Flexible packaging power lithium ion battery pack for electric automobile

A technology for lithium-ion battery packs and electric vehicles. It is applied in electric vehicles, secondary batteries, transportation and packaging, etc. It can solve the problems of affecting battery performance, inability to control temperature, and inability to operate battery packs, etc., so as to achieve no explosion hazard. , light weight, high mass specific energy and high specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

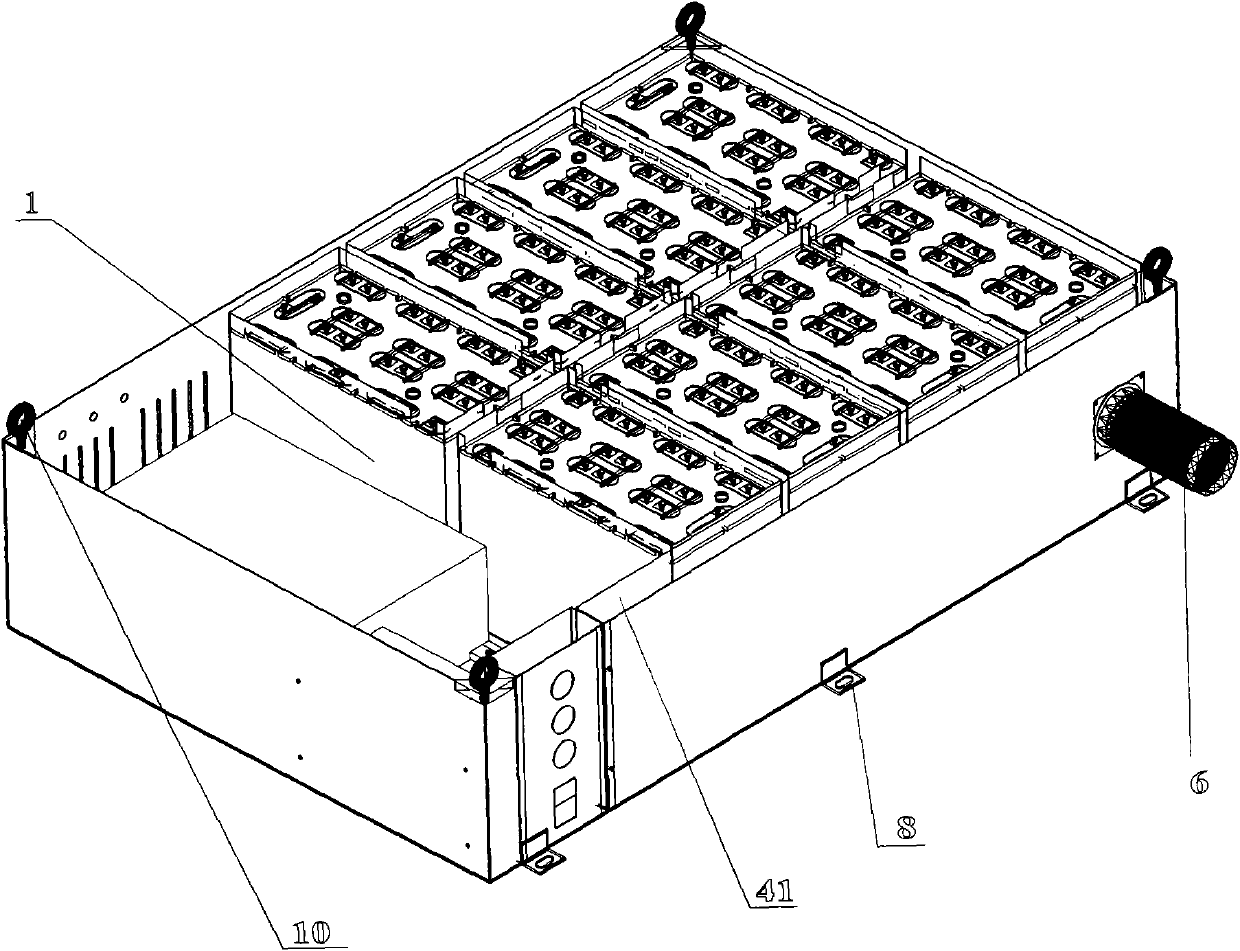

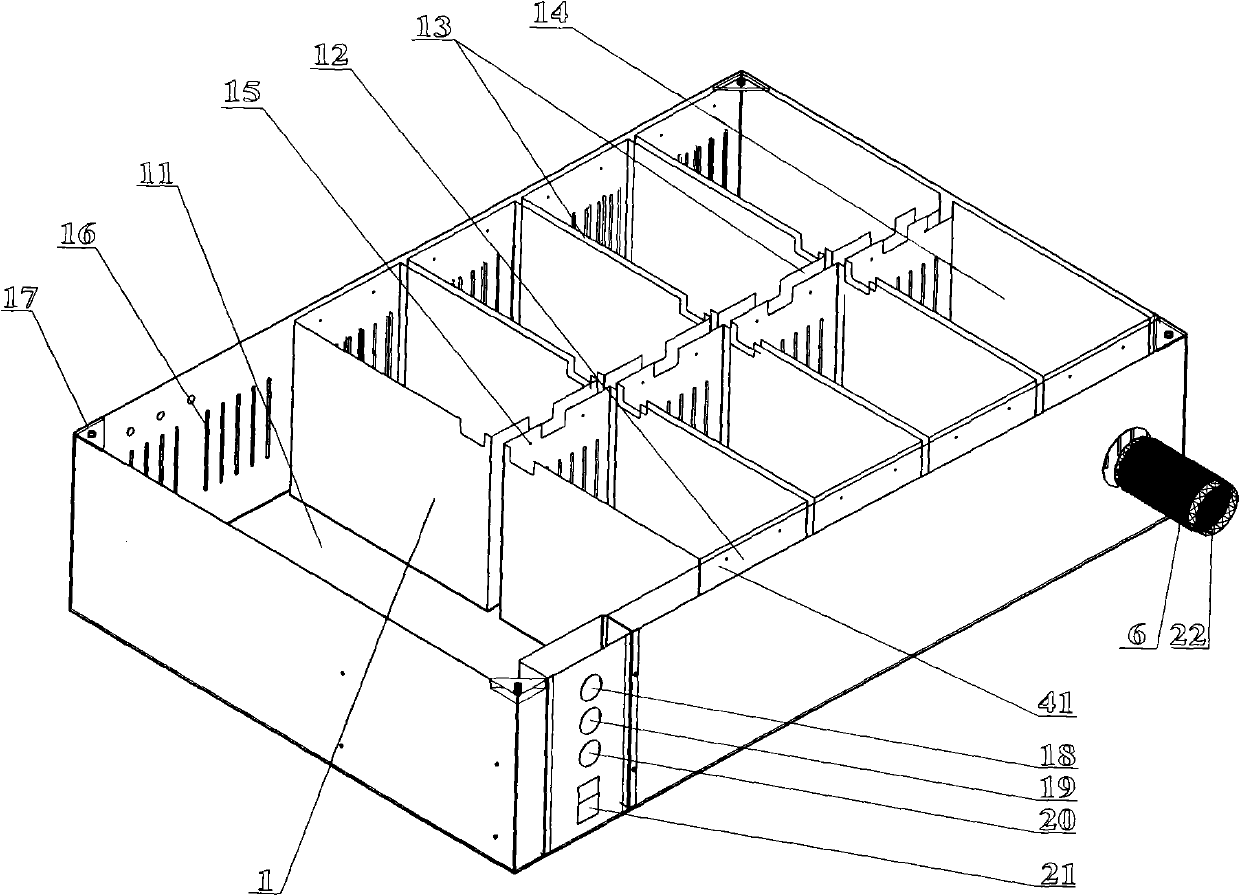

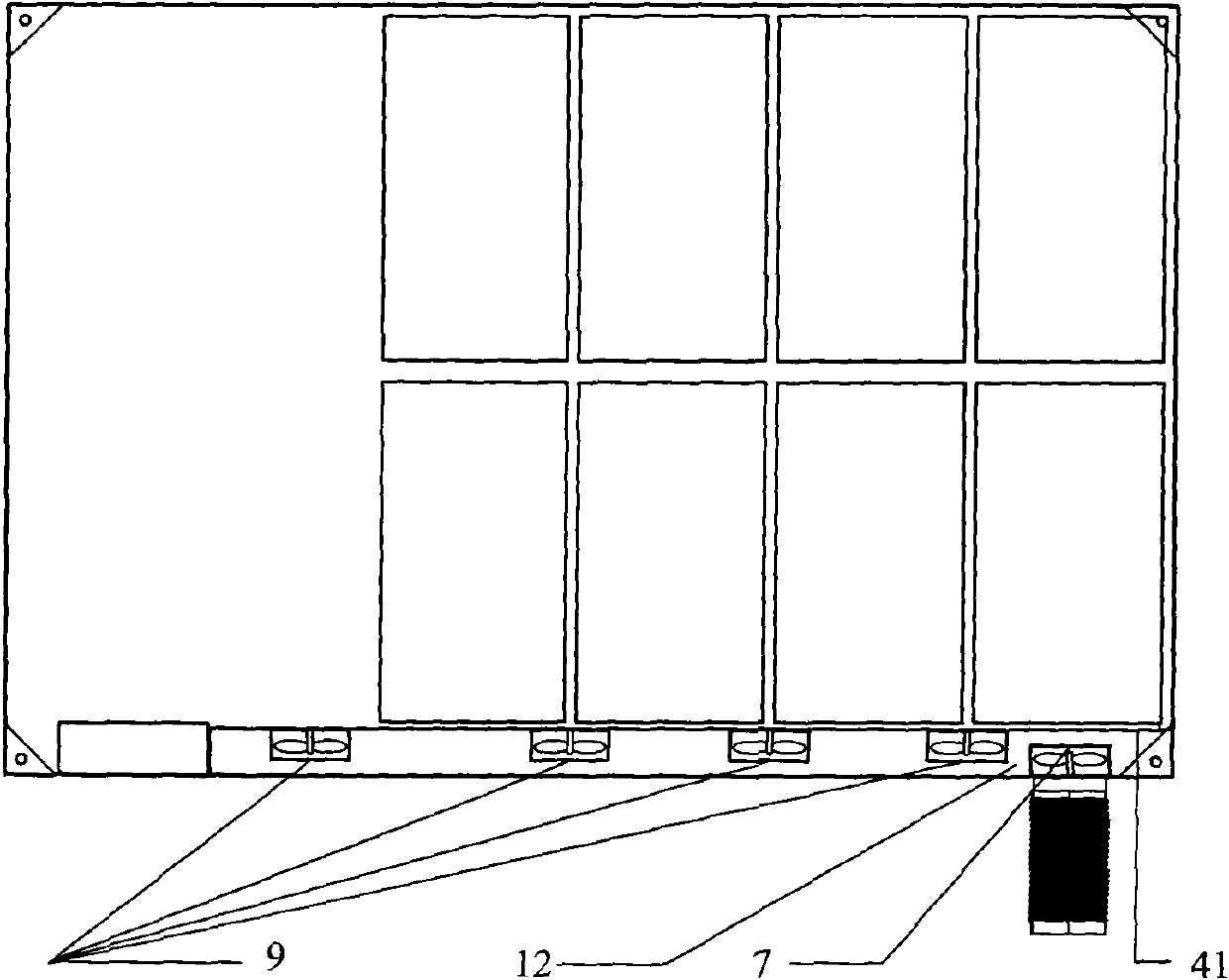

[0024] Referring to the accompanying drawings, the inner cavity of the battery box is divided into the following independent functional areas by several partitions 1 and movable partitions 41 welded vertically on the bottom of the box: eight battery