Electric heating composite floor heating core and manufacturing method thereof

An electro-heating composite and electro-heating floor technology is applied in heating methods, ohmic resistance heating parts, household heating and other directions, which can solve the problems of insufficient durability and poor health care function, and achieve the effect of increasing the emission power intensity and solving the power attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

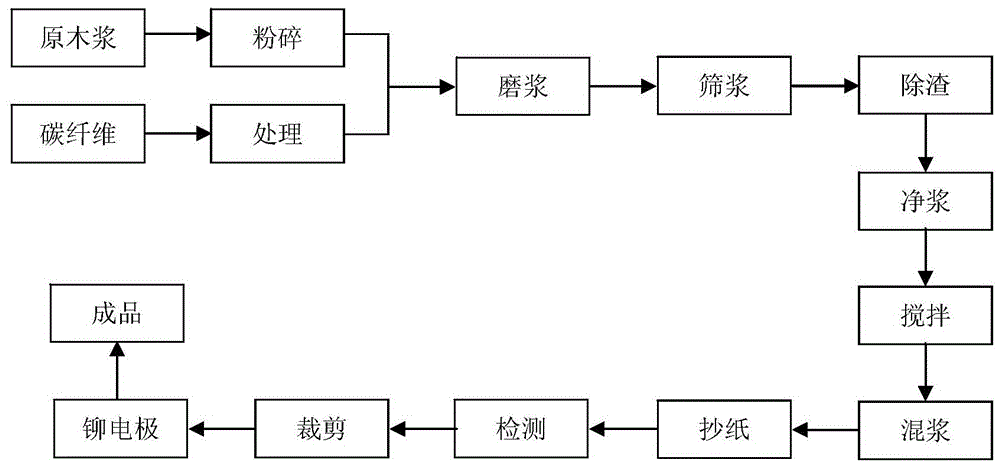

[0040] Such as figure 1 Shown, technological process of the present invention is as follows:

[0041] After pulverized raw wood pulp and treated carbon fiber are mixed and refined, pulping→sieving→slagging→cleaning→stirring→mixing→papermaking→testing→cutting→riveting electrodes→finished products, refer to the Chinese invention patent application No. 200710011037.4 and 201210457292.2. Wherein, the research emphasis of the present invention lies in:

[0042] (1) The short electrode or long electrode is riveted with carbon fiber (carbon crystal) electric heating paper, see Figure 2-1 to Figure 2-4 ;

[0043] (2) Wiring and laying of short-electrode electric heating floor heating core, see Figure 3-1 to Figure 3-4 ;

[0044] (3) Wiring and laying of the heating core of the long-electrode electric heating floor, see Figure 4-1~Figure 4-2 .

[0045] Such as diagram 2-1 , Figure 2-3 As shown, between the short electrodes 1 is carbon fiber (carbon crystal) electric heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com