Intelligent temperature control thermal underwear

A technology of thermal underwear and intelligent temperature control, applied in the field of thermal clothing, can solve problems such as inconvenience, uneven heating, high voltage, etc., and achieve the effects of comfortable wearing, convenient and diverse use, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

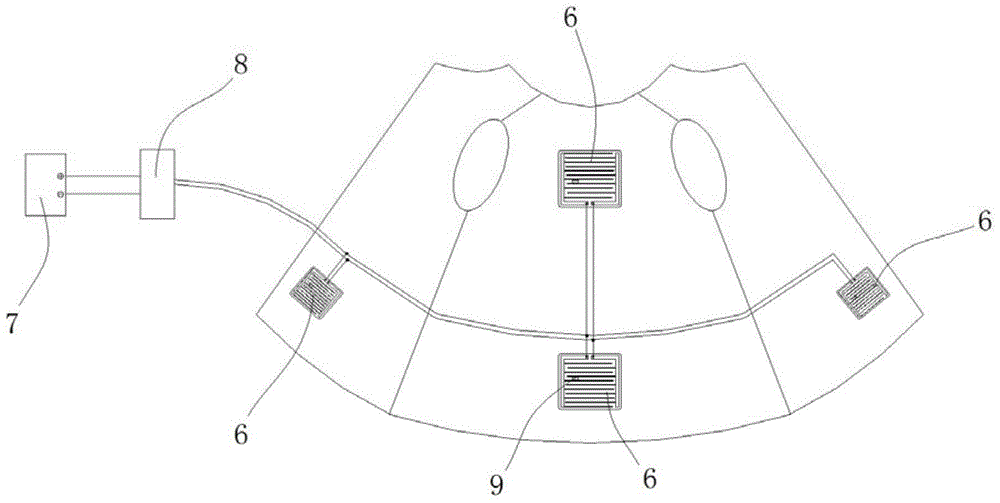

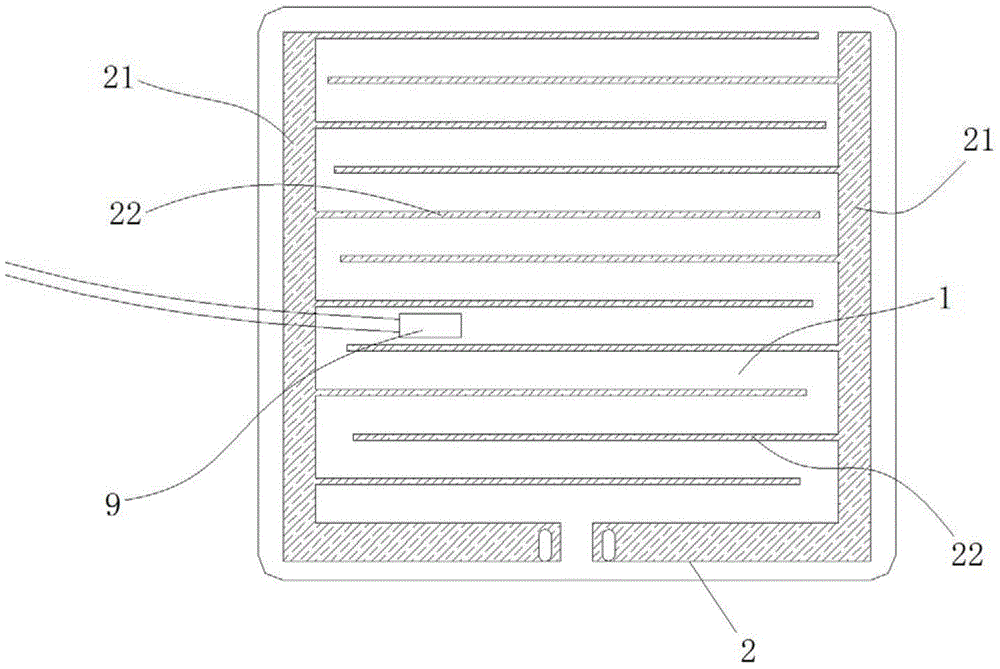

[0065] like figure 1 As shown, the thermal vest of an embodiment introduces such as figure 2 For the low-voltage transparent electric heating film 6 of the structure shown, a piece of the above-mentioned low-voltage transparent electric heating film 6 is arranged on the vest and the spine, lumbar spine, and abdomen of the body; the battery 7 that provides heating energy and the working energy of the control module passes through the contacts Or the connection wire is electrically connected with the control module 8, the battery 7 and the control module 8 can be integrated into a box, and all the low-voltage transparent electric heating films are connected to the control power output interface of the control module 8 by lead wires in parallel; A thin-film thermistor 9 is pasted on a piece of low-voltage transparent electrothermal film to monitor the real-time temperature of the low-voltage transparent electrothermal film.

[0066] An operation button and a working indicator l...

Embodiment 2

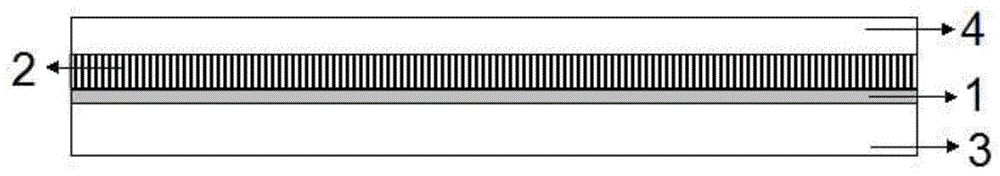

[0071] This embodiment is basically the same as Embodiment 1, except that the internal electrodes and the bus bars are made of different materials. The transparent conductive material can be used as the inner electrode, and the metal material can be used as the bus bar; or different metal materials can be used as the inner electrode and the bus bar respectively; or the transparent conductive material can be used as the bus bar, and the metal material can be used as the inner electrode. In this embodiment, metal copper foil or silver paste is preferably used as the material of the bus bar, and graphene with at least 5 layers is used as the material of the internal electrodes. In this embodiment, it is more preferable to use metal platinum as the material of the bus bar and 10-layer graphene as the material of the internal electrodes. Single-layer graphene is used as the material of the transparent conductive layer (square resistance is 250Ω / □). The graphene internal electrode ...

Embodiment 3

[0075] This embodiment is basically the same as Embodiment 1, the difference lies in the specific design of the electrodes.

[0076] In order to ensure that the internal electrodes are arranged at different positions of the bus bar, the difference between the highest voltage and the lowest voltage does not exceed 10%. During the production of this embodiment, the number of intervals n generated by the internal electrodes, the longest length l of the internal electrodes, and the width W of the bus bar 1. The thickness H of the bus bar is measured and processed accurately, so that it conforms to the above formula (2).

[0077] This embodiment requires that the electrodes be arranged as follows: the length of the inner electrode is 108 mm, 15 intervals are generated in total, the width of the bus bar is 8 mm, and the thickness is 25 μm. After testing, the difference between the highest voltage and the lowest voltage at different positions of the bus bar is 0.2%.

[0078] Connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com