Antibacterial solution, paper diaper prepared through antibacterial solution and preparation method for paper diaper

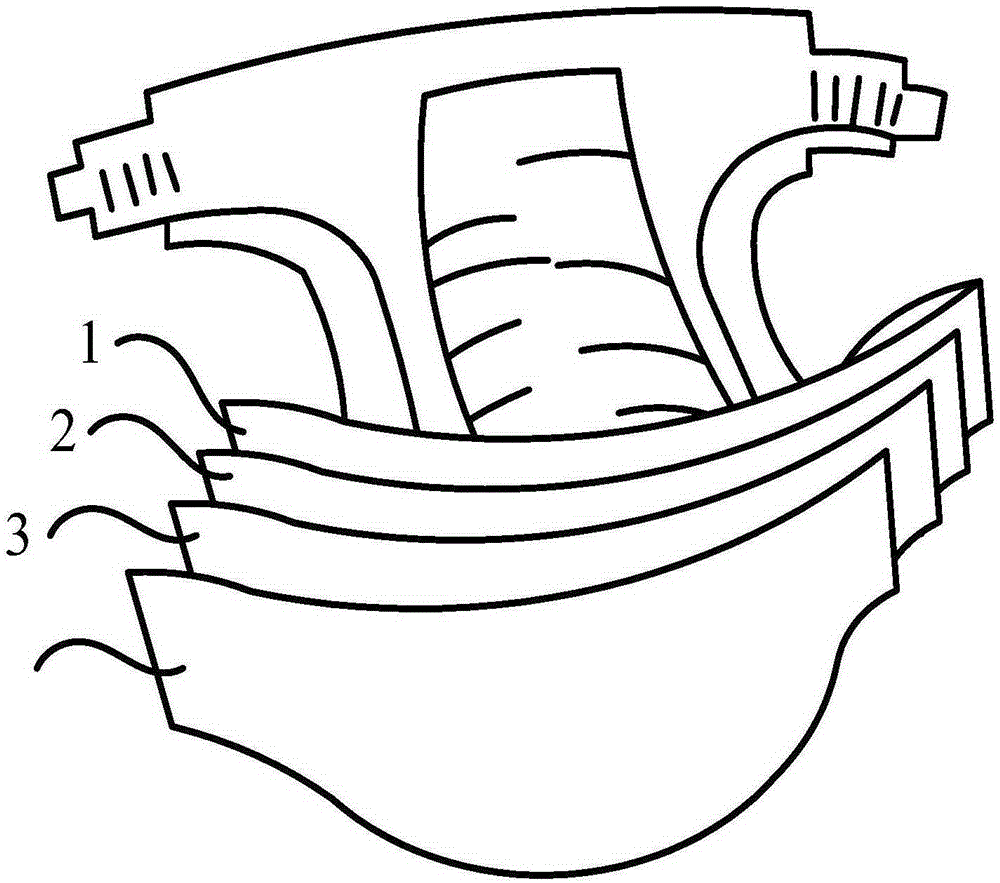

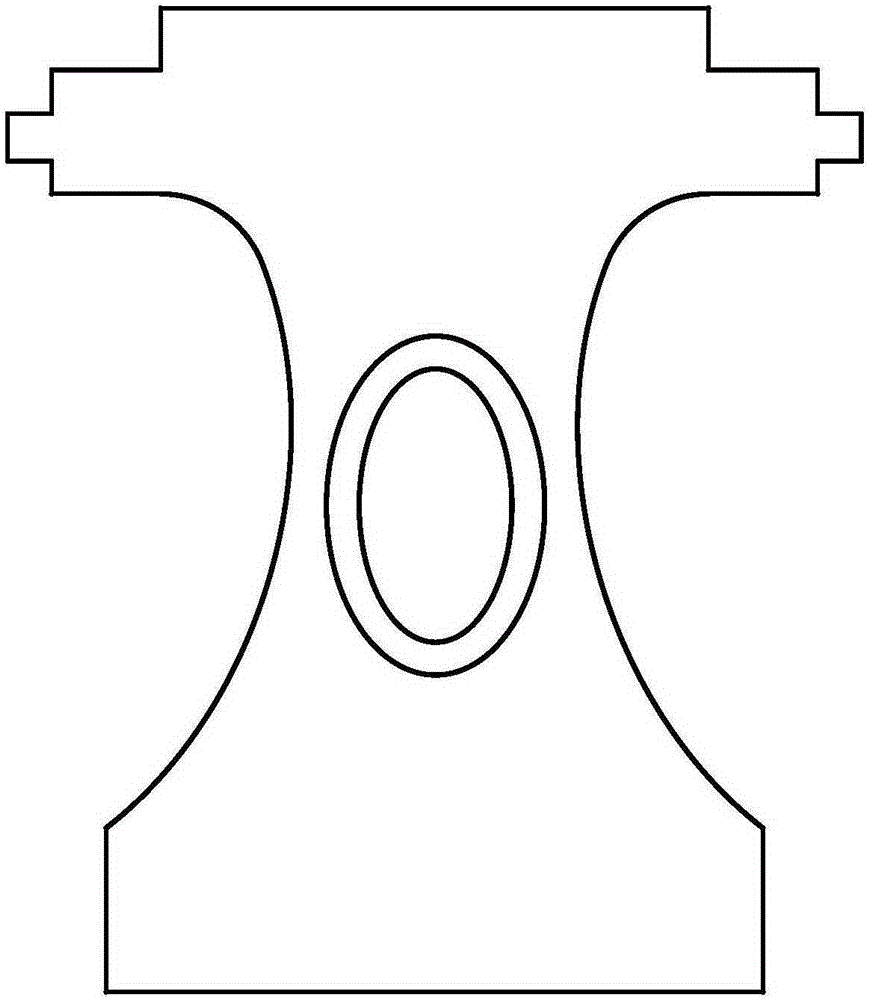

A diaper and solution technology, applied in the field of sanitary products, can solve the problems of needing to be replaced every 2-3 hours, rash on the baby's skin, poor absorption capacity, etc., to avoid rash and discomfort, and to achieve high antibacterial effect. and safety, strong bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

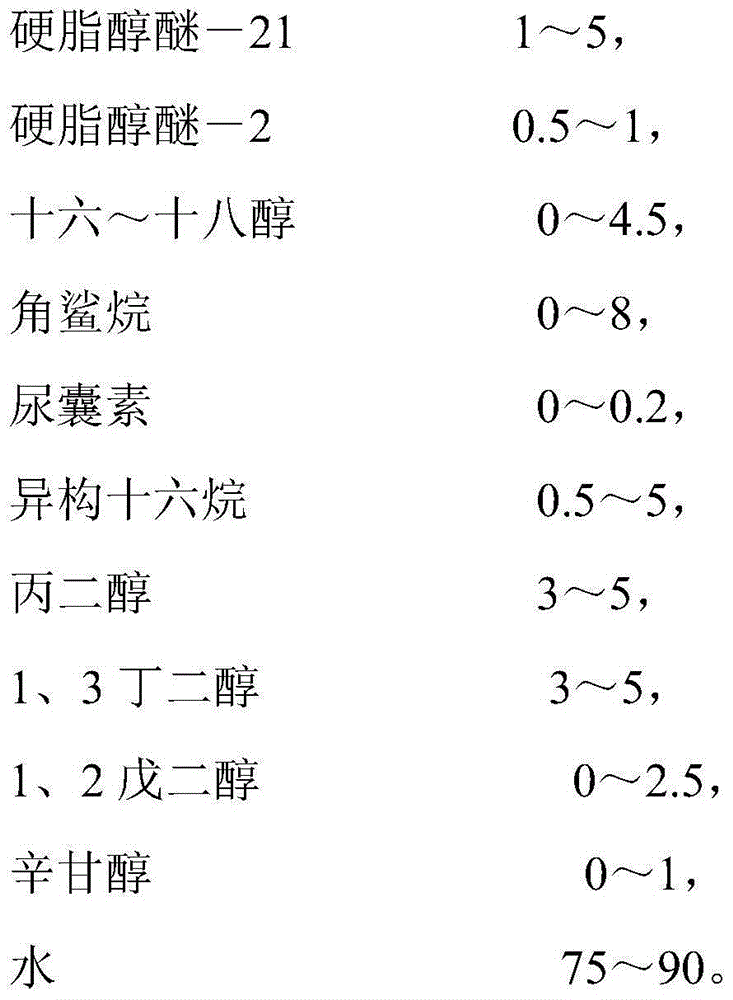

[0038] The antibacterial solution is composed of the following components by mass: stearyl ether-21:1; stearyl ether-2:0.5; cetearyl to stearyl alcohol: 1; squalane: 2; allantoic Elements: 0.2: Isomerized hexadecane: 0.5; Propylene glycol: 3; 1, 3 butanediol: 5; 1, 2 pentanediol: 2.5; Caprylyl glycol: 0.5; Water: 83.8.

[0039] During production, cetearyl-stearyl alcohol, squalane and iso-hexadecane are mixed with stearyl ether-21 and stearyl ether-2 according to the above ratio and heated to 80 degrees to form an oil phase. And allantoin, propylene glycol, 1,3 butanediol, 1,2 pentanediol, caprylyl glycol and water, according to the above-mentioned ratio, form the aqueous phase after mixing uniformly in the stirring pot. Slowly add the oil phase to the water phase, and keep stirring until it is completely dissolved.

[0040] Among them, cetyl-stearyl alcohol, squalane and iso-hexadecane are emollients, which are attached to the non-woven fabric, so that the non-woven fabric h...

Embodiment 2

[0043] The implementation of this example is the same as that of Example 1, except that the bacteriostatic solution of this example consists of the following components by mass: stearyl ether-21:5; stearyl ether-2:1; Cetyl to octadecyl alcohol: 2; squalane: 8; allantoin: 0.2; iso-hexadecane: 5; propylene glycol: 5; ; Caprylyl glycol: 1; Water: 90.

Embodiment 3

[0045] The implementation of this example is the same as that of Example 3, except that the bacteriostatic solution of this example is composed of the following components by mass: stearyl ether-21:1; stearyl ether-2:0.5; Cetyl to octadecyl alcohol: 0.01; Caroxane: 0.01; Allantoin: 0.01; Isomerized hexadecane: 0.5; Propylene glycol: 3; ; Glycolic alcohol: 0.02; Water: 75.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com