Method and device for drying coking coal in coking industry

A drying method and coking coal technology, applied in coking ovens, petroleum industry, heating devices, etc., can solve the problems of power consumption reduction, achieve the effects of reducing dust, reducing load, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

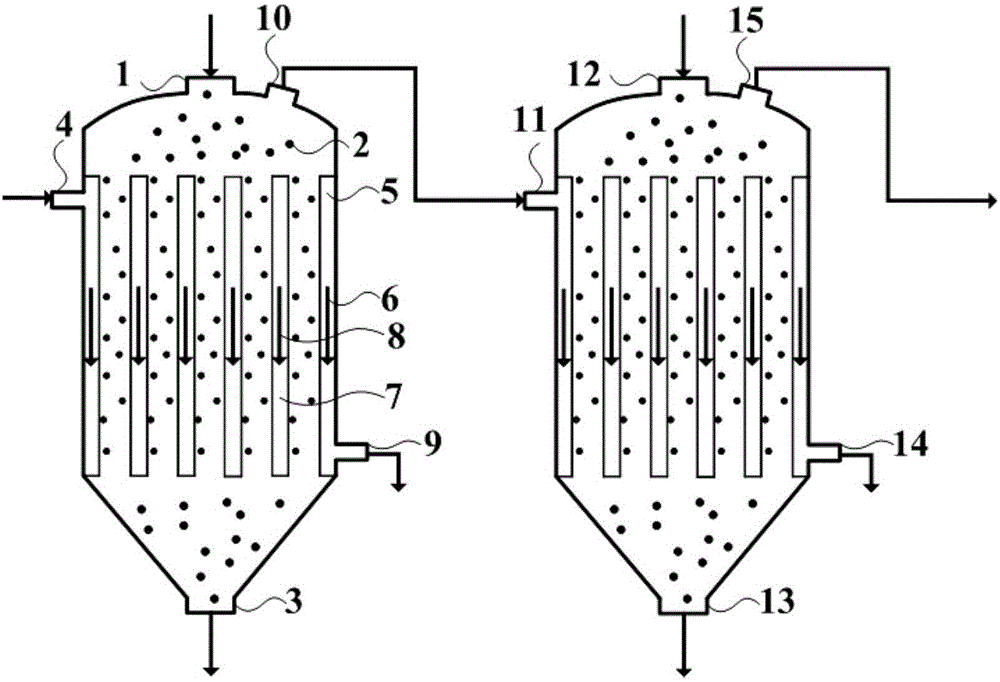

Method used

Image

Examples

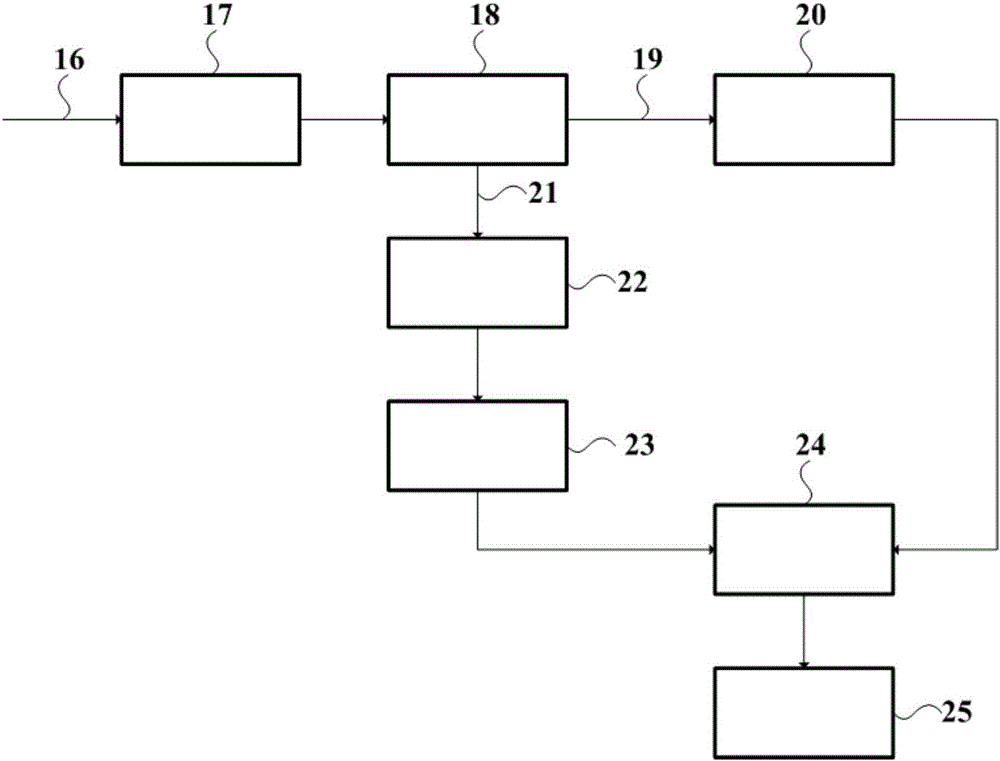

Embodiment 1

[0037] This embodiment is a multi-effect drying scheme for coking coal classification, such as figure 2 shown. The coking coal raw material 16 first enters the pre-dryer 17 for pre-drying. After the coking coal raw material no longer sticks to each other, it enters the vibrating screening sieve 18 from the coal inlet of the screening sieve. The vibrating screening sieve inlet is above the screening sieve. Coal raw material enters from above and rolls down along the inclined screen screen. At the same time, the screen vibrates up and down under the action of the vibrating power mechanism. The upper part of the net rolls along the sieving wire mesh to the coarse particle outlet of the sieving sieve at the bottom, and enters the coarse particle dryer 20 of the moving bed drying system for drying. The fine particle component 21 with a particle size of less than 0.3 mm passes through the screen and falls to the lower part of the screen, leaves the screen 18 from the fine particle...

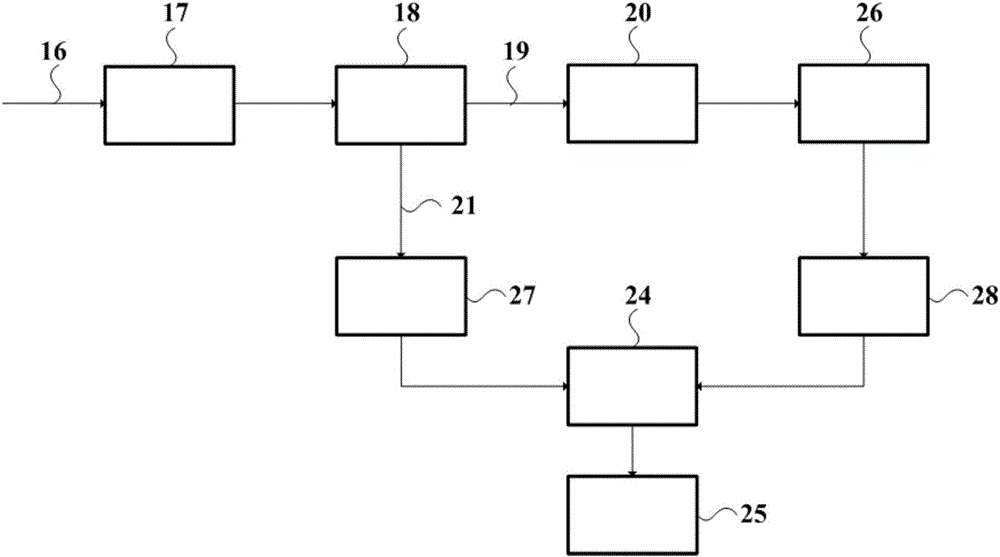

Embodiment 2

[0043] The coking coal drying scheme of the present embodiment is as follows: image 3 As shown, the coking coal raw material 16 first enters the pre-dryer 17 for pre-drying. After the coking coal raw material no longer sticks to each other, it enters the screening sieve 