Standard device and measuring method using mass method for detecting high-pressure gas filling flow

A high-pressure gas, standard device technology, applied in the direction of mass flow measurement device, indirect mass flowmeter, etc., can solve the problems of the compressed natural gas filling station lagging behind the natural gas vehicle, and the measurement and detection of the compressed natural gas filling machine lagging behind the natural gas vehicle, etc. The effect of high accuracy, stable lifting and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

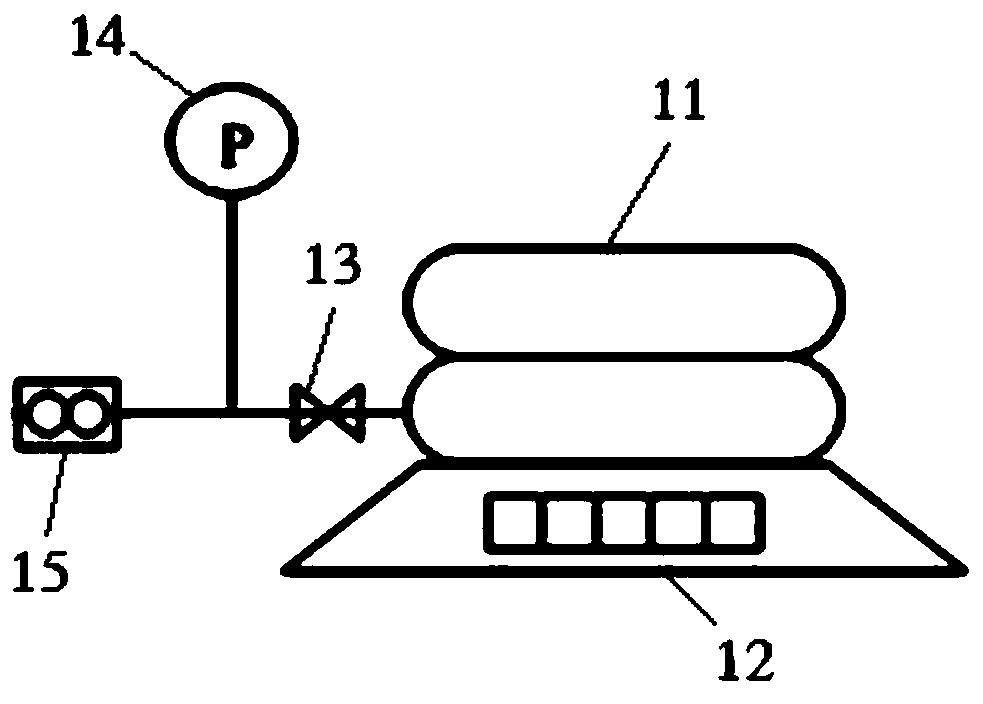

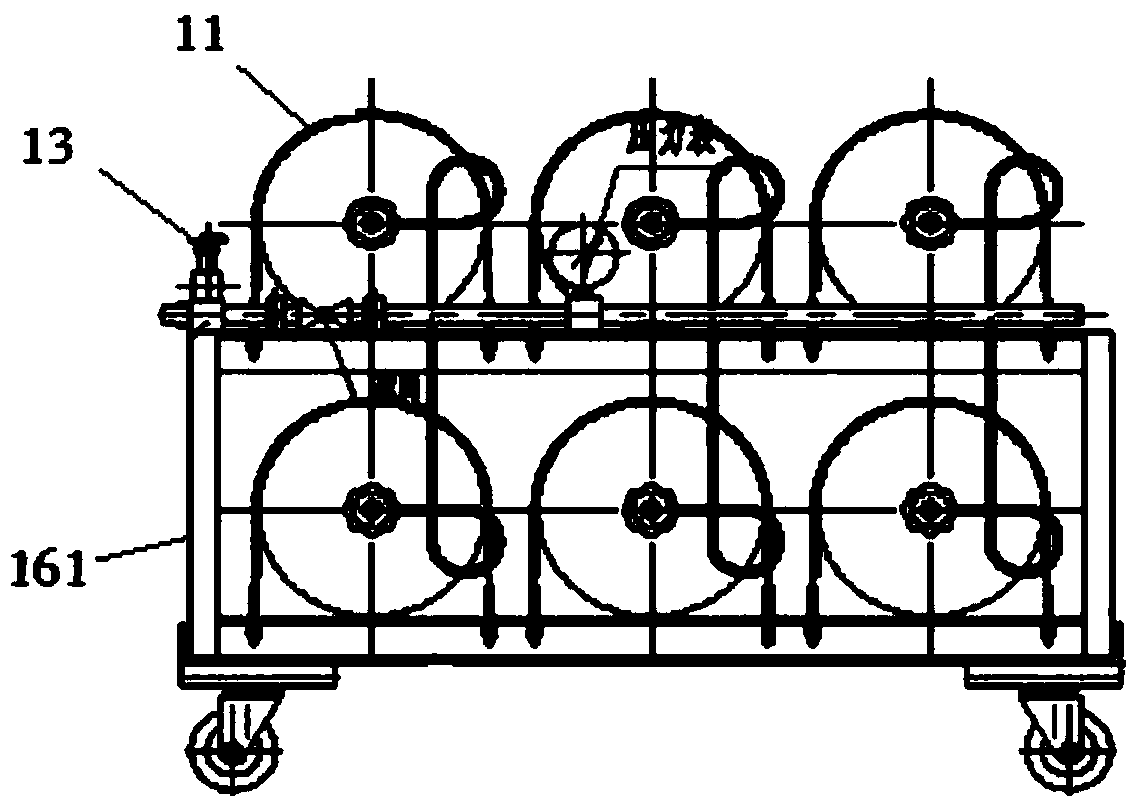

[0061] like figure 1 As shown, a standard device 1 for detecting the filling flow rate of high-pressure gas by mass method includes several high-pressure gas bottle groups 11, electronic balance 12 and lifting device 16, and the lifting device 16 is as figure 2 , is used to lift the high-pressure gas cylinder group 11 as a whole, and the gas cylinder valve 13, precision pressure gauge 14 and flow indicator 15 are also provided on the air pipe.

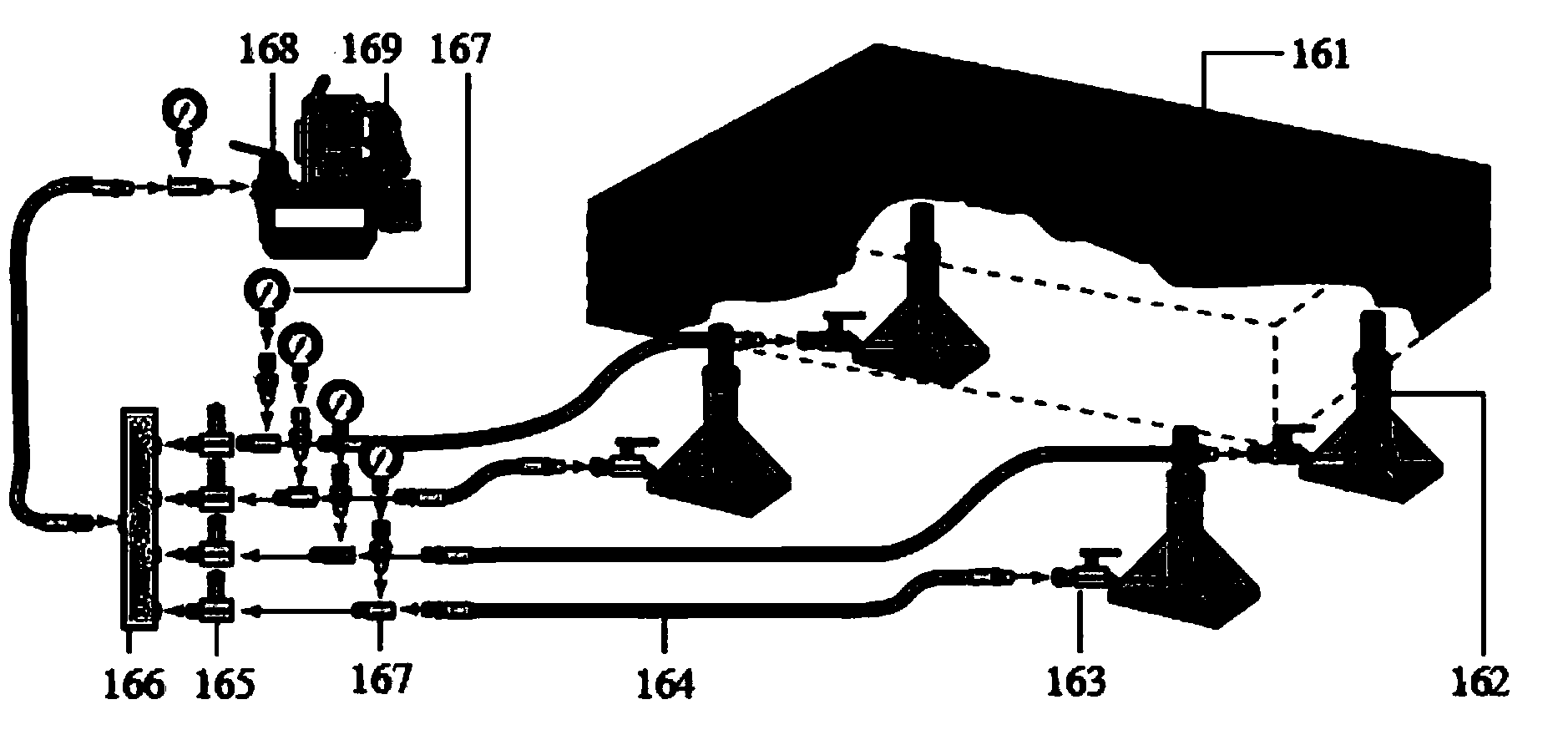

[0062] The concrete structure of lifting device 16 is as figure 2 As shown, the hydraulic synchronous automatic lifting device 16 is selected for use, including a wheeled loading cart 161 that is convenient to fix the high-pressure gas cylinder group 11, and is easy to move. The bottom of the loading cart 161 is provided with four hydraulic cylinders 162, and the soft The pipe 164 is provided with a safety lock valve 163, and all the hoses 164 are connected to an oil circuit block 166. The hose 164 is also provided with a needle va...

specific Embodiment 2

[0068] like Figure 5 As shown, the present invention also provides a gas flow detection method whose verification object is a CNG dispenser 2, wherein the CNG dispenser 2 includes a dispenser body, an intake valve 21, a flow meter 22, a pressure gauge 24, an electromagnetic Valve 25 and gas filling gun valve 23, and use the standard device 1 for detecting high-pressure gas filling flow rate using the mass method as described above, and use the following steps to detect:

[0069] Step 1. Connect the standard device 1 to the air filling gun valve 23 of the inspected CNG filling machine 2, and the intake valve 21 to the high pressure air source 5, and select compressed air as the high pressure air source 5;

[0070] Step 2, return the indication value of the electronic balance 12 in the standard device 1 to zero, and return the indication value of the CNG dispenser 2 to zero;

[0071] Step 3, start the lifting device 16, place the high-pressure gas bottle set 11 on the electron...

specific Embodiment 3

[0104] Such as Figure 6 As shown, the present invention also provides a detection method that the verification object is the flow rate of the verification device 3 of the CNG dispenser, wherein the verification device 3 of the CNG dispenser comprises a verification device body, an inlet valve 31, a mass flow meter 32, and a pressure gauge 34 , display 35 and outlet valve 33, use the standard device 1 that utilizes mass method to detect high-pressure gas filling flow rate as described above, adopt the following steps to detect:

[0105] Step 1. Connect the standard device 1 to the outlet valve 33 of the CNG filling machine verification device 3 under inspection, and the inlet valve 31 is connected to the high-pressure gas source 5;

[0106] Step 2, return the indication value of the electronic balance 12 in the standard device 1 to zero, and return the indication value of the display 35 to zero;

[0107] Step 3, start the lifting device 16, place the high-pressure gas bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com