Multi-group symmetrical array high-power optical fiber coupling semiconductor laser packaging structure and method

A symmetrical array and fiber coupling technology, which is applied in the direction of semiconductor laser devices, semiconductor lasers, laser devices, etc., can solve the problems of complex installation and adjustment of lasers and difficulties in industrial applications, so as to improve the quality of light sources, avoid uneven heat dissipation, and increase output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

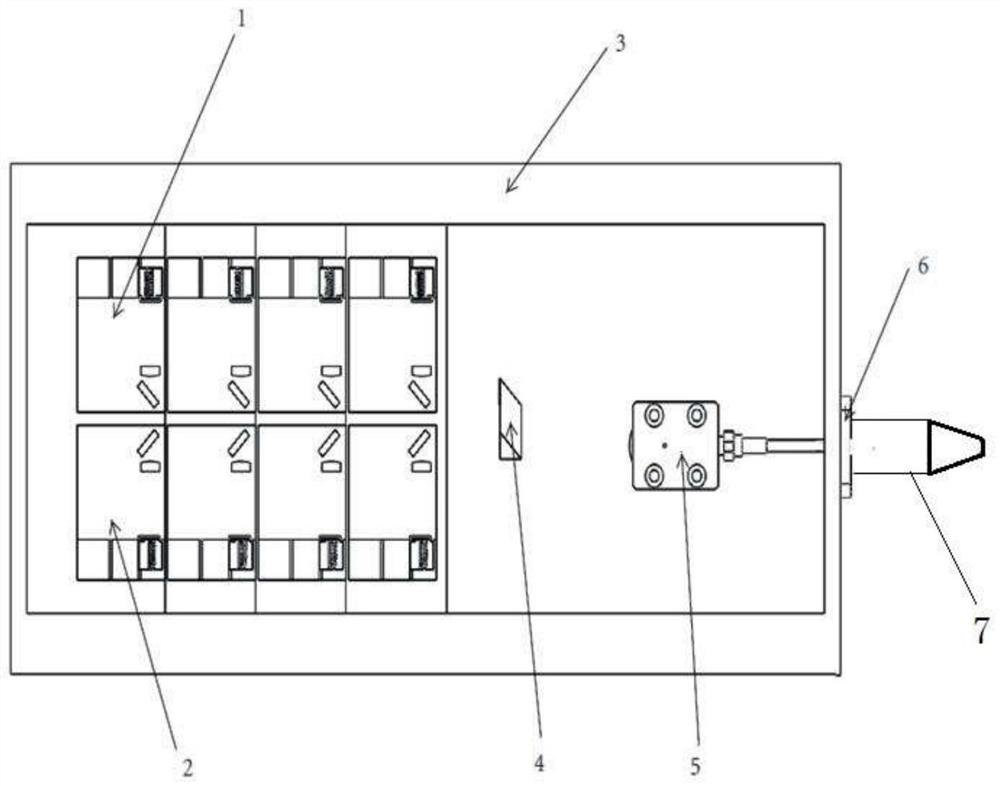

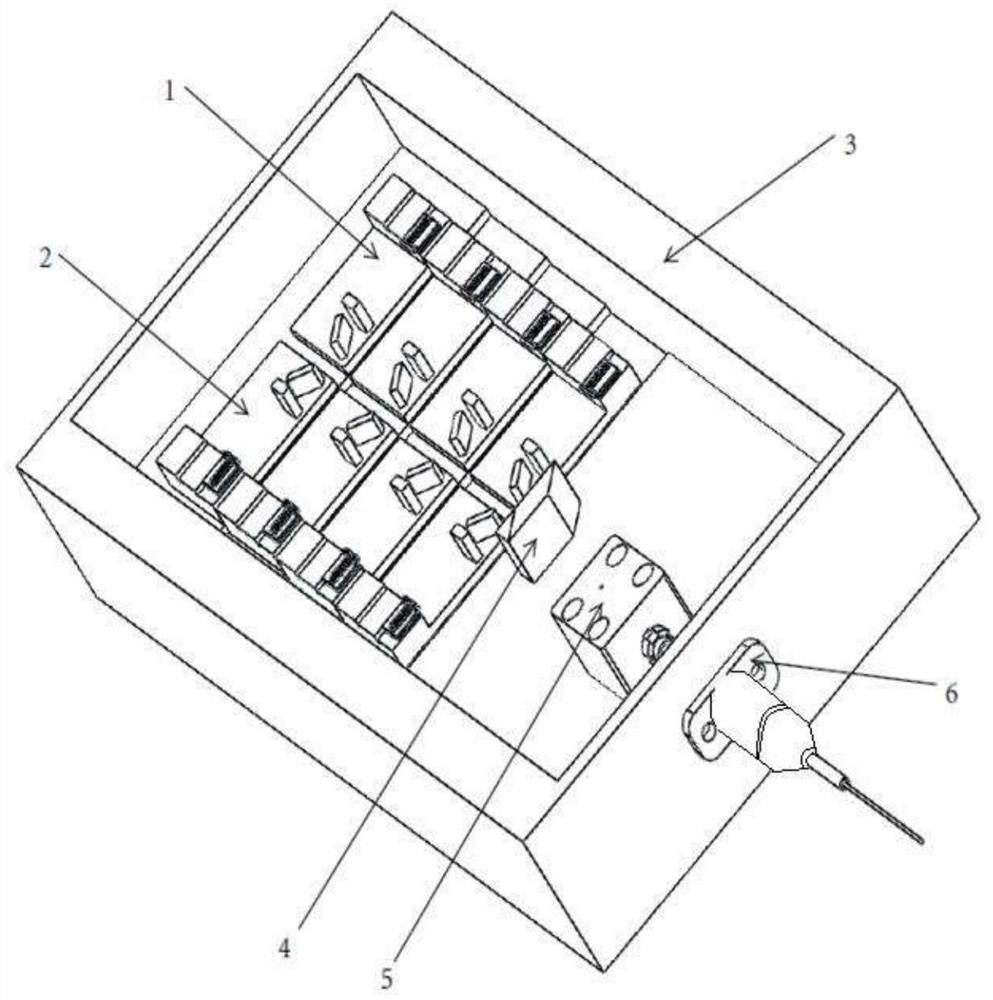

[0041] Embodiment 1: as Figure 1-2 As shown, this embodiment provides a multi-group symmetrical array high-power fiber-coupled semiconductor laser packaging structure, including a housing 3, an R-type single-group laser 1, an L-type single-group laser 2, a polarization beam combiner 4 and a fiber coupling device, of which,

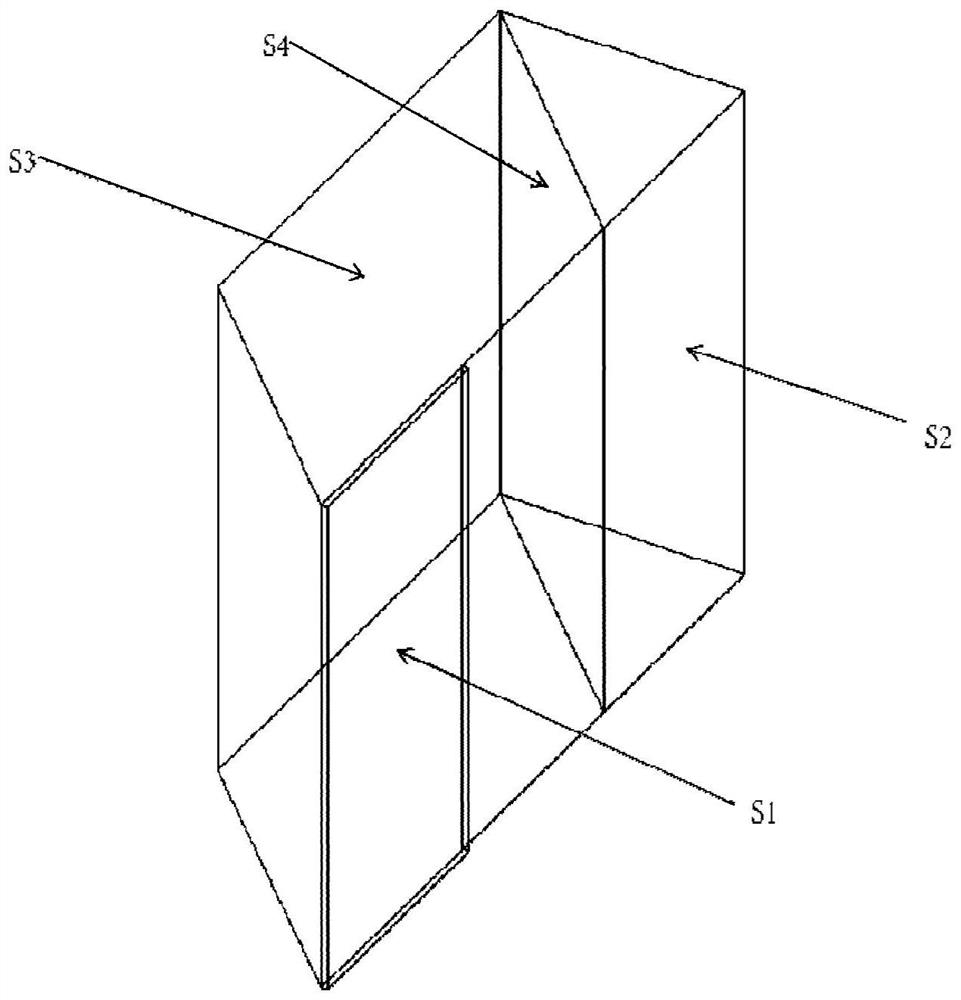

[0042] The housing 3 is a cuboid, one side of the cuboid is provided with a groove 12, and one side of the lower surface of the groove 12 is provided with a step 13, and the housing structure is as follows: Figure 7-8 As shown, the two ends of the upper surface of the step 13 are respectively provided with an R-type single-group laser 1 and an L-type single-group laser 2, and the lower surface of the groove 12 in front of the step 13 is provided with a polarization beam combiner 4, and the lower surface of the groove 12 is another A fiber optic coupler is arranged on the casing 3 on one side.

[0043] The R-type single-group laser 1 includes a base plate...

Embodiment 2

[0053] Embodiment 2: A high-power fiber-coupled semiconductor laser packaging structure with multiple groups of symmetrical arrays, the structure is as described in Embodiment 1, the difference is that the shape of the groove 12 is a cuboid, and one side of the lower surface of the groove 12 is set There are 4 sets of steps.

Embodiment 3

[0054] Embodiment 3: A high-power fiber-coupled semiconductor laser packaging structure with multiple groups of symmetrical arrays, the structure is as described in Embodiment 1, the difference is that the fiber coupler includes a coupling lens 5, a fixing seat 6 and an optical fiber assembly 7, and the coupling The lens 5 is assembled on one end of the fixing base 6 , the fiber assembly 7 is assembled on the other end of the fixing base 6 , the fixing base 6 is assembled on the housing 3 , the coupling lens 5 is inside the housing 3 , and the optical fiber assembly 7 is outside the housing 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Laser damage threshold | aaaaa | aaaaa |

| Angle of incidence | aaaaa | aaaaa |

| Laser damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com