18 (using a rolling sieve) from the coal inlet of the screening sieve. Above the screening screen, the coking coal raw material enters from above and rolls down along the inclined screening wire mesh. At the same time, under the action of the rolling power mechanism, the coarse particles 19 with a particle size greater than 0.3mm are screened by the screening wire. The net is trapped on the upper part of the net, and rolls along the screening wire mesh to the coarse particle outlet of the screening screen at the bottom, and enters the coarse particle dryer 20 of the moving bed drying system. Fine particles 21 with a particle size of less than 0.3 mm pass through the screen and fall to the lower part of the scr...

Embodiment 3

[0046] This example is basically the same as Example 1, except that the pre-drying process reduces the moisture content of the coal to less than 6%, and the classified fine powder granules are not dried after being granulated by mechanical pressure, but directly mixed with the dried coal. Coarse particles cooled to below 50°C are mixed and stored, and then enter the coking and coal charging process. When the moisture content of the coking coal raw material is low, the drying process can be paralleled, that is, the coal inlet of each effect dryer enters the coal material that has not been dried, and the coal material can be discharged after drying to complete the drying. This embodiment is suitable for coking coal raw materials with low water content, and the parallel operation of moving bed dryers also increases the drying efficiency and output of coal materials.

[0047]The moisture of the dried coarse particles is controlled below 2%, the moisture of the granulated fine powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com