Water-based electric heating coating composition, water-based electric heating coating, preparation method of water-based electric heating coating and electric heating film prepared by water-based electric heating coating

An electrothermal paint and composition technology, applied in the field of paint, can solve problems such as VOC emission and power attenuation, and achieve the effect of reducing production and use emissions and solving power attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing the above-mentioned water-based electrothermal coating, wherein the method comprises the following steps:

[0049] (1) mixing and grinding carbon nanotubes, graphene, nano carbon black and aqueous dispersion resin;

[0050] (2) mixing the mixed slurry obtained in step (1) with the aqueous resin emulsion;

[0051] Wherein, the auxiliary agent is optionally introduced in step (1) and / or step (2).

[0052] According to the present invention, the grinding conditions are not particularly limited, and may be conventional conditions in the art. For example, the grinding temperature can be room temperature (for example, 5-45°C);

[0053] Wherein, in step (1), the grinding process includes the first grinding process and the second grinding process, the conditions of the first grinding process include: the grinding speed can be 700-800rpm, and the grinding time can be 50 -70min, the conditions of the second grinding pr...

Embodiment 1

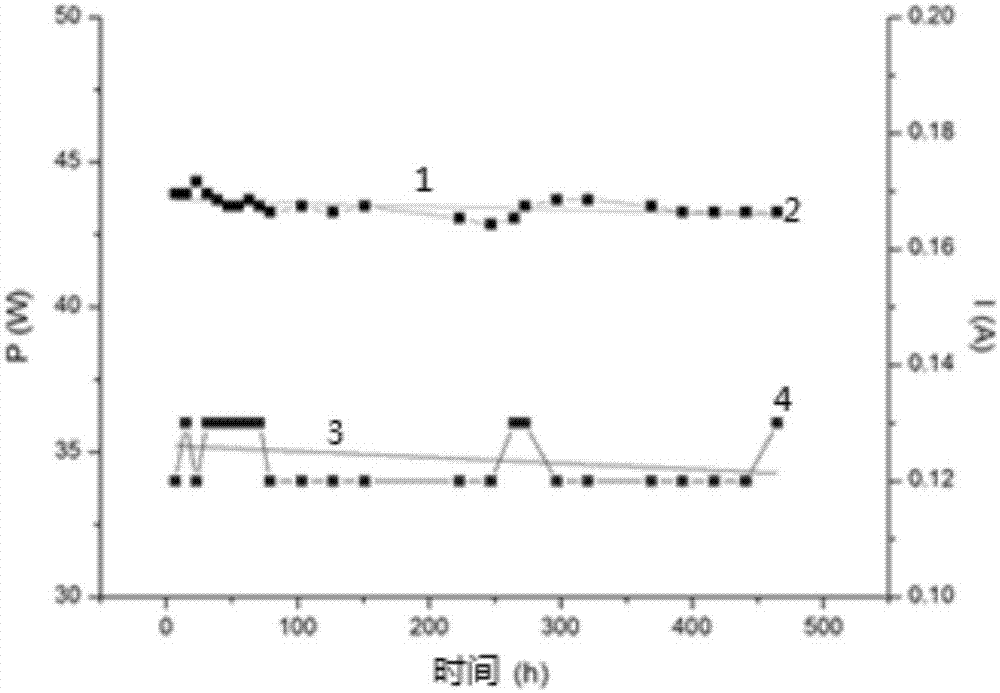

[0070] This example is used to illustrate the composition for water-based electric heating paint of the present invention, the water-based electric heating paint and its preparation method and the electric heating film prepared therefrom

