Sludge rapid drying device with crushing device

一种破碎装置、快速干燥的技术,应用在污泥干燥、干燥固体物料、干燥气体布置等方向,能够解决搅拌叶片承力不均匀、影响污泥干燥效率、污泥干燥不均匀等问题,达到利于热量的传递、便于热量传递、加快干燥速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

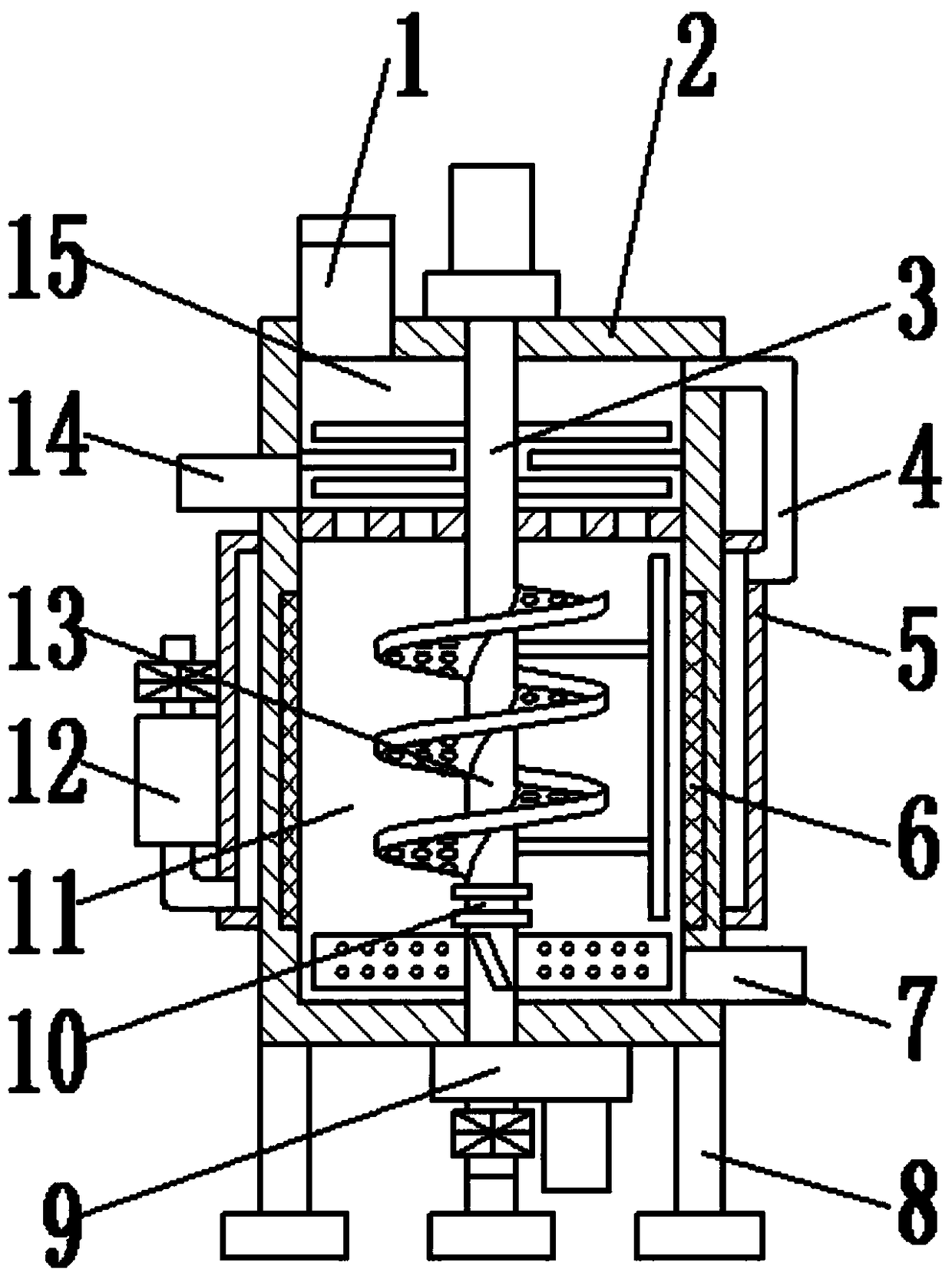

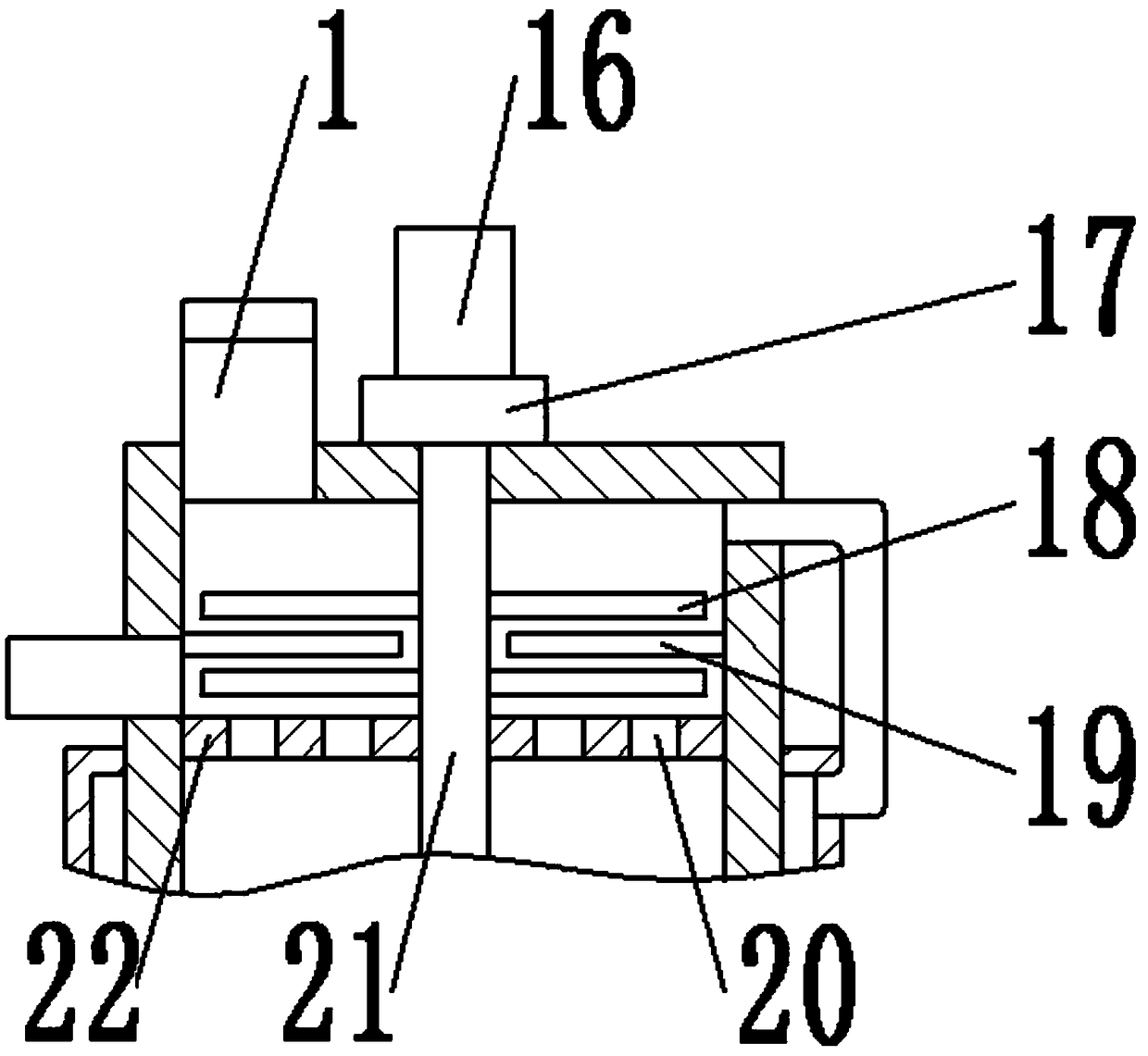

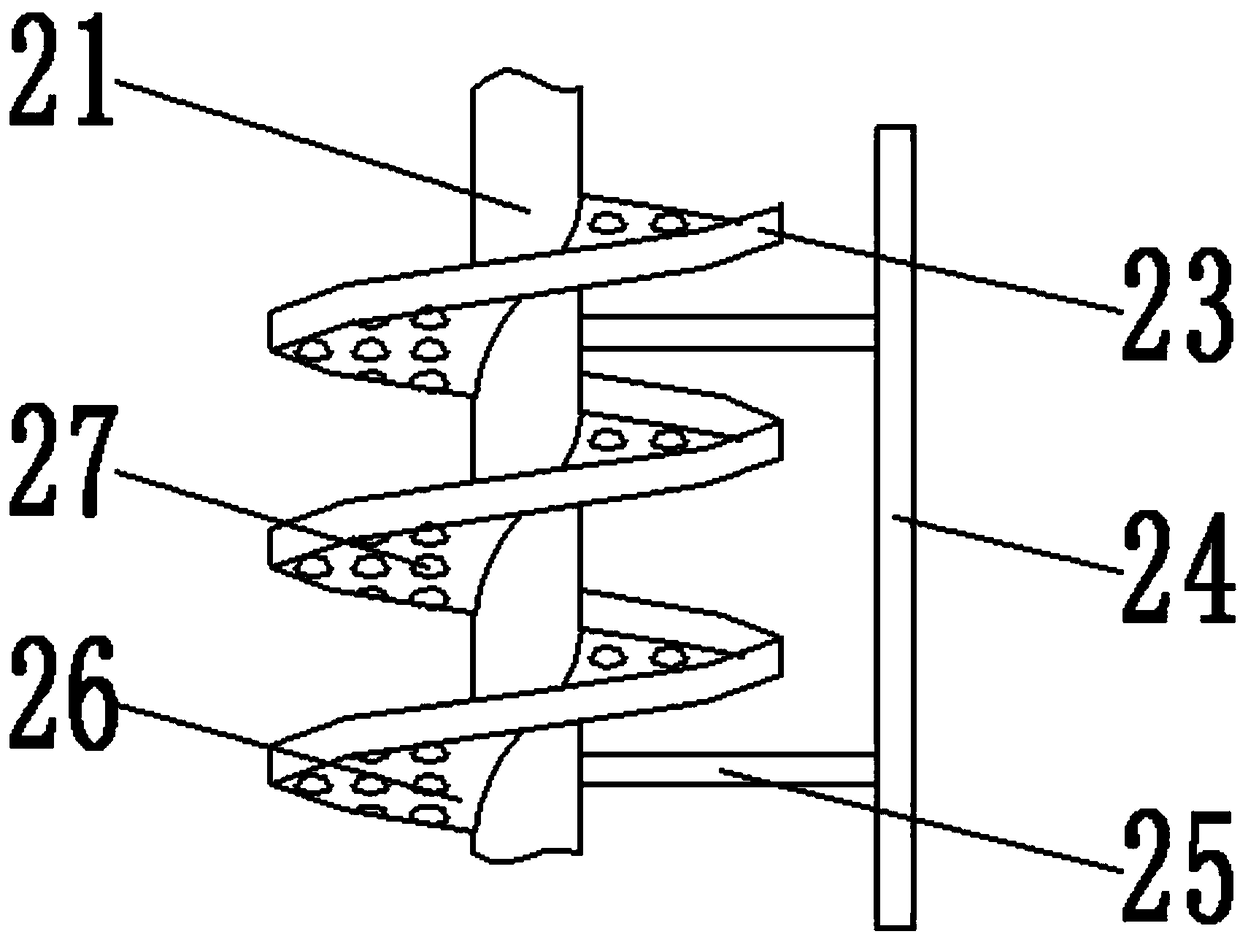

[0019] see Figure 1-5, a sludge rapid drying equipment with a crushing device, including a tank body 2; the tank body 2 is set as a hollow cylinder made of stainless steel, and the interior is divided into a crushing chamber 15 and a drying chamber 11 by a partition 22; A number of blanking holes 20 are evenly distributed on the partition 22; a feeding pipe 1 is arranged on the top surface of the tank body 2; a sealing cover is arranged at the opening of the feeding pipe 1; a crushing device is arranged in the crushing chamber 15 3; the crushing device 3 is composed of a first motor 16, a first rotating shaft 21, a fixed blade 19 and a rotating blade 18; the first motor 16 is connected to the first rotating shaft 21 through a reducer 17, and the first motor 16 and reducer 17 are fixed on the top surface of the tank body 2; the first rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com