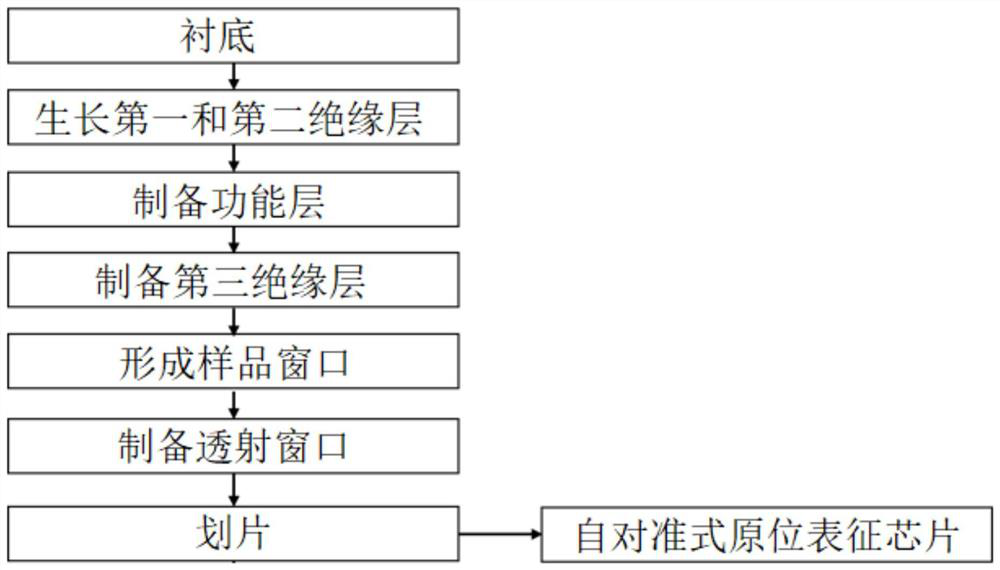

[0043] Second embodiment A method for preparing a self-aligned in-situ characterization chip

[0044] Such as figure 2 Shown is a method for preparing a self-aligned in-situ characterization chip according to the second embodiment of the present invention, which is used to prepare the self-aligned in-situ characterization chip according to the first embodiment of the present invention.

[0045] Such as figure 2 As shown, in this embodiment, the preparation method of the self-aligned in-situ characterization chip comprises the following steps:

[0046] Step S1: preparing a substrate sheet, growing a first insulating layer 2 and a second insulating layer 2' on the front and back sides of the substrate sheet respectively;

[0047] Wherein, the first insulating layer 2 is deposited and grown on the surface of the substrate by low pressure chemical vapor deposition (LPCVD), plasma enhanced chemical vapor deposition or atomic layer deposition. The substrate is a 4-inch Si (100)...

no. 3 example

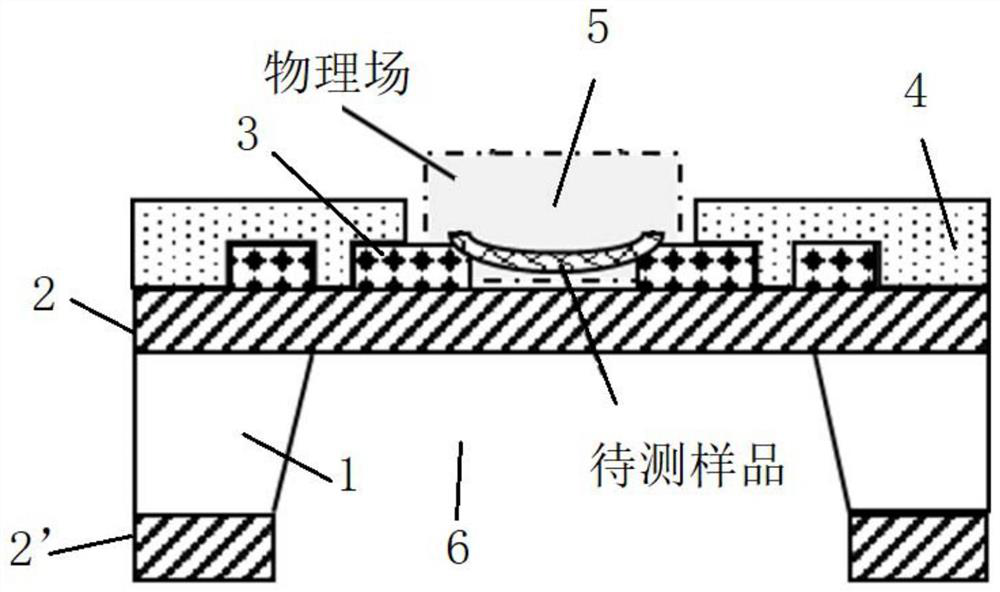

[0071] The third embodiment A method of using a self-aligned in-situ characterization chip

[0072] According to the third embodiment of the present invention, the self-aligned in-situ characterization chip used in the method for using the self-aligned in-situ characterization chip is the same as the above-mentioned self-aligned in-situ characterization chip according to the first embodiment of the present invention. The quasi-type in-situ characterization chip is exactly the same, and this method is used for in-situ observation of a sample to be tested by a transmission electron microscope (TEM).

[0073] Such as image 3 As shown, the method for using the self-aligned in-situ characterization chip specifically includes the following steps:

[0074] Step S1': providing a self-aligned in-situ characterization chip according to the first embodiment of the present invention;

[0075] Step S2': Prepare a sample to be tested in the sample window 5 of the self-aligned in-situ cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com