Air purifying and filtering system

A filtration system and air purification technology, applied in chemical instruments and methods, disinfection, separation methods, etc., can solve the problems of high cost, troublesome use, inability to obtain dry clean air, etc., and achieve the effect of reducing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

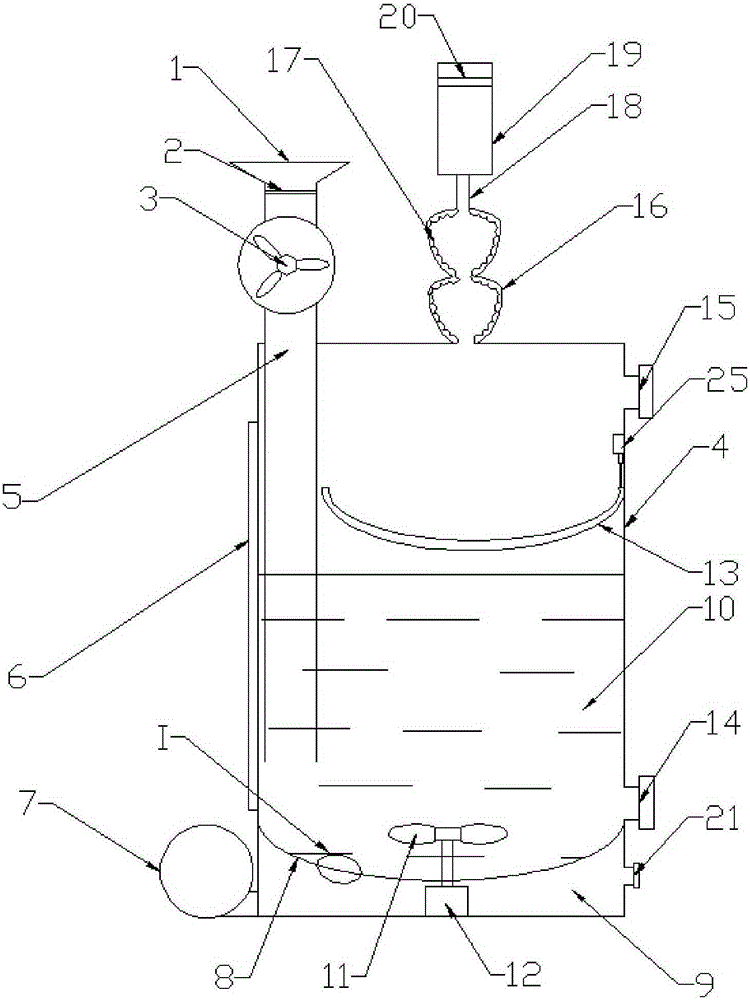

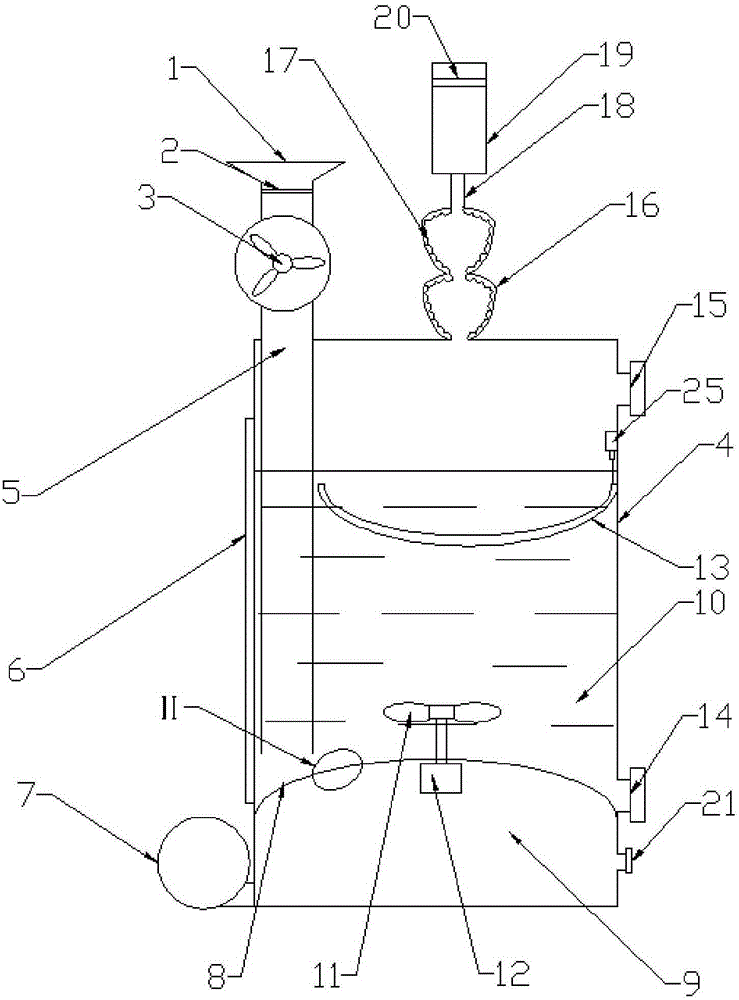

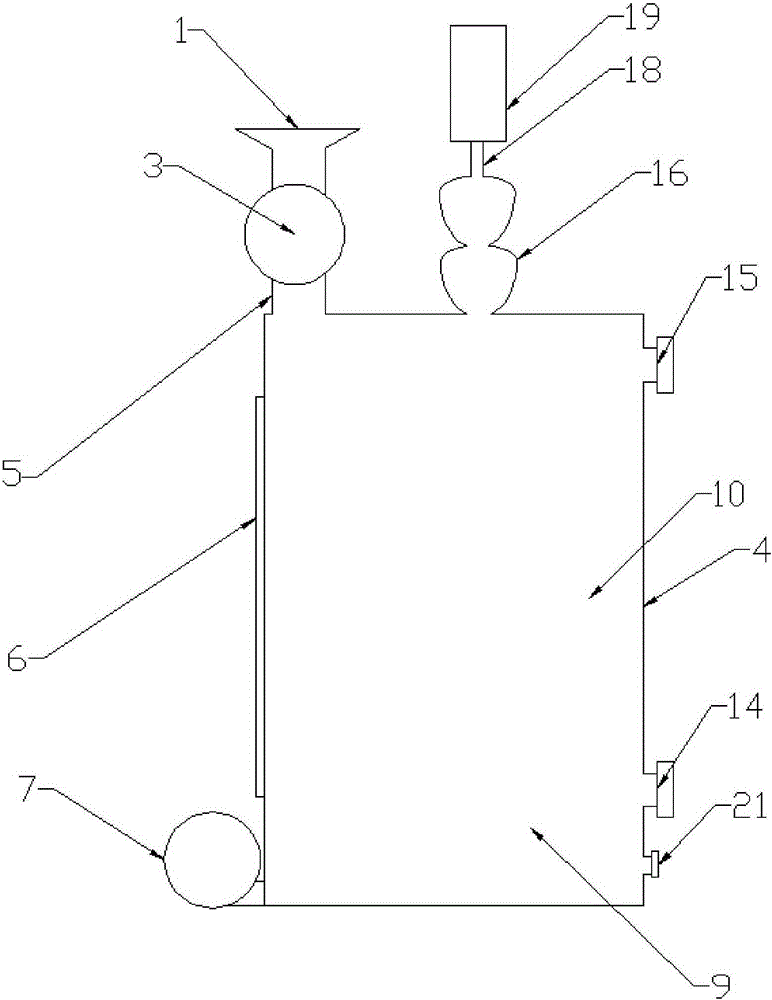

[0038] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0039] Such as Figures 1 to 7 Shown, a kind of air purification filter system comprises box body 4, and described box body 4 is arranged on its inner flexible diaphragm 8 and is divided into two parts from top to bottom, and the upper part is the washing chamber 10 of filling water, and the lower part In order to connect the pneumatic chamber 9 of the air pump 7, the side wall of the pneumatic chamber 9 is provided with an exhaust hole 21 with a sealing cover, and the upper end and the lower end of the side wall of the water washing chamber 10 are respectively provided with a water inlet 15 and a water outlet 14 , the water inlet 15 and the water outlet 14 all have sealing covers, the top of the box body 4 is provided with an air inlet 1 and an air outlet 18, and the air inlet 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com