Random oiling device for sewing thread/seaming thread

The technology of overlocking thread and sewing thread is applied in the field of sewing thread/overlocking thread random oiling device, which can solve the problems of increasing production cost, high thread breakage rate and high selling price, and can eliminate thread breakage, reduce purchase cost and prevent thread breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

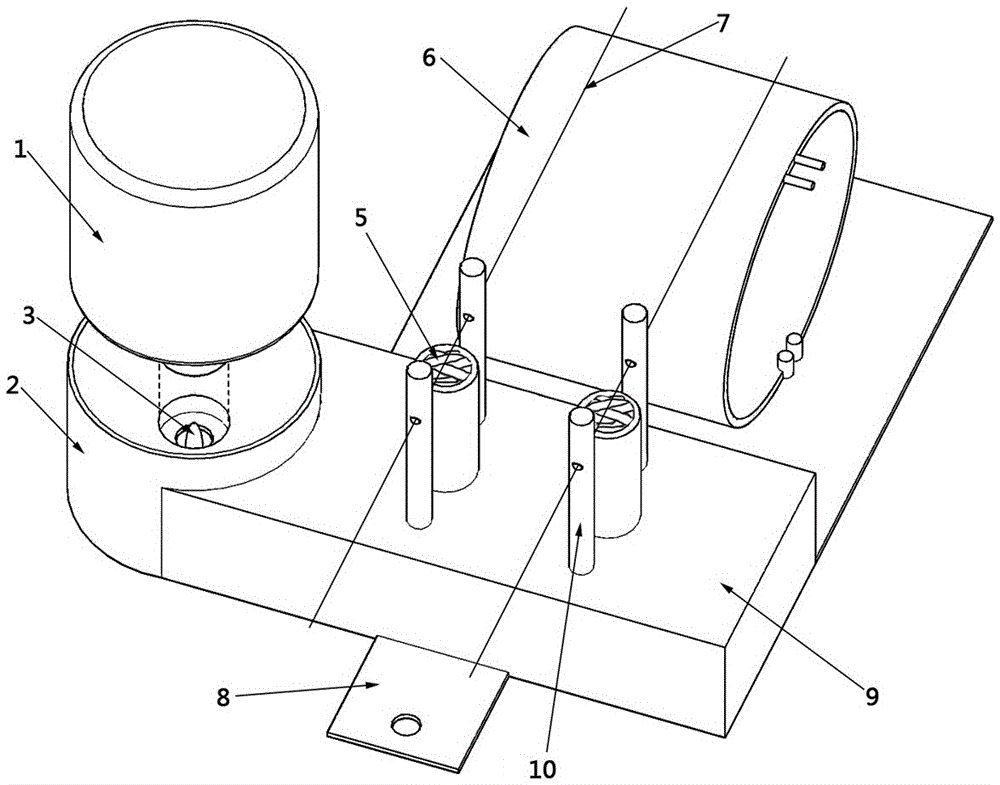

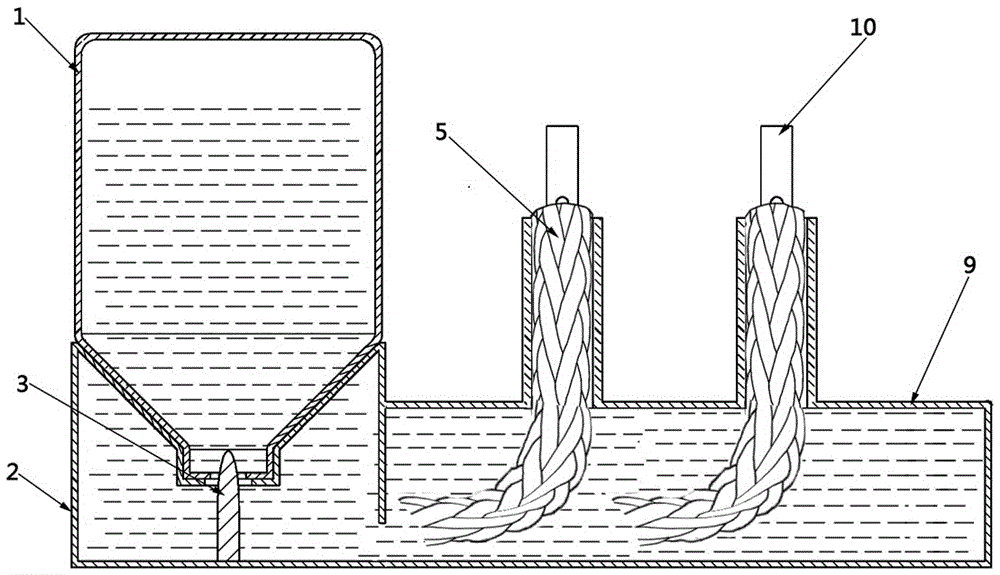

[0031] Such as figure 1 , 2 As shown, the first implementation of the random oil passing device of the present invention is: the oil passing device includes an oil bottle 1, a bottle seat 2, an oil box 9, a grease nipple 5, a threading rod 10, a bottom plate 8 and an electric heating ring 6 and the like.

[0032] The oil bottle 1 is used to contain the oily solution, and flexible sealing layers such as sealing paper or sealing film are pasted on the bottle mouth. The bottle holder 2 is a cylindrical cover shell with an opening upward, and an upright insertion rod 3 is fixed at the center of the bottom surface inside the cover housing, and the upper end of the insertion rod 3 is a spiked portion. Bottle seat 2 can be the casing of single wall or contain the closed shell of cavity ( figure 2 ). The bottle base 2 is used to accept the bottleneck of the oil bottle 1, and after being connected to the bottleneck, the upper end of the insertion rod 3 is used to pierce the flexibl...

Embodiment 2

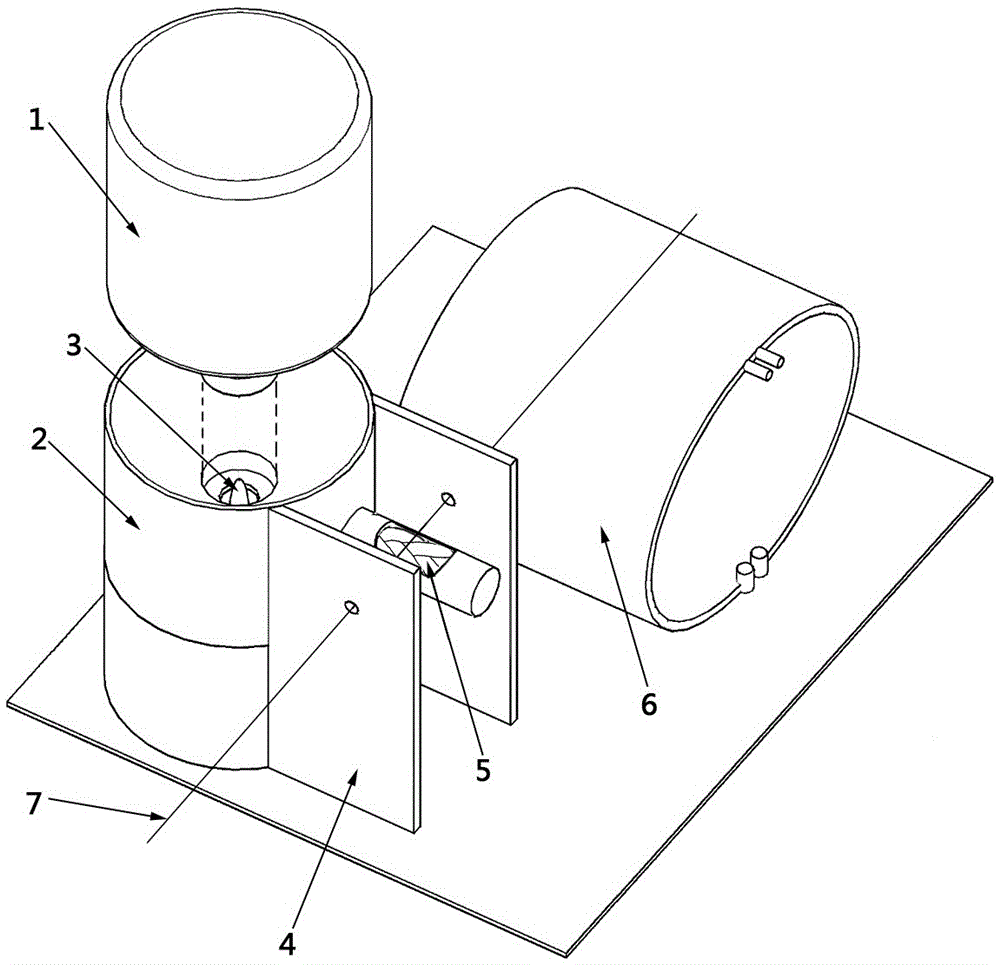

[0037] Such as image 3 , 4 As shown, the second realization of the random oil passing device of the present invention is: the oil passing device includes an oil bottle 1, a bottle seat 2, an oil rubbing nozzle 5, a threading plate 4, a bottom plate and an electric heating ring 6 and the like.

[0038] The structure and matching relationship between the oil bottle 1 and the bottle holder 2 are the same as those in Embodiment 1, and the bottle holder 2 can also be a single-wall casing or a closed shell containing a cavity. The bottom surface of oil box 9 is provided with base plate, and base plate is a whole plate, doubles as the fixture that this oil passing device integral body is fixed on the sewing machine or the seaming machine. The oil rubbing nozzle 5 is made up of a pipe shell with one end closed, one end open and one end tightly plugged in the oil rope core in the pipe shell ( Figure 4 ). The pipe shell of oil rubbing nozzle 5 is horizontally arranged, and its open e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com