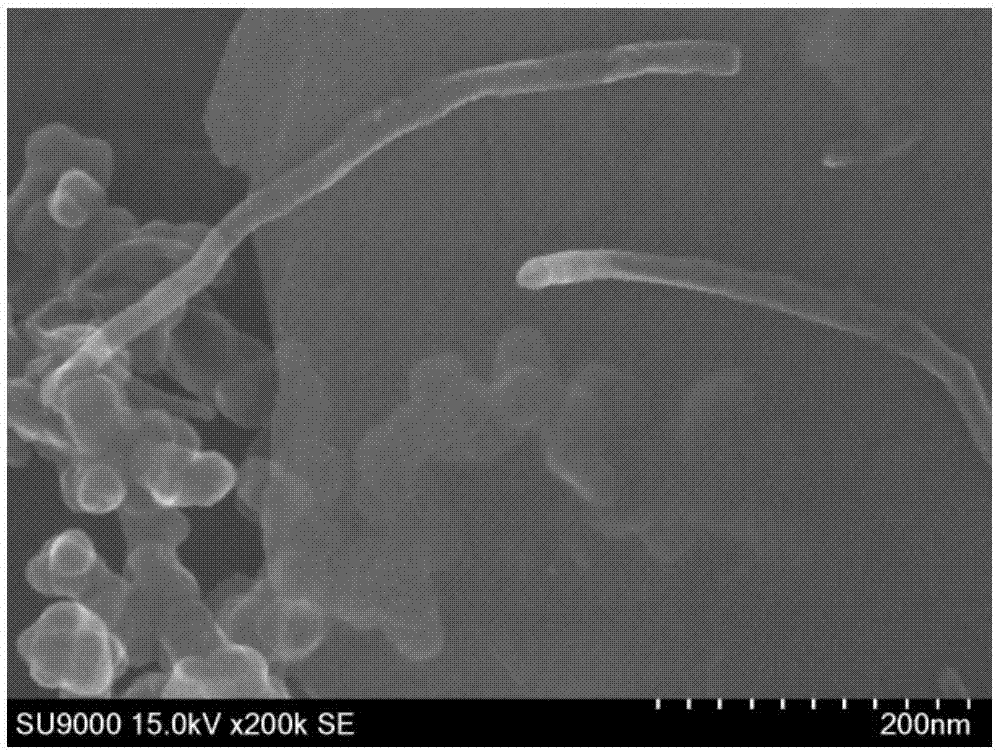

[0071] (1) Water-based dispersion resin (water-based acrylic resin) 1000g, defoamer (polyether modified polydimethylsiloxane) 10g, dispersant (polyether dispersant) 200g, defoamer (organic silicon and Silica composite) 10g, deionized water 4000g are put into grinding kettle and stir 30min with the rotating speed of 800rpm, prepare mixed solution; Then graphene powder 100g, carbon nanotube powder (multi-walled carbon nanotube) 100g 300 g of conductive carbon black powder was added to the mixed solution, and the grinding kettle was ground and stirred at a speed of 800 rpm for 60 min to obtain a dispersion containing carbon nanotubes, graphene and nano-carbon black;

[0072] (2) zirconium beads are added to the dispersion liquid of step (1) to ...

Embodiment 2

[0079] This example is used to illustrate the composition for water-based electric heating paint of the present invention, the water-based electric heating paint and its preparation method and the electric heating film prepared therefrom

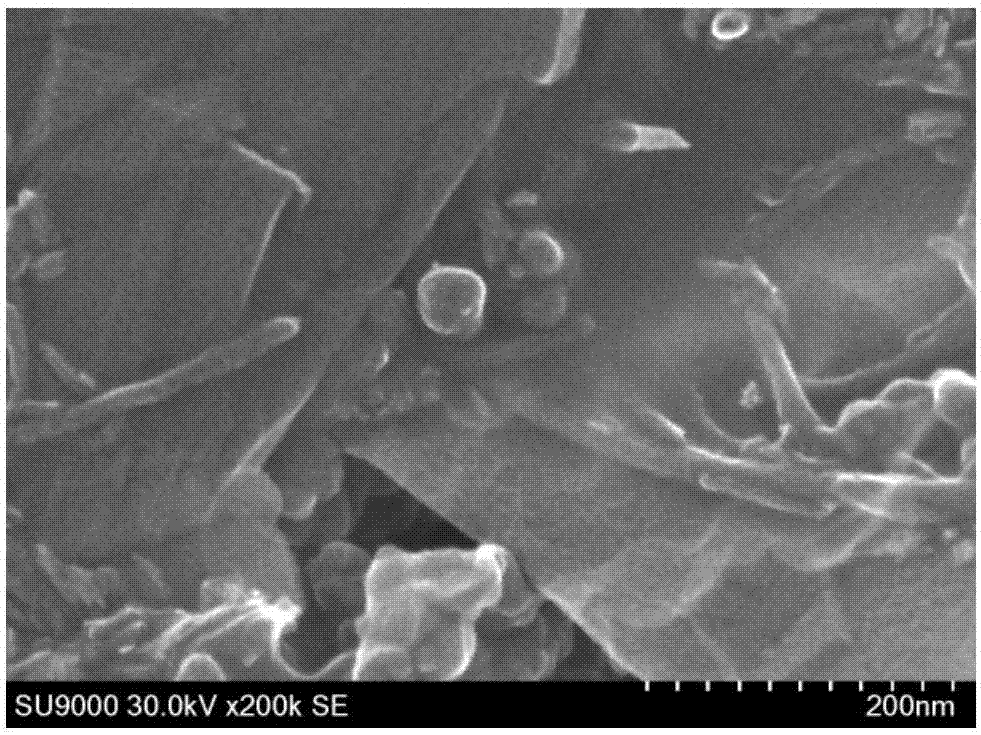

[0080] (1) Water-based dispersion resin (water-based polyurethane resin) 1000g, defoamer (BYK-017) 50g, dispersant (polyester dispersant) 1000g, defoaming agent (silicone and silica composite) 100g, Put 7000g of deionized water into the grinding kettle and stir for 30min at a speed of 800rpm to prepare a mixed solution, then add 200g of graphene powder, 300g of carbon nanotube powder, and 500g of conductive carbon black powder into the mixed solution, and grind The kettle was ground and stirred at a speed of 800 rpm for 60 min to obtain a dispersion containing carbon nanotubes, graphene and nano-carbon black;

[0081] (2) zirconium beads are added to the dispersion liquid of step (1) to be mixed with mixed slurry, wherein the consumption of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com