Constant-temperature battery box of electric automobile and heat management control method of constant-temperature battery box

A technology for electric vehicles and battery boxes, which is applied to secondary batteries, battery pack parts, battery boxes/coats, etc. It can solve the problems of heating battery boxes, etc., and achieve the effects of increasing driving range, reducing costs, and large available capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

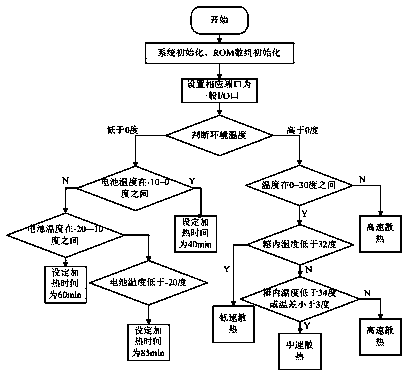

[0028] The invention discloses a constant temperature battery box and a heat management control method thereof, wherein the battery is a 330Ah lithium iron phosphate battery of Shenzhou Yuanwang. Firstly, FLUENT software is used to simulate the flow field, so as to determine the selection of fans, heating film and insulation materials, and propose structural solutions to the problems of fixed battery pack and low temperature at both ends, and finally develop a set of thermal management software The hardware control system uses fuzzy control to control the heating film and fan, and uses VB software to make the real-time display and historical data query interface of the battery thermal management system.

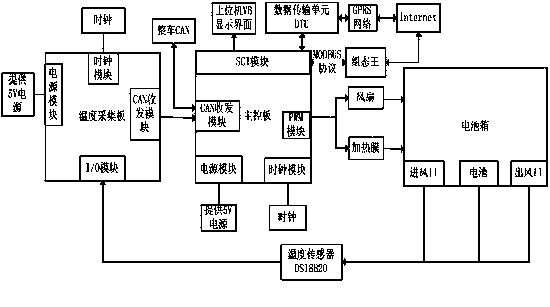

[0029] refer to figure 1, the temperature of the battery, air inlet and air outlet in the battery box is detected by the temperature sensor DS18B20, collected by the I / O module of the temperature acquisition board, and then transmitted to the main control board through the CA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com