module areas 14, hot air collection area 12, battery management circuit area 11. There are air ducts 13 between adjacent partitions, and ventilation grids 16, air outlets 22 with bellows 6, hanging angles 17, hanging rings 10, feet 8, and horizontal bars are installed on the partitions and the side walls of the battery box Hole 15, output hole 18, charging hole 19, signal wire hole 20, circuit breaker hole 21.

[0025] Soft-pack power lithium-ion battery cells 23 are pasted with sponge double-sided adhesive tape 24 on the outside, and then neatly placed in the battery module area of the box in sequence, pressed on the horizontal bar 33, and pass through the end hole 34 of the horizontal bar and the horizontal wall of the separator...

Embodiment 2

[0030] The main structure and manufacturing process of the battery pack in Example 2 are the same as those in Example 1, and will not be described again. The difference is that the battery cell placed in the battery module area is pressed on the horizontal bar 33, and then the battery cover 31 is covered. The cover plate is a plexiglass plate with a thickness of 10 mm. There are lug grooves 27, signal line holes 28, threaded holes 29, handle holes 30 and non-through grooves 32 consistent with the shape of the metal connecting bar on the cover plate. During assembly, the metal connection bars 3, 4, 5 are put into the non-through groove, and then the corresponding additional metal connection bars 39, 40, 38 are put on, the battery lugs are clamped in the middle, and the screws 26 are used for fastening together. There are tab fixing holes 35 and signal line No. 36 on the additional metal connection strips, and the two connection strips are silver-plated copper plates with a thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com