Flexible heating film assembly and preparing method thereof

A heating film and flexible technology, applied in the field of flexible heating film components and their preparation, can solve the problems of silicon carbide components burning, cannot be washed, poor room temperature toughness, etc., achieve good elastic modulus and bending strength, and ensure washing resistance. , the effect of uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

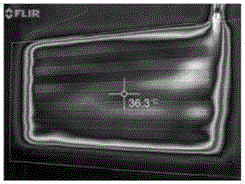

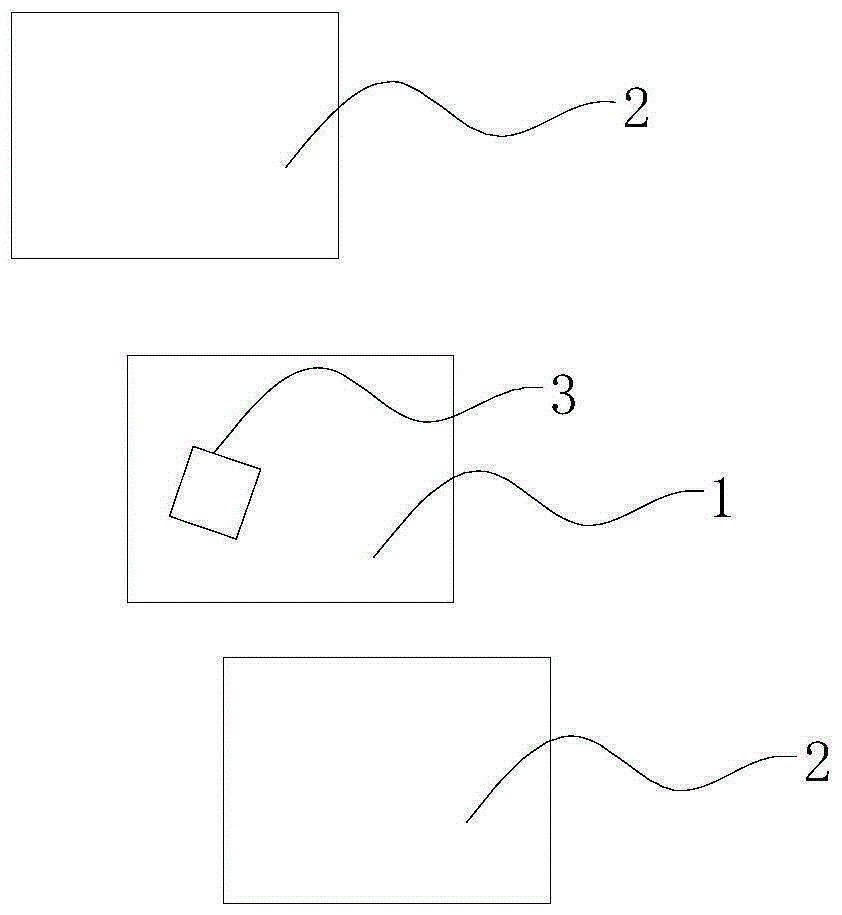

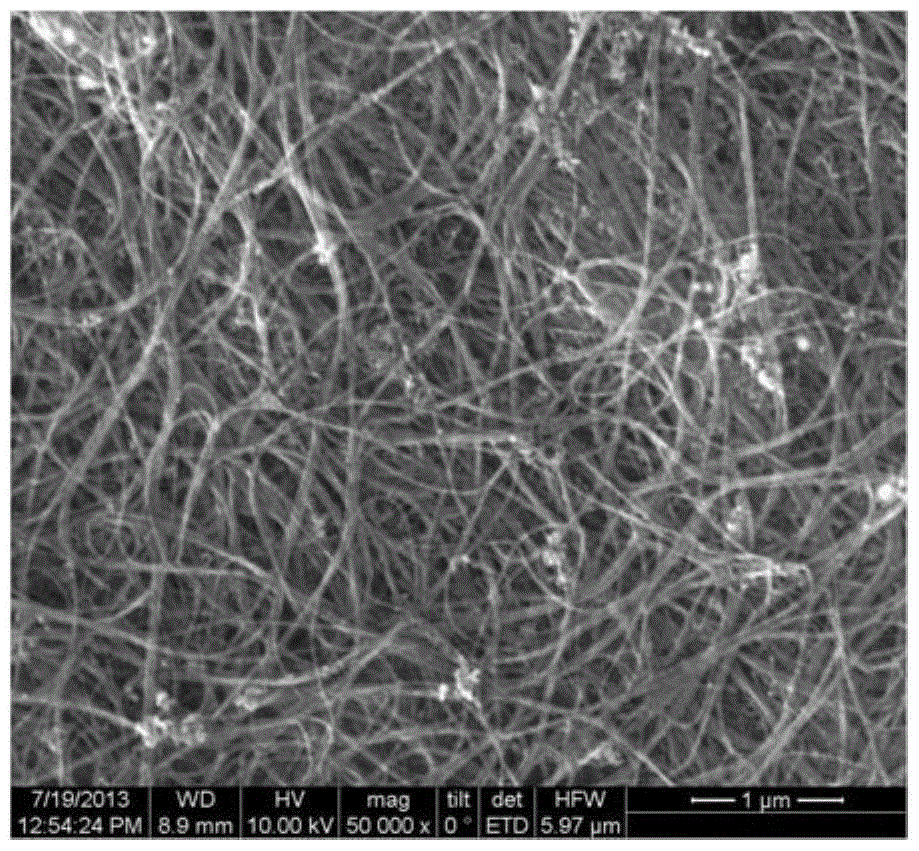

Embodiment 1

[0051] Cut out a flexible heating membrane module with a size of 10*10cm, according to Figure 4 The structures shown are composited, from top to bottom are polytetrafluoroethylene porous membrane (5 μm), carbon nanotube membrane with circuit system (5 μm), and polytetrafluoroethylene porous membrane (5 μm). A 40°C temperature sensor is connected in series in the circuit, but the heating will be stopped when the temperature exceeds 40°C, and the heating will be started when the temperature is lower than 40°C. Power on the circuit through a USB external power bank, and use a temperature measuring gun to measure the temperature of different points on the film. The test position is as follows: Figure 8 As shown, the measurement results are shown in Table 1.

Embodiment 2

[0053] Cut out a flexible heating membrane module with a size of 10*10cm, according to Figure 5 The structures shown are composited, from top to bottom are polytetrafluoroethylene porous membrane (5 μm), carbon nanotube membrane with circuit system (5 μm), and polytetrafluoroethylene porous membrane (5 μm). A 40°C temperature sensor is connected in series in the circuit, but the heating will be stopped when the temperature exceeds 40°C, and the heating will be started when the temperature is lower than 40°C. Power on the circuit through a USB external power bank, and use a temperature measuring gun to measure the temperature of different points on the film. The test position is as follows: Figure 8 As shown, the measurement results are shown in Table 1.

Embodiment 3

[0055] Cut out a flexible heating membrane module with a size of 30*30cm, according to Figure 4 The structures shown are composited, from top to bottom are polytetrafluoroethylene porous membrane (5 μm), carbon nanotube membrane with circuit system (5 μm), and polytetrafluoroethylene porous membrane (5 μm). A 40°C temperature sensor is connected in series in the circuit, but the heating will be stopped when the temperature exceeds 40°C, and the heating will be started when the temperature is lower than 40°C. The circuit is energized in the form of external direct current through the wire, the output voltage is controlled at 5V, and the temperature of different points on the film is measured with a temperature measuring gun. The test position is as follows: Figure 8 As shown, the measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com