A kind of carbon conductive paste and preparation method thereof

A technology of conductive paste and resistance, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of high square resistance of carbon conductive paste, power rise of conductive film, and power attenuation and other issues, to achieve the effect of low cost, high density, and suppression of stress changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

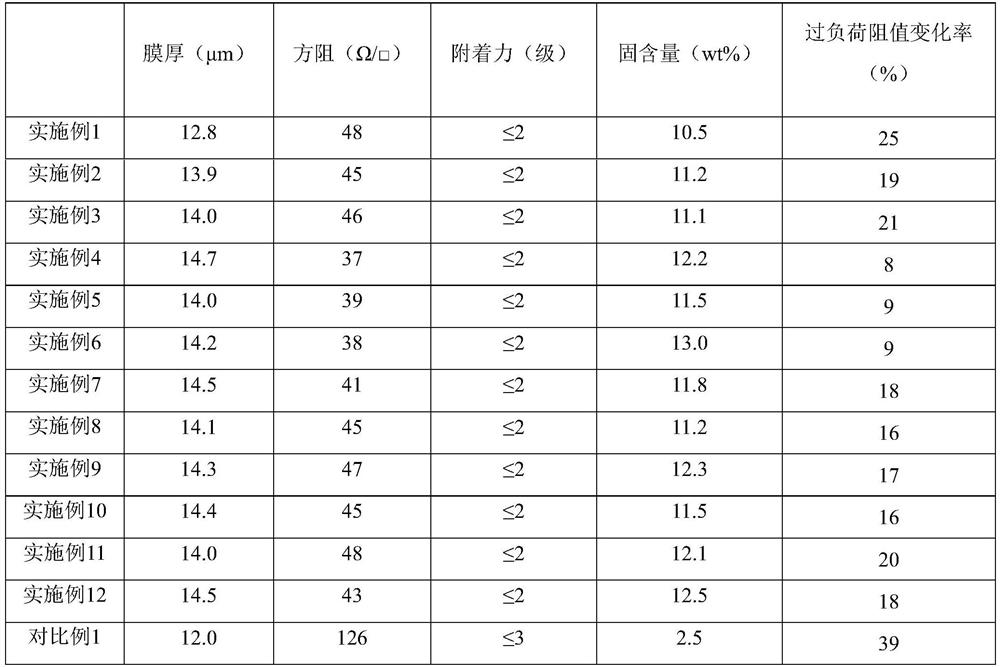

Examples

Embodiment 1

[0029] A. According to the following formula of carbon conductive paste, weigh each component for later use: 500 parts of graphene oxide aqueous solution, 40 parts of mesophase carbon microspheres, 10 parts of carbon nanotubes, 5 parts of carbon black, 25 parts of strontium titanate, 10 parts of DP460NS epoxy resin glue, 3 parts of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 850 parts of ethanol aqueous solution with a volume fraction of 70%;

[0030] B. Washing, stirring, and crushing mesophase carbon microspheres, carbon nanotubes, carbon black, and strontium titanate with ethanol aqueous solution with a volume fraction of 70% at a mass fraction ratio of 1:10 to obtain mesophase carbon microspheres Ball suspension, carbon nanotube suspension, carbon black suspension, strontium titanate suspension;

[0031] C. Uniformly mixing the graphene oxide aqueous solution with the mesophase carbon microsphere suspension, carbon nanotube suspension, carbon black suspension,...

Embodiment 2

[0036] A. According to the following formula of carbon conductive paste, weigh each component for later use: 500 parts of graphene oxide aqueous solution, 40 parts of mesophase carbon microspheres, 10 parts of carbon nanotubes, 5 parts of carbon black, 15 parts of strontium titanate, 10 parts of potassium sodium niobate, 10 parts of DP460NS epoxy resin glue, 3 parts of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, the volume fraction is 70% 850 parts of ethanol aqueous solution;

[0037] B. Washing, stirring and crushing mesophase carbon microspheres, carbon nanotubes, carbon black, strontium titanate, potassium sodium niobate and ethanol aqueous solution with a volume fraction of 70% at a ratio of 1:10 in parts by mass, Obtain mesophase carbon microsphere suspension, carbon nanotube suspension, carbon black suspension, strontium titanate suspension, potassium sodium niobate suspension;

[0038] C. Uniformly mixing the graphene oxide aqueous solution with the mesoc...

Embodiment 3

[0043]A. According to the following formula of carbon conductive paste, weigh each component for later use: 500 parts of graphene oxide aqueous solution, 40 parts of mesophase carbon microspheres, 10 parts of carbon nanotubes, 5 parts of carbon black, 15 parts of strontium titanate, 10 parts of titanium dioxide, 10 parts of DP460NS epoxy resin glue, 3 parts of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 1000 parts of ethanol aqueous solution with a volume fraction of 70% share;

[0044] B. The mesophase carbon microspheres, carbon nanotubes, carbon black, strontium titanate, and titanium dioxide are washed, stirred, and crushed with ethanol aqueous solution with a volume fraction of 70% at a ratio of 1:10 to obtain the mesophase Carbon microsphere suspension, carbon nanotube suspension, carbon black suspension, strontium titanate suspension, titanium dioxide suspension;

[0045] C. Uniformly mixing the graphene oxide aqueous solution with the mesocarbon microsphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com