Processing technique for high-strength corrugated board

A technology of corrugated cardboard and processing technology, which is applied in the direction of papermaking, paper machine, textile and papermaking, etc., can solve the problems that the quality of corrugated cardboard cannot be guaranteed, and achieve the effect of high strength, high water resistance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

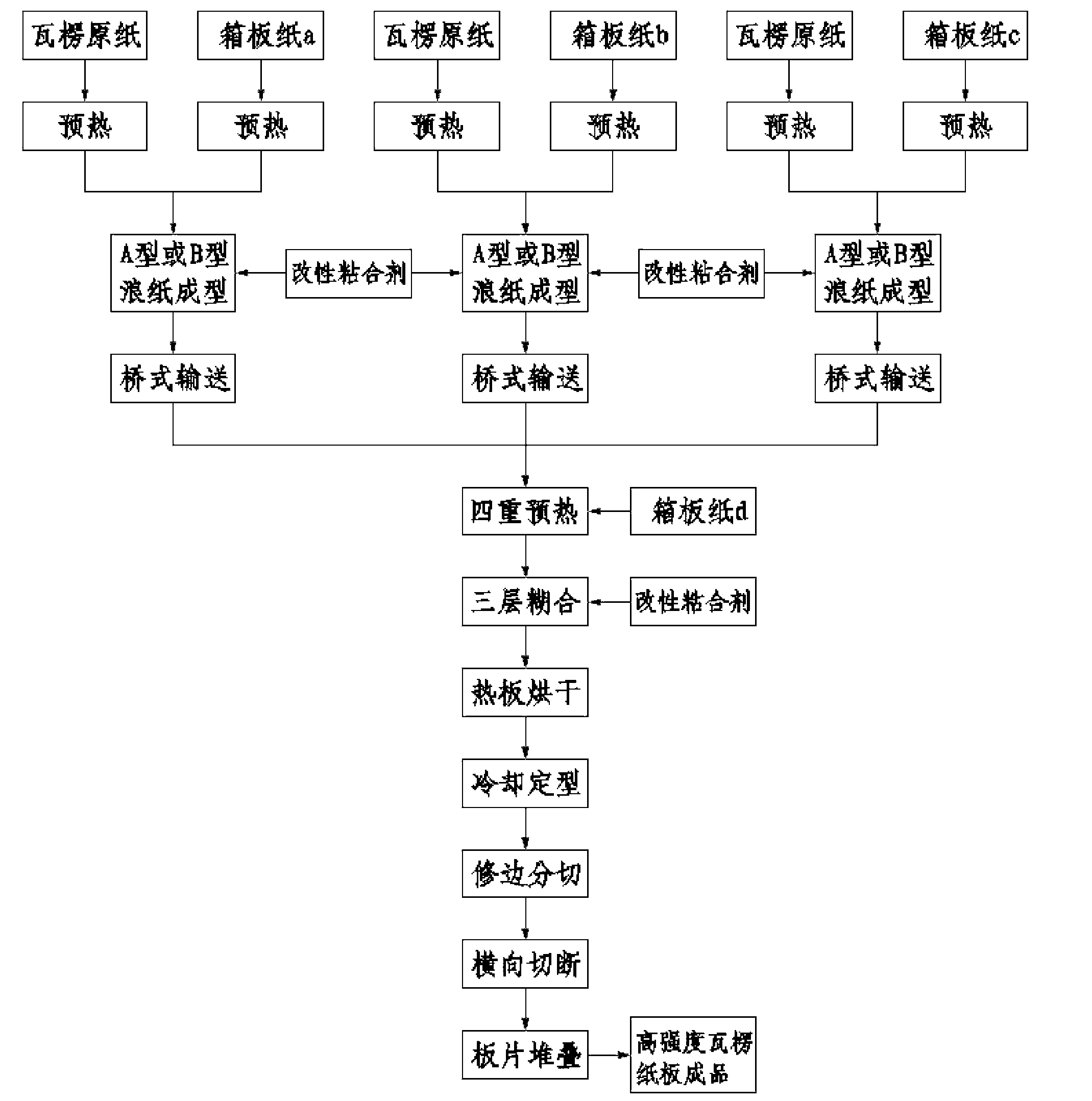

[0026] figure 1 It is a process flow diagram of an embodiment of the present invention; it shows the production process of processing seven layers of high-strength corrugated cardboard:

[0027] First of all, put the reel base paper for lining paper, face paper and corrugated paper on the automatic paper holder respectively. Each paper web is preheated by preheater respectively. The corrugated base paper enters the single-facer after being adjusted by the pre-processor and ironed. After being corrugated by corrugating rollers and coated with adhesive, it is bonded with the face paper to form single-face corrugated paper. The flute type of the single-facer can be determined according to requirements. The single-sided corrugated paper produced is sent to the three-story flyover conveyor, where it accumulates in waves and is slowly transported forward. Finally to the quadruple preheater. Here, the three kinds of single-sided corrugated paper and the inner paper from the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com