Large-carrying-capacity and environmentally-friendly direct current cable used for fixed laying

A DC cable, high-carrying-capacity technology, applied to power cables, circuits, and electrical components with shielding layers/conductive layers, etc., can solve cable polarity reversal test non-compliance, space charge accumulation, and reduce cable service life, etc. problems, to achieve high strength, improve service life, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

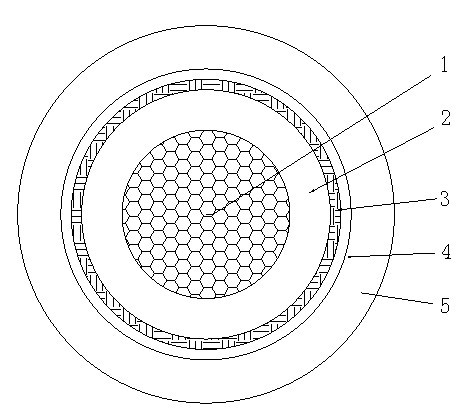

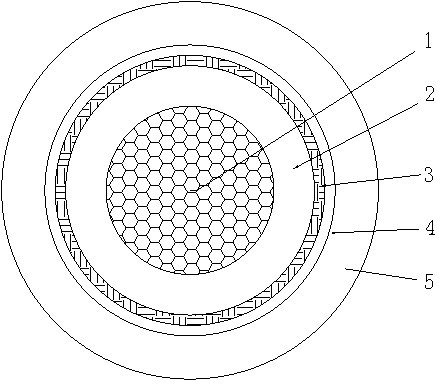

[0016] Such as figure 1 As shown, an environment-friendly DC cable for fixed laying with high ampacity according to the present invention mainly includes a circular compacted stranded copper conductor 1 located at the axis of the cable, and is extruded outside the circular compacted stranded copper conductor 1 EPDM rubber insulation layer 2, outside the EPDM rubber insulation layer 2, a copper tape wrapping protective layer 3, low-smoke, halogen-free, flame-retardant wrapping tape 4 and low-smoke, halogen-free, flame-retardant, environmentally friendly outer sheath are arranged in sequence 5.

[0017] in:

[0018] 1. The cable conductor adopts Class 2 tight-pressed and stranded circular conductors specified in the GB / T3956-2008 standard, and multiple anaerobic annealed copper wires with a diameter of 2.5mm or 3.0mm are used for stranding according to the cross-sectional size of the cable. The tight pressing of the die makes the copper wires tightly bonded, the surface is smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com