Self-supporting light-emitting optical cable and manufacturing method thereof

A self-supporting, optical cable technology, applied in the field of optical cables, can solve problems such as optical fiber core disconnection, achieve better performance, strong load-bearing, and eliminate disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

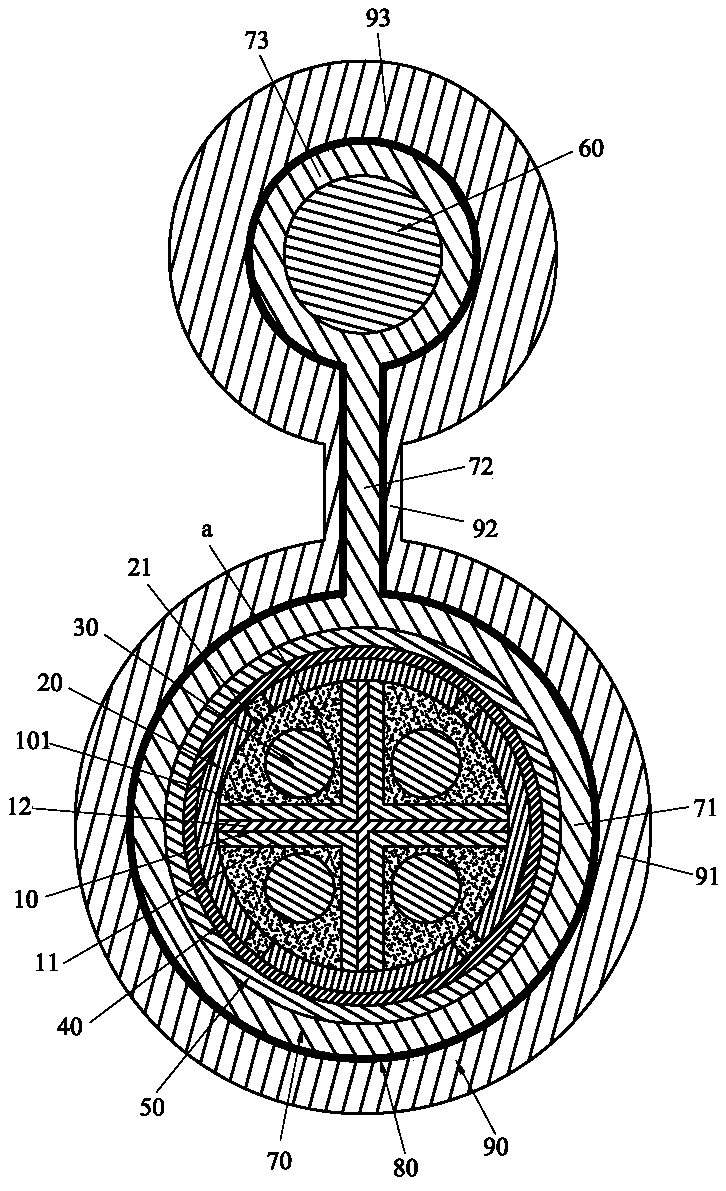

[0035] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a reinforced inner frame 10, a heat shrinkable sleeve 20, a plurality of optical fibers 30, a waterproof layer 40, a metal shielding layer 50, a steel Stranded wire 60 , a ballistic braided layer 70 , a light emitting layer 80 and a flame retardant transparent sheath layer 90 .

[0036] The peripheral side of the reinforced inner frame 10 is formed with a plurality of placement positions 101 arranged at intervals. The reinforced inner frame 10 includes an outer carbon fiber frame body 11 and an inner metal frame body 12, and the inner metal frame body 12 is embedded in the formed outer carbon fiber frame body. In the frame body 11; in this embodiment, the cross-section of the reinforced inner frame 10 is cross-shaped, correspondingly, there are four placement positions 101, and the inner metal frame body 12 is made of aluminum alloy